Load-sensitive rotation buffer valve and crane rotation hydraulic system

A rotary buffering, load-sensitive technology, applied in cranes, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of large swing of the turntable when stopped, large space-time travel when starting, and unstable output flow, etc., to eliminate pressure fluctuations, The effect of stable flow and small pressure shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

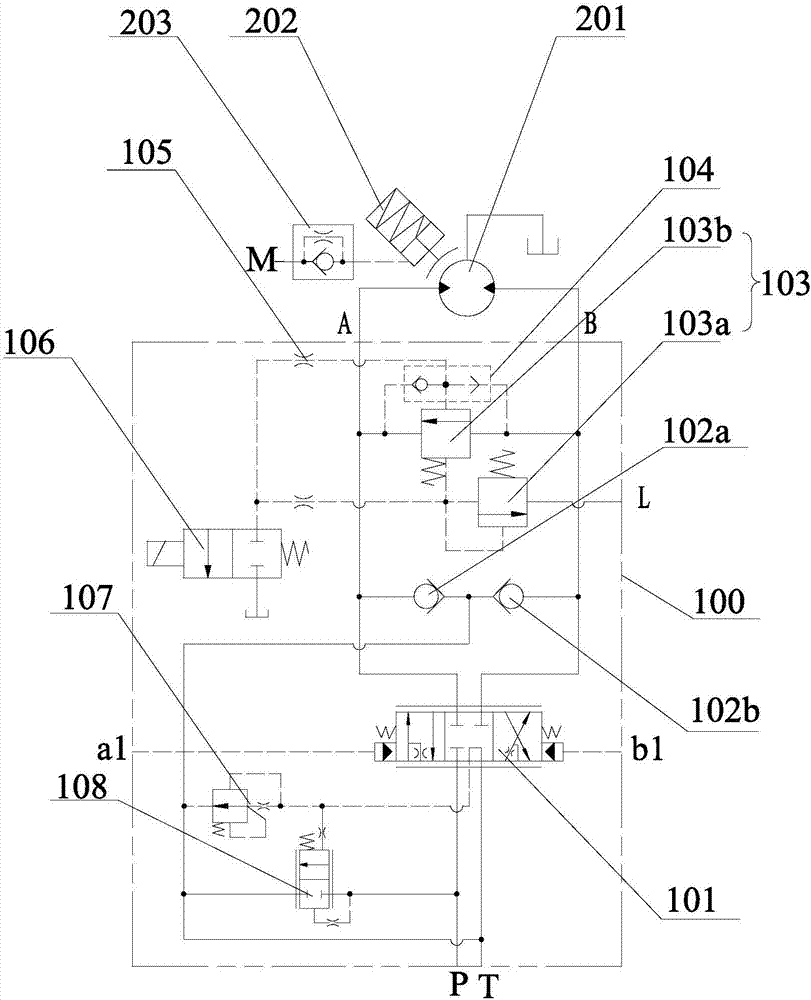

[0021] Load Sensing Swing Shock Valve 100, such as figure 2 As shown, including the valve body, the valve body has oil inlet port P, oil return port T, first working oil port A, second working oil port B, first pilot oil port a1, second pilot oil port The oil port b1, the oil discharge port L port, the A port and the B port are respectively used to communicate with the oil ports on both sides of the rotary motor 201, and the valve body is provided with a rotary reversing valve 101 and a pilot relief valve 103. The reversing valve 101 is a pilot-operated proportional reversing valve. The oil inlet port and the oil return port of the reversing reversing valve 101 are respectively connected with the P port and the T port of the valve body, and the two working oil ports of the reversing reversing valve 101 are respectively connected with A port and B port of the valve body are connected, and the first pilot oil port and the second pilot oil port of the rotary reversing valve 101 ...

Embodiment 2

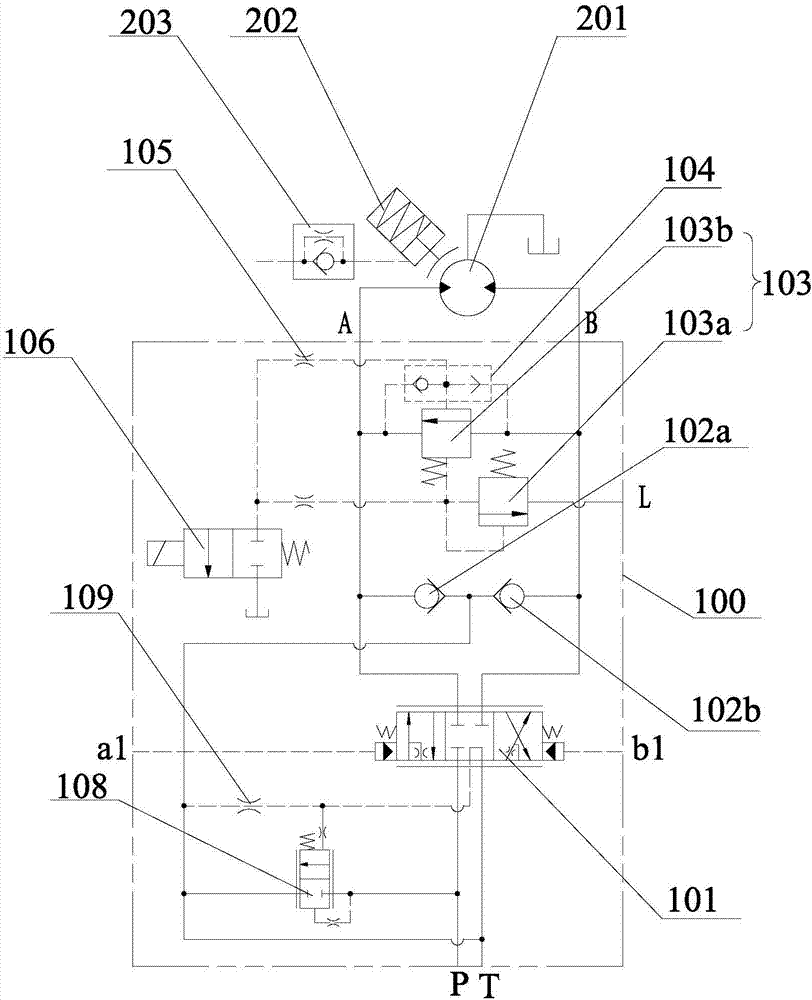

[0033] Load Sensing Swing Shock Valve 100, such as image 3 As shown, the difference between the present embodiment and the first embodiment lies in the use of the damping valve 109 and the bag body constant flow valve 107 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com