Automatic coal leveling sampling loading station

A technology for loading stations and coal trucks, which is applied in the field of automatic flat coal sampling and loading stations, which can solve the problems of high labor intensity, inability to meet actual production, and poor working environment by manual leveling, so as to avoid safety and dust hazards, work easily, Effects of Sampling Science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

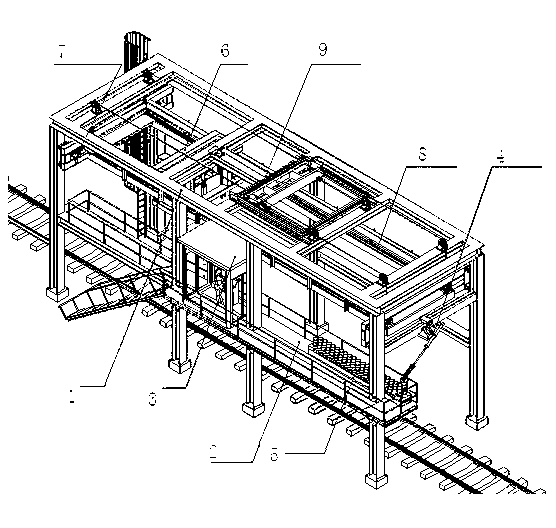

[0027] Such as figure 1 Shown: an automatic flat coal sampling and loading station, including a base frame 1, an operating platform 2, an operating room 3, a sampling manipulator 4, a coal separator 5 for retaining samples, a coal scraping car 6, a coal scraping car hydraulic drive device 7, a lift Track beam 8, hydraulic lifter 9, hydraulic power system and automatic control electrical system;

[0028] The base frame 1 is the load-bearing and fastening support of all the transmission and execution parts of the system. The main body of the base frame 1 is made of H-shaped steel through riveting. The whole is simple and solid. After the surface is treated by shot blasting and stainless steel thermal spraying, Beautiful and generous, it can withstand wind and rain for 30 years without corrosion;

[0029] The operating platform 2 is located in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com