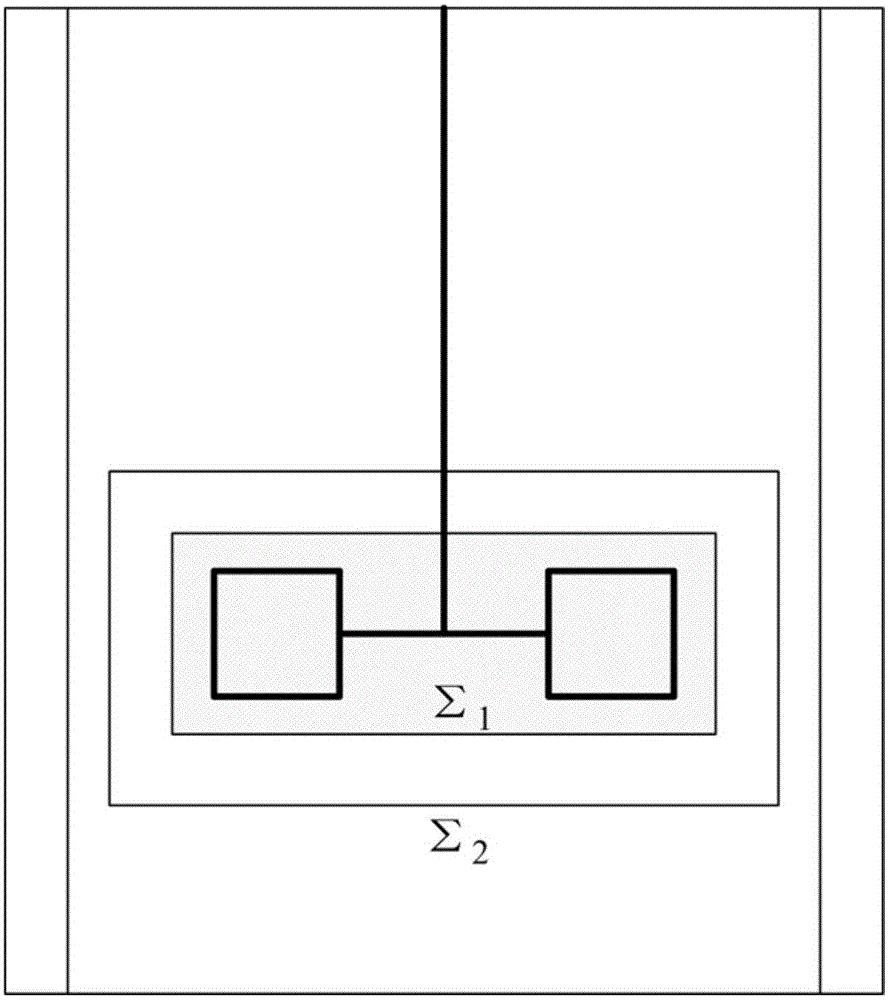

Stirred tank reactor simulation method based on immersed boundary method

A stirring reactor and simulation method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limited applications, difficult direct numerical simulation of turbulent flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

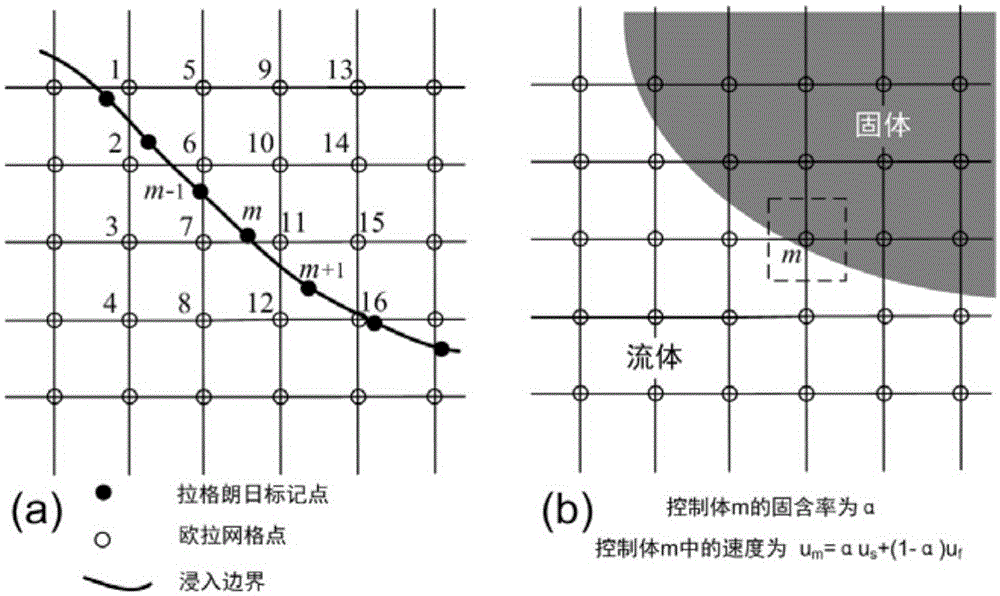

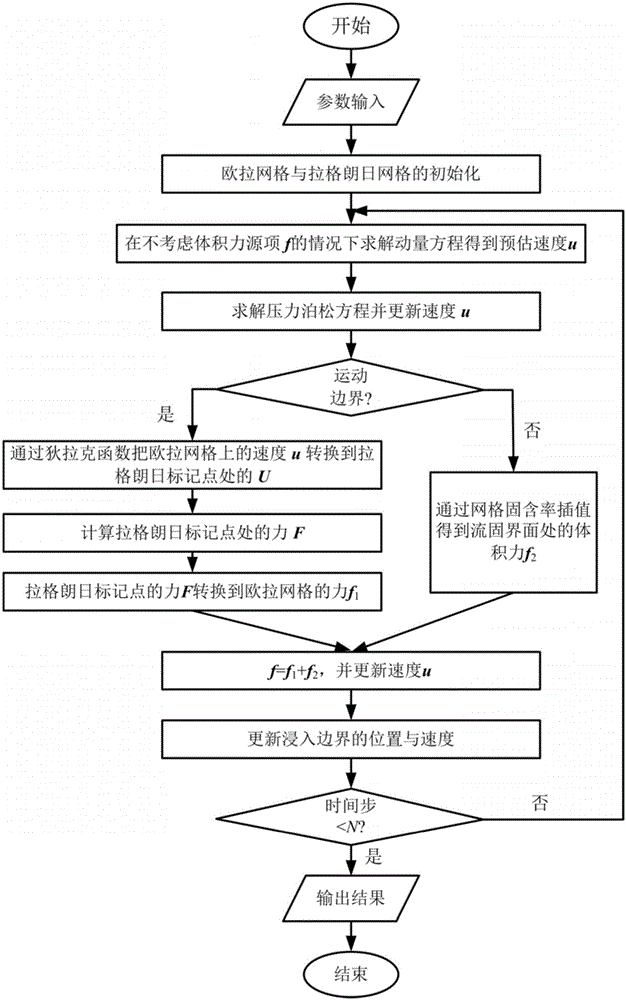

Method used

Image

Examples

Embodiment 1

[0169] 1. Preparation stage:

[0170] Determination and setting of calculation parameters, calculation parameters include numerical parameters (time step, grid number and process number, etc.) and physical parameters (stirred tank structural parameters, fluid density, fluid viscosity, particle diameter and particle density, etc.).

[0171]The accurate structural parameters of the stirred tank can be obtained from its design drawings; in the absence of drawings, we can use length measurement tools, such as micrometers, to measure the length. The main structural parameters are the height and diameter of the stirred reactor, the geometry and size of the stirring paddle, etc.

[0172] The viscosity of the fluid is measured by any of a capillary viscometer, a falling ball viscometer or a coaxial cylinder viscometer.

[0173] The density of the fluid is measured with a densitometer.

[0174] The particle diameter was measured with a laser particle size analyzer.

[0175] Particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com