Diesel engine piston cooling nozzle testing tool and use method thereof

A piston cooling nozzle and detection tooling technology, applied in the direction of mechanical measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as cylinder scuffing, cylinder scuffing failure, and insufficient pressure, and achieve a simple overall structure, Avoid the failure of the cylinder, and the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

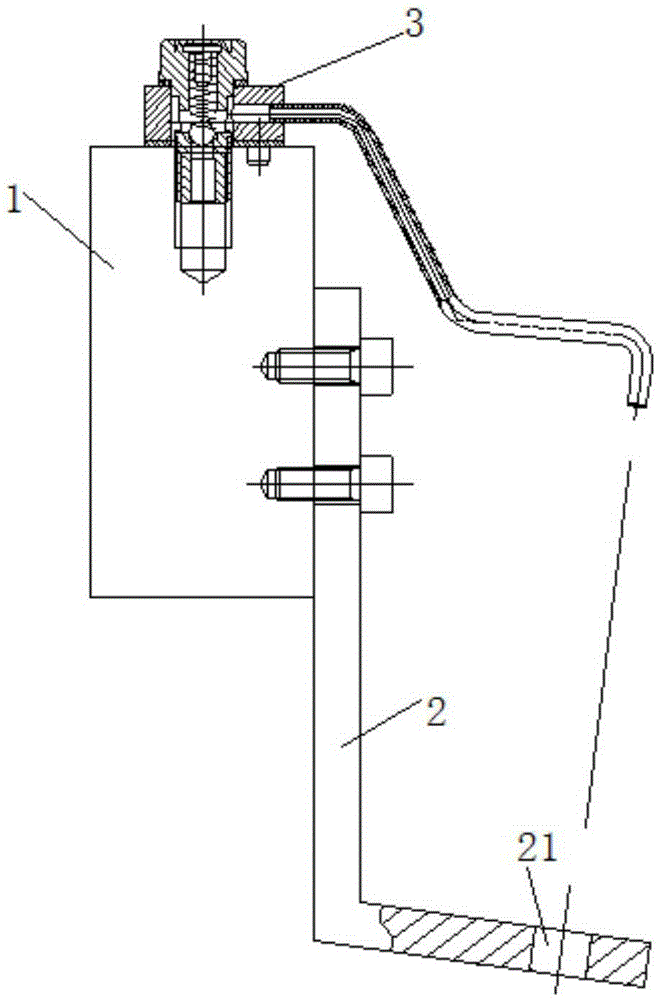

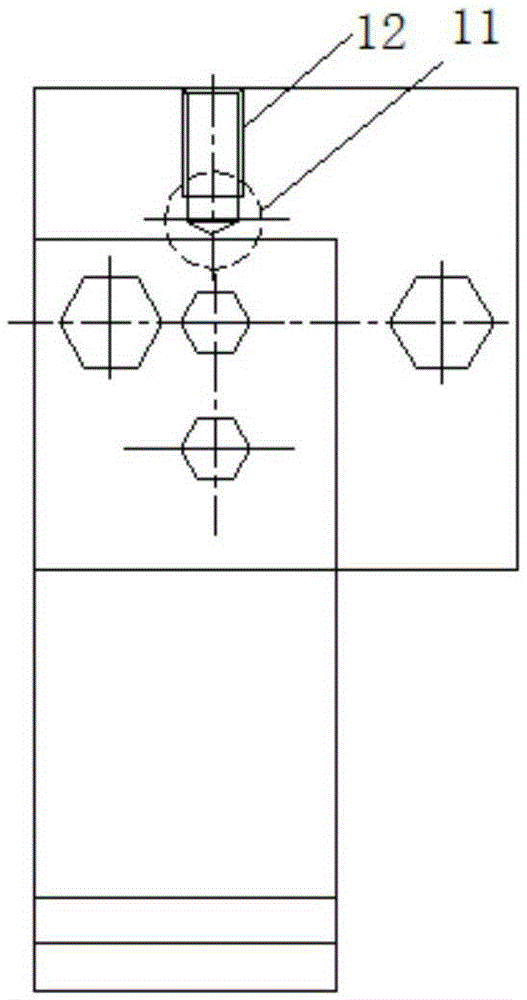

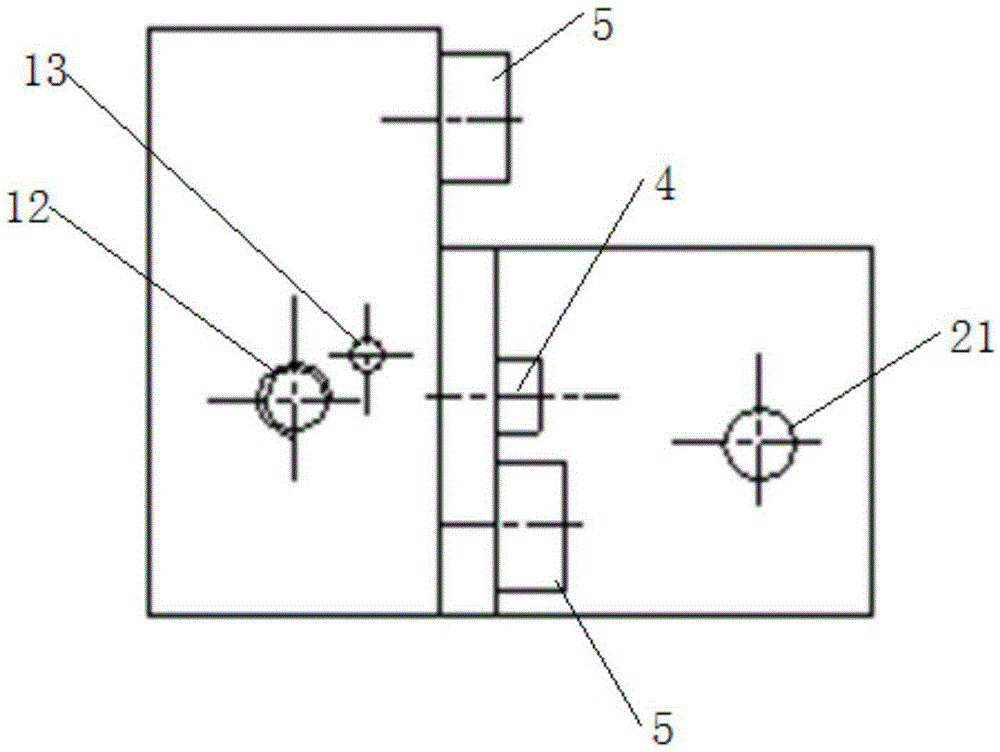

[0024] like Figure 1~3 As shown, the present embodiment includes a bottom plate 1 and a backing plate 2. The back side of the bottom plate 1 is provided with a φ16 oil inlet hole 11 for communicating with the nozzle 3 to be tested and an external oil inlet pipe. The nozzle 3 to be tested is arranged on the top of the bottom plate 1. The backing plate 2 includes an integrally formed vertical part and a horizontal part, one end of the vertical part is connected to the front of the bottom plate 1, the other end of the vertical part is connected to the horizontal part, and the gap between the horizontal part and the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com