Welding special machine for short pipe-flange and pipe-pipe pieces

A pipe fitting welding and flange technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unstable rotation, axial movement, and affecting the quality of workpieces, etc., and achieve stable rotation and no axial movement , Fast and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

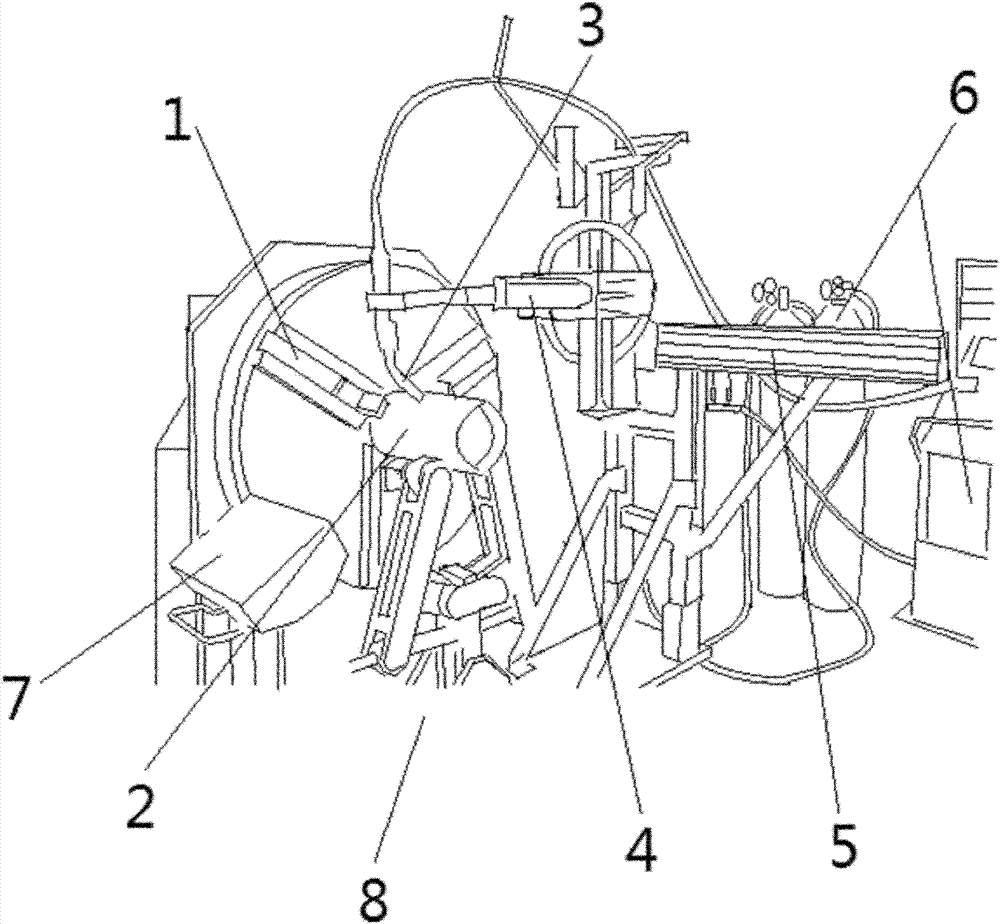

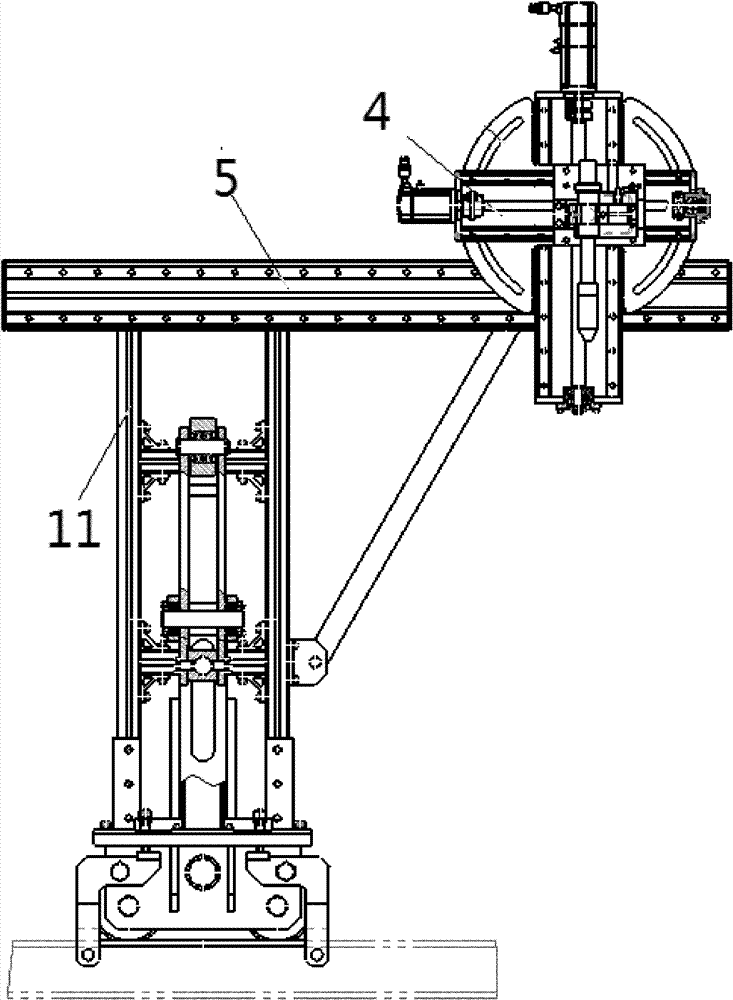

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the roller frame 8 with a gun frame is composed of a mobile trolley, a self-centering roller frame 10, an aluminum profile support 11, a servo cross carriage 4, a traverse carriage 5, a pivoting arm mechanism 9 and a welding torch 3 mechanism and the like. The equipment is light in weight, can be moved horizontally on the guide rail, and is equipped with a locking mechanism to meet the needs of welding pipes of different lengths.

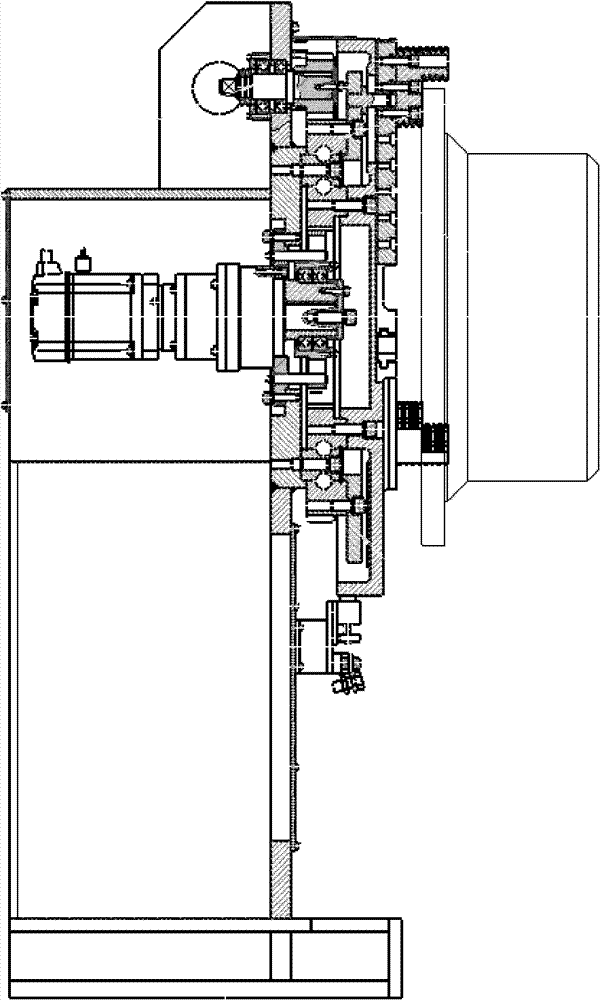

[0015] The self-centering roller frame 10 is fixed on the mobile base, which can clamp workpieces with a pipe diameter of Φ108-Φ630mm, while ensuring that the central height of the supporting pipe fittings of 1040mm remains unchanged. The roller frame is easy and efficient to open and close.

[0016] The servo cross carriage 4 is used to realize welding horizontal swing and vertical movement in the welding process, and can also realize automatic control of arc length. Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com