Hydraulic turning overhauling device and method for large vertical axial-flow pump unit

A technology for overhauling devices and vertical shafts, which is applied to axial flow pumps, components of pumping devices for elastic fluids, mechanical measuring devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

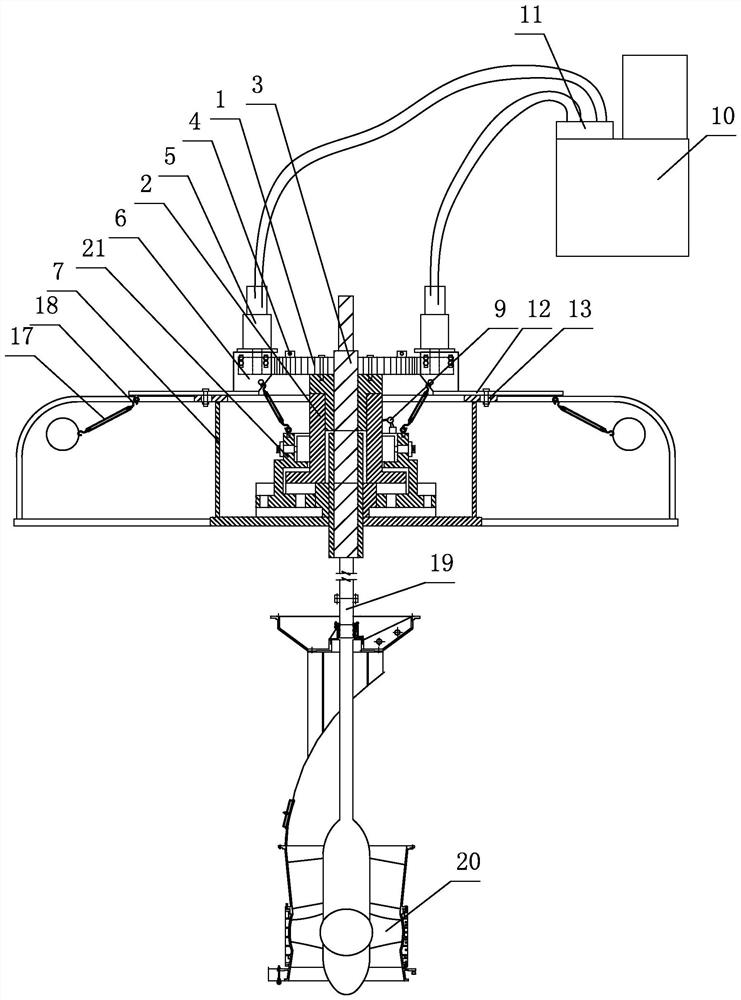

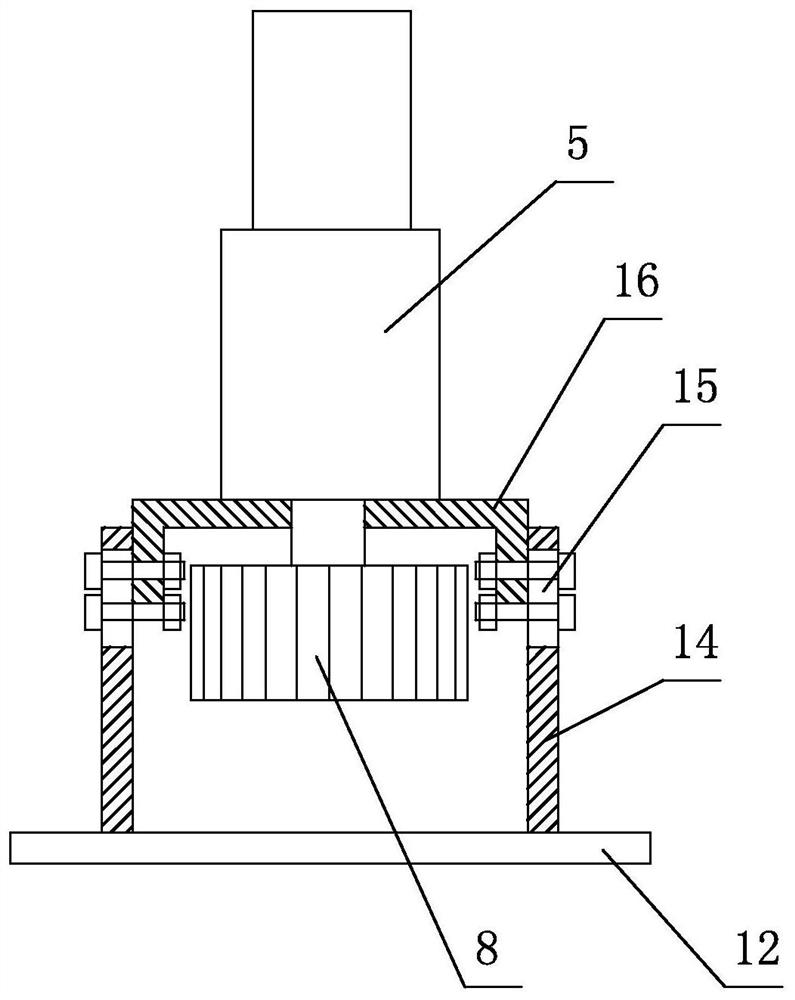

[0034] Such as Figure 1-2 As shown, the hydraulic barring maintenance device for large vertical axial flow pump unit includes:

[0035] A gear plate 1, the gear plate 1 is mounted on the thrust bearing 2 through bolts, the motor main shaft 3 passes through the center of the gear plate 1, the upper surface of the gear plate 1 is provided with a lifting ring 4, and the gear plate 1 is hoisted by the lifting ring 4;

[0036] There are two hydraulic motors 5, the two hydraulic motors 5 are arranged symmetrically around the motor spindle 3, and the two hydraulic motors 5 work synchronously, and the hydraulic motors 5 are installed on the motor housing through the adjustable support base 6 7, the adjustable support base 6 is used to adjust the horizontal posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com