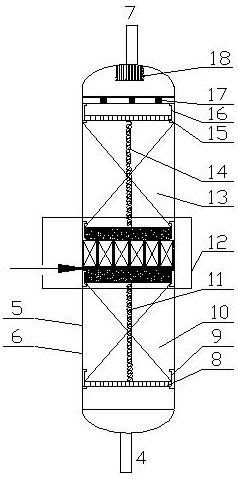

Fixed Bed Flow Reactor and Its Application

A reactor and fixed bed technology, which is applied in the field of upflow reactors, can solve problems such as clogging distributors, affecting fluid distribution, clogging, etc., and achieve the effects of alleviating the increase in pressure drop, reducing dust generation, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

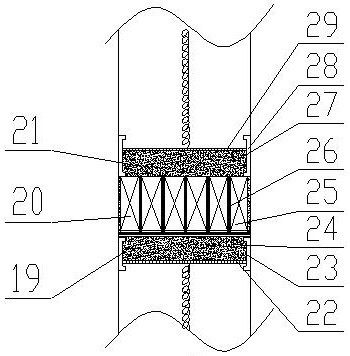

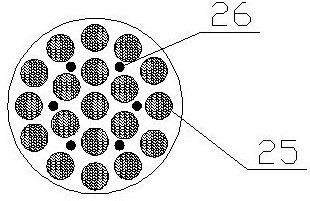

[0055] Using the upflow reactor described in the present invention, the raw material oil and hydrogen I are mixed using a conventional static mixer (model SV2.3 / 25-6.4-500), and then the mixture is introduced into the upflow as reactor feed Type reactor (the diameter of the reactor is 100mm), hydrogen II is introduced into the hydrogen inlet of the linkage filter dust layer, wherein the mass ratio of hydrogen I to hydrogen II is 5:1; the direction of material flow in the reactor is as follows: The sliding grille is 100mm, the first catalyst bed is 600mm, the linkage filter dust layer is 260mm, the second catalyst bed is 800mm, the upper sliding grille is 80mm; the lower sliding grille includes slideways and grille plates, and the slideway length is 100mm ;The upper sliding grille includes a slideway and a grille plate, and the length of the slideway is 80mm; the linkage type filter dust layer includes an upper linkage layer, a filter dust layer, and a lower linkage layer; the u...

Embodiment 2

[0057] Using the upflow reactor of the present invention, the raw material oil and hydrogen I are mixed with a conventional static mixer (model SV2.3 / 25-6.4-500), and then the mixture is introduced into the upflow as reactor feed type reactor (the diameter of the reactor is 100mm), the hydrogen gas II is introduced into the hydrogen inlet of the linkage filter dust layer, and the mass ratio of the hydrogen gas I to the hydrogen gas II is 3:1; the flow direction of the material in the reactor is as follows The sliding grille is 100mm, the first catalyst bed layer is 500mm, the linkage filter dust layer is 200mm, the second catalyst bed layer is 600mm, the upper sliding grille is 80mm, and the gland is 100mm; the lower sliding grille includes slideways and grille plates, sliding The length of the channel is 100mm; the upper sliding grille includes the slideway and the grille plate, and the length of the slideway is 80mm; the linkage type filter dust layer includes the upper linka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com