Manufacturing method of flexible liquid crystal display device

A flexible liquid crystal display and manufacturing method technology, which is applied in identification devices, nonlinear optics, optics, etc., can solve the problems that display devices cannot meet the designer's requirements for product shape, residue, glass substrate thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] see Figure 2A to Figure 9 , the embodiment 1 provides a method for manufacturing a flexible liquid crystal display device, comprising:

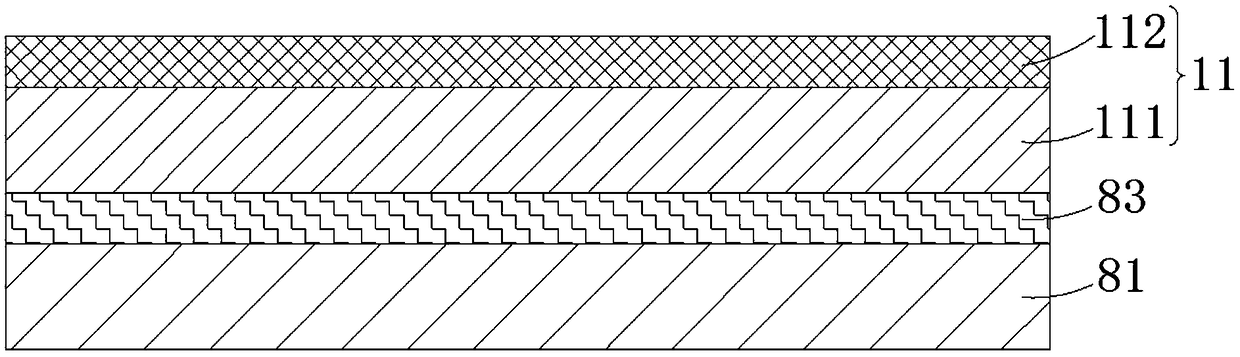

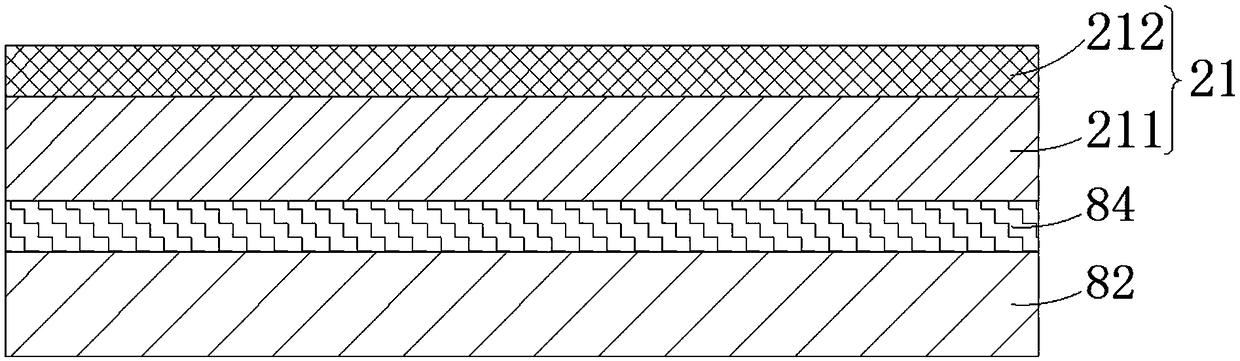

[0073] Step 1, such as Figure 1A and Figure 1B As shown, a first flexible conductive film 11 , a second flexible conductive film 21 , a first rigid substrate 81 , a second rigid substrate 82 , a first UV peelable adhesive film 83 and a second UV peelable adhesive film 84 are provided.

[0074] The first flexible conductive film 11 includes a first flexible substrate 111 and a first conductive layer 112 disposed on the first flexible substrate 111, and the second flexible conductive film 21 includes a second flexible substrate 211 and The second conductive layer 212 is disposed on the second flexible substrate 211 .

[0075] The first UV peelable adhesive film 83 and the second UV peelable adhesive film 84 all have double-sided adhesiveness, and the first UV peelable adhesive film 83 and the second UV peelable adhesive film 84 all ...

Embodiment 2

[0133] see Figure 10A to Figure 10D , see also Figure 2A to Figure 9 , the embodiment 2 provides a method for manufacturing a flexible liquid crystal display device, comprising:

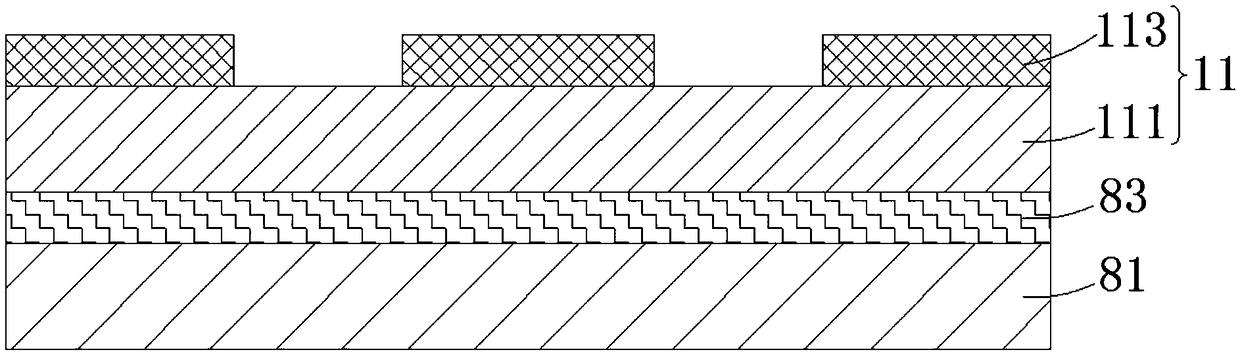

[0134] Step 1', such as Figure 10A , Figure 10B , Figure 10C as well as Figure 10D As shown, a first flexible conductive film 11 and a second flexible conductive film 21 are provided, and the first flexible conductive film 11 includes a first flexible substrate 111 and a first conductive layer disposed on the first flexible substrate 111 112 , the second flexible conductive film 21 includes a second flexible substrate 211 and a second conductive layer 212 disposed on the second flexible substrate 211 .

[0135] The first conductive layer 112 and the second conductive layer 212 are patterned respectively to obtain the first electrode 113 and the second electrode 213 .

[0136] The step 1' is completed on the reel production line, which is provided with an unwinding shaft and a rewinding sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com