Method for simulating discrete element muck pile form

A simulation method and discrete element technology, applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problems of low accuracy of blasting shape simulation, inability to reflect the essence of blasting, and large workload, etc., to reduce computing time and The effect of resource occupation, improving efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

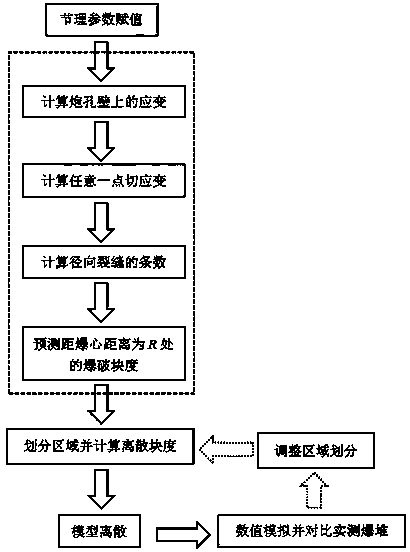

[0026] The present invention firstly assigns the mechanical parameter values of the complete rock mass to the mechanical parameters of the artificial joints to ensure that the artificial discretization does not affect the mechanical properties of the rock mass; then, calculates the predicted blasting fragmentation of each part of the rock mass model according to the Harris blasting theory; According to the numerical calculation, the model needs to be divided into partitions, and the average blasting fragmentation in each area is used as the fragmentation of discrete blocks; finally, the preset fragmentation or model partition can be corrected according to the results of blasting pile simulation.

[0027] Concrete flowchart of the present invention sees figure 1 , which will be combined below figure 1 The steps of the method of the present invention are further described.

[0028] Step 1. Assign the mechanical parameters of the artificial joints in the discrete element progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com