A fixed bed flow reactor and its application

A reactor and fixed bed technology, applied in the field of up-flow reactors, can solve the problems of clogging the distributor, affecting the fluid distribution, and increasing the pressure drop of the bed, so as to offset and alleviate the impact force, reduce the generation of dust, and slow down the degree of floating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

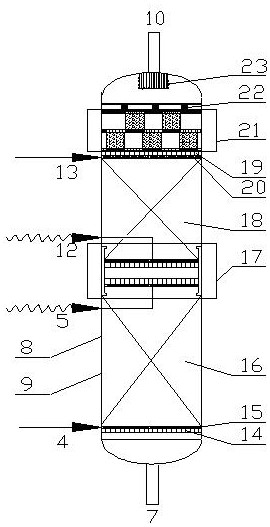

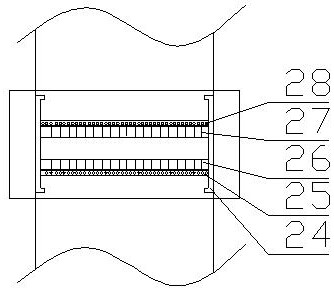

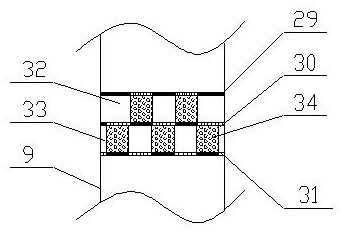

[0050] Using the upflow reactor described in the present invention, part of the raw oil and hydrogen are mixed with a conventional static mixer (model SV2.3 / 25-6.4-500), and then the mixture is used as the reactor feed from the bottom Introduced into an upflow reactor (the diameter of the reactor is DN100), the second and third reaction materials enter from the feed inlets at the bottom and top of the lower catalyst bed respectively; while the first and second circulating materials enter from the upper The feed inlet at the bottom and top of the catalyst bed enters; along the material flow direction in the reactor, there are supporting grids, the first catalyst bed 600mm, the sliding grid layer 200mm, the second catalyst bed 600mm, and the catalyst dust filter layer 200mm ; Wherein, the liquid phase feed that the reaction material inlet, the second reaction material inlet, the third reaction material inlet enters the reactor accounts for 66wt%, 17wt%, 17wt% of the total liquid ...

Embodiment 2

[0052] Using the upflow reactor of the present invention, the raw material oil and hydrogen are mixed with a conventional static mixer (model SV2.3 / 25-6.4-500), and then the mixture is introduced from the bottom as the reactor feed Upflow reactor (reactor diameter is DN100), the second reaction material and the third reaction material enter from the feed inlet at the bottom and top of the lower catalyst bed respectively; while the first circulating material and the second circulating material enter from the upper catalyst bed The feed inlets at the bottom and top of the bed enter; along the material flow direction in the reactor, there are support grids, first catalyst bed 800mm, sliding grid layer 200mm, second catalyst bed 800mm, catalyst dust filter layer 200mm, Gland 100mm; Wherein, the liquid phase feed that the reaction material inlet, the second reaction material inlet, the third reaction material inlet enters the reactor accounts for 72wt%, 18wt%, 18wt% of the total liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com