Error correction and compensation method and device based on calibration board in direct-writing exposure machine

A technology of error correction and compensation method, which is applied in the direction of photolithography exposure device, photomechanical equipment, microlithography exposure equipment, etc. It can solve errors, different exposure parameters and alignment parameters, and affect the quality of imaging results in different areas of exposure, etc. problem, to achieve the effect of low cost, solving poor alignment, convenient and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

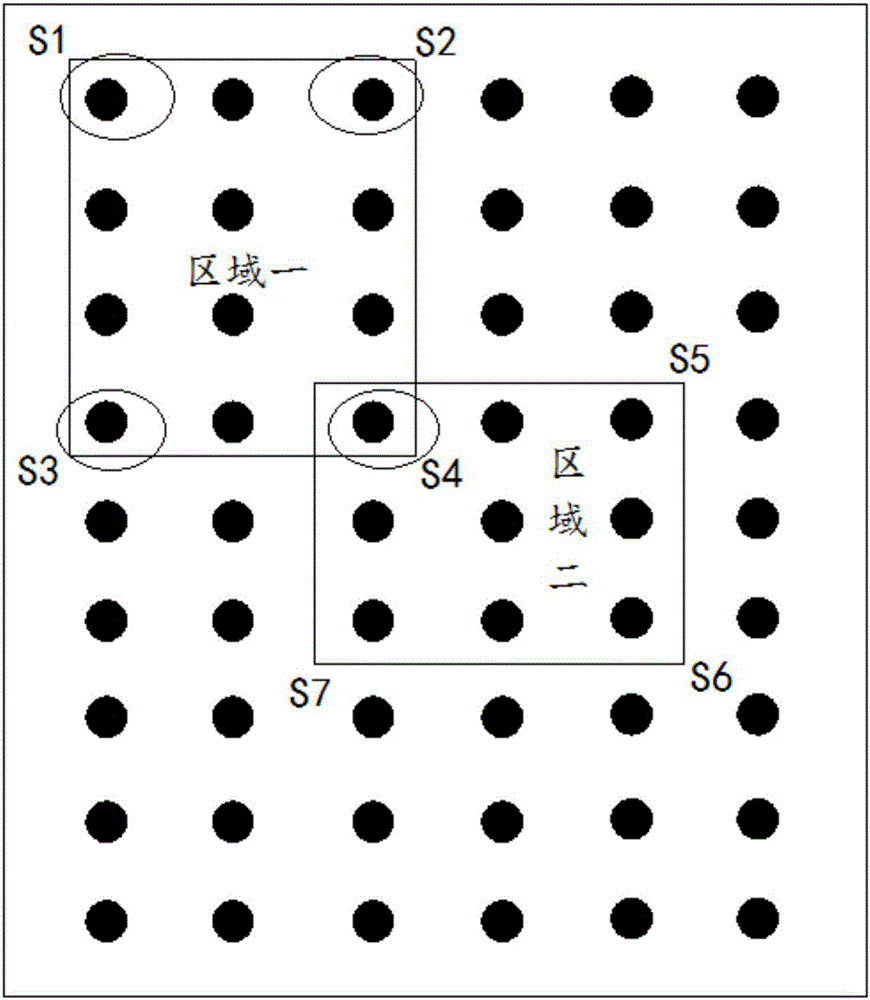

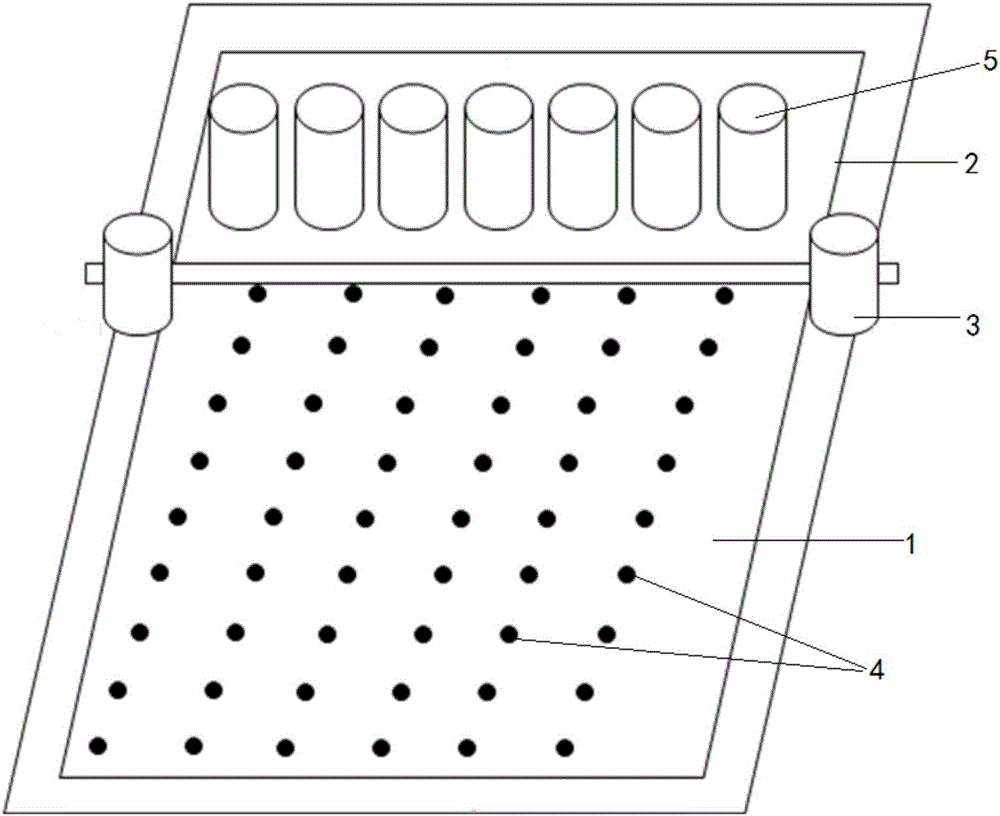

[0042] Embodiment: In the present invention, the vertex coordinate values of any two regions on the calibration plate are collected, and the arbitrary regions are quadrilaterals, and the two regions have overlapping parts. The specific implementation method is as follows:

[0043] In area one, first place the calibration plate with equidistant marking points on the platform; then collect the coordinate values at the vertices s1, s2, s3 and s4 of the quadrilateral formed by any position on the calibration plate through the sensor, which is recorded as: (x s1 ,y s1 ), (x s2 ,y s2 ), (x s3 ,y s3 ), (x s4 ,y s4 );

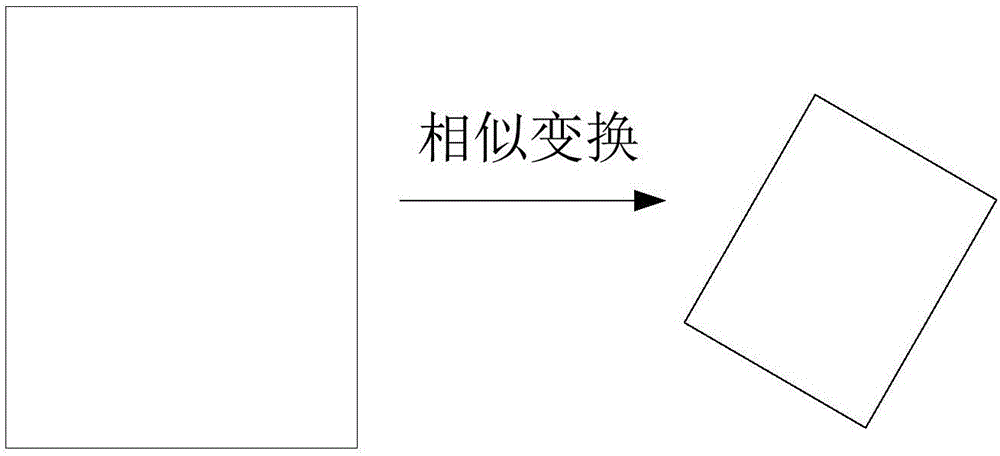

[0044] Then calculate the size expansion and contraction variation of the quadrilateral according to the figure similarity transformation model, the specific method is: the rotation angle in the figure similarity transformation is α, and the expansion and contraction of four vertices x-axis direction is (s1 x , s2 x , s3 x , s4 x ), the expansion and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com