A P-type SE-PERC double-sided solar cell and a preparation method thereof

A solar cell, double-sided technology, applied in the field of solar cells, can solve the problems of inaccuracy and deformation of the alignment of the front silver sub-grid electrode and the laser doped region, so as to enhance the short-wave response, improve the photoelectric conversion efficiency, and improve the output capability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

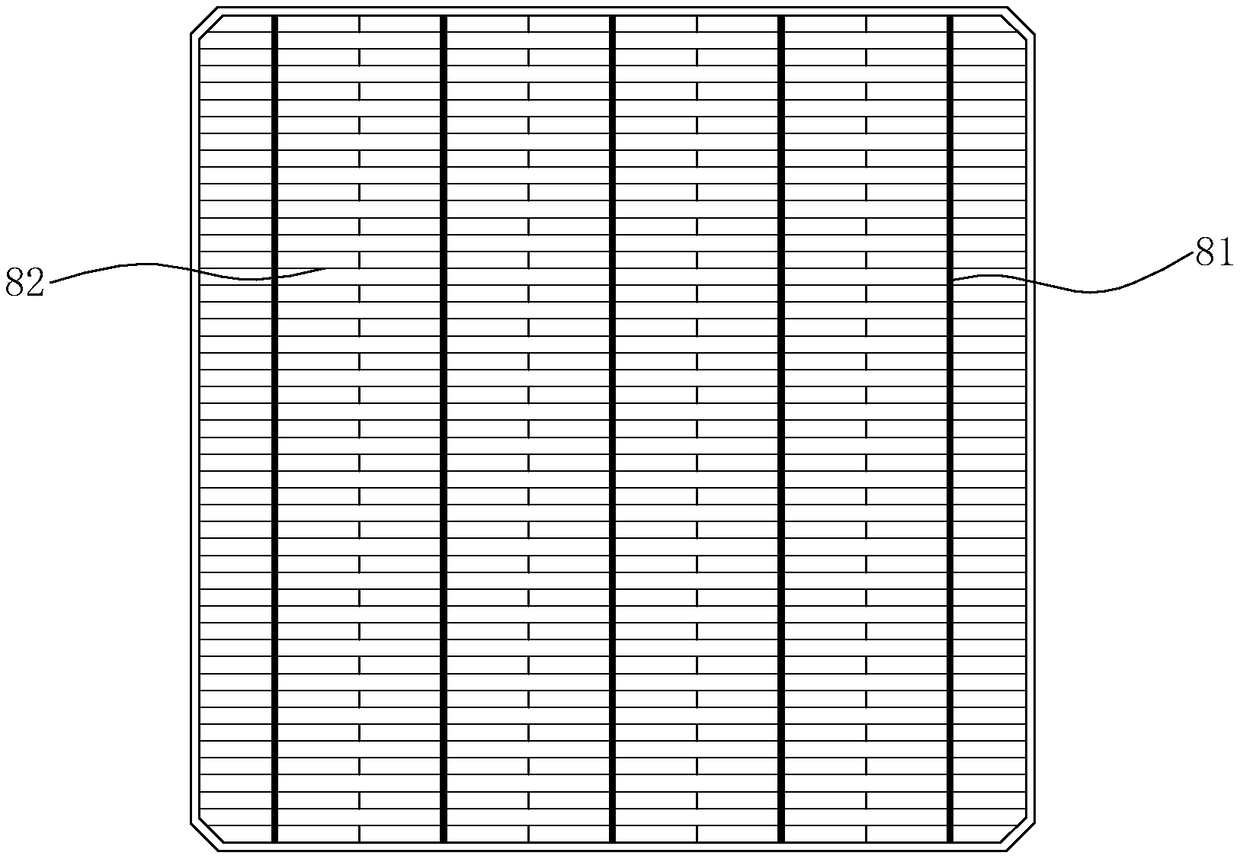

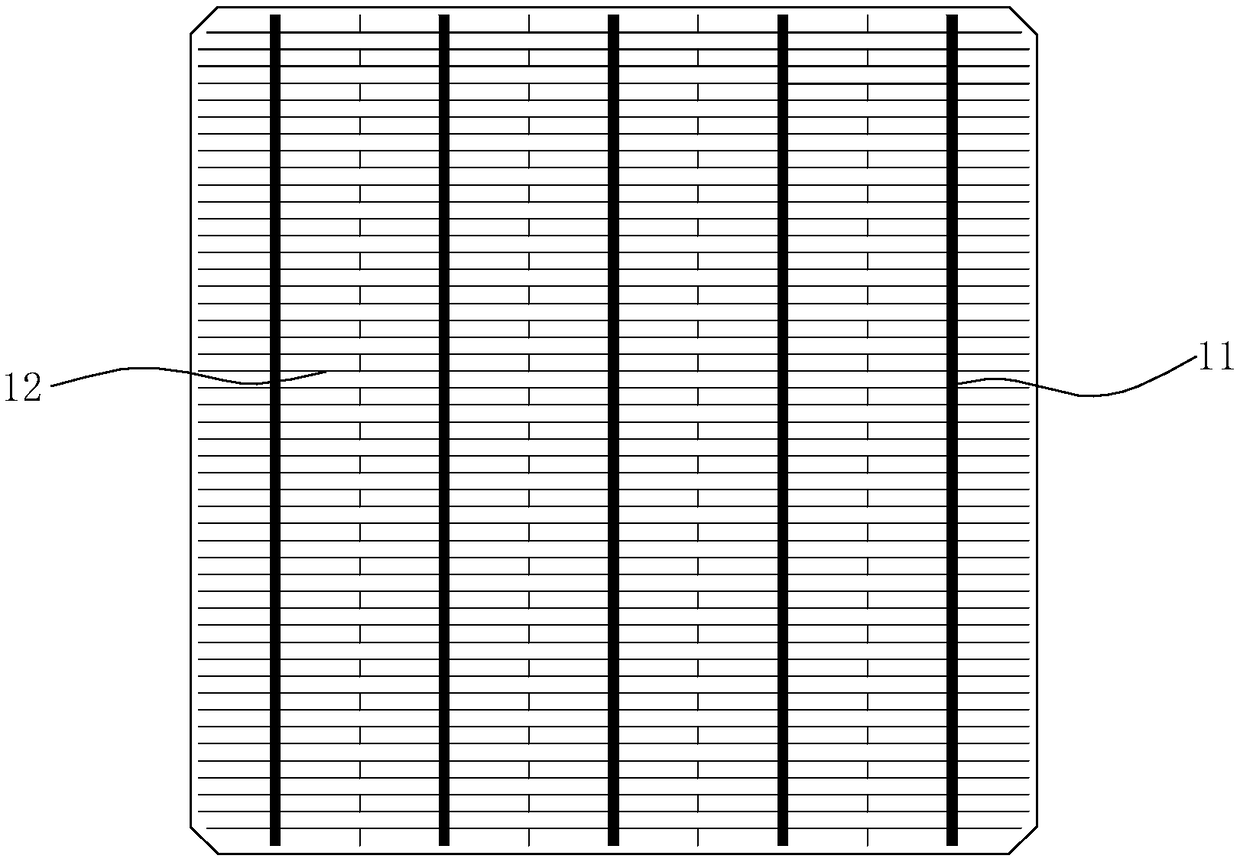

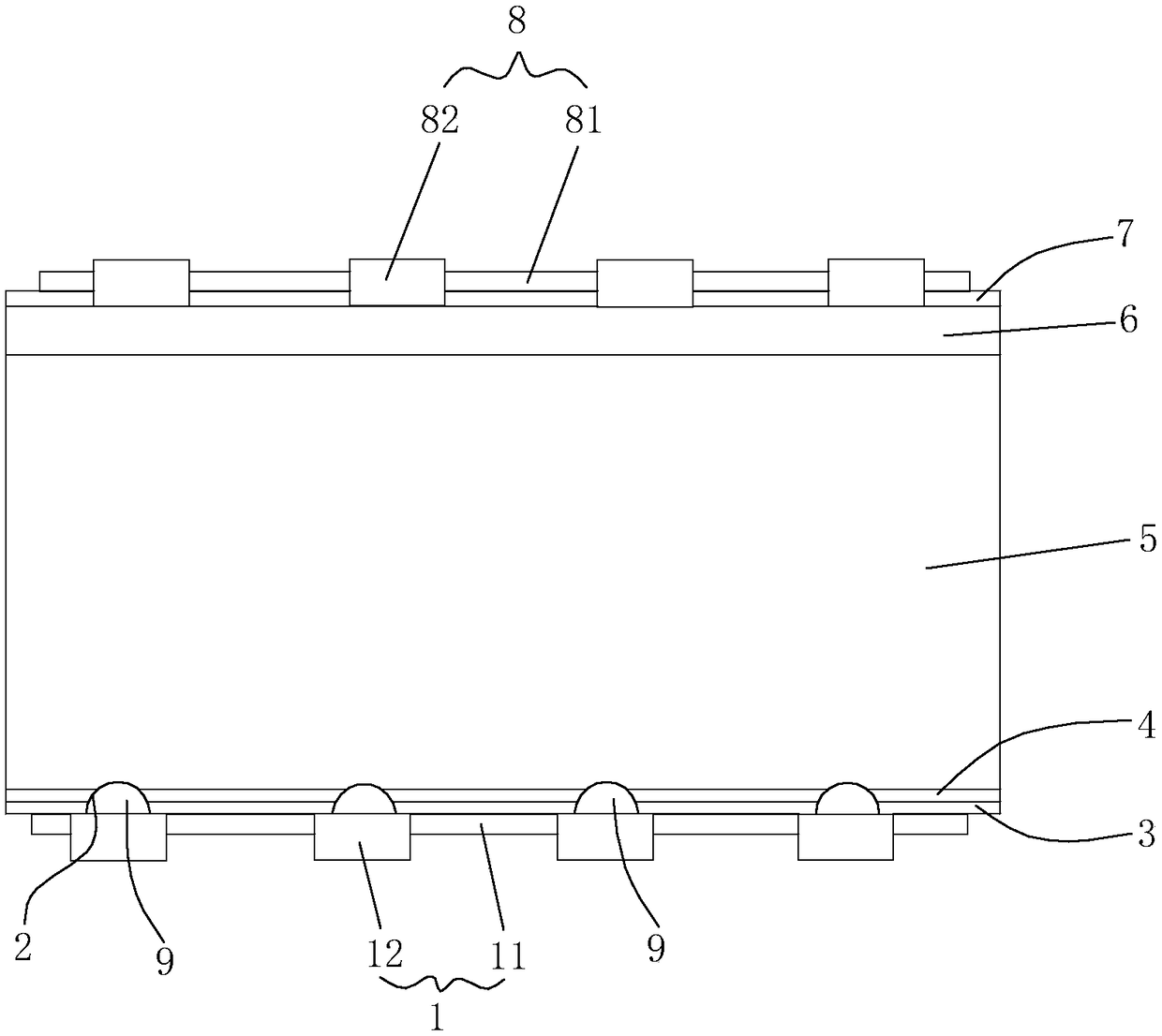

[0046] Embodiments of the P-type SE-PERC double-sided solar cell of the present invention are as follows Figure 1 to Figure 4 As shown, it includes a back electrode 1, a back silicon nitride film 3, a back aluminum oxide film 4, a P-type silicon 5, an N-type silicon 6, a front silicon nitride film 7 and a front silver electrode 8 arranged in sequence from bottom to top. The silver electrode 8 is composed of a front silver main grid electrode 81 made of silver and a front silver sub grid electrode 82 made of silver. The front silver sub grid electrode 82 is perpendicular to the front silver main grid electrode 81. The back electrode 1 is made of silver material. The back silver main gate electrode 11 and the back aluminum sub-gate electrode 12 made of aluminum, the back aluminum sub-gate electrode 12 and the back silver main gate electrode 11 are perpendicular to each other.

[0047]On the back of the solar cell, there is also a laser groove area 2 on the back after opening th...

Embodiment 2

[0067] The difference between Embodiment 2 and Embodiment 1 of the P-type SE-PERC double-sided solar cell of the present invention is that, as Figure 5 As shown, in the second embodiment, several laser grooves 10 are designed with grooved areas with different widths, and the width of the laser grooves 10 gradually widens from the middle to both sides. The width of the laser groove 10 is in the range of 80-300um. The laser groove 10 in the middle is the narrowest, with a width of 80um, the laser groove 10 on the outermost two sides is the widest, with a width of 300um, and the distance between adjacent laser grooves 10 is equal to 1.2mm. The distance between 10 can also be selected within the range of 0.8-2 mm. The preparation method of embodiment two is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com