Electroluminescence device based on boron-containing organic compound

An electroluminescent device and organic compound technology, applied in the field of high-efficiency, long-life organic electroluminescent devices, can solve the problems of difficult exciton utilization, high fluorescence radiation efficiency, efficiency roll-off, and large configuration changes. Achieve the effect of reducing the exciton quenching effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

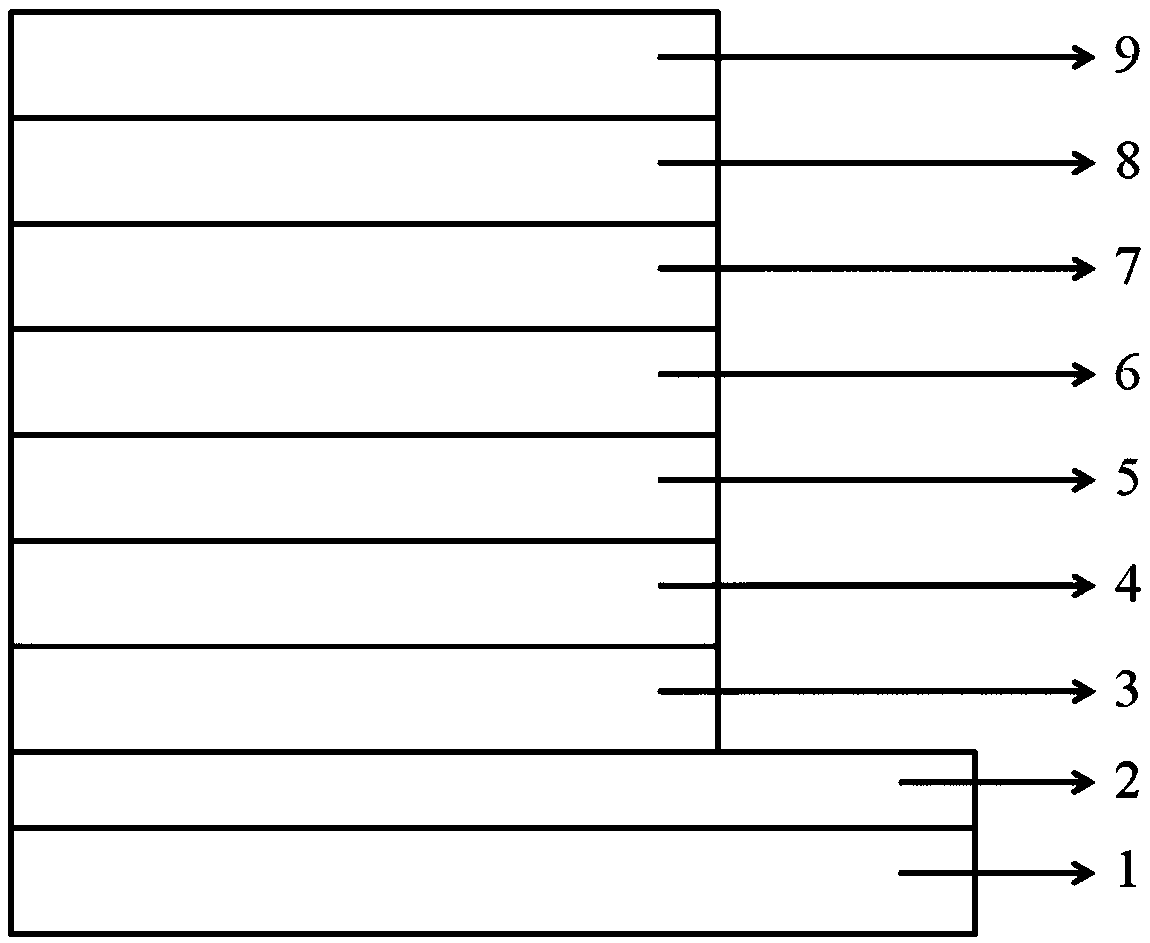

[0110] The structure of the organic electroluminescent device prepared in Example 1 is as follows: figure 1 As shown, the specific preparation process of the device is as follows:

[0111] Clean the ITO anode layer 2 on the transparent glass substrate layer 1, ultrasonically clean it with deionized water, acetone, and ethanol for 30 minutes each, and then treat it in a plasma cleaner for 2 minutes; dry the ITO glass substrate and place it in a vacuum In the cavity, the vacuum degree is less than 1*10 -6 Torr, on the ITO anode layer 2, a mixture of HT1 and P1 with a film thickness of 10 nm is evaporated, the mass ratio of HT1 and P1 is 97:3, and this layer is the hole injection layer 3; then, HT1 with a thickness of 50 nm is evaporated, and the layer As the hole transport layer 4; then vapor-deposit 20nm-thick EB1, which serves as the electron blocking layer 5; further, vapor-deposit a 25nm light-emitting layer 6, wherein the light-emitting layer includes a host material and a...

Embodiment 2~21

[0113] The preparation methods of Examples 2-21 are similar to those of Example 1, and the selection of specific materials is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com