Stacked-disk stabilizer

A stabilizer and disc stacking technology, which is applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of differential pressure sticking, drill tool failure, increased slewing resistance, and high technical requirements, so as to prevent drilling deviation and reduce Effects of slewing resistance and optimized contact conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

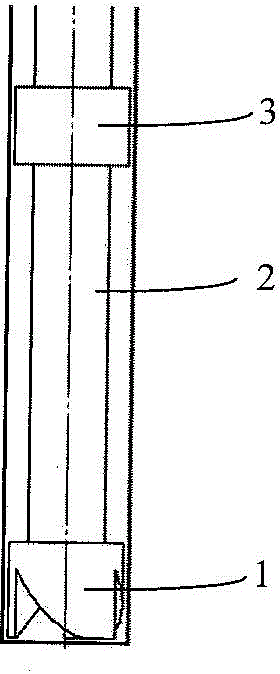

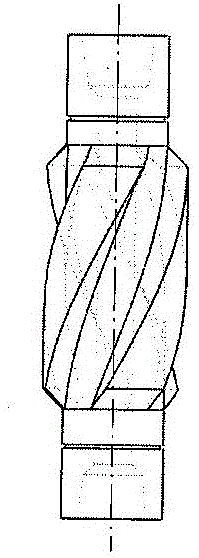

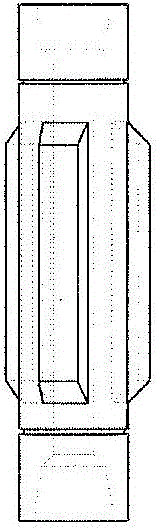

[0027] see Figure 5 with Image 6 Shown, is the first embodiment of the present invention, and this embodiment is a three-stack disk straight-through slot stabilizer, which is composed of a threaded connection part 41, a stabilizer body 42, an annular disk 43, a chamfer 48, an arc plate 47, The ring groove 44, the hollow space 46 and the through groove 45 are formed. Three annular disks 43 and arc-shaped plates 47 are welded together with the stabilizer body 42. The arc-shaped plates 47 are located between the annular disks 43, and the three annular disks 43 are provided with Three longitudinal through grooves 45, the center track of the through groove 45 is a straight line, the outer diameter of the arc-shaped plate 47 is smaller than the outer diameter of the annular disk 43, and an annular groove 44 is formed between the outer wall of the arc-shaped plate 47 and the annular disk 43. There is a hollow space 46 between 43 , the upper and lower ends of the stabilizer body 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com