High-temperature performance virtual track test method for asphalt mixture

A technology of asphalt mixture and rutting test, which is applied in the direction of material inspection, analysis of materials, strength characteristics, etc., can solve the problems of capital consumption, shortened test cycle, poor test repeatability and reproducibility, and avoid the deviation of the position of the test piece , avoid abnormal fluctuations, and shorten the test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

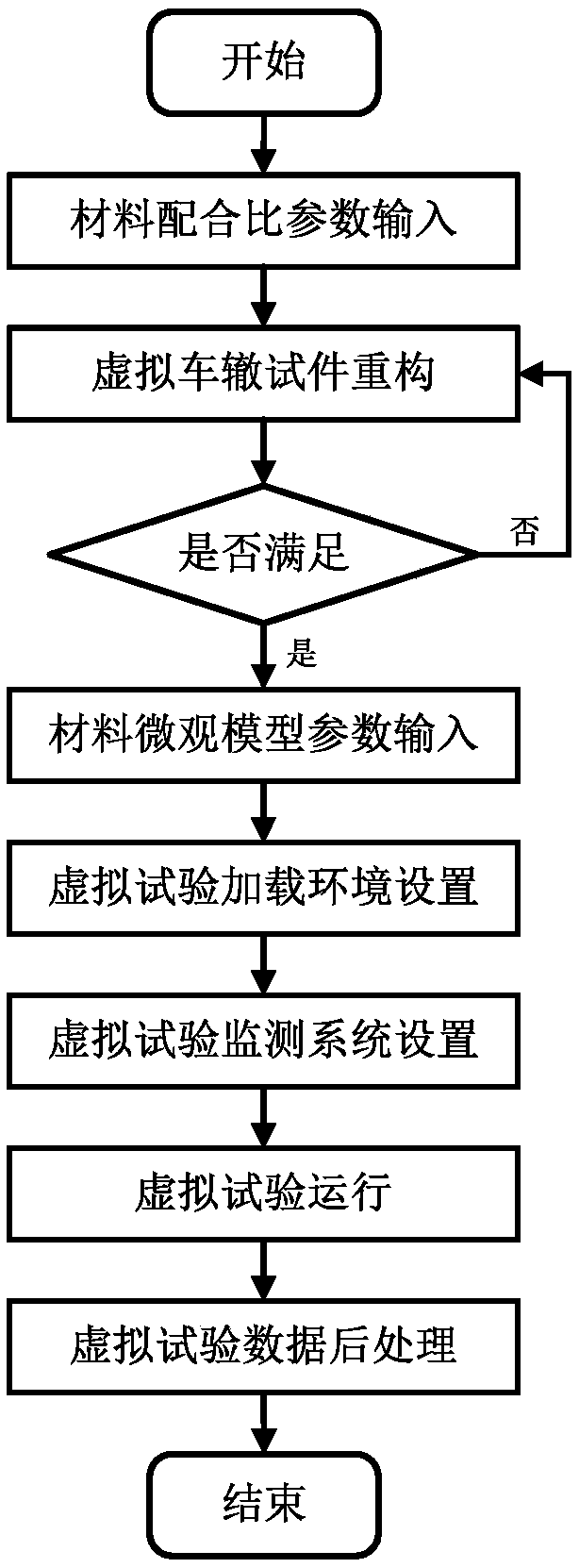

[0037] A kind of asphalt mixture high temperature performance virtual rutting test method of the present invention comprises the following steps:

[0038] (1) Material mix ratio parameter input: According to the laboratory mix ratio test results of asphalt mixture AC-13, the mass of coarse aggregates of 13.2~16mm, 9.5~13.2mm, 4.75~9.5mm, 2.36~4.75mm, etc. are obtained and void ratio, and calculate the volume of coarse aggregate at each level according to the aggregate density, which provides key parameters for subsequent reconstruction of virtual rutting specimens;

[0039] (2) Reconstruction of the virtual rut specimen: firstly, the "wall" is used to construct the size space of the asphalt mixture rut specimen of 300mm×300mm×50mm, and then it is retrieved from the constructed three-dimensional coarse aggregate particle library with real morphological characteristics And put various grades of coarse aggregate into the size space of the virtual specimen to generate coarse aggre...

Embodiment 2

[0058] A virtual rutting test method for asphalt mixture high temperature performance, comprising the following steps:

[0059] (1) Material mix ratio parameter input: According to the laboratory mix ratio test results of asphalt mixture AC-20, 19~26.5mm, 16~19mm, 13.2~16mm, 9.5~13.2mm, 4.75~9.5mm, 2.36~ 4.75mm and other grades of coarse aggregate mass and void ratio, and calculate the volume of each grade of coarse aggregate according to the aggregate density, providing key parameters for subsequent reconstruction of virtual rutting specimens;

[0060] (2) Reconstruction of the virtual rut specimen: firstly, the "wall" is used to construct the size space of the asphalt mixture rut specimen of 300mm×300mm×50mm. Then, it is retrieved from the constructed three-dimensional coarse aggregate particle library with real morphological characteristics and placed in the size space of the virtual specimen to generate coarse aggregate with the target gradation and volume, and carry out r...

Embodiment 3

[0079] A virtual rutting test method for asphalt mixture high temperature performance, comprising the following steps:

[0080] (1) Material mix ratio parameter input: According to the on-site mix ratio of asphalt mixture AC-25, 26.5~31.5mm, 19~26.5mm, 16~19mm, 13.2~16mm, 9.5~13.2mm, 4.75~9.5mm, 2.36-4.75mm and other coarse aggregate mass and void ratio, and calculate the volume of each grade of coarse aggregate according to the aggregate density, providing key parameters for subsequent reconstruction of virtual rut specimens;

[0081] (2) Reconstruction of the virtual rut specimen: firstly, the "wall" is used to construct the size space of the asphalt mixture rut specimen of 300mm×300mm×70mm. Then, it is retrieved from the constructed three-dimensional coarse aggregate particle library with real morphological characteristics and placed in the size space of the virtual specimen to generate coarse aggregate with the target gradation and volume, and carry out rough collection. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com