Dynamic torque detection system

A detection system and dynamic torque technology, applied in force/torque/power measuring instrument calibration/testing, measuring devices, instruments, etc., can solve the problems of low measurement accuracy, improve measurement accuracy, facilitate replacement, and strong impact resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

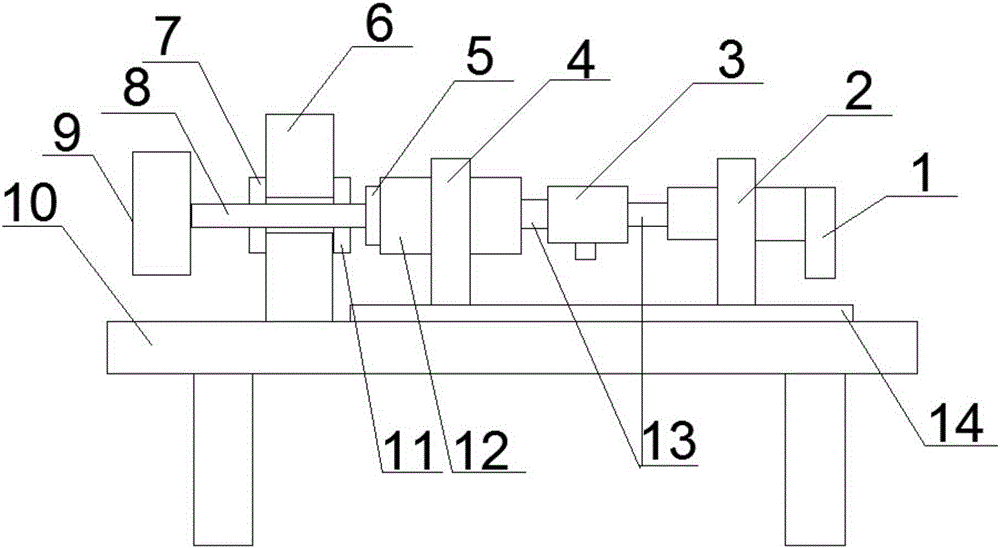

[0023] Such as figure 1 As shown, the dynamic torque detection system includes a machine base 10 and a torque sensor 3, an electric and pneumatic torque wrench 1 is fixedly installed on the said machine base 10, and one end of the torque sensor 3 is connected with the electric and pneumatic torque wrench through a shaft coupling 13. The output shaft of the wrench 1 is connected, and the other end of the torque sensor 3 is connected with a sleeve 12 through a coupling 13, and the sleeve 12 is rotatably fixed on the machine table 10; Torque braking device for continuous braking.

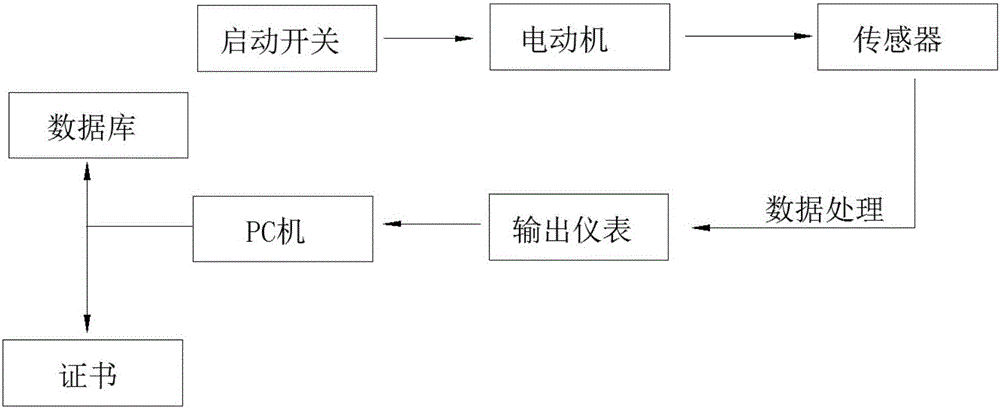

[0024] The working process of the present invention: start the switch of the electric and pneumatic torque wrench 1, the electric and pneumatic torque wrench 1 rotates at high speed, drives the torque sensor 3 to rotate through the shaft coupling 13, and the torque sensor 3 drives the sleeve 12 to rotate through the shaft coupling 13, Thus, the torque braking device connected to the sleeve 12 is drive...

Embodiment 2

[0028] Based on Embodiment 1, the torque braking device includes bolts 8 and bolts 8 for tightening workpieces 9; the machine table 10 is provided with a sliding guide rail 14, and the electric and pneumatic torque wrench 1 is fixed on the sliding guide rail 14 by the clamping mechanism 2 Above, the sleeve 12 is fixed on the sliding guide rail 14 through the bearing 4 . Continuous braking can be realized by tightening the bolt 8, and when the sleeve 12 drives the bolt 8 to gradually tighten the workpiece 9, the sleeve 12 will follow the bolt 8 to move, therefore, by setting the sliding guide rail 14 to ensure that the electric and pneumatic torque wrench 1 and the torque sensor 3 move together with the bolt. In addition, the slide rail 14 facilitates replacement of the bolt 8 , the sleeve 12 and the torque sensor 3 .

Embodiment 3

[0030] Based on the above-mentioned embodiment, the machine table 10 is provided with a fixed plate 6, and a through hole is opened on the fixed plate 6. One end of the bolt 8 is connected to the sleeve 12 through the connector 5, and the other end is connected to the workpiece 9 through the through hole. . By setting the fixing plate 6, it can be ensured that the bolts 8 passing through the fixing plate 6 will not deviate during the tightening process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com