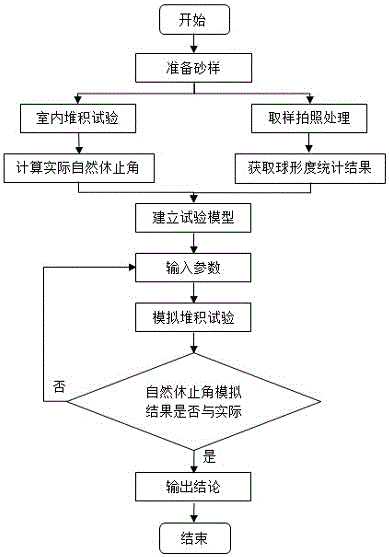

Discrete element combined particle and discrete element stacking test simulation method thereof

A technology of particle accumulation and simulation method, which is applied in the field of discrete element composite particles and discrete element accumulation test simulation field, which can solve the problems of friction coefficient exceeding the actual value, difficulty in revealing sand, and difficulty in particle interlocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

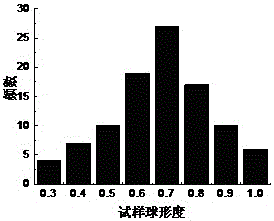

Method used

Image

Examples

Embodiment Construction

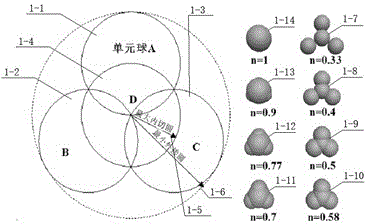

[0039] A discrete element combination particle, including Clump particles with various degrees of sphericity, the Clump particle is composed of four unit balls: unit ball A, unit ball B, unit ball C and unit ball D, and the unit ball A The radii of unit ball B and unit ball C are equal, and described unit ball A, unit ball B and unit ball C are arranged around unit ball D in a circular distribution mode, and unit ball A, unit ball B and unit ball C All are tangent to or intersect with the unit sphere D, and the value of the sphericity n of the Clump particles is 0.33≤n≤1. The discrete element composite particle is a composite Clump particle or a single Clump particle, and the composite Clump particle is a combination of particles with various shapes composed of multiple Clump particles with different sphericity, and the single Clump particle is A combination of particles with only one shape composed of Clump particles with one degree of sphericity, the sphericity n of the Clum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com