Track generating method facing toward complex curved surface processing and track generating system thereof

A complex surface and trajectory generation technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as difficult hardware architecture design, low search efficiency, and large amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

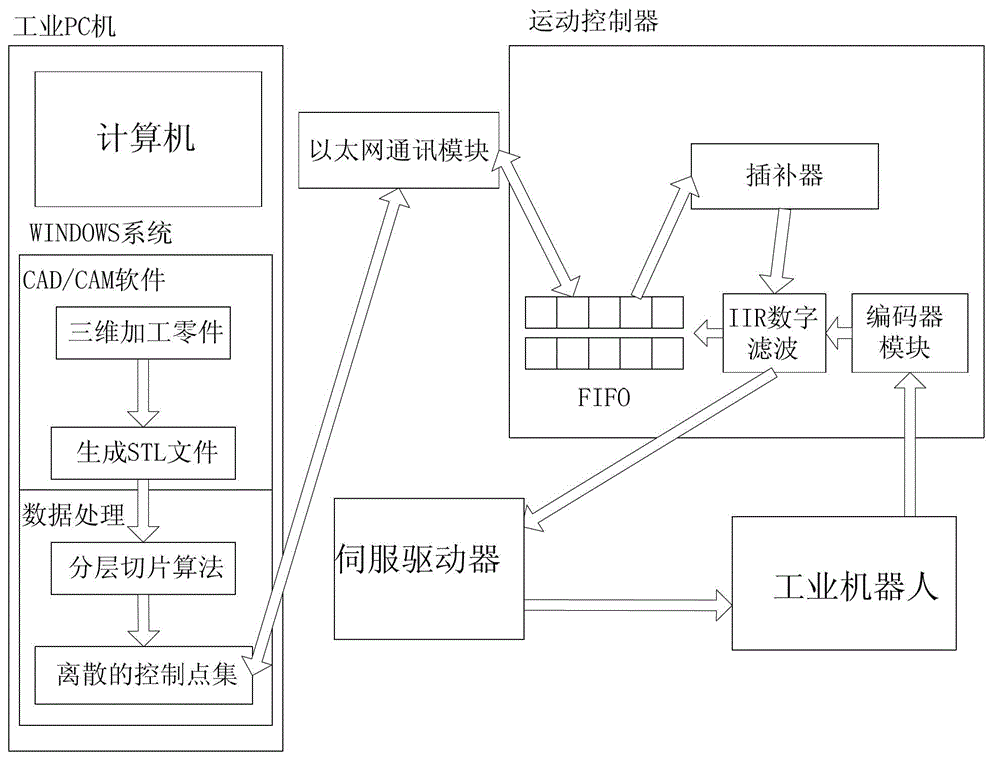

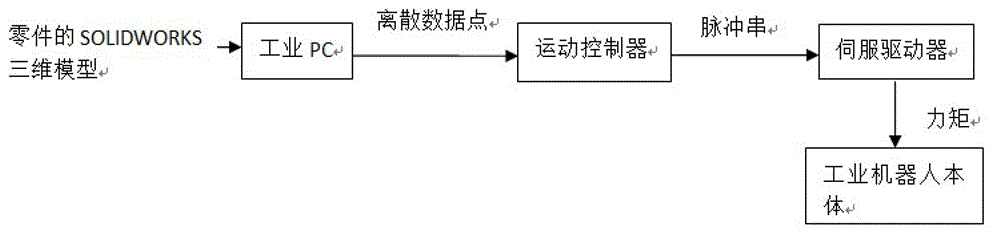

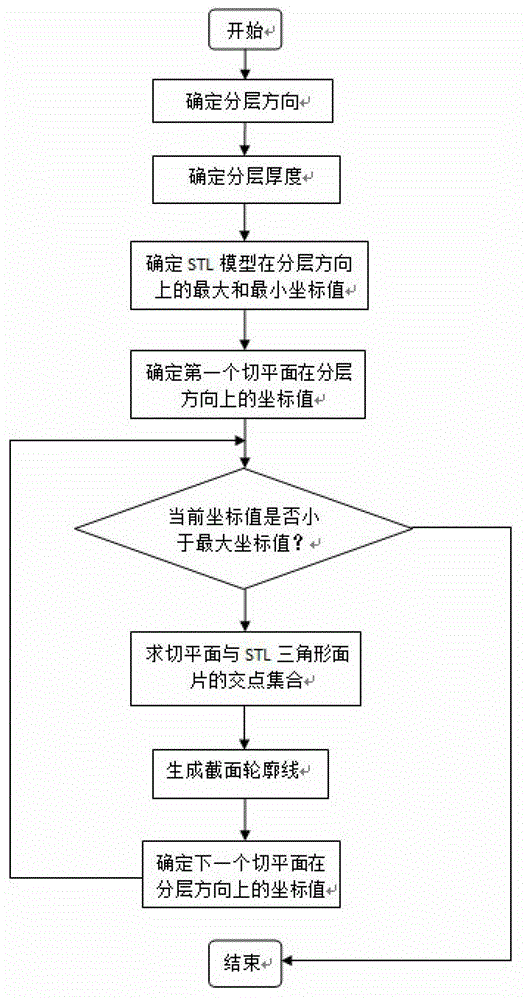

[0062] like figure 1 As shown, a trajectory generation system for complex surface processing, including industrial PC, motion controller, servo drive and industrial robot body. At the same time, if figure 2 As shown, the industrial PC uses the layered slicing algorithm based on the STL model to generate a discrete set of control points for the three-dimensional parts to be processed and then transmits it to the motion controller through the Ethernet communication module. Perform interpolation calculations, and then output pulse trains to the servo drive to drive the industrial robot body for coordinated motion in torque control mode.

[0063] The motion controller includes hardware circuits such as integrated soft core, Ethernet interface, interpolator, encoder module, IIR digital filter, FIFO buffer module, system interrupt, etc. Download discrete data points to the FIFO buffer module for buffer storage; the interpolator is used to perform linear interpolation calculations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com