Trolley for concrete construction on multiple sections by employing mining method and construction method thereof

A technology of concrete and mine method, which is applied in the fields of earth drilling, mining equipment, shaft lining, etc. It can solve the problems of hidden safety hazards and impact on the construction period, and achieve the effects of construction safety, improvement of construction efficiency, and improvement of the degree of mechanized construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

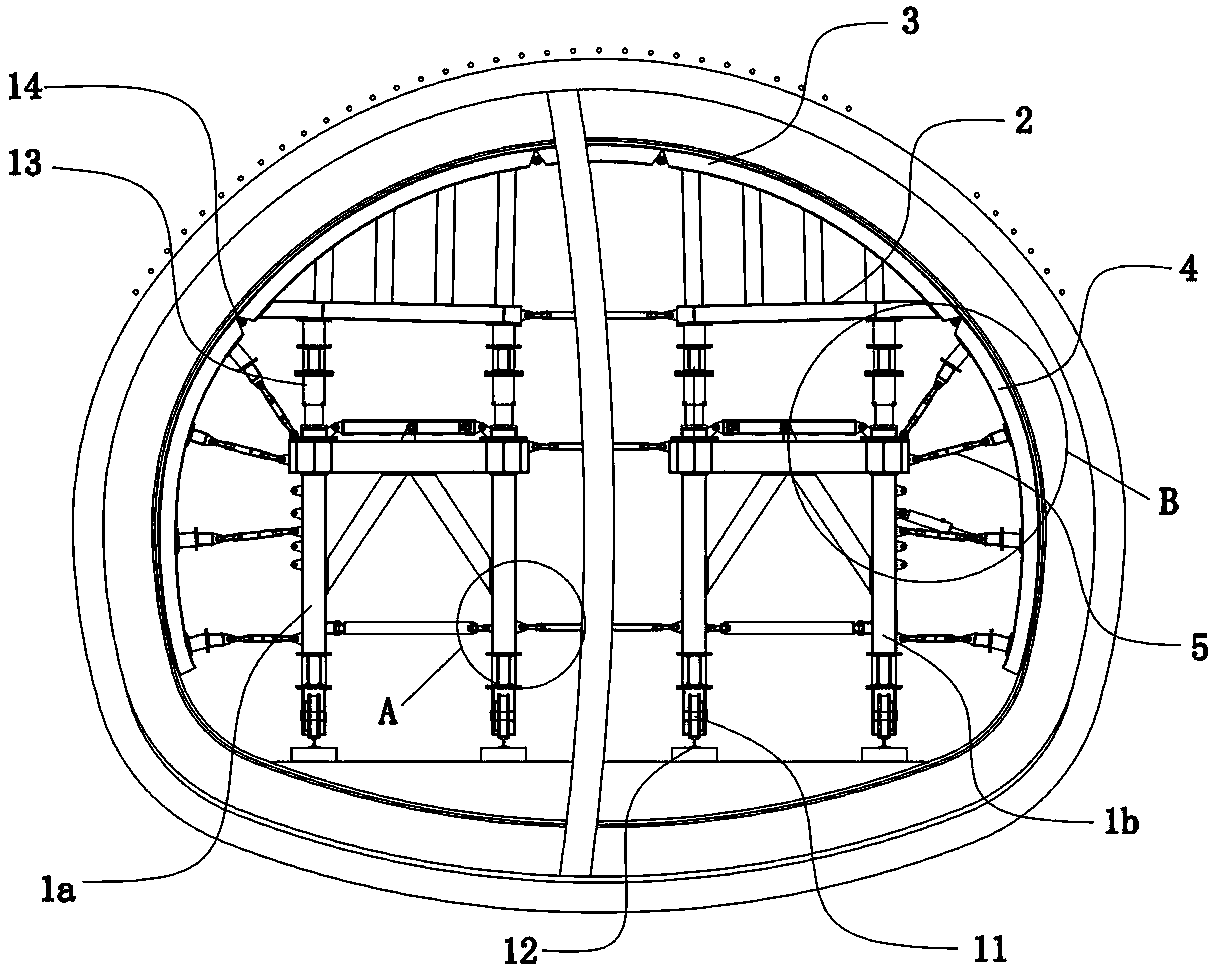

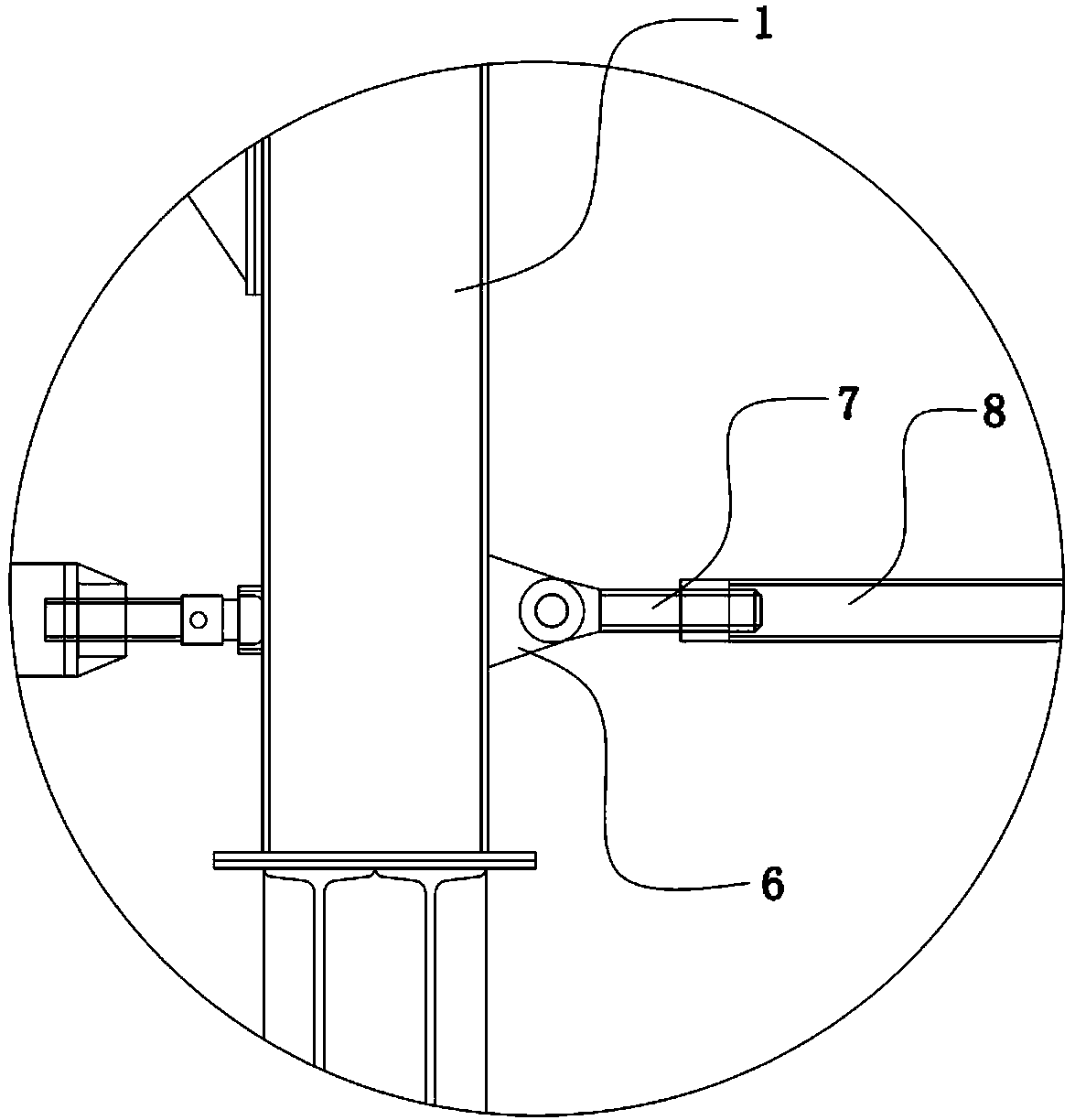

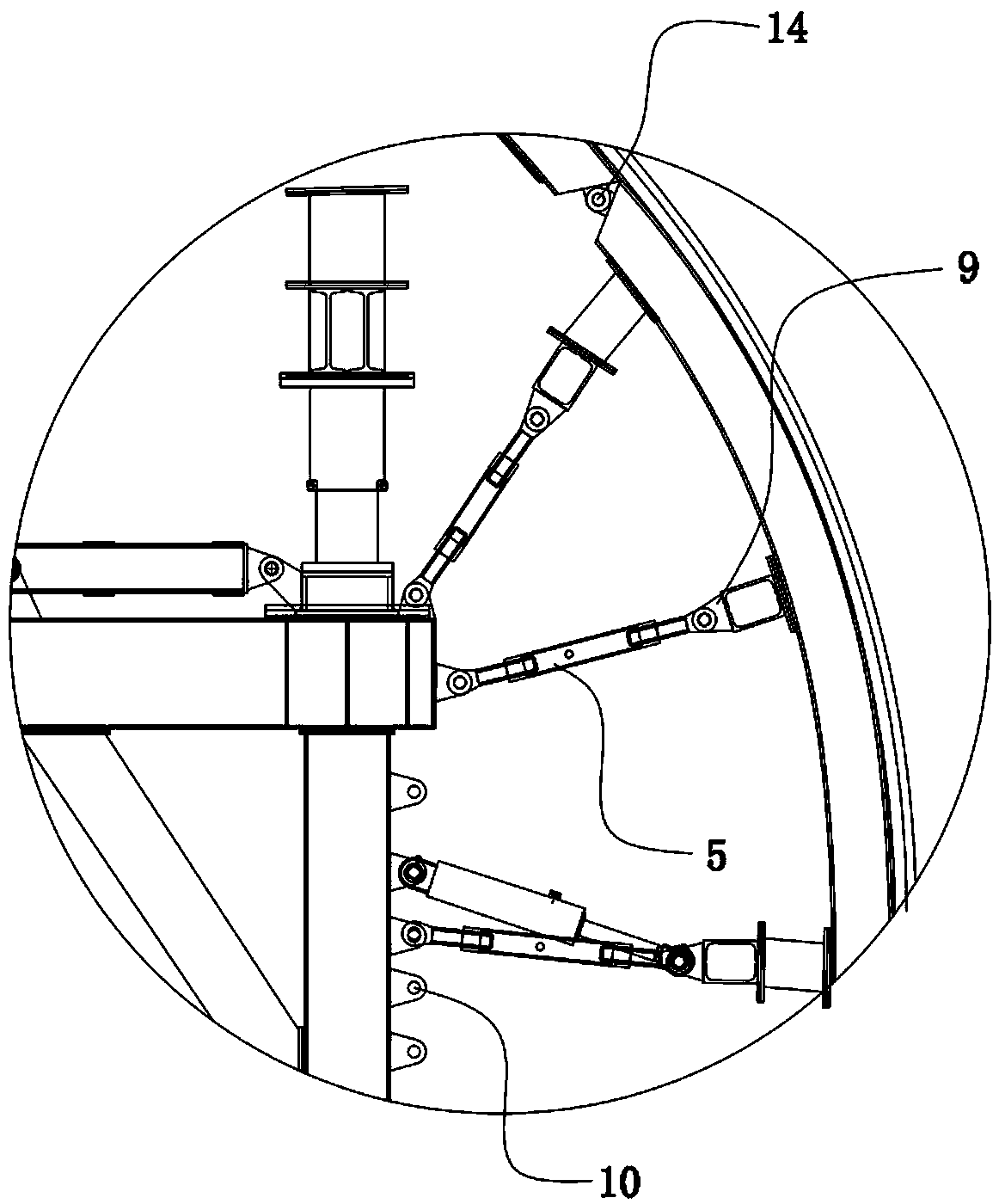

[0033] Such as Figure 1 to Figure 3 As shown, the present embodiment is a trolley for concrete pouring construction of various cross-section forms in the mining method, including a vehicle frame, which is connected with a formwork, and the trolley adopts a 6m lining trolley, and the length of 6m is a running water section. Segmented overall pouring, the vehicle frame includes a portal frame 1 and a top arch frame 2 arranged above the portal frame 1, a top formwork 3 is arranged above the top arch frame 2, and side templates 4 are provided on both sides of the portal frame 1. A late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com