Aramid fiber fibre-silastic fabric, production method thereof and use in soft pipeline

A kind of aramid fiber cloth and aramid fiber technology, applied in the direction of fiber type, fiber processing, textile material processing, etc., can solve the problems of difficult surface treatment, low comprehensive performance, low qualification rate, etc., to solve the problem of aramid fiber Effects of deformation and dislocation, improved tensile and tear strength, good mechanical properties and process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

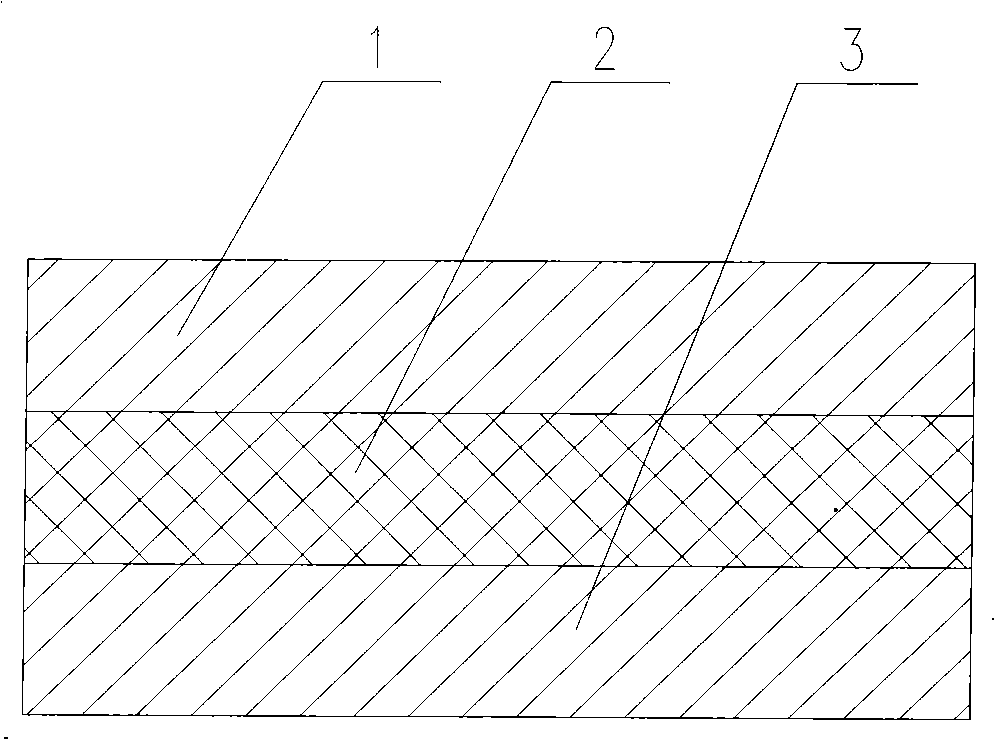

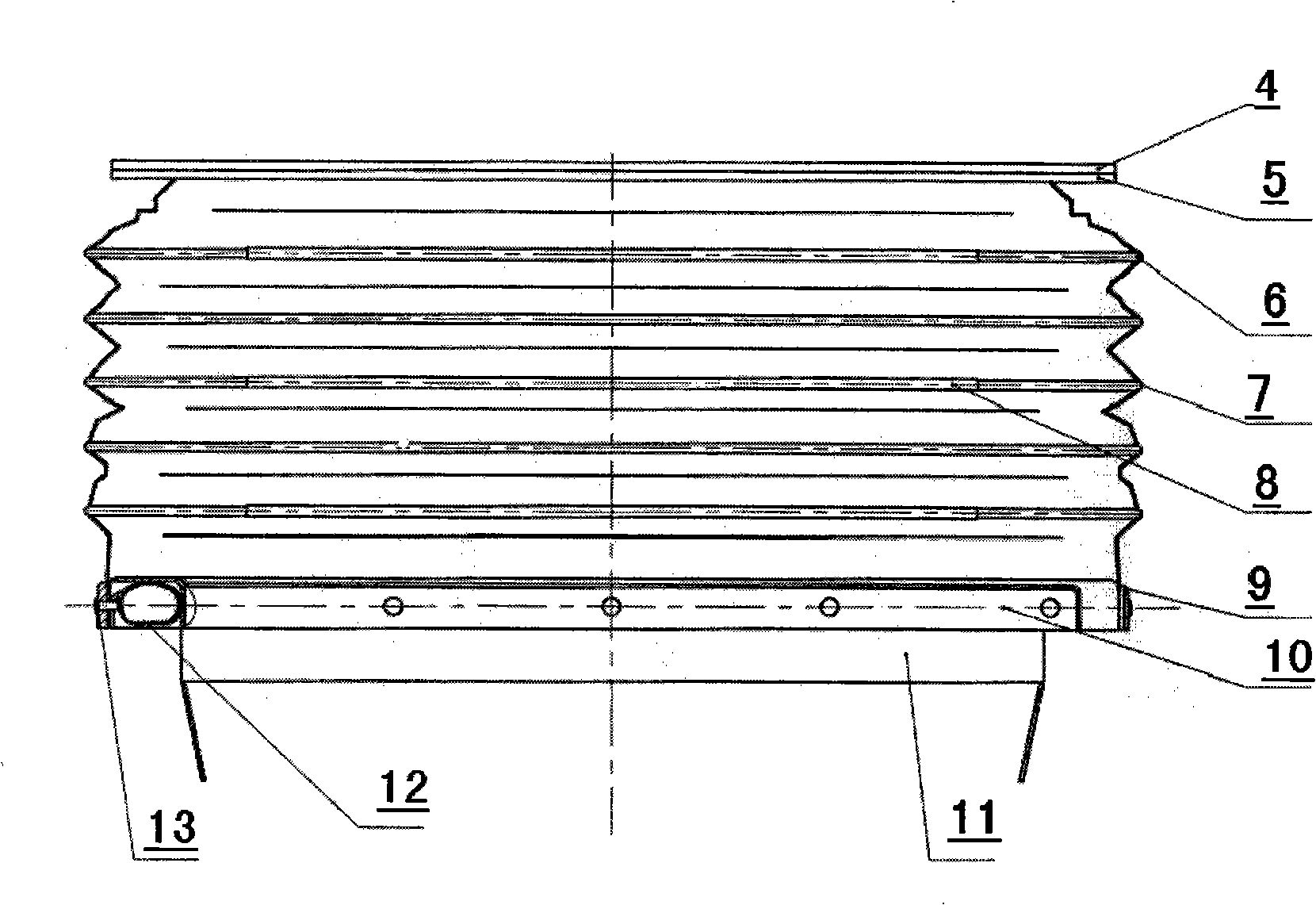

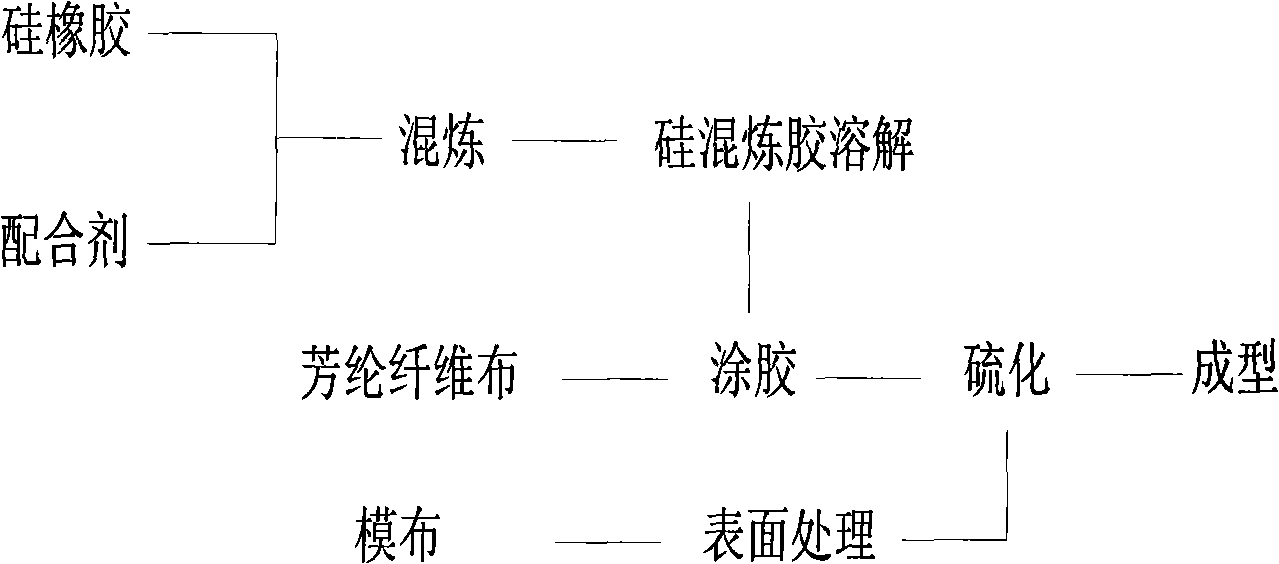

[0046] A kind of manufacturing process of aramid fiber-silicone rubber cloth:

[0047] The invention relates to a production method of aramid fiber-silicone rubber cloth, which is to coat the surface of the aramid fiber with a silicon compound coating by means of penetrating and two-roller rolling. In the mixing process of silicone rubber, halogen-free flame retardants, reinforcing agents, pigments, and other modification additives are added; the silicone rubber paste is made by adding solvents and coupling agents; halogen-free The flame retardant is antimony trioxide, magnesium hydroxide, and aluminum hydroxide in a ratio of 1:7:7; the reinforcing agent is fumed white carbon black; the pigment is rose red; the solvent is 120# gasoline, coupled The agent is silane, and the release agent is surfactant sodium dodecylbenzenesulfonate.

[0048] Its production steps are as follows:

[0049] Step 1: Make mixed silica gel according to the conventional technology of rubber processin...

Embodiment 2

[0063] A kind of manufacturing process of aramid fiber-silicone rubber cloth:

[0064] The invention relates to a production method of aramid fiber-silicone rubber cloth, which is to coat the surface of the aramid fiber with a silicon compound coating by means of penetrating and two-roller rolling. Silicone compounded rubber is added with halogen-free flame retardants, reinforcing agents, solvents, pigments, and other modification additives during the mixing process; the silicon compounded rubber paste is formed by adding solvents and coupling agents after stirring; The halogen-free flame retardant is composed of antimony trioxide, magnesium hydroxide and aluminum hydroxide in a ratio of 1:5:9. The reinforcing agent is fumed white carbon black, the pigment is rose red; the solvent is 120# gasoline, the coupling agent is silane, and the release agent is surfactant sodium dodecylbenzenesulfonate.

[0065] Its production steps are as follows:

[0066] Step 1: Make mixed silica ...

Embodiment 3

[0081] A kind of manufacturing process of aramid fiber-silicone rubber cloth:

[0082] The invention relates to a production method of aramid fiber-silicone rubber cloth, which is to coat the surface of the aramid fiber with a silicon compound coating by means of penetrating and two-roller rolling. Silicone compounded rubber is added with halogen-free flame retardants, reinforcing agents, solvents, pigments, and other modification additives during the mixing process; the silicon compounded rubber paste is formed by adding solvents and coupling agents after stirring; The halogen-free flame retardant is composed of antimony trioxide, magnesium hydroxide and aluminum hydroxide in a ratio of 1:9:5. The reinforcing agent is fumed white carbon black, the pigment is rose red; the solvent is 120# gasoline, the coupling agent is silane, and the release agent is surfactant sodium dodecylbenzenesulfonate.

[0083] Its production steps are as follows:

[0084] Step 1: Make mixed silica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com