Up-down rotary display stand for forging steel ingot

A technology of lifting, rotating, and steel ingots, which is used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. It can solve problems such as limiting the range of forging specifications of steel ingots, bending and deformation of cylinder piston rods, and damage to cylinder seals. , to achieve the effect of improving the forging range, overcoming the eccentric load and improving the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

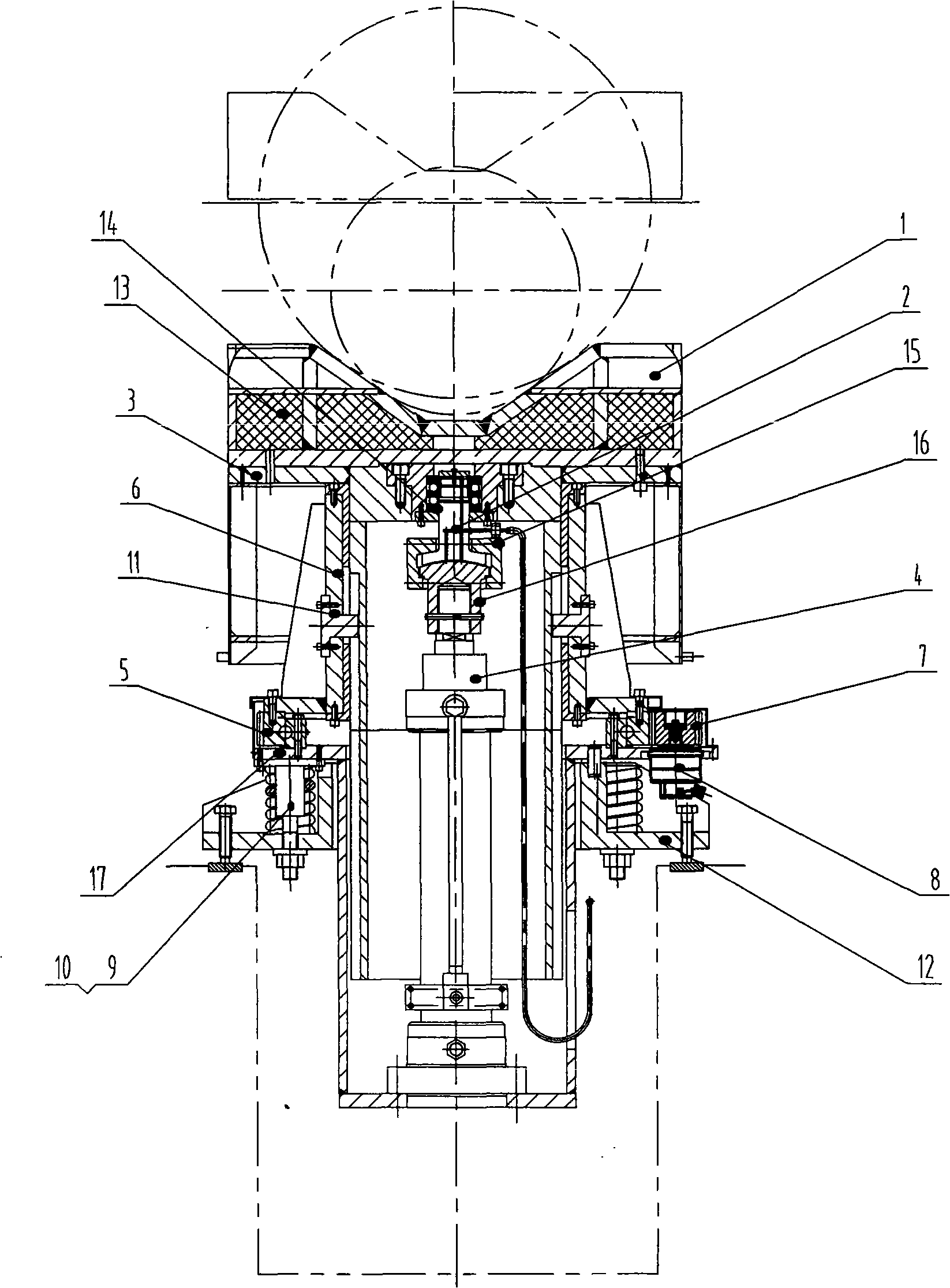

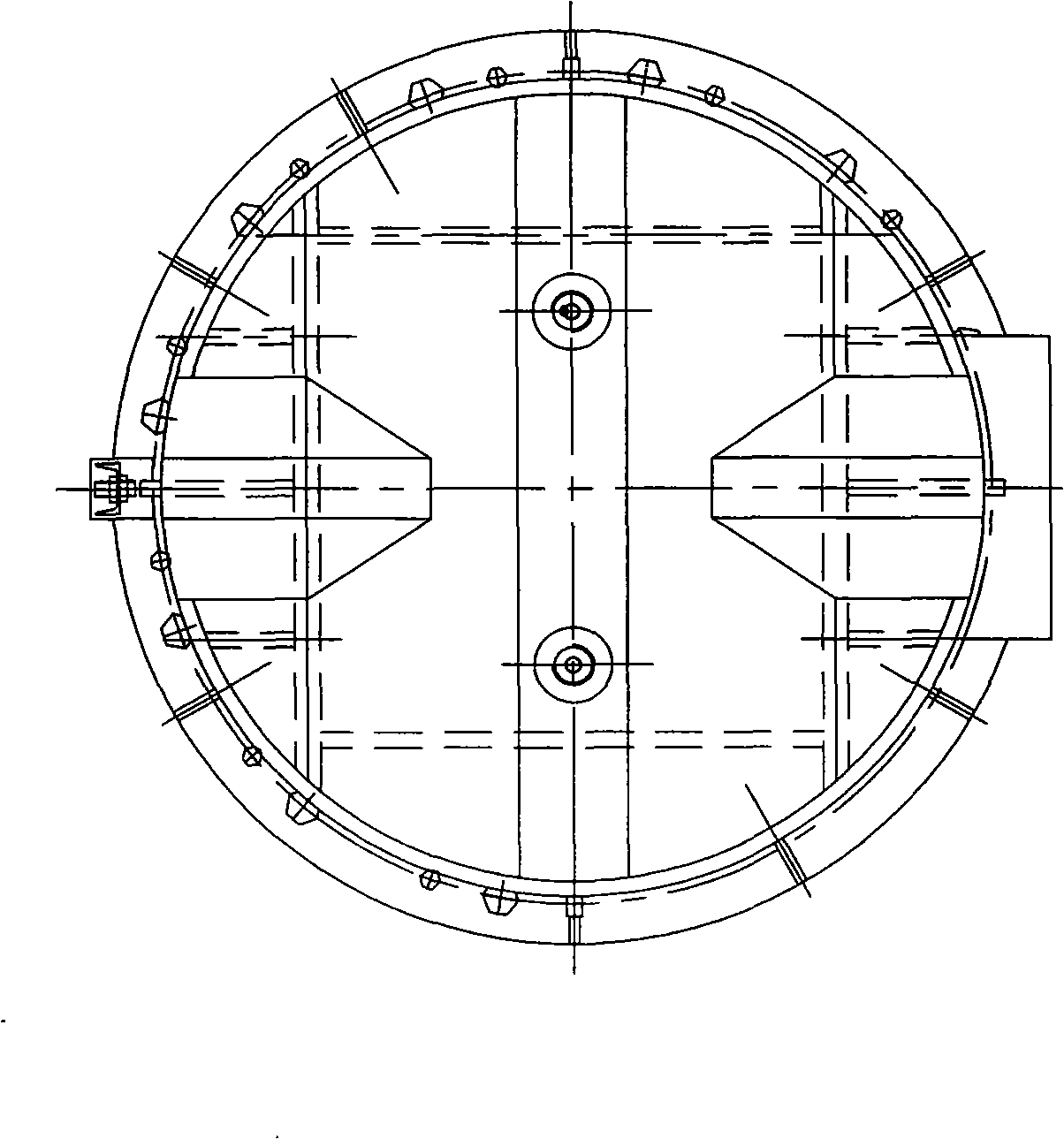

[0013] Such as figure 1 , 2 As shown, a lifting and rotating platform for forging steel ingots includes: a lifting device, a rotating device and a base. The clamping block 15, the spherical joint 16, and the lifting cylinder 4 are formed. The steel ingot supporting platform 1 is bolted to the rotary lifting platform 3 and supported on the upper end surface of the thrust bearing 14. The thrust bearing 14 is connected to the stop of the supporting block 2, and the supporting block 2 and the spherical joint 16 pass through the clamping block. 15 is connected, and the spherical connection head 16 is threadedly connected with the piston rod of the lifting cylinder 4, and the lifting action of the steel ingot lifting rotary table is realized when the piston rod of the lifting cylinder 4 rises or falls.

[0014] Described rotating device is made of the turntable bearing 5 with external tooth, rotating guiding bracket 6, pinion 7, variable motor 8, guide key 11. Four pieces of guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com