Propelling trolley

A trolley and propulsion mechanism technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of poor eccentric load bearing capacity, difficult operation, and unfavorable construction of mobile formwork bridge building machines, so as to avoid eccentric loads. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

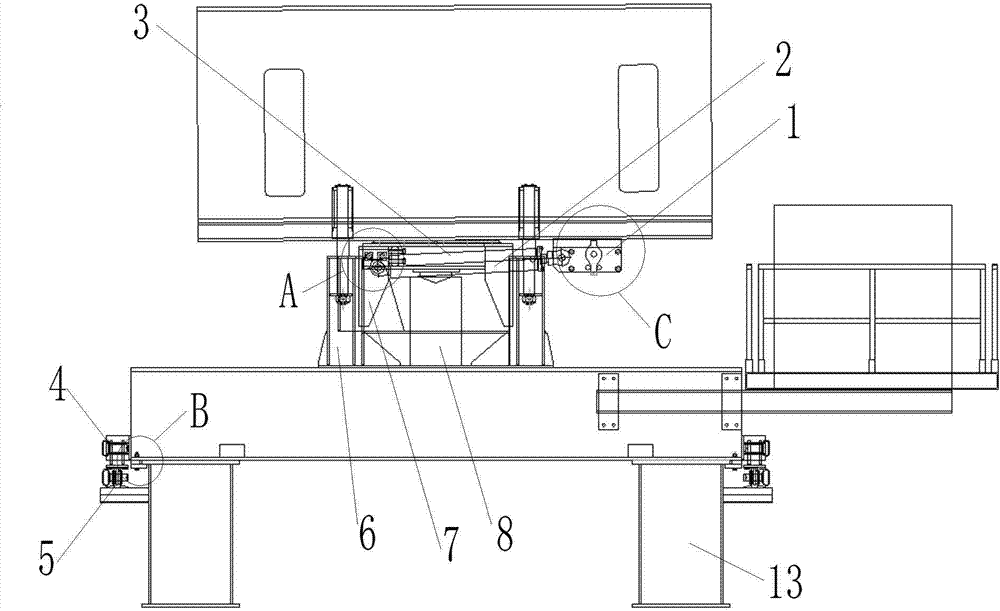

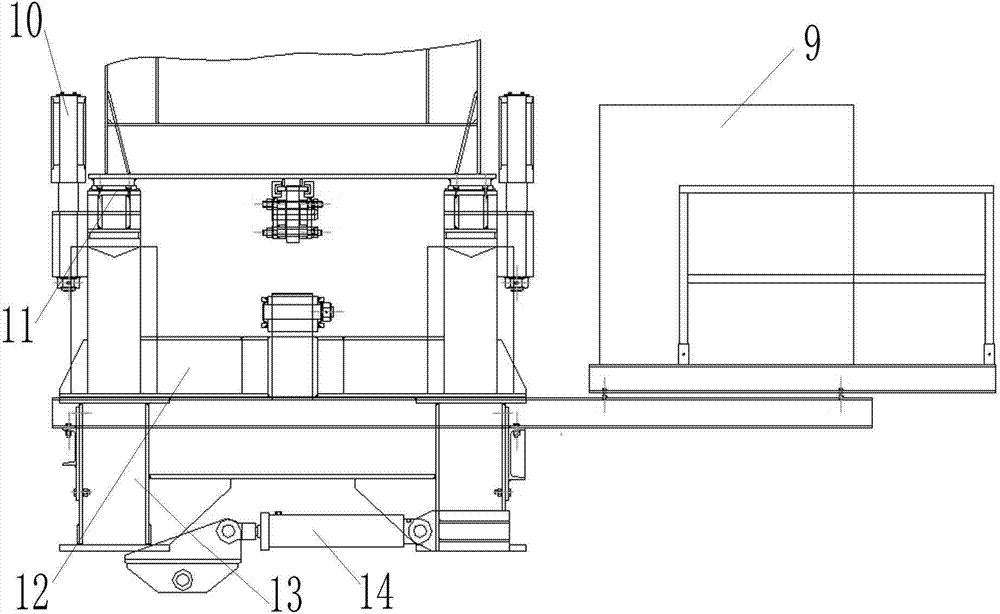

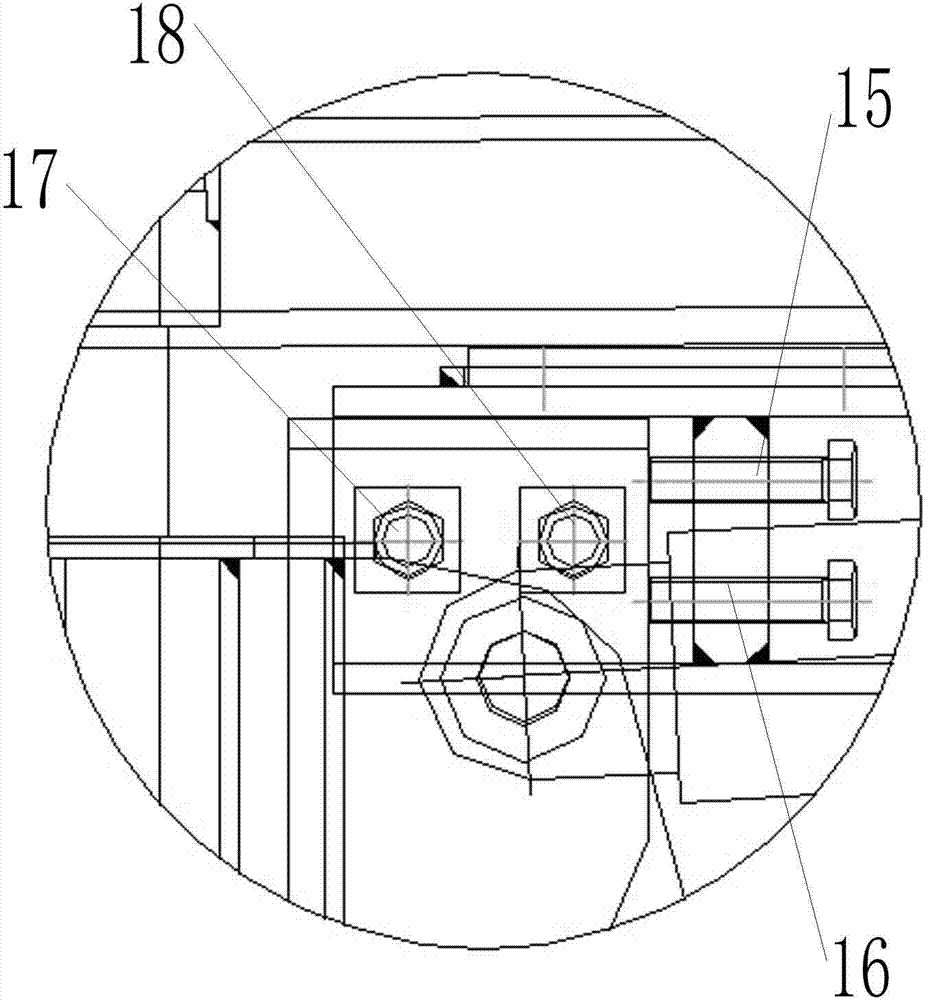

[0022] Attached below figure 1 to attach Figure 7 The present invention will be further described.

[0023] This propulsion trolley comprises trolley base 26, some connecting frame bodies 6 and hydraulic control system 9 installed on the top of trolley base 26, adjustment frame 7 on the up and down sliding installation and connecting frame body 6, vertically installed on the trolley base 26. Oil cylinder A, a traverse device that moves the trolley base 26 laterally relative to the corbel beam 13, a slope adjustment device arranged on the adjustment frame 7, and a longitudinal shift device installed on the trolley base 26 to move the main beam longitudinally, the oil cylinder A is connected to the hydraulic control system 9 . Under the action of the lateral movement device and the vertical movement device, the propulsion trolley can drive the main beam to move horizontally or vertically, and the oil cylinder A can push the adjustment frame upwards to realize the lifting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com