Patents

Literature

53 results about "Cauchy boundary condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a Cauchy (French: [koʃi]) boundary condition augments an ordinary differential equation or a partial differential equation with conditions that the solution must satisfy on the boundary; ideally so to ensure that a unique solution exists. A Cauchy boundary condition specifies both the function value and normal derivative on the boundary of the domain. This corresponds to imposing both a Dirichlet and a Neumann boundary condition. It is named after the prolific 19th-century French mathematical analyst Augustin Louis Cauchy.

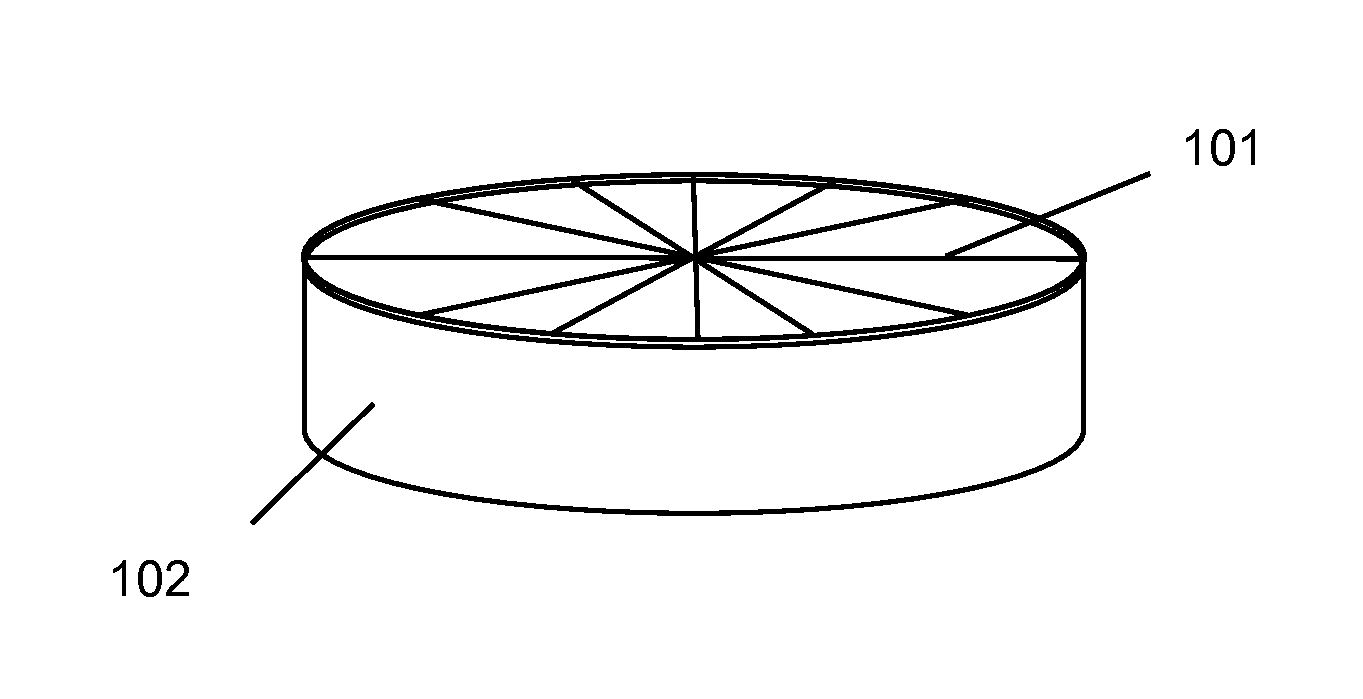

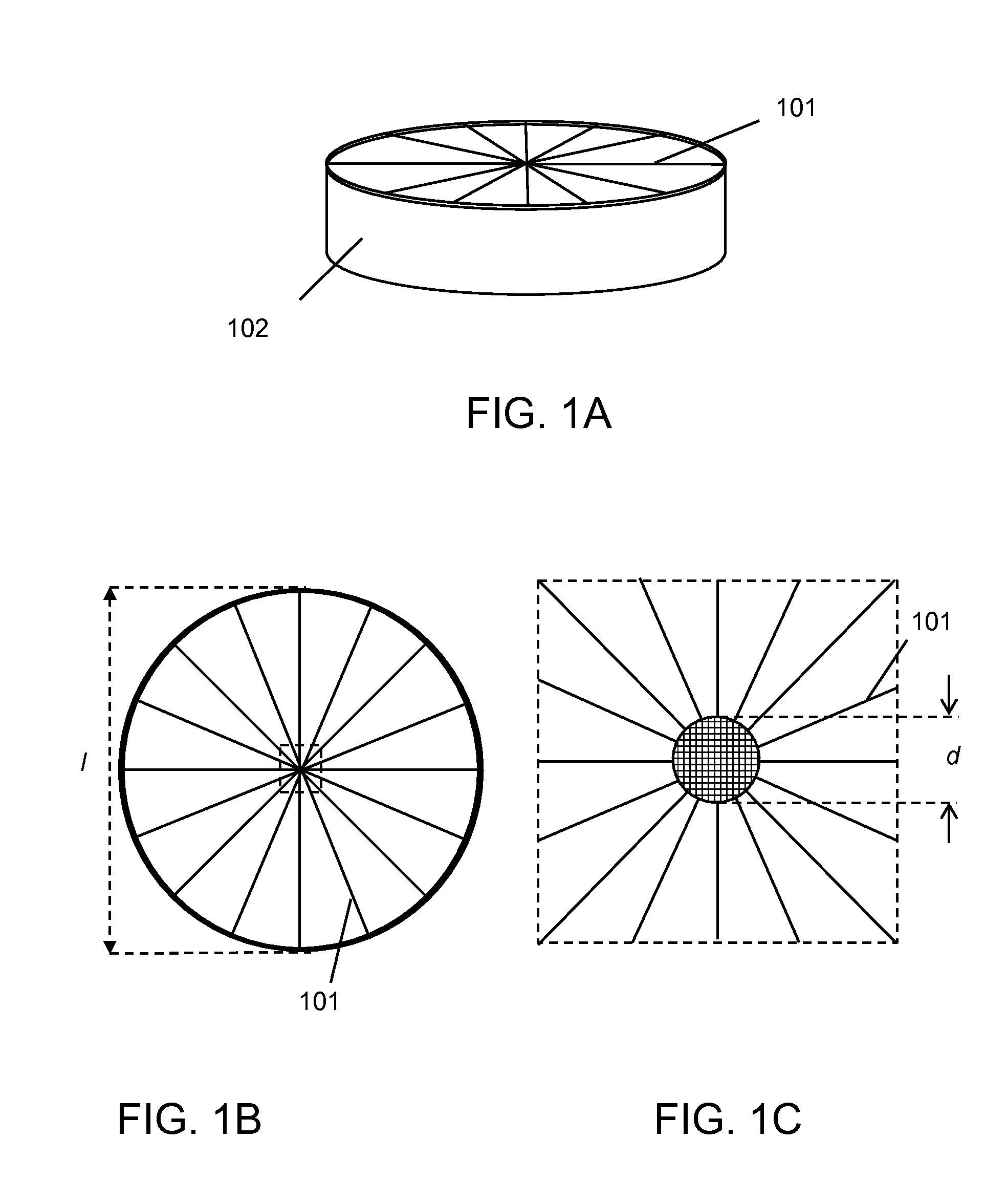

Vector vortex waveplates

ActiveUS20170010397A1Good optical performanceWide spectral rangePolarising elementsPretreated surfacesLiquid-crystal displaySpectral bands

Method for fabrication of vector vortex waveplates of improved quality due to reduced singularity size and widened spectral band, the method comprising creating a boundary condition for vortex orientation pattern of a liquid crystal polymer on a substrate using materials with reversible photoalignment, equalizing exposure energy over the area of the waveplate by redistributing the energy of radiation used for photoalignment from the center of the beam to its peripheries, and using vector vortex waveplate as a linear-to-axial polarization converter. Fabrication of spectrally broadband vector vortex waveplates further comprises two or more liquid crystal polymer layers with opposite sign of twist.

Owner:BEAM ENG FOR ADVANCED MEASUREMENTS

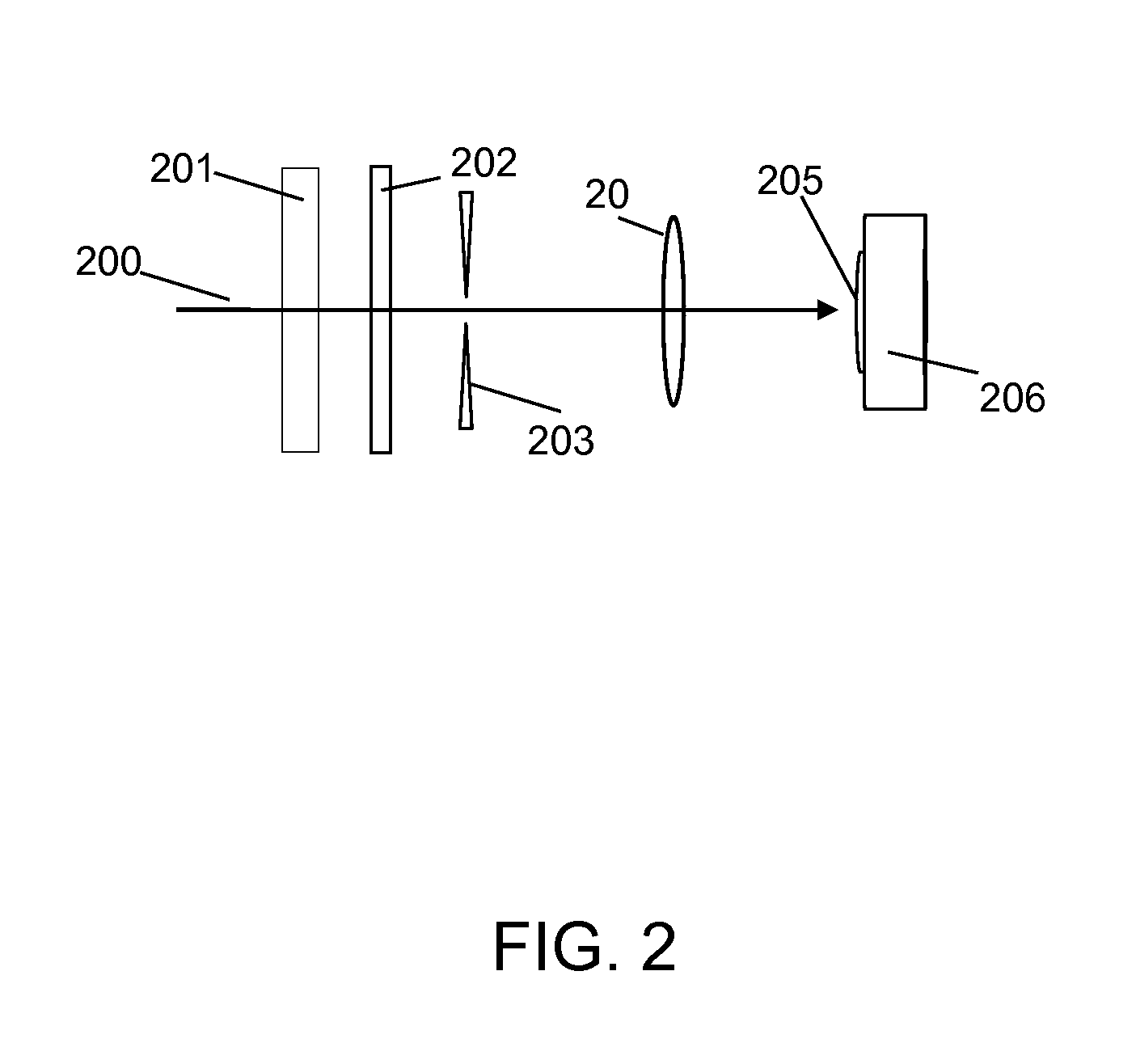

Structural dynamical model modification-based prestress recognition method

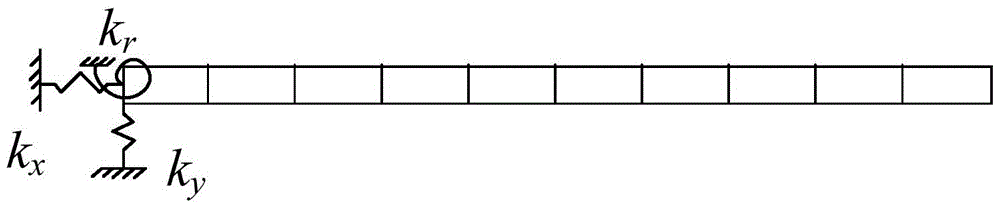

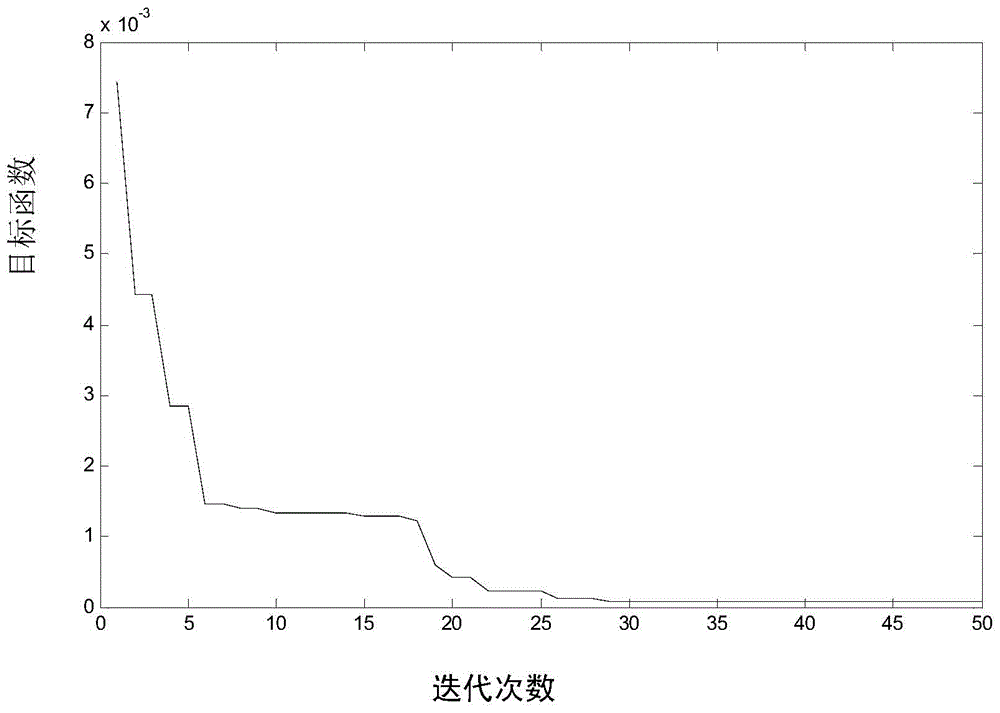

InactiveCN105740541AEasy to iterateEasy to identifyDesign optimisation/simulationSpecial data processing applicationsPattern recognitionElement model

The invention discloses a structural dynamical model modification-based prestress recognition method, and relates to the prestress recognition of pre-tensioning structures. The method comprises the following steps: establishing a finite element model of a structure; converting the boundary condition such as clamped support or simple support into spring support in three or two directions, and applying an axial prestress at the same time; calculating a fixed frequency and a fixed vibration mode of the structure through commercial finite element software; carrying out test and recognition by utilizing a test modal analysis technology, so as to obtain the fixed frequency and the fixed vibration mode of the structure; and recognizing the spring support rigidity and prestress of the boundary at the same time on the basis of a model modification technology. The method is simple, high in recognition precision and convenient to operate; and through considering the influences of the boundary condition, the reliability is high. By taking MAC as a target function, the completeness of the test data is supplemented; the optimization through a genetic algorithm is more beneficial for obtaining the globally optimal solution; and the whole modification model can be automatically driven to carry out solving.

Owner:XIAMEN UNIV

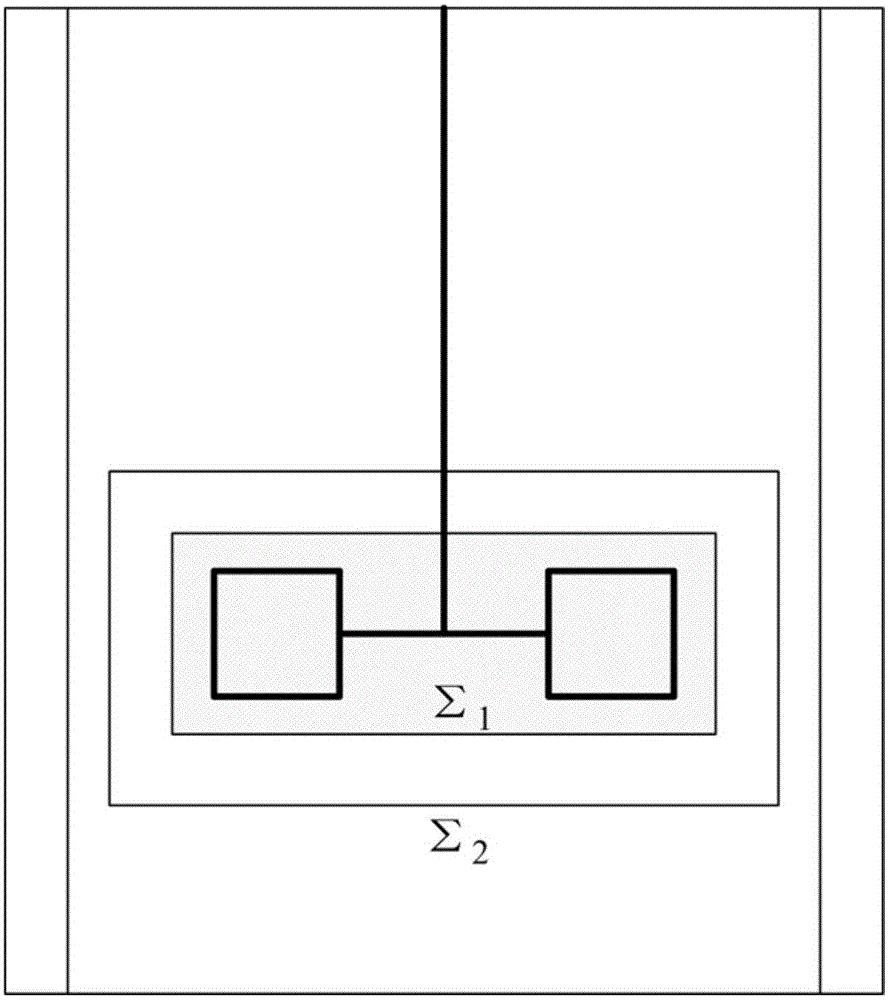

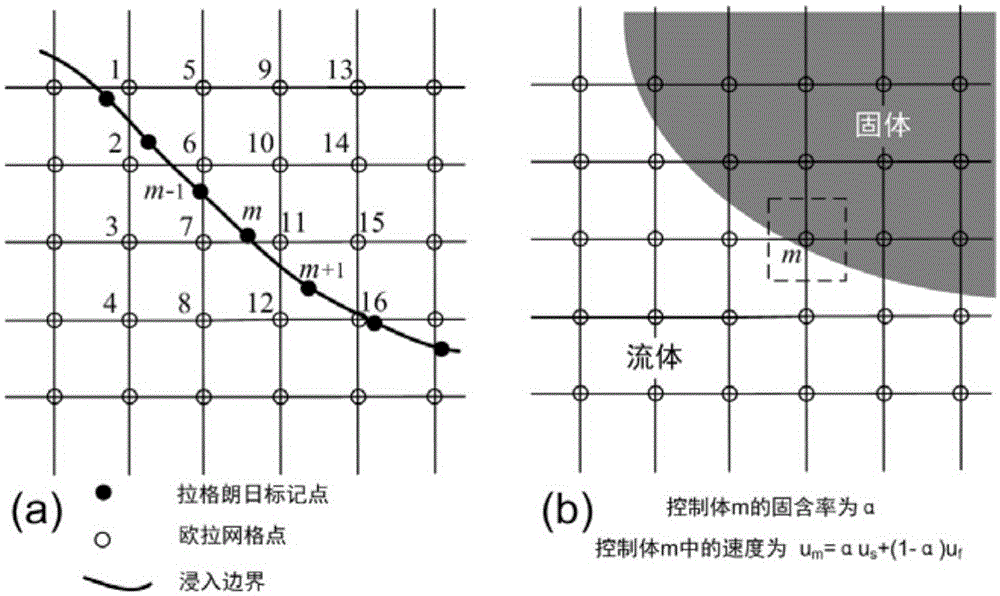

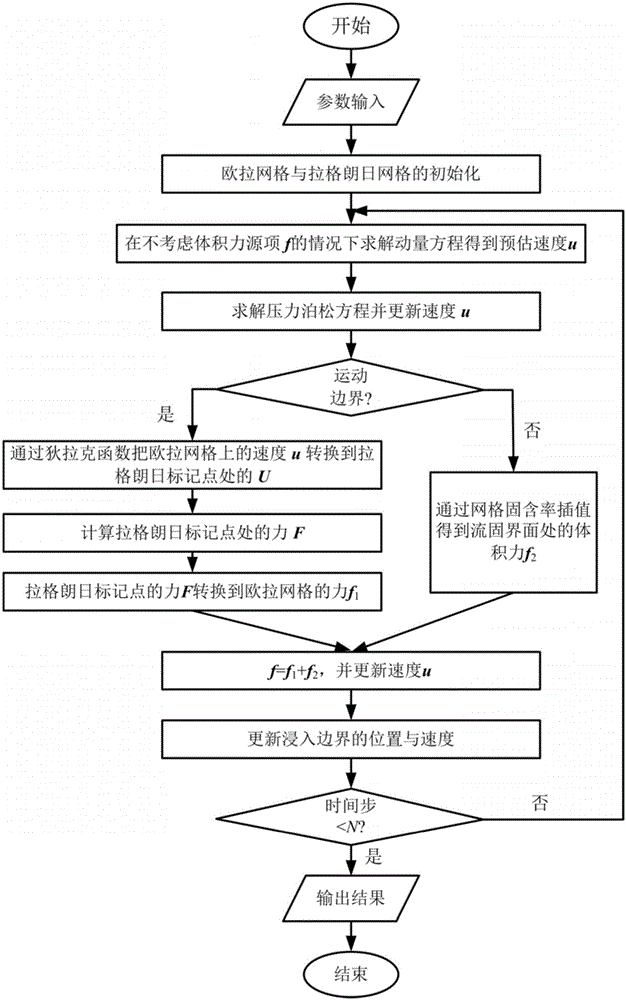

Stirred tank reactor simulation method based on immersed boundary method

ActiveCN105069184APromote generationReduce workloadSpecial data processing applicationsBoundary knot methodSolid particle

The present invention provides a stirred tank reactor simulation method based on an immersed boundary method. The method includes: a preparation phase including determination and setting of calculating parameters, generation of fluid grid files, generation of Lagrange mark point information, and preparation of calculating resources; numerical calculation: setting boundary conditions of computational domains and solving velocity fields and temperature fields based on fluid grids; combining with a discrete element method to achieve an interface analytic simulation of two-phase flow of particle flow, wherein the immersed boundary method is directly employed to apply non-slip boundary conditions to particle surfaces; a post-processing phase, and outputting information of each Euler mesh and information of each particle after a simulation is completed. According to the characteristics of different boundaries, in the calculation, the mixed immersed boundary method is employed to process, and the mass numerical simulation of turbulent flow in the stirred tank reactor is achieved through combination of large eddy simulation and high performance parallel computing technology. The simulation method may be applied to simulation of turbulent flow and simulation of solid particle suspension in the stirred tank reactor and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

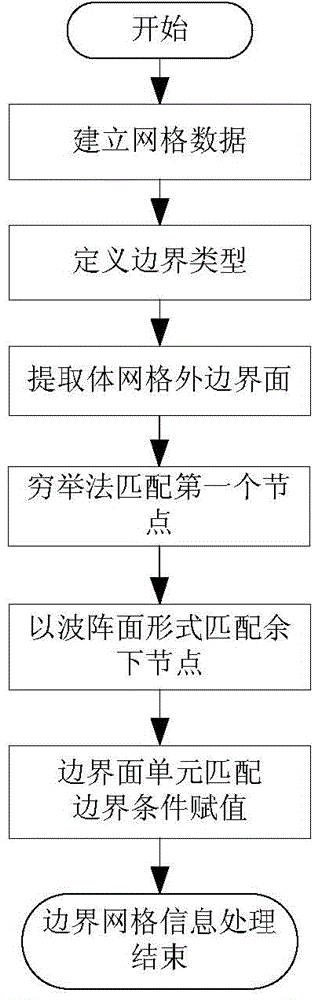

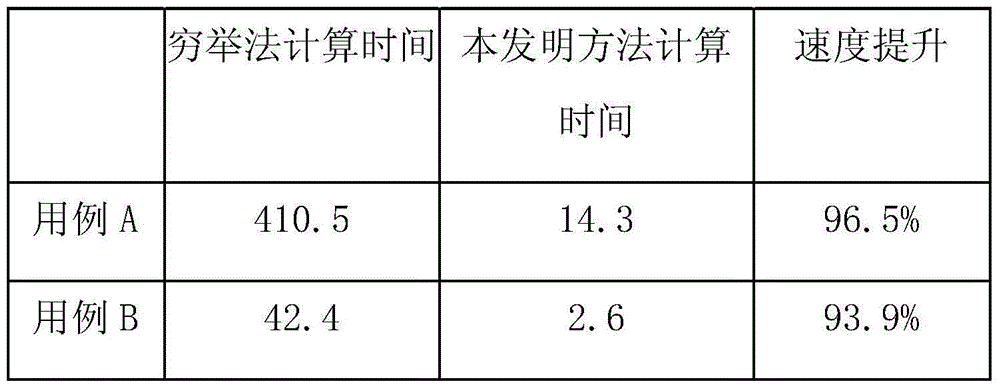

Grid boundary condition processing method of unstructured grid CFD computation

The invention belongs to the technical field of grid computation, and specifically relates to a grid boundary condition processing method of unstructured grid CFD computation. The method comprises the following steps: establishing grid information; defining a boundary type; extracting grid outer boundary information; realizing the matching of a first node through a method of exhaustion; matching the remaining nodes in a wave front form; matching a boundary surface unit; and assigning a boundary condition. According to the method, a method for rapidly matching between unstructured boundary surfaces and grid surfaces is utilized, so that the grid boundary conditions of unstructured grids in Tecplot form can be rapidly mapped to corresponding boundary surfaces of infield body grids, the rapid processing of boundary condition information of the unstructured grids can be realized and the computer time can be effectively decreased.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

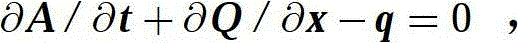

Method for carrying out parallelization numerical simulation on hydrodynamic force conditions of river provided with cascade hydropower station

InactiveCN102722611AImprove versatilityImprove portabilitySpecial data processing applicationsInformation technology support systemEngineeringWater level

Owner:TSINGHUA UNIV

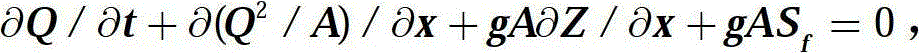

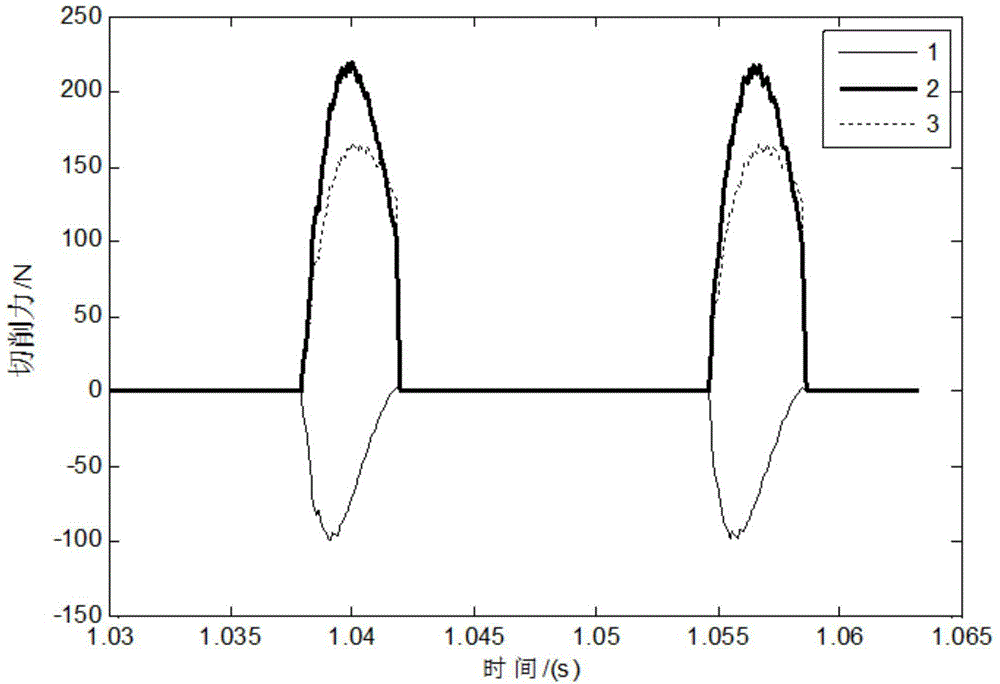

Modeling method for judging cutting force of orthogonal turn-milling machining end face on basis of boundary conditions

InactiveCN104794337AAccurately reflectHigh expressionSpecial data processing applicationsModel methodVirtual machining

The invention discloses a modeling method for judging the cutting force of an orthogonal turn-milling machining end face on the basis of boundary conditions. The method includes the five steps of firstly, establishing a tool coordinate system; secondly, dividing the tool end face into a plurality of microelements in the radial direction; thirdly, judging whether the microelements participate in cutting or not through the boundary conditions; fourthly, obtaining thickness of cuttings, and calculating the microelement cutting force on the basis of the thickness; fifthly, adding the cutting force on all the microelements participating in cutting to obtain the total cutting force. By means of the method for judging the cutting state of the microelements through a united boundary condition equation, the disadvantage that in the prior art, when the orthogonal turn-milling machining end face blade cutting force is predicted, the cutting progress needs to be divided into multiple stages to be discussed is avoided; due to the fact that the influences of jumping are taken into consideration, the prediction effect is more accurate. The expression is simple and easy to understand, the complex characteristic angle calculation is omitted, and the modeling method is suitable for development of virtual machining simulation systems and has good application aspects.

Owner:BEIHANG UNIV

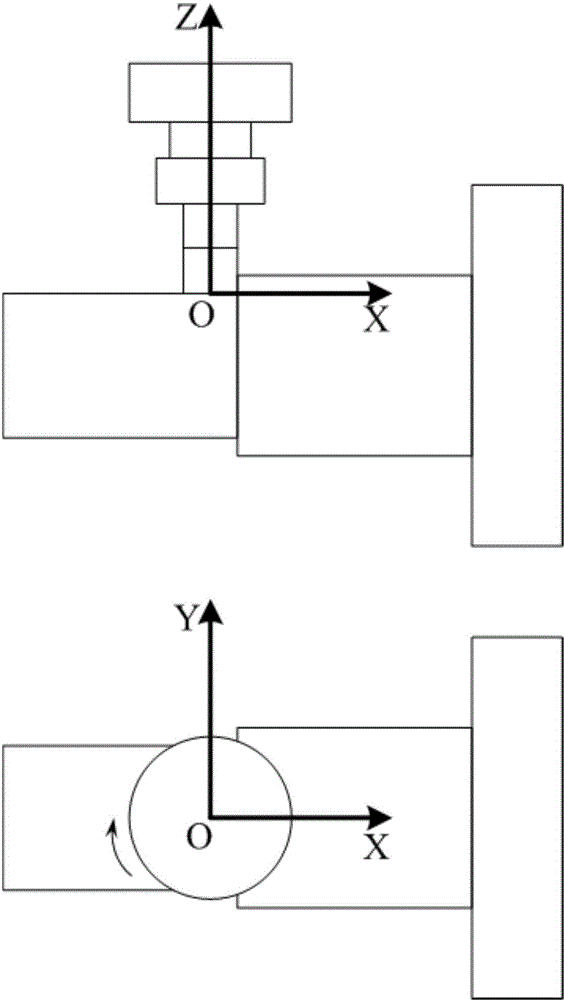

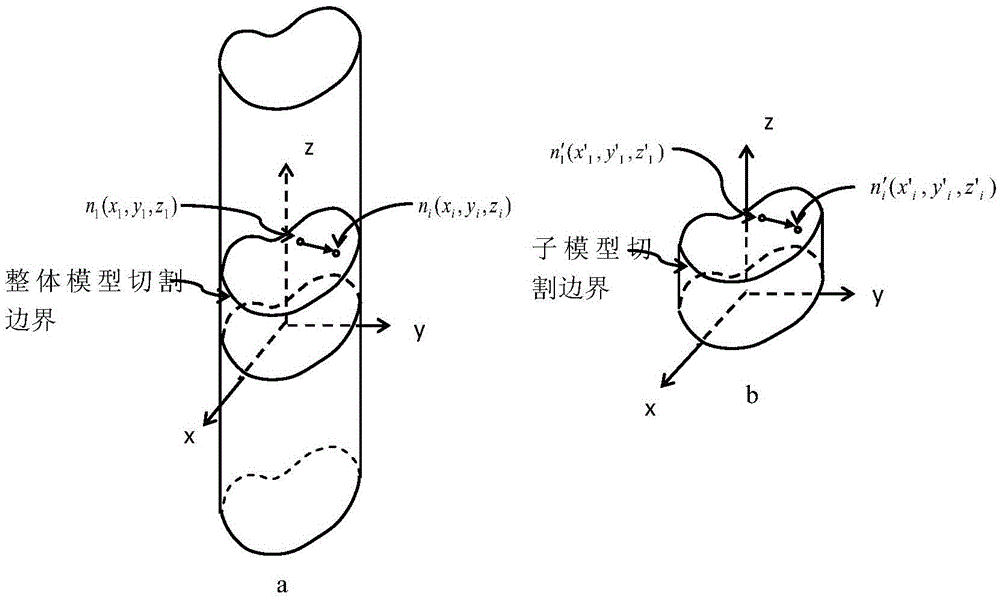

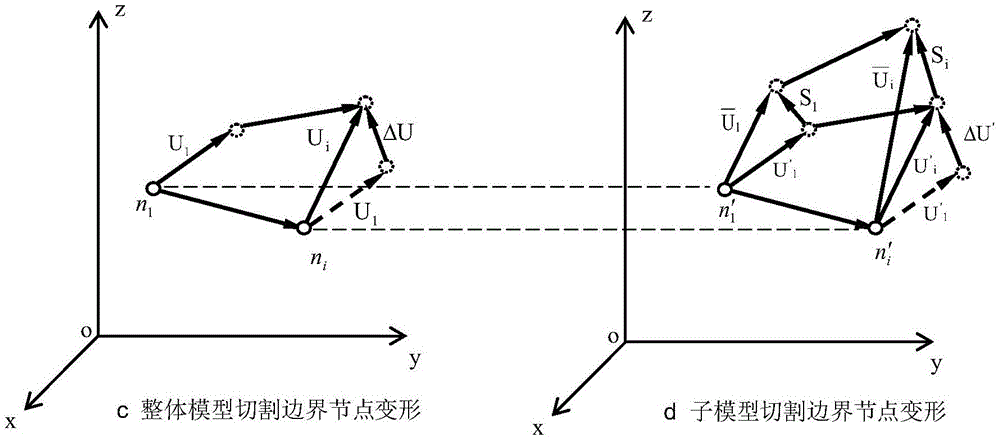

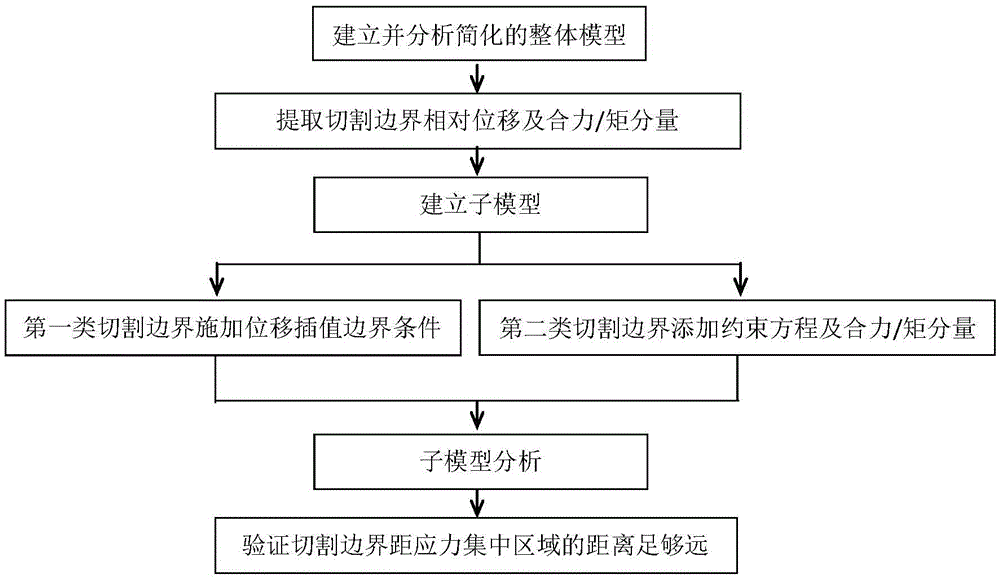

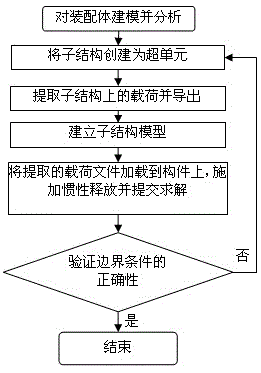

New submodel finite element analysis method based on cutting boundary deformation constraint

ActiveCN105550464APrecise structureAccurate forceDesign optimisation/simulationSpecial data processing applicationsStress concentrationReduced model

The invention discloses a new submodel finite element analysis method based on cutting boundary deformation constraint. The content of the method comprises: building a complete machine simplified model, analyzing; carrying out postprocessing to cutting boundary nodes of the complete machine model; building a finite element model-a submodel of a partial structure; adding a deformation coupling constraint equation to the cutting boundary of the submodel, adding a displacement interpolation boundary condition and a force boundary condition; analyzing the submodel; and checking that the distance from a cutting boundary to a stress gathered region is far enough. The method of the invention is advantaged by that when applying the boundary conditions to the cutting boundary of the submodel, the displacement interpolation boundary condition is added to one part of the cutting boundary, the constraint equation and the force boundary condition are added to the other part; the accuracy of the boundary conditions of the submodel is ensured; compared with the traditional submodel finite element analysis method, in adoption of the new submodel finite element analysis method, the demand of the complete machine model is reduced; the complete machine model is greatly simplified; and the complete machine analysis efficiency and the calculation precision of the submodel are improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

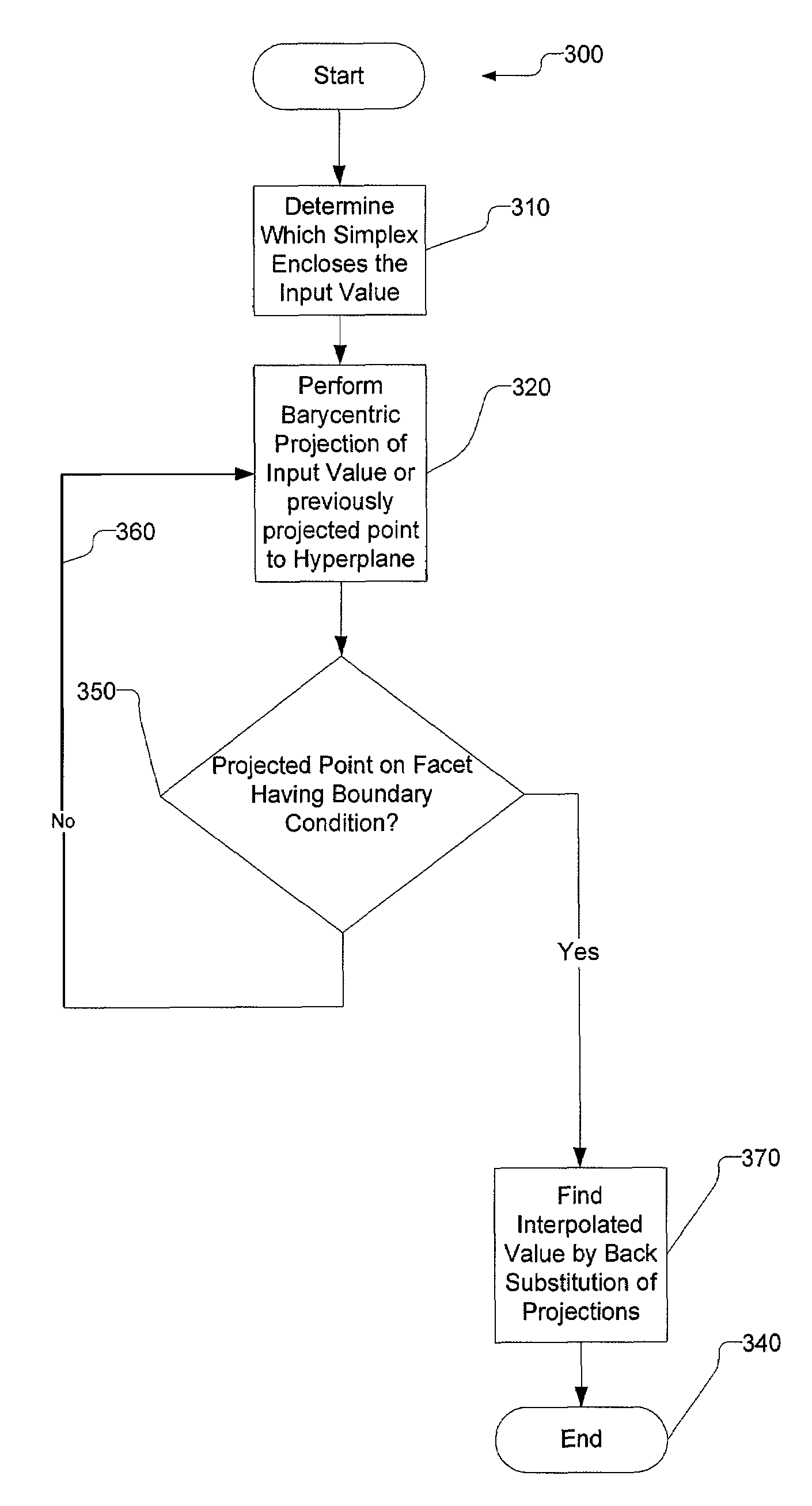

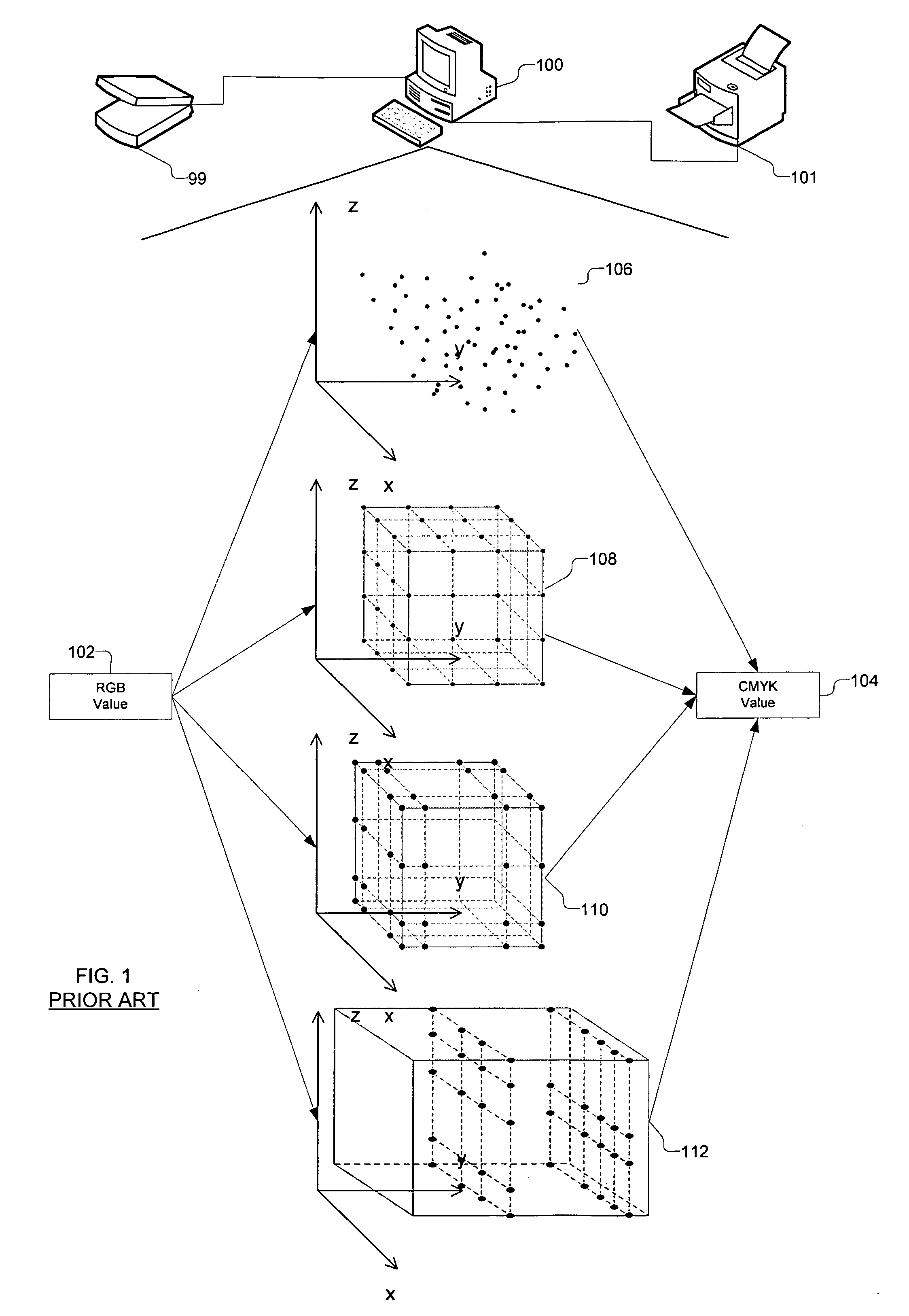

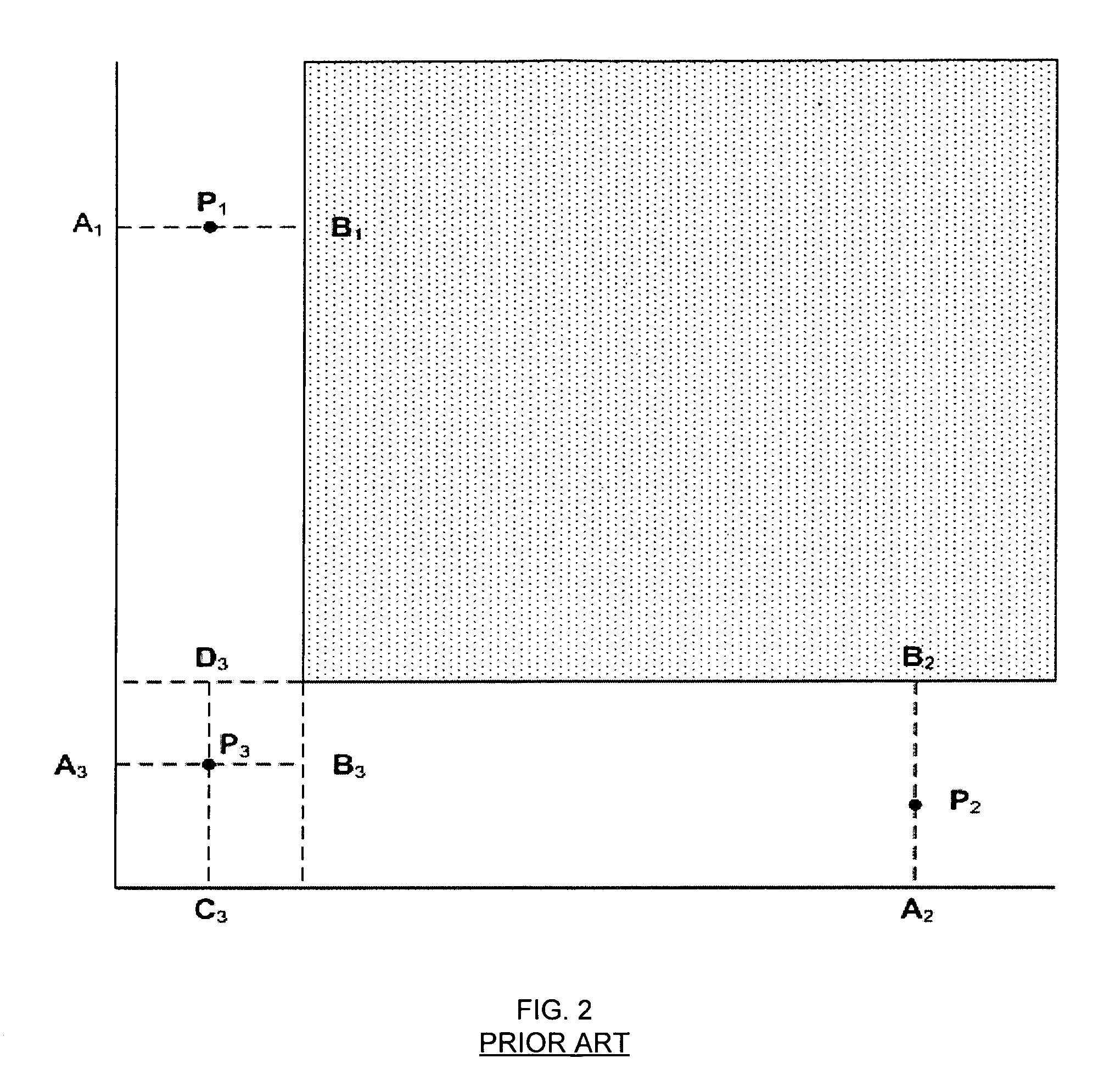

Color conversion using barycentric projections

ActiveUS7423791B2Digitally marking record carriersDigital computer detailsColor transformationRobin boundary condition

A method and apparatus for interpolating values for a color space from an input color value. A unit hypercube enclosing the input value is generated based on values from a look up table. A set of boundary conditions are then imposed on the unit hypercube. To perform the actual interpolation, an initial barycentric projection is performed from a selected vertex of the unit hypercube through the input value onto a boundary of the unit hypercube. If the projection satisfies one of the boundary conditions, an interpolated value is calculated using the projection by back substitution. If the initial projection does not satisfy a boundary condition, an intermediate value is generated from the previous projection and successive barycentric projections are performed using respectively different vertices of the unit hypercube through intermediate values onto a boundary of the unit hypercube until a projection satisfies one of the boundary conditions.

Owner:CANON KK +1

Multi-loop cable steady-state temperature rise acquisition method adapting to various boundary conditions

ActiveCN106021189ASimple calculationAccurate calculationDesign optimisation/simulationComplex mathematical operationsHeat flowSteady state temperature

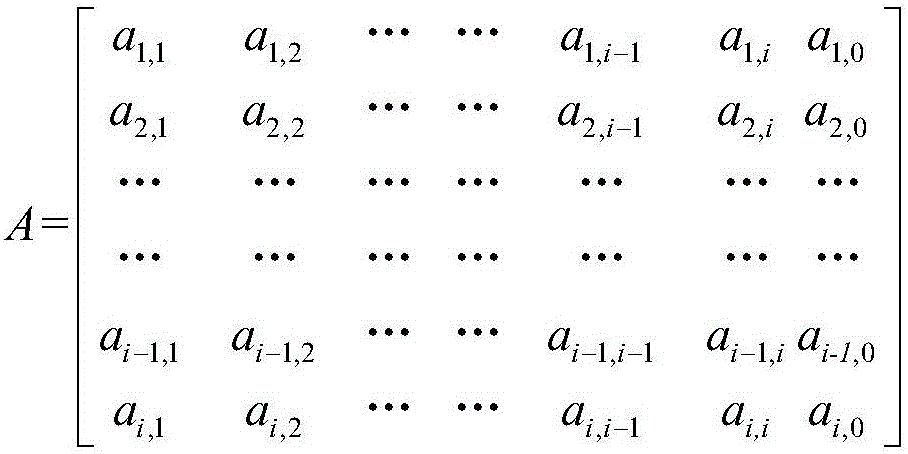

The invention relates to a multi-loop cable steady-state temperature rise acquisition method adapting to various boundary conditions. The method comprises the following steps: 1) constructing a multi-loop cable steady-state temperature rise model adapting to various boundary conditions according to a thermal field superposition principle; 2) acquiring an initial temperature rise matrix T<0> according to a set initial heat flow matrix Q<0>; 3) performing reduction according to the initial temperature rise matrix T<0> and the boundary conditions to form a reduced heat flow matrix Q<1>; 4) acquiring a next-step temperature rise matrix T<1> according to the reduced heat flow matrix Q<1>; and 5) judging whether a maximum difference value among all elements which correspond to the initial temperature rise matrix T<0> and the next-step temperature rise matrix T<1> is greater than a convergence threshold or not, if so, substituting T<0> with T<1> and returning to the step 3), and otherwise, judging that a current corresponding temperature rise matrix is a steady-state temperature rise matrix. Compared with the prior art, the multi-loop cable steady-state temperature rise acquisition method has the advantages of easiness and accuracy in calculation, high calculation efficiency, advanced algorithm, adaptability to various boundary conditions, and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

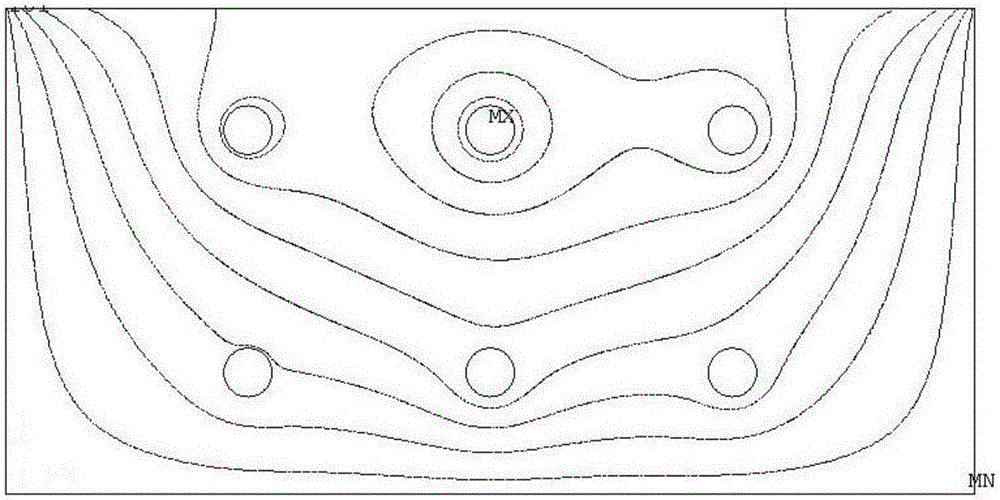

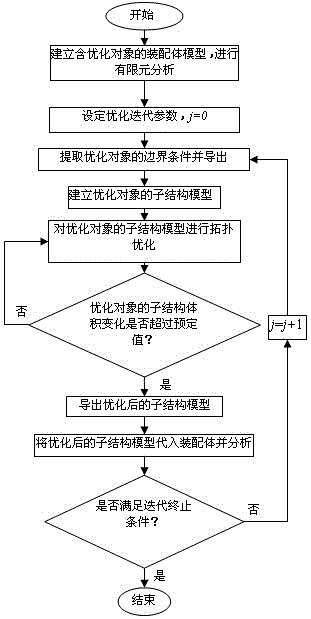

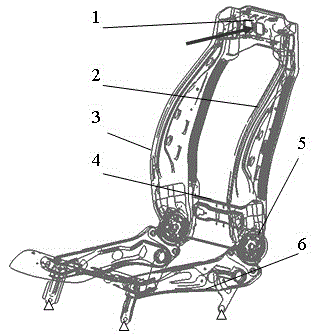

Component topology optimization design method for complex assembly

The invention relates to a component topology optimization design method for a complex assembly, and aims to solve the problem of difficulty in the determination of boundary conditions in a topology optimization design process for components of the complex assembly. The method comprises the following steps of: establishing and analyzing an assembly finite element model, and extracting and exporting the boundary conditions of a sub-structure which is a component to be optimized in the assembly model; loading the extracted boundary conditions onto the component to be optimized, and performing topology optimization on the component by utilizing a density method; when a change in the size of an optimization object exceeds a preset value, re-extracting the boundary conditions of the component, and continuing performing the topology optimization on the component; and when the optimization object is consistent with an iteration stopping condition, stopping optimization iteration to obtain a final optimal structure. An accurate optimal structure of the component can be obtained by accurately determining the boundary conditions of the component, and the problems of a plurality of design variables, inaccurate contact definition of combination parts between components and large calculated amount caused by the direct adoption of the assembly for the topology optimization design are solved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

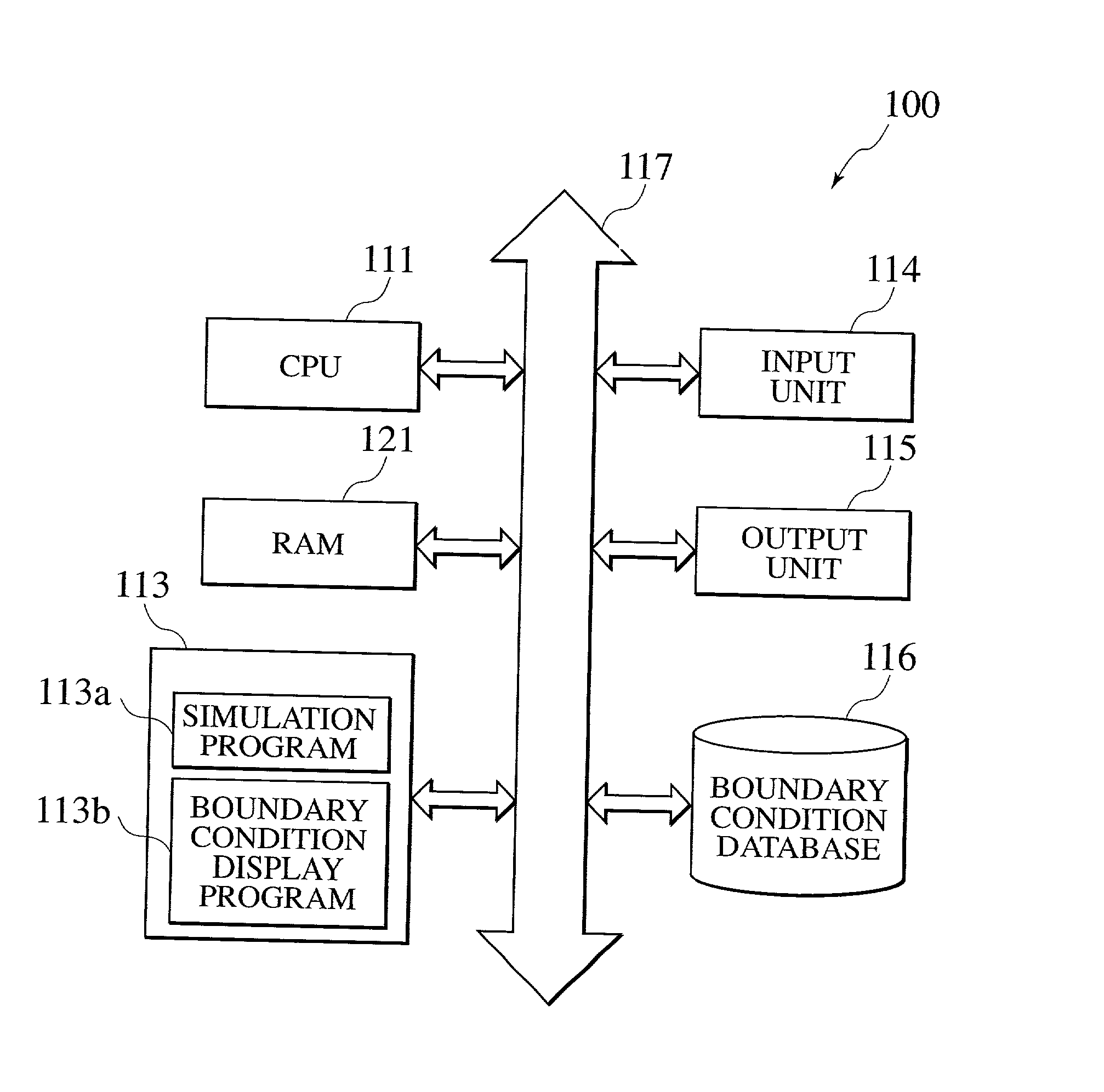

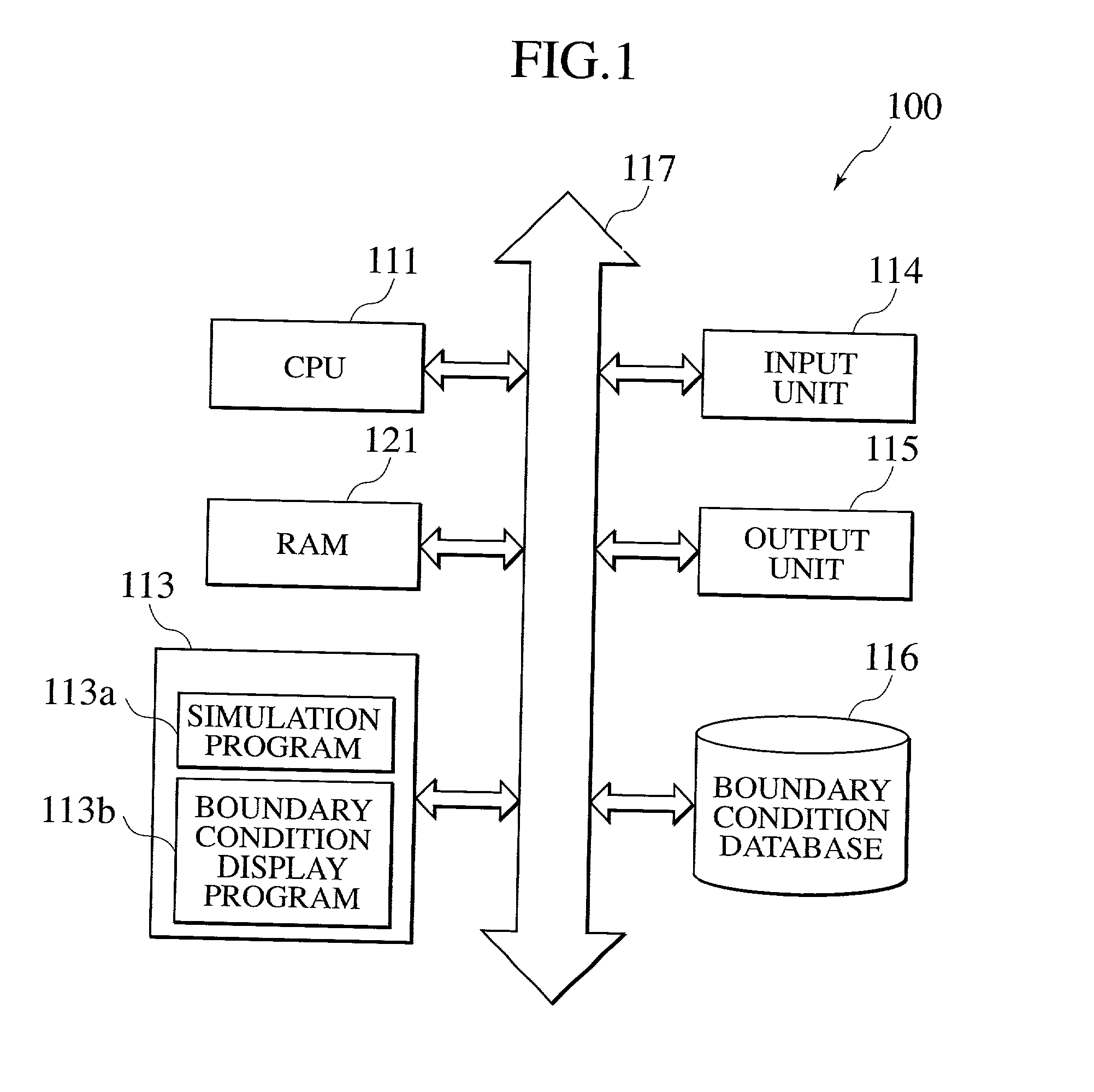

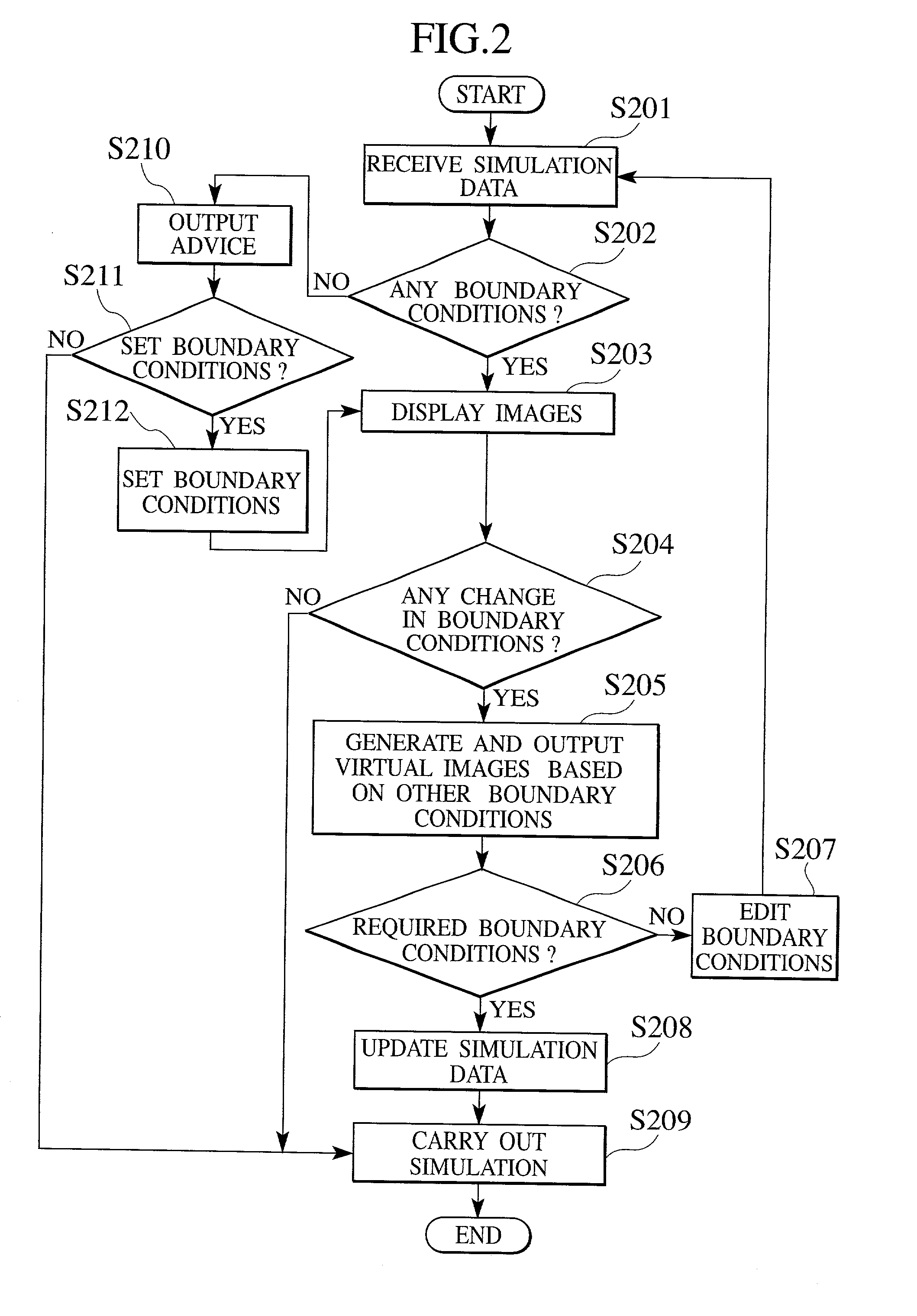

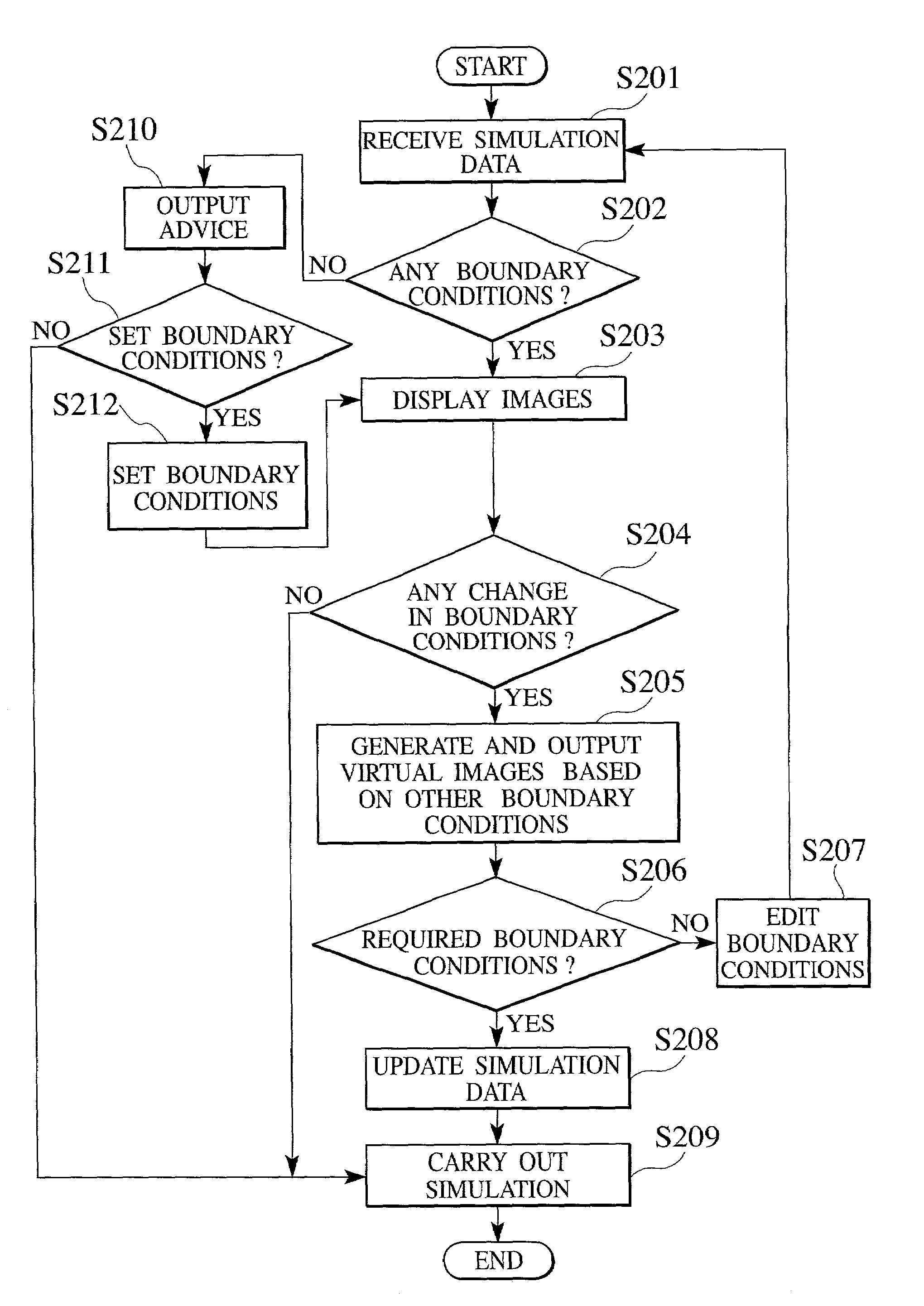

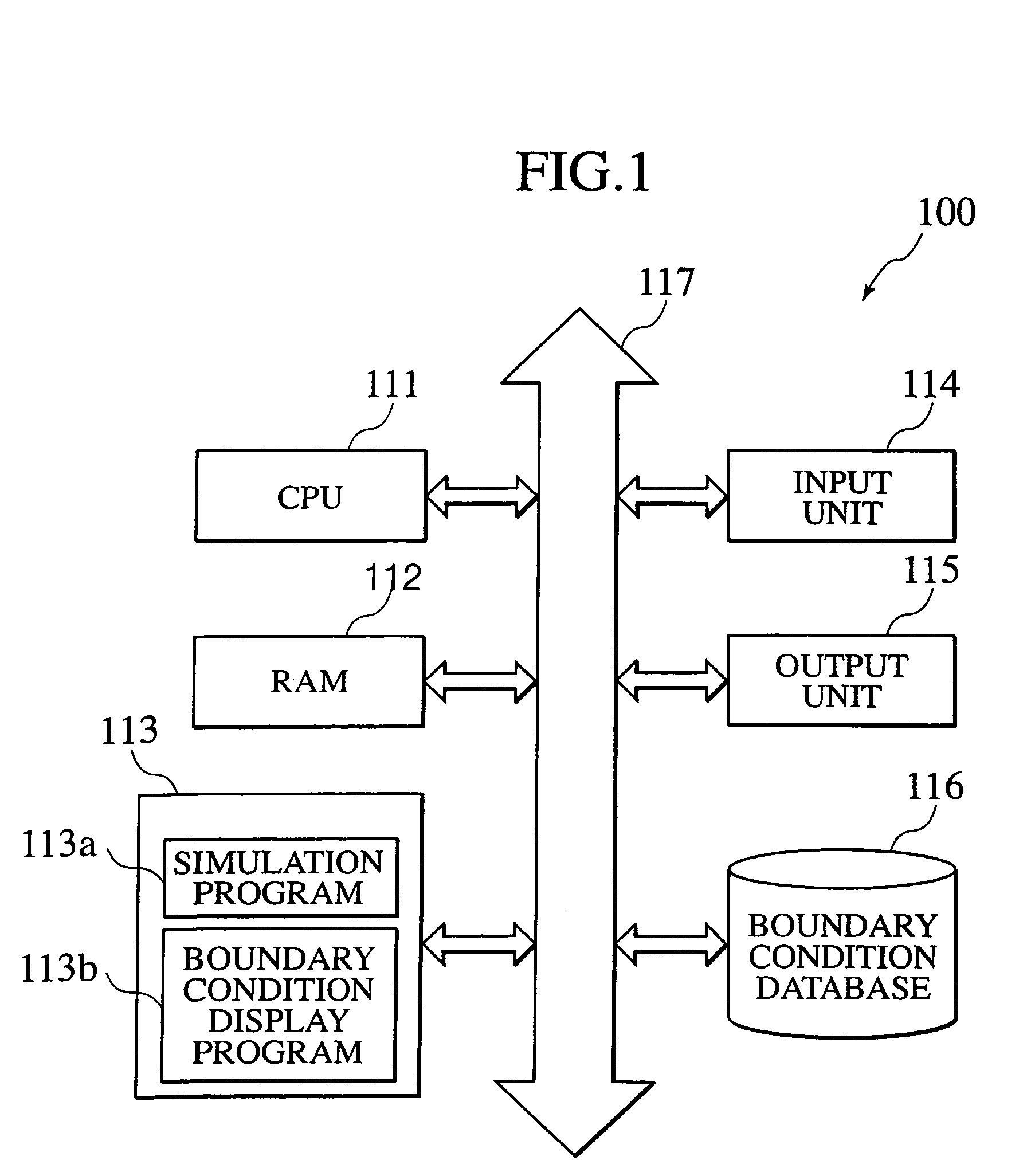

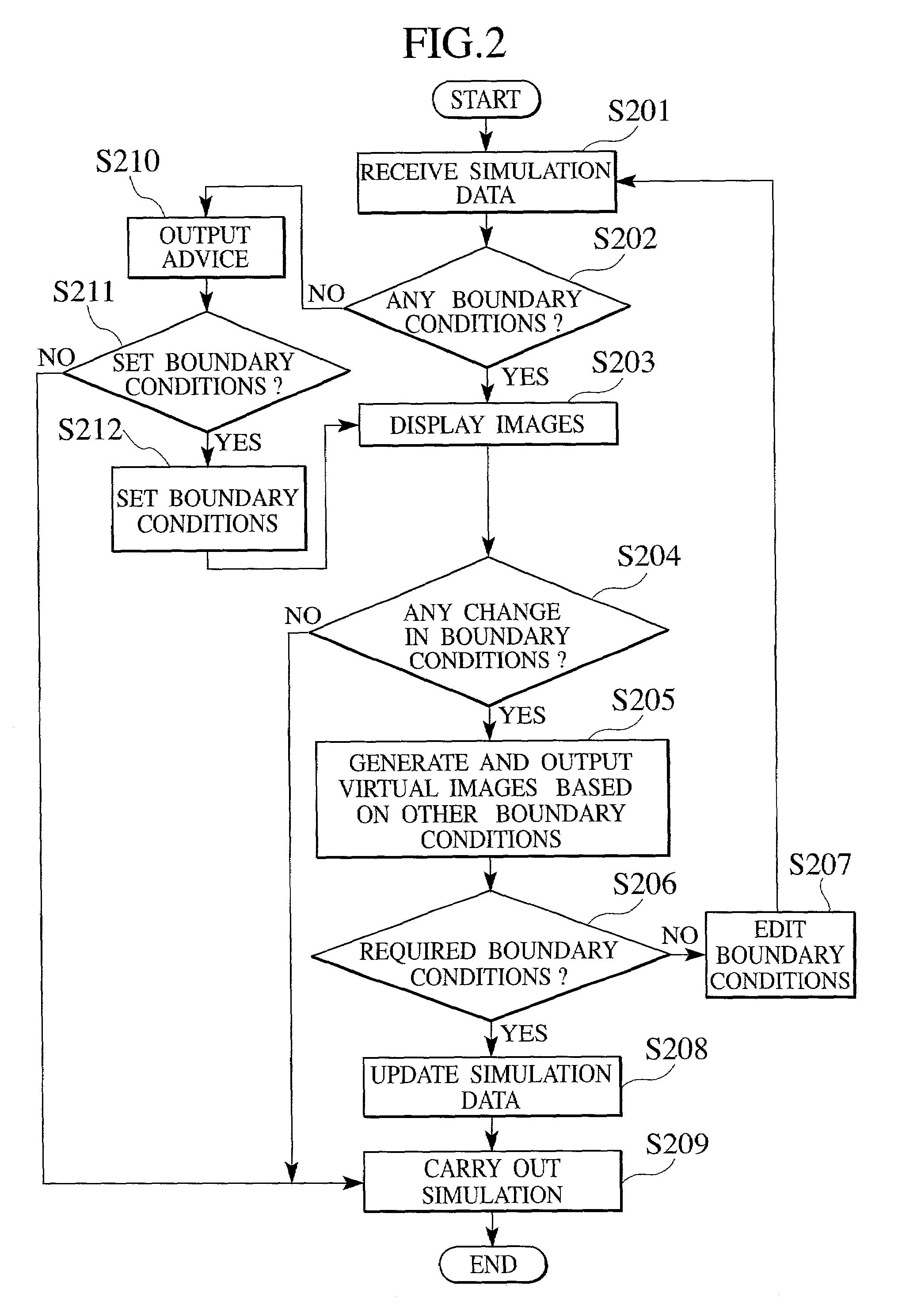

Simulation method, simulation program, and semiconductor device manufacturing method each employing boundary conditions

InactiveUS20020087298A1Analogue computers for electric apparatusSemiconductor/solid-state device manufacturingParallel computingCauchy boundary condition

An aspect of the present invention provides a method of carrying out a simulation with simulation data, including, determining whether or not the simulation data includes boundary conditions set for a boundary of a calculation area set for the simulation, computing the influence of the boundary conditions on the inside of the calculation area if the simulation data includes the boundary conditions, displaying the influence of the boundary conditions on the inside of the calculation area, prompting to enter an instruction whether or not the boundary conditions are changed, and if an instruction to make no change in the boundary conditions is entered, carrying out the simulation with the simulation data.

Owner:KK TOSHIBA

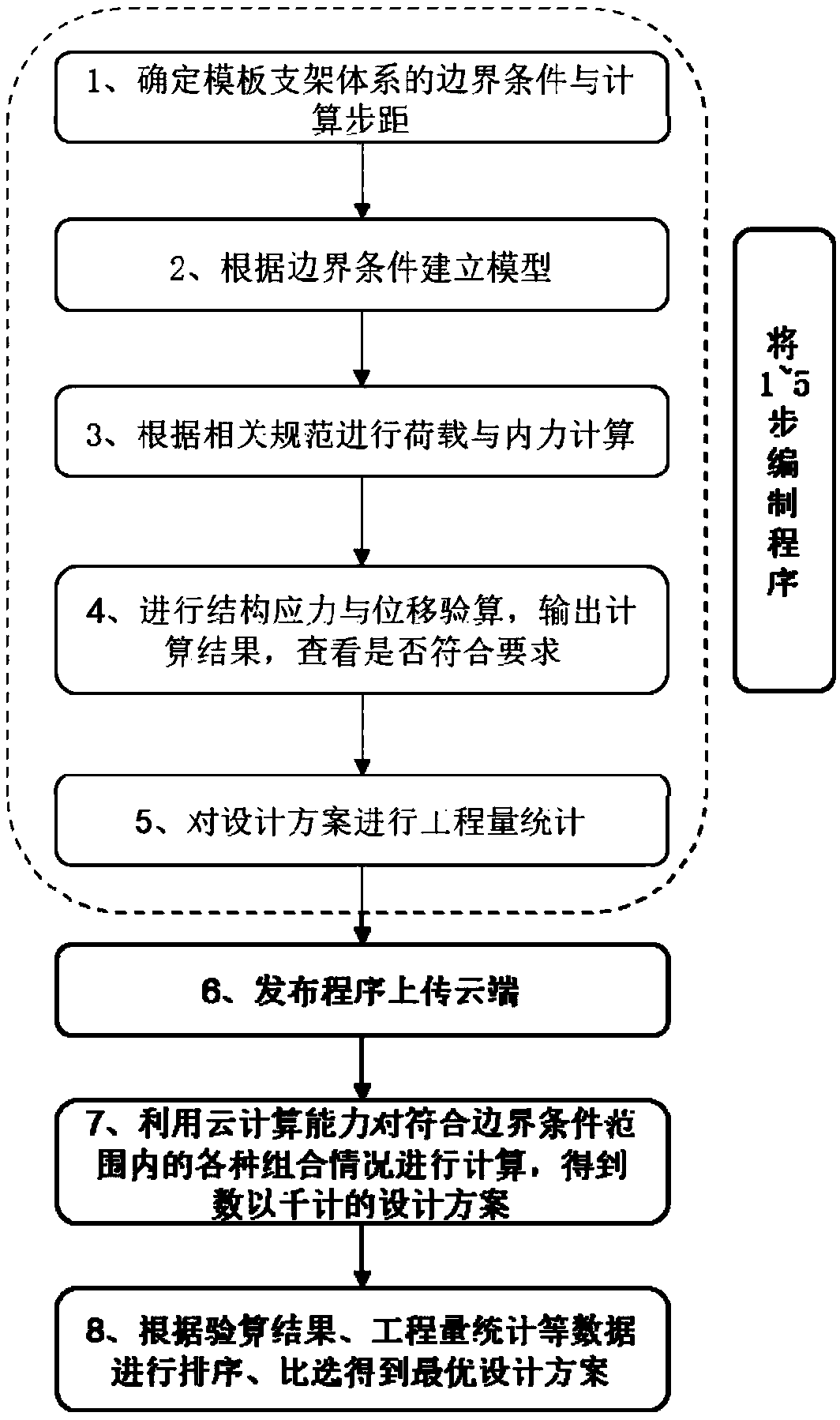

Formwork support system derivative design method

ActiveCN109359434ALow costImprove computing efficiencyGeometric CADDesign optimisation/simulationSupporting systemEngineering

The invention relates to a formwork support system derivative design method. 1. Determine the boundary conditions and calculation steps of the formwork support system; 2, establish a parametric modelaccording to that boundary condition; 3, load and internal force calculation; 4. Checking the stress and displacement of the structure, outputting the calculation result to check whether it meets thedesign requirements; 5, count that engineering quantity of the design scheme; 6, upload that publishing program to the cloud; 7, compute various combinations according with that boundary conditions byusing the cloud computing capability, and obtaining thousands of design scheme; 8, arrange that statistical data of the project quantity according to the calculation result, and comparing and selecting the most design scheme. This method adopts the derivative design principle, according to the set boundary condition scope and the step distance request, compiles the program to construct the model,outputs the stress, the displacement and the project quantity statistical result, utilizes the cloud computing ability, has greatly improved the design efficiency, and reduced the engineering material, saves the cost.

Owner:BEIJING MUNICIPAL ROAD & BRIDGE

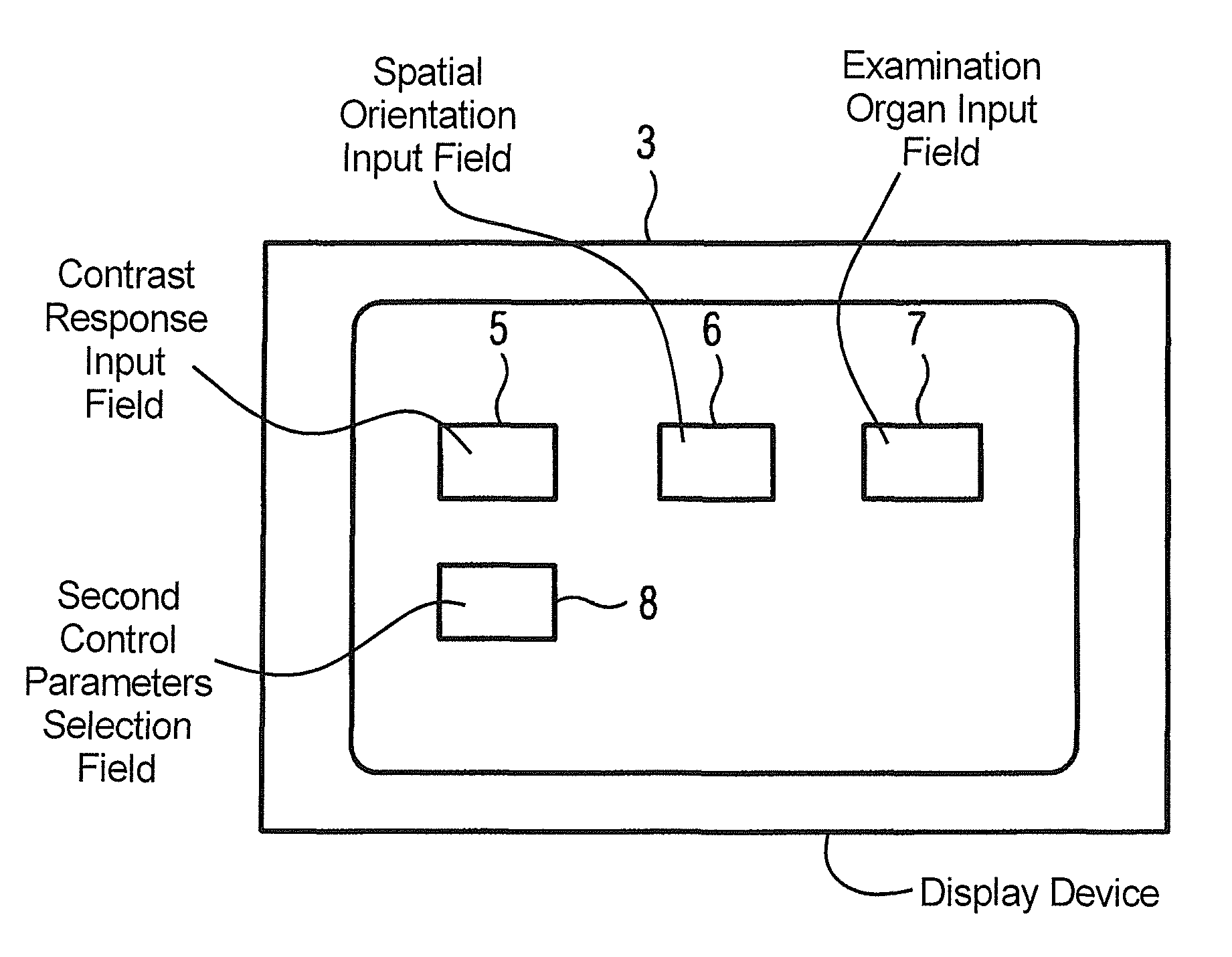

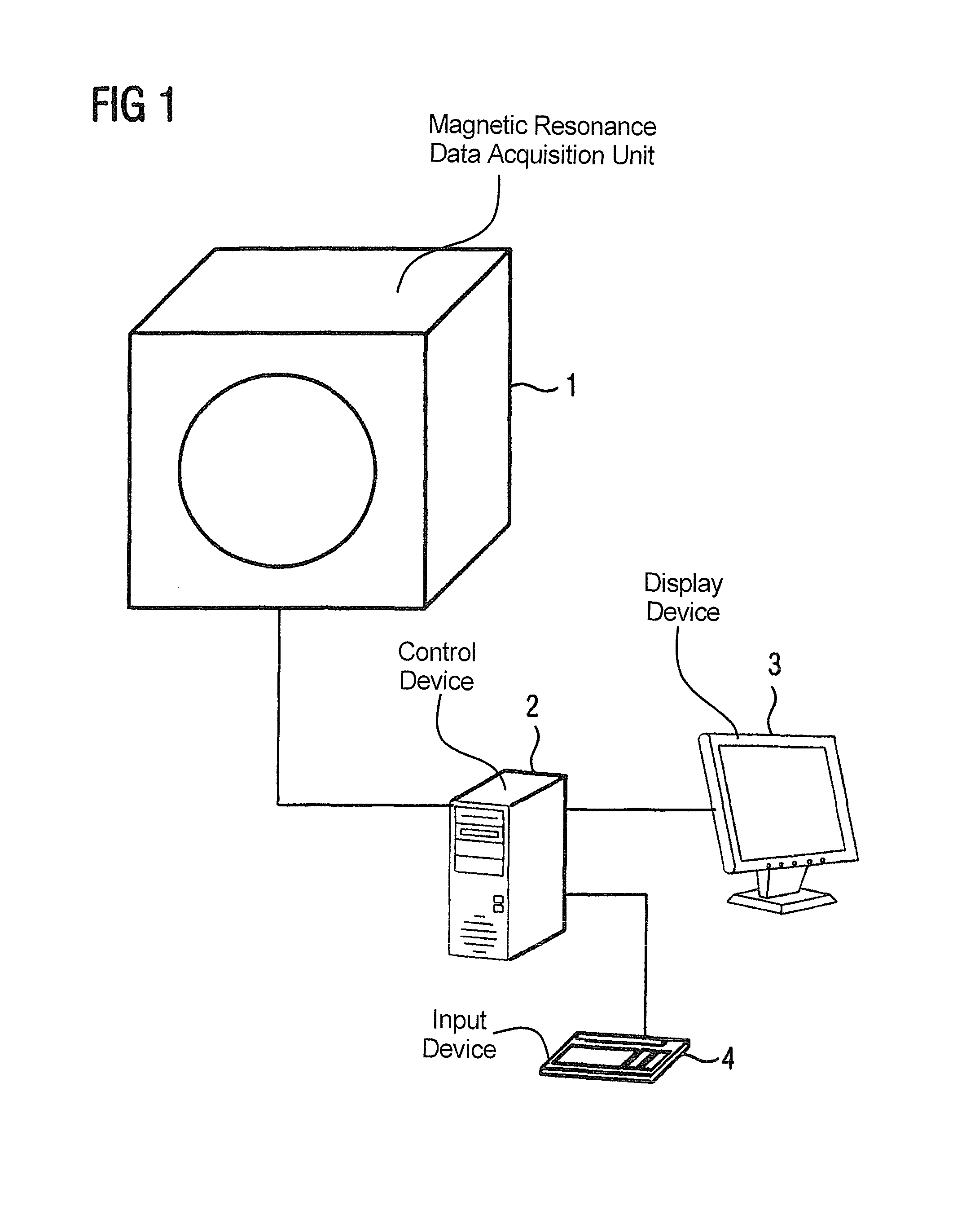

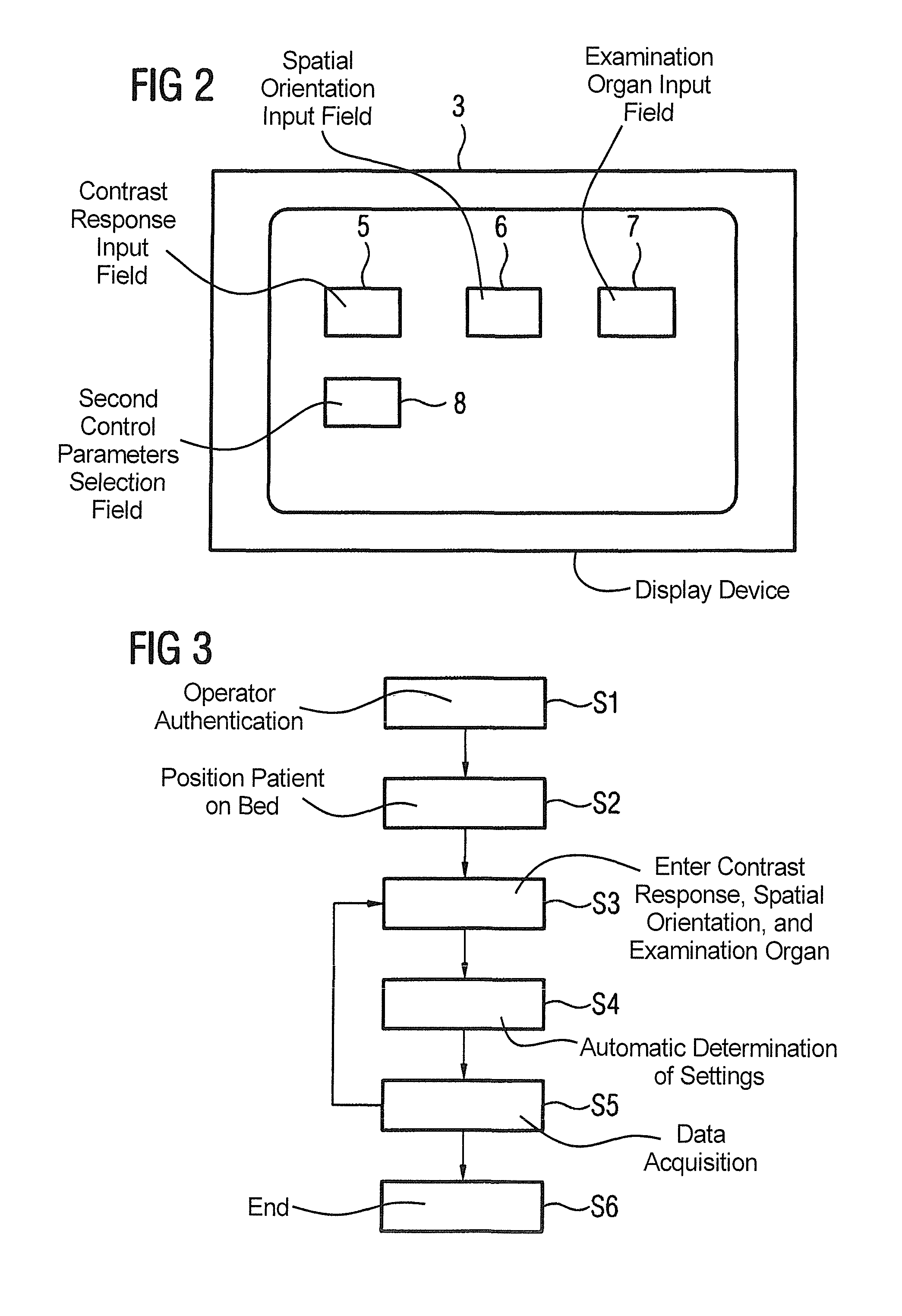

Streamlined diagnostic MR imaging requiring only three control parameters of operator selected boundary conditions

InactiveUS7990141B2Easy to measureSimplify creationMagnetic measurementsDiagnostic recording/measuringSpatial OrientationsData set

In a method for operation of a magnetic resonance system, at least one control device is fashioned for image data acquisition and corresponding components, and only three first control parameters defining primary boundary conditions are selected by an operator of the system, namely the contrast response, the spatial orientation of the at least one image data set to be acquired and the examination organ. Additional, second control parameters, required to control the components for image acquisition and defining secondary boundary conditions, are automatically determined by the control device using the first control parameters.

Owner:SIEMENS HEALTHCARE GMBH

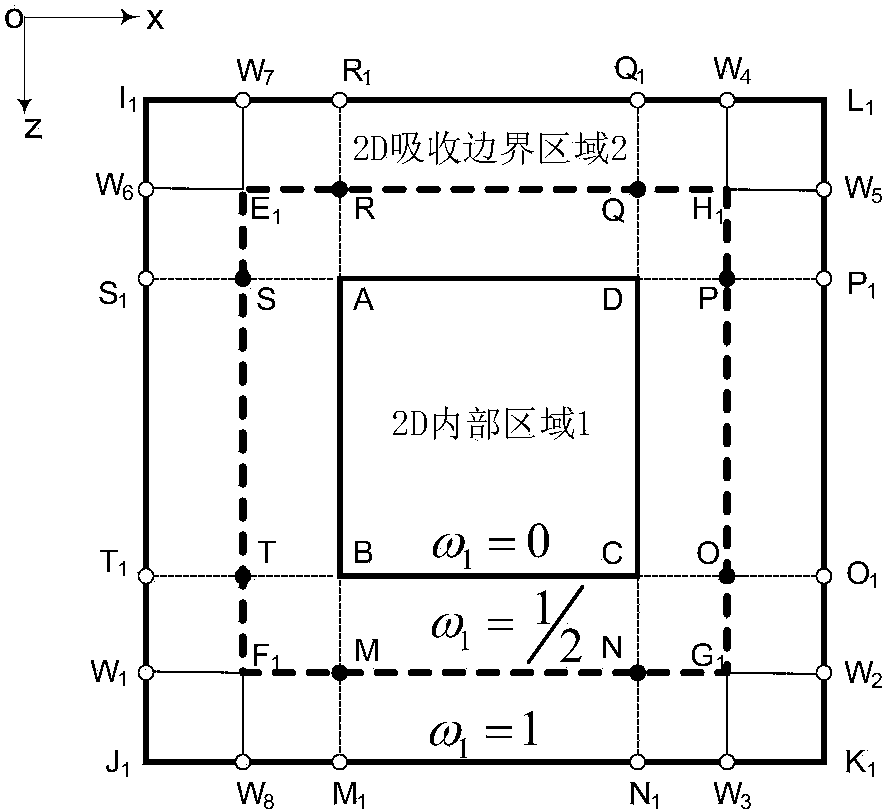

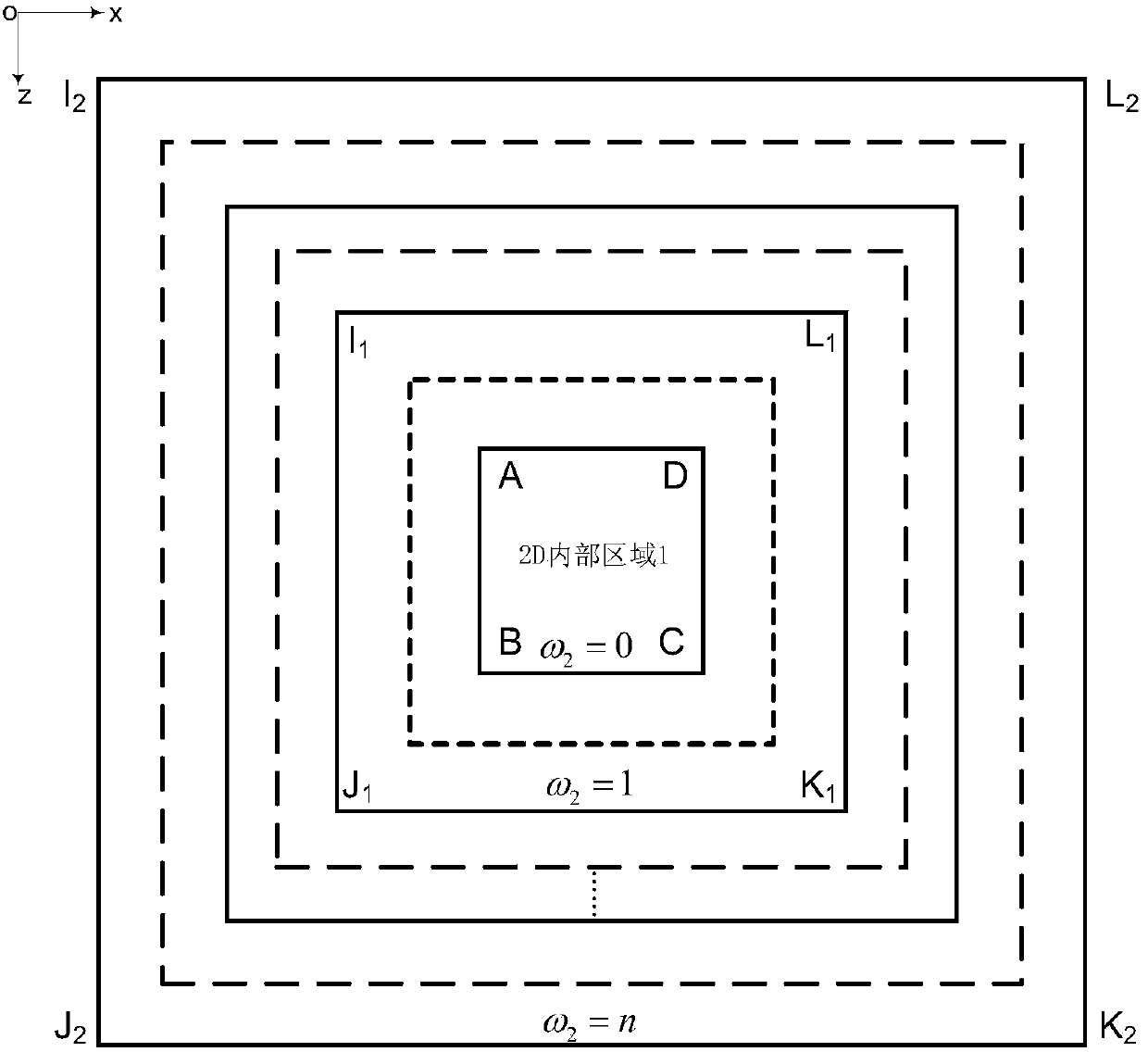

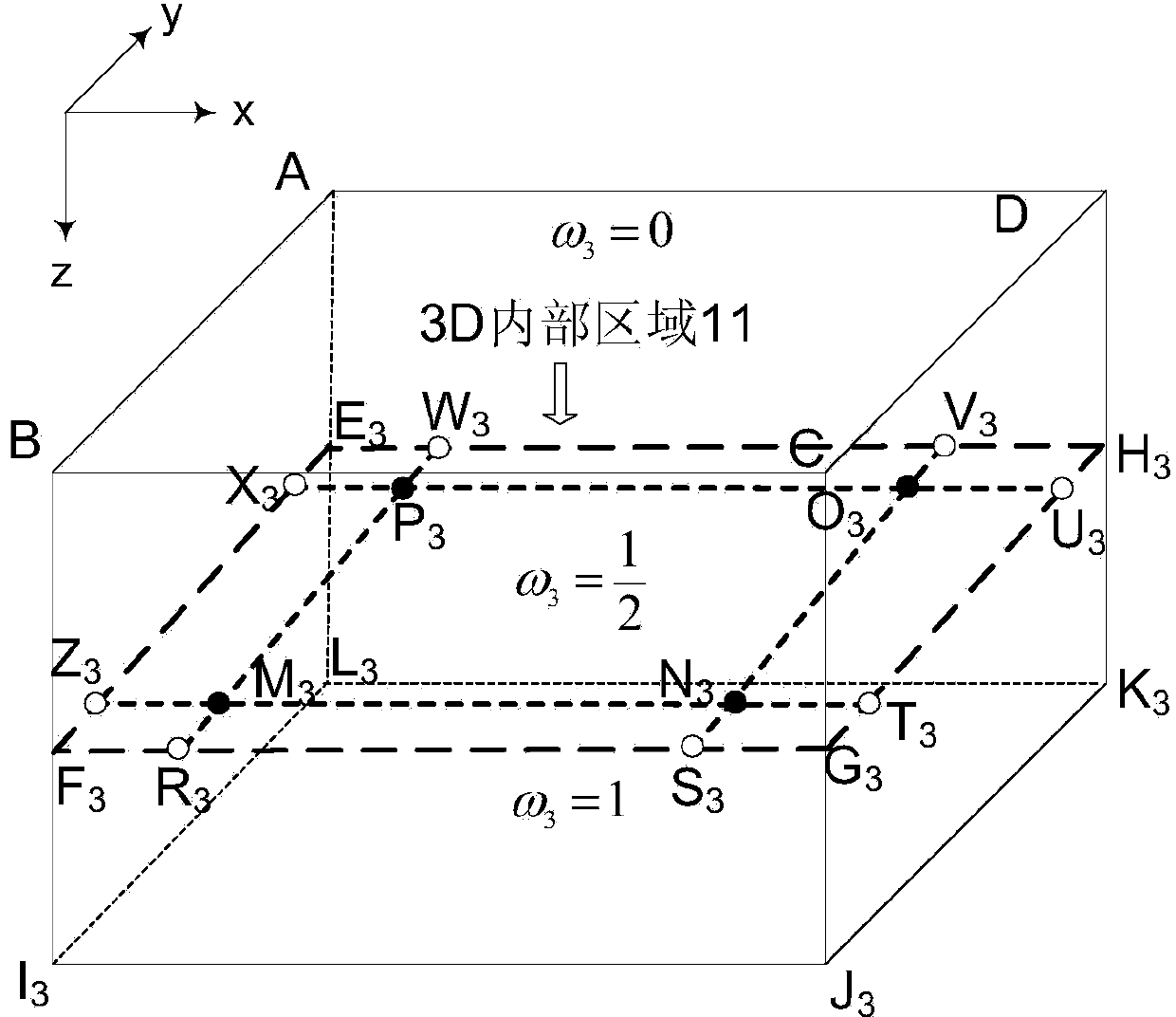

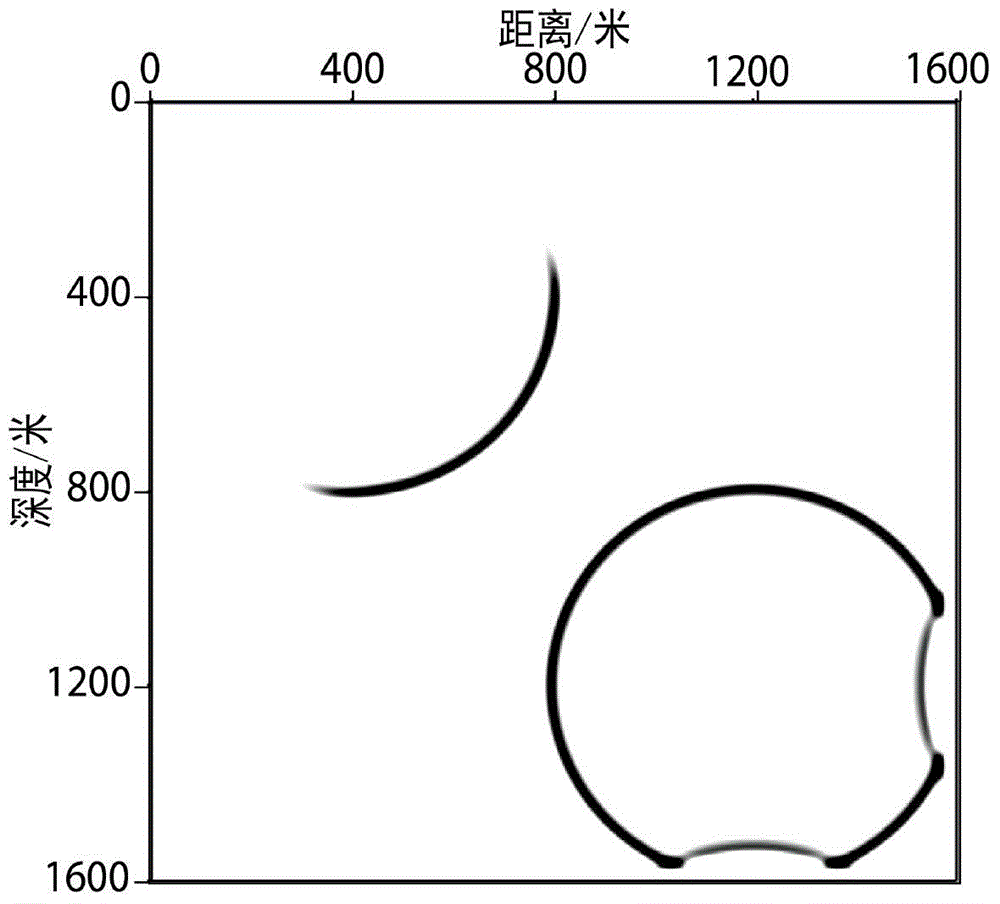

Implementation method for mixed absorbing boundary condition applied to variable density acoustic wave equation

ActiveCN103698814AImproved the effect of suppressing border reflectionsSuppression is effectiveSeismic signal processingWave equationWave field

The invention relates to an implementation method for a mixed absorbing boundary condition applied to a variable density acoustic wave equation. The implementation method comprises the steps of dividing a whole simulation region into an internal region and a boundary region, calculating the wave field value of a sound wave of each absorbing boundary layer by using the variable density acoustic wave equation and a variable density AWWE (Arbitrary Wide-angle wave equation) respectively, and performing linear weighting on the two calculation results to obtain the wave field value of the sound wave of each absorbing boundary layer. On the basis of realizing a single variable density AWWE absorbing boundary layer and in 2D (2 dimensional) and 3D (3 dimensional) space coordinate systems, the wave field value of the sound wave of each absorbing boundary layer is calculated by respectively adopting a combination mode of processing edges of the variable density AWWE and processing angles of a modified 15-degree one-way wave equation, and a combination mode of processing faces of the variable density AWWE, the processing edges of the modified 15-degree one-way wave equation and the processing angles of a 5-degree one-way wave equation, and the mixed absorbing boundary condition of the variable density AWWE is realized. The implementation method can be widely applied to the numerical simulation of constant density and variable density acoustic wave equations.

Owner:CHINA NAT OFFSHORE OIL CORP +1

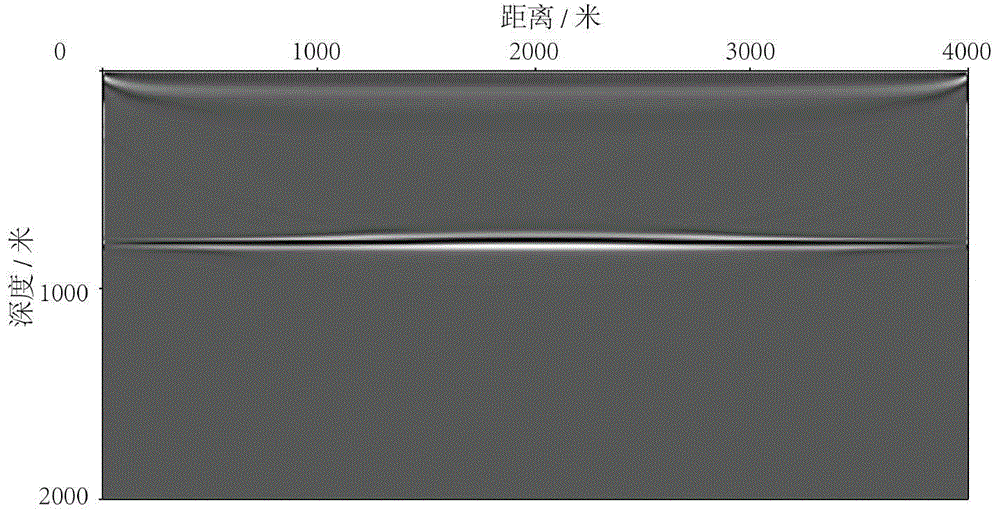

Reverse time migration method of carbonatite reservoir

InactiveCN104133987AEliminate boundary reflection interferenceReduce storage requirementsSeismic signal processingSpecial data processing applicationsReverse timeWave equation

The invention discloses a reverse time migration method of a carbonatite reservoir. By aiming at a phenomenon that a fracture-cavity pore construction of carbonatite is always companied with fracture and big-angle form distortion formed due to construction movement, the reverse time migration method is used for precisely depicting the carbonatite. A finite difference method is used for solving a wave equation to simulate a seismic wave field; a processing method for the wave field to transmit to a boundary adopts a PML (Perfectly Matched Layer) absorbing boundary condition; a seismic origin wave field recovery part adopts a reverse PML wave field recovery technology; and a calculation part adopts a GPU (Graphics Processing Unit) parallel acceleration technology. The PML absorbing boundary condition is adopted, so that the invention can more effectively eliminate boundary reflection interference than a random boundary condition; since the reverse PML wave field recovery technology is adopted, compared with a traditional wave field storage strategy, the invention can greatly reduce requirements on a storage amount on the premise that a calculated amount is not increased, a wave field recovery effect is good, amplitude fading is avoided, and operation efficiency is improved by adopting the GPU parallel acceleration technology.

Owner:NORTHEAST GASOLINEEUM UNIV

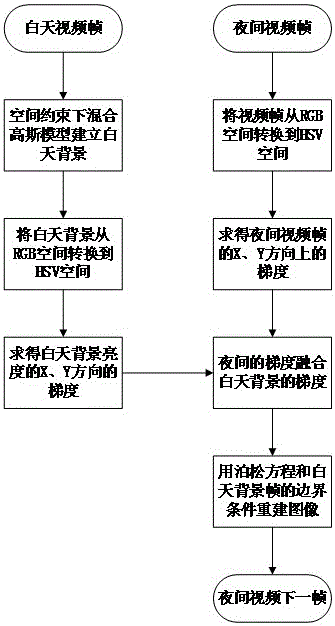

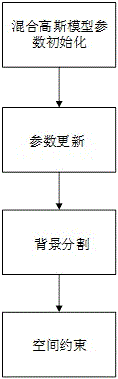

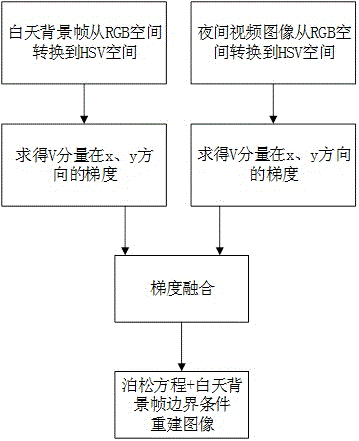

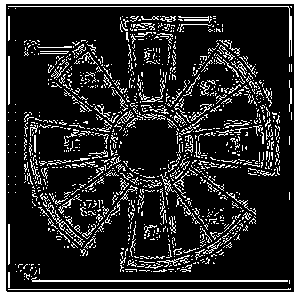

Night video enhancement method based on gradient integration

ActiveCN106296626AReduce black noiseEnhanced Highlight DetailsImage enhancementImage analysisModel extractionInformation integration

The invention relates to a night video enhancement method based on gradient integration. Day background frames can be extracted by utilization of spatial constraint conditions and a Gaussian mixture model, and gradient information of day video background frames is integrated into night video gradient images, so the detailed information lost in the night video images can be compensated. Restored images can be obtained by use of a poisson equation and the boundary conditions of the day background frames. The video image brightness is enhanced, and moreover, a color fidelity effect is achieved.

Owner:SHANGHAI UNIV

An in-plane thermoelectric device structure design method based on COMSOL software

ActiveCN109635442AReduce experiment costShorten experiment timeGeometric CADDesign optimisation/simulationIn planePhysical field

The invention discloses an in-plane thermoelectric device structure design method based on COMSOL software, and the method comprises the following steps: selecting a three-dimensional space dimensionand a thermoelectric effect physical field in a COMSOL software model guide, and carrying out the steady-state research; Establishing a geometric physical model of the thermoelectric device needing tobe solved; Defining related global parameters and endowing model material attributes; Setting an initial value and boundary conditions of the model; Dividing grids and calculating; And changing boundary current conditions, calculating and comparing the boundary current conditions through COMSOL software to obtain the working state of the thermoelectric device under the optimal current, and carrying out post-processing on the obtained result. Numerical simulation of temperature fields of thermoelectric devices of different structures during working is achieved, the temperature field distribution rule of the thermoelectric devices is explored, the experiment cost and time are reduced, and theoretical guidance and technical support are provided for structure optimization of the thermoelectric devices.

Owner:WUHAN UNIV OF TECH

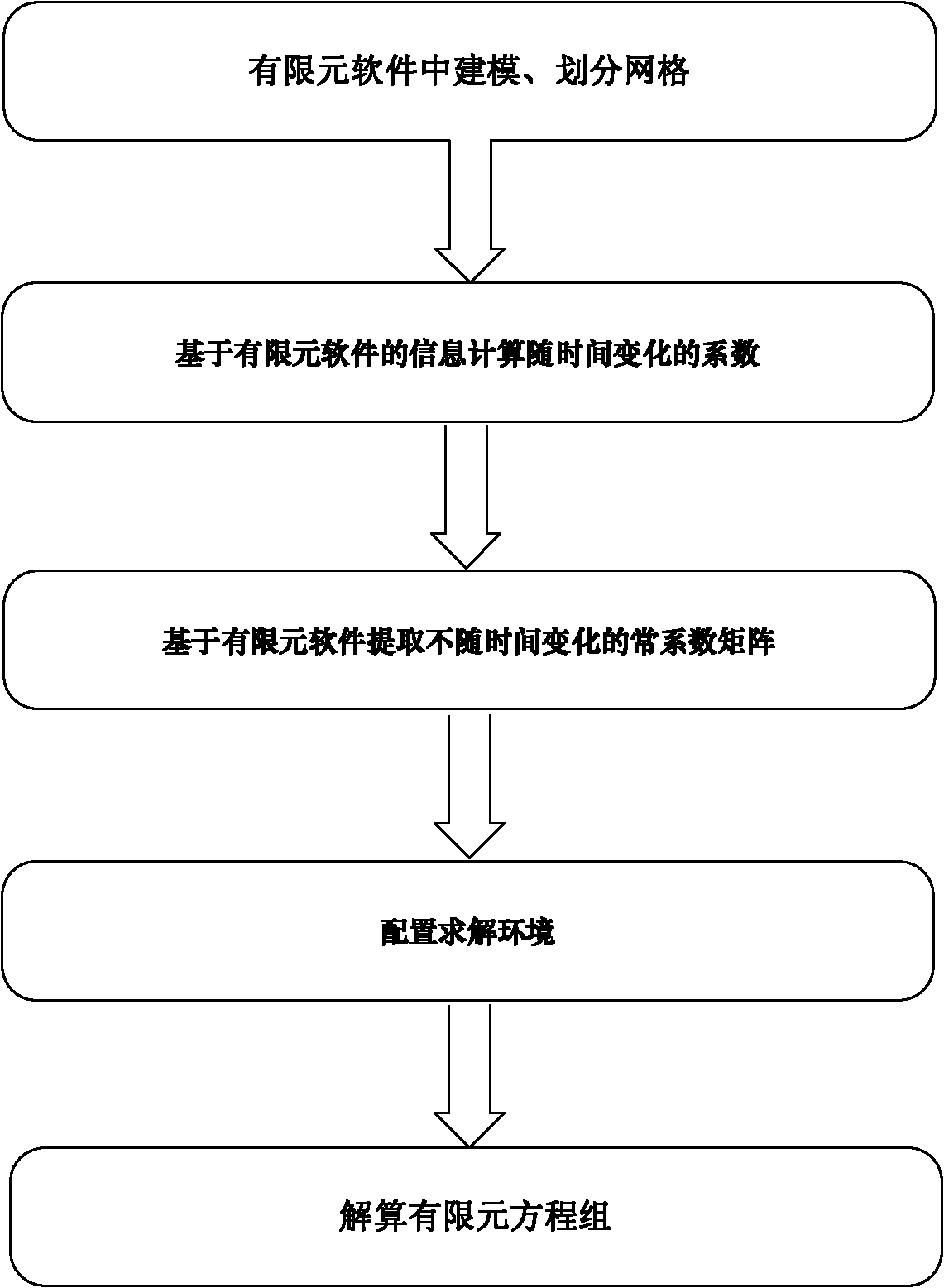

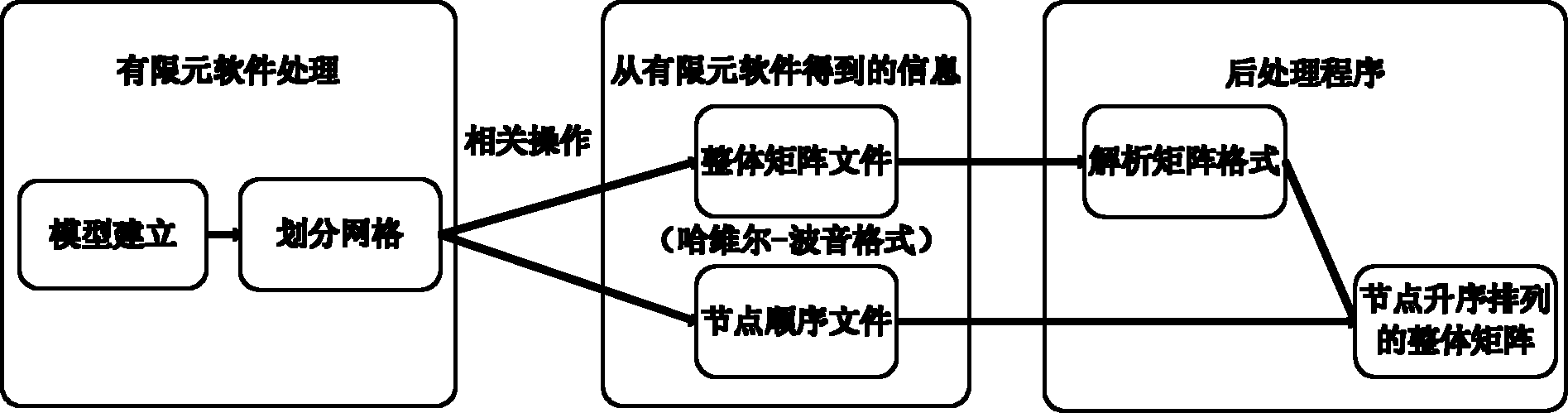

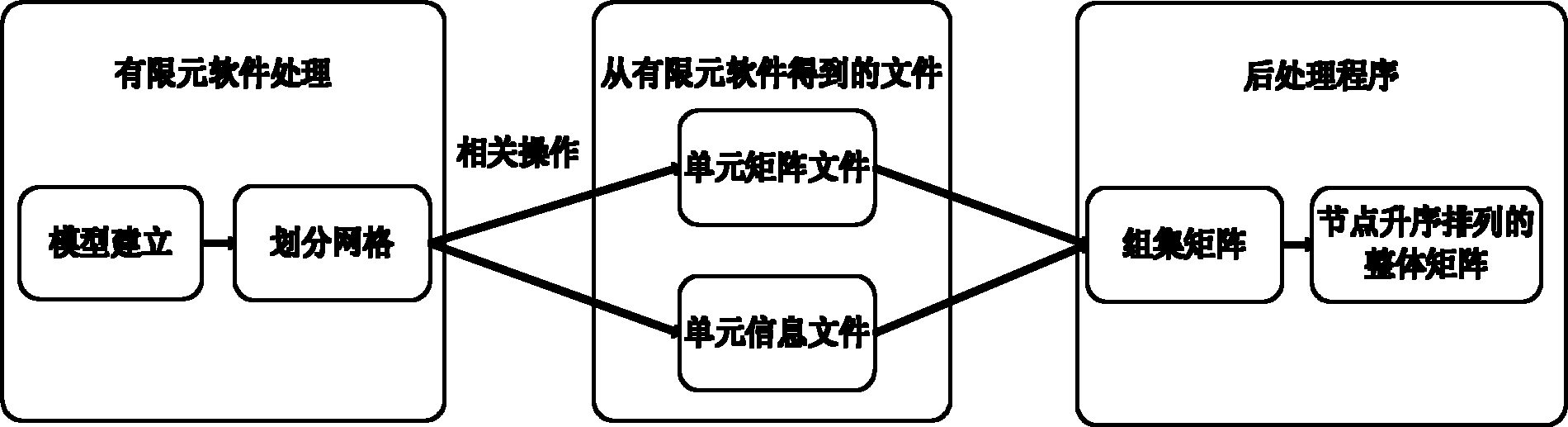

Thermal analysis modeling method for data extraction

InactiveCN102156775ASolve modelingSolve the problem of difficult mesh divisionSpecial data processing applicationsSimulationElement modeling

The invention provides a thermal analysis modeling method for data extraction, which comprises the following steps of: firstly, establishing a model in finite element software, and dividing grids; secondly, calculating coefficients changing with time changes on the basis of information of the finite element software; thirdly, extracting a constant coefficient matrix without changing with the timechanges on the basis of the finite element software; fourthly, configuring a solving environment; fifthly, setting initial conditions and boundary conditions; and sixthly, resolving the model. When the modeling method is adopted, the powerful modeling and grid-dividing functions of the finite element software can be utilized; the problem of difficulty in establishing a complex model and dividing the grids is solved; the workload of the finite element modeling can be reduced; and complex boundary conditions can be loaded conveniently and quickly.

Owner:BEIHANG UNIV

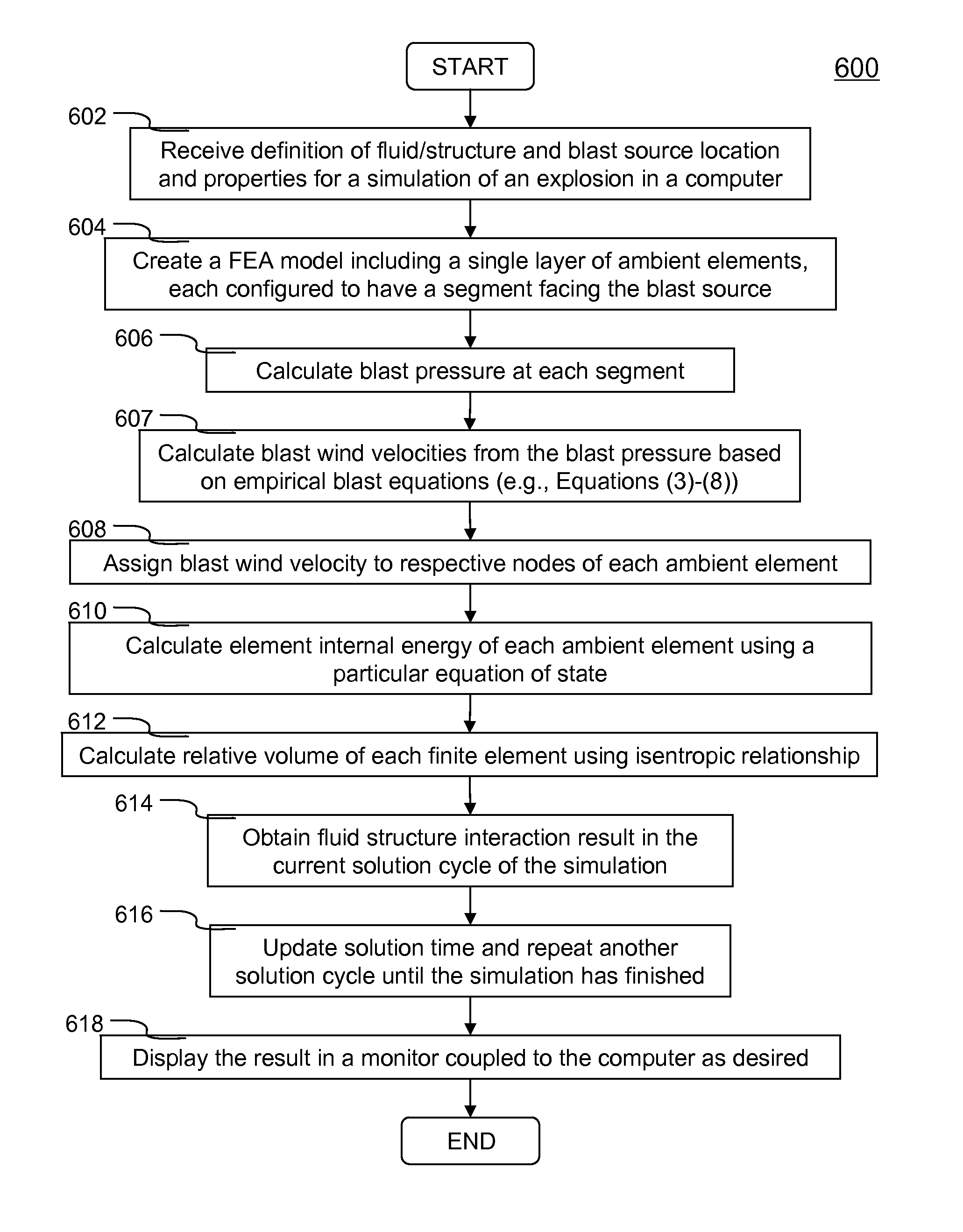

Explosion simulation in finite element analysis

ActiveUS8200464B2Reduce computing timeImprove userComputation using non-denominational number representationDesign optimisation/simulationNODALElement analysis

Systems and methods of simulating an explosion in time-marching finite element analysis are disclosed in the present invention. A method is configured for increasing user (e.g., engineer or scientist) productivity by reducing computation time of simulating fluid-structure interaction due to an explosion. The method comprises a creation of a finite element analysis model that includes structure, surrounding fluid, a blast source of the explosion and a single layer of ambient elements each having a segment representing a boundary of the fluid facing the blast source. Each ambient element is associated with a particular finite element representing the fluid at the boundary. The ambient elements are configured to be situated between the blast source and the structure such that the simulation can be carried on a set of boundary conditions specified thereon. The boundary conditions comprise a set of nodal velocities that are determined from the empirical formula (e.g., Friedlander equation).

Owner:ANSYS

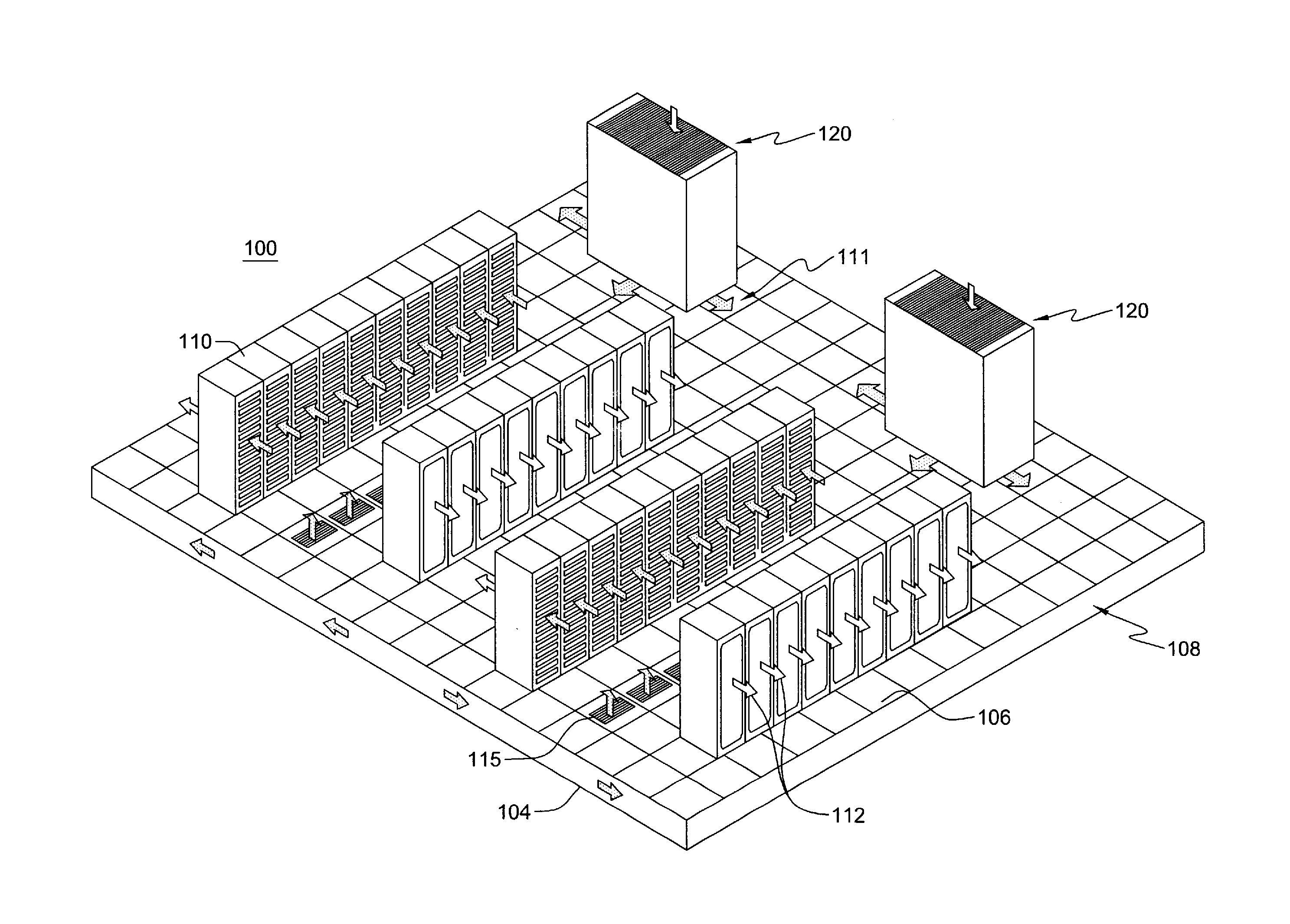

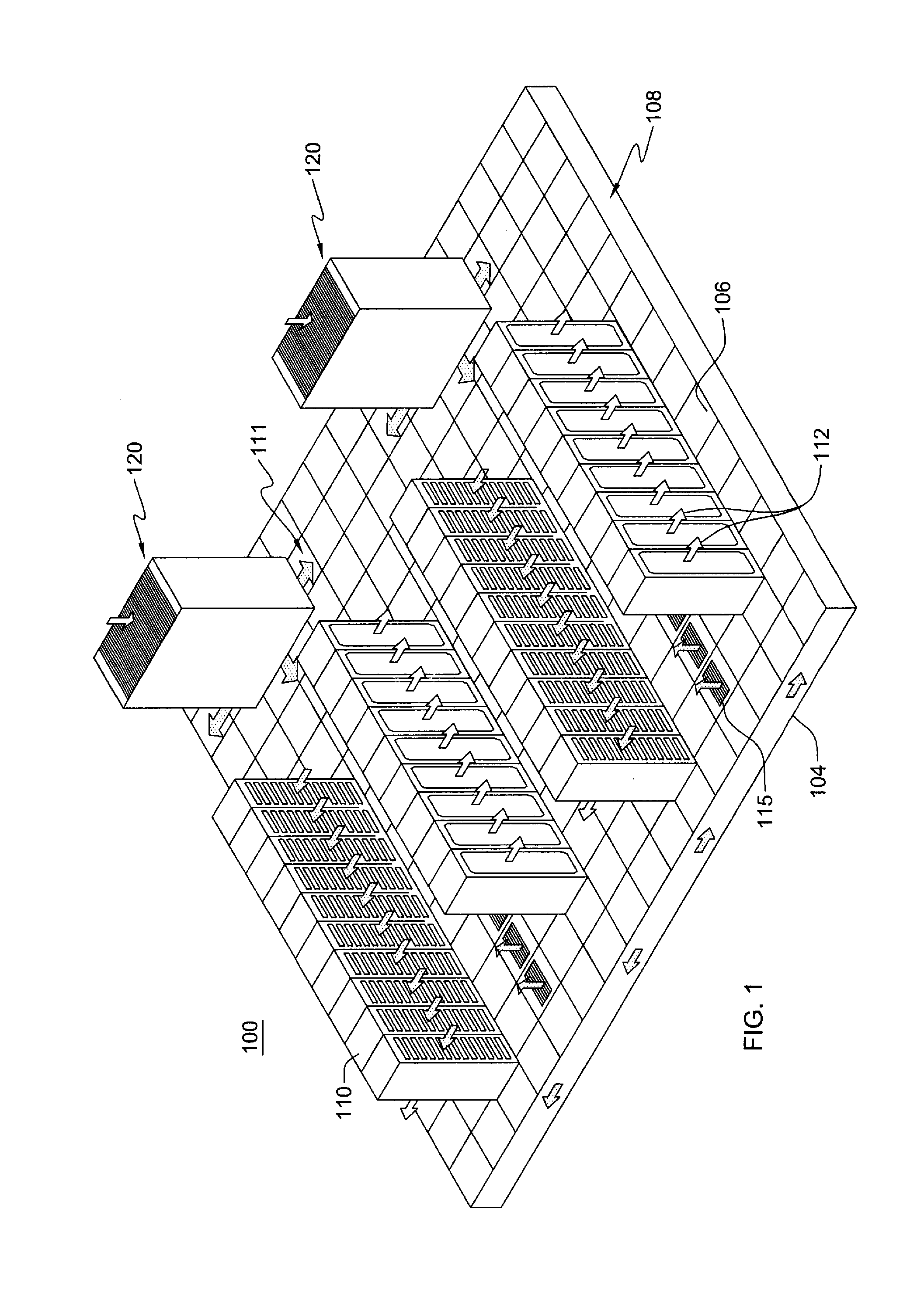

Bounded domain modeling with specified boundary conditions and mass balancing

ActiveUS20160350460A1Design optimisation/simulationElectrical apparatus contructional detailsRobin boundary conditionCauchy boundary condition

Computational fluid dynamics modeling of a bounded domain is provided which includes solving iteratively a computational fluid dynamics model of the bounded domain using mass flow boundary conditions that are specified. The solving includes automatically adjusting the specified mass flow boundary conditions for at least one iteration of the solving. The automatically adjusting includes mass balancing flows at a boundary of the bounded domain to provide corrected mass flow boundary conditions for the solving. The mass balancing includes applying different corrections to mass in-flow across the domain boundary, compared with mass out-flow across the boundary. The mass balancing may include multiplying mass in-flows across the boundary by (1−CF), and mass out-flows across the boundary by (1+CF), where CF is a determined correction factor, and net mass flow is positive for mass out-flow exiting the domain, and negative for mass in-flow entering the domain.

Owner:IBM CORP

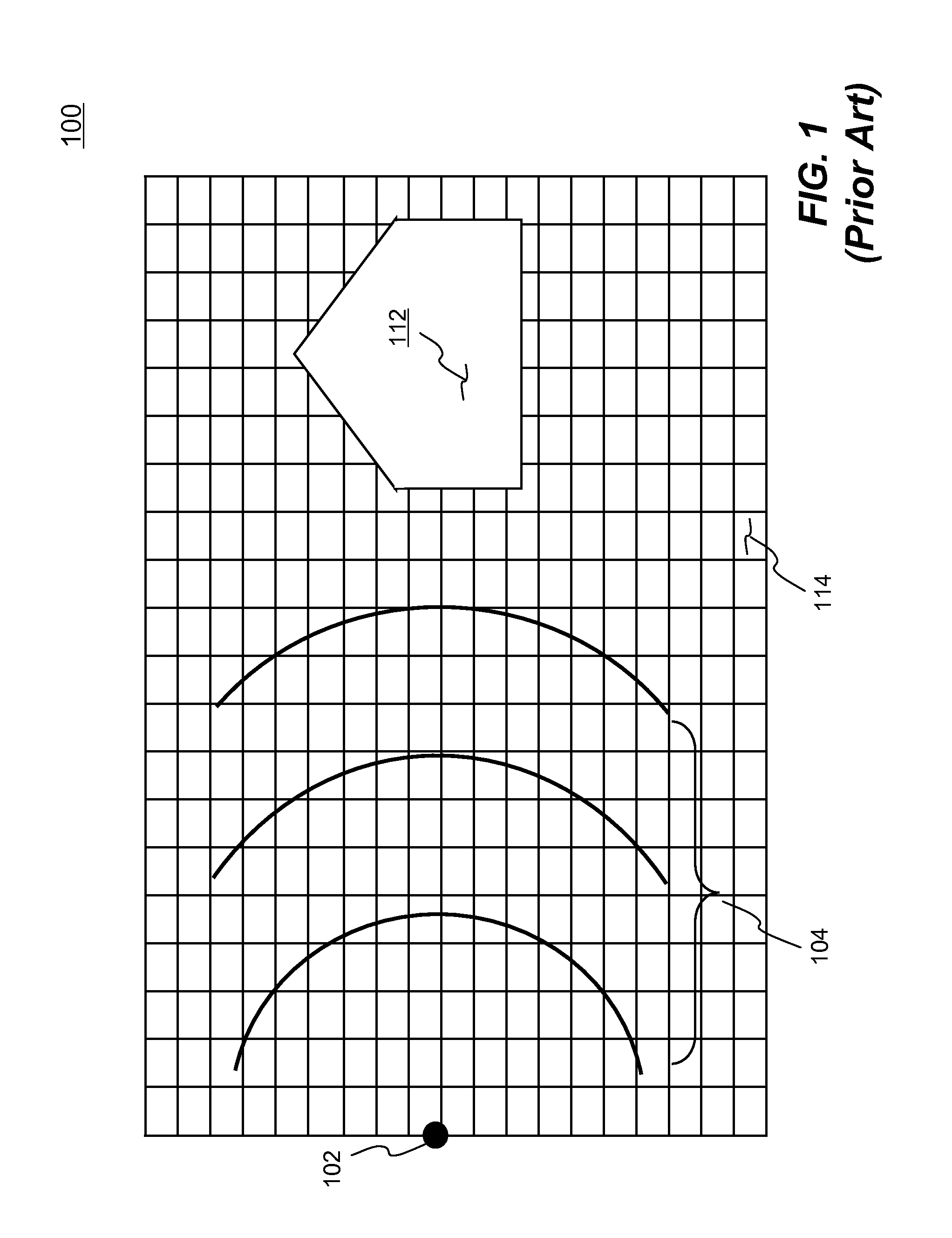

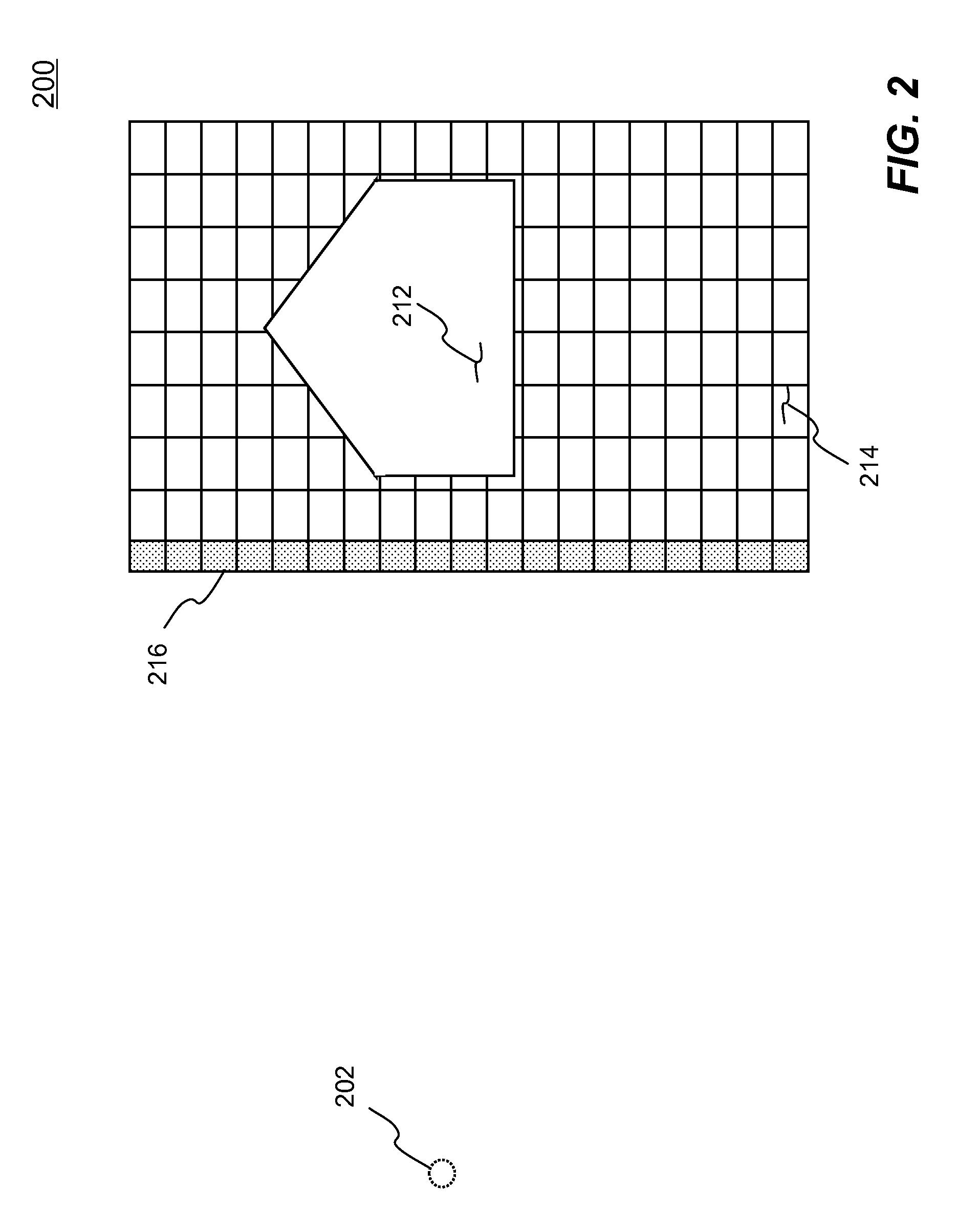

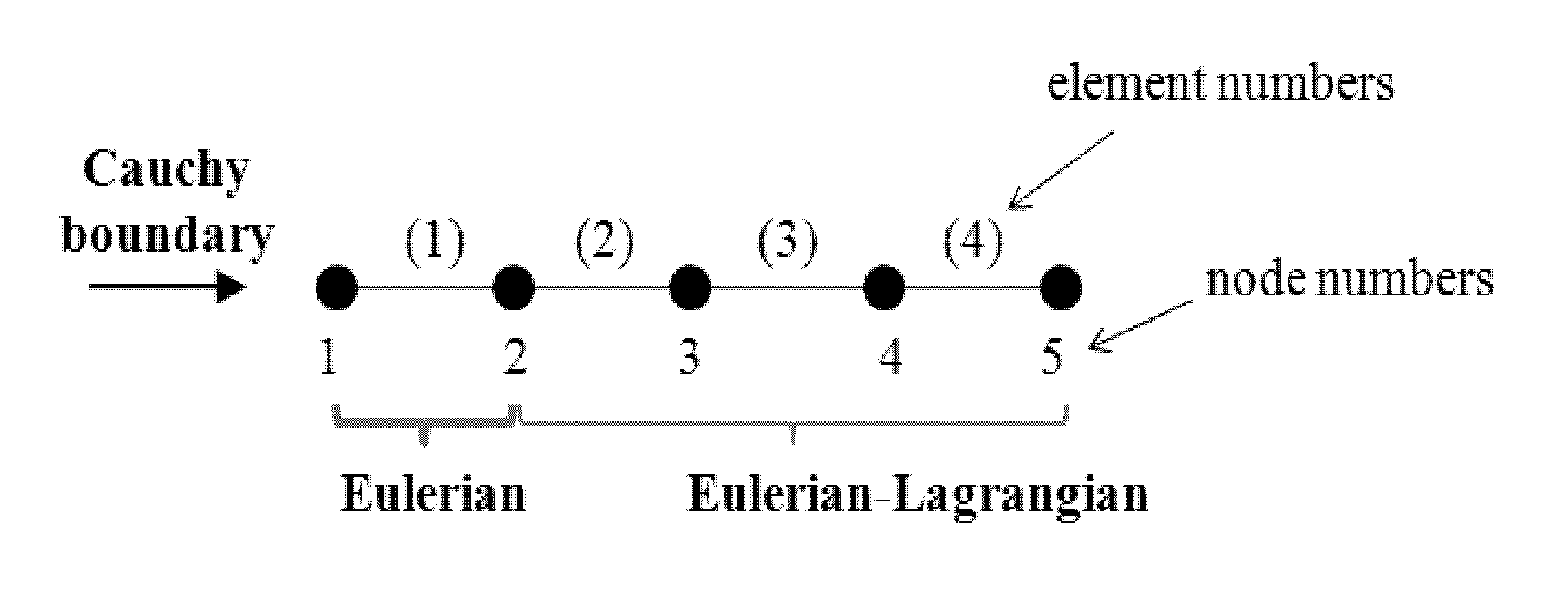

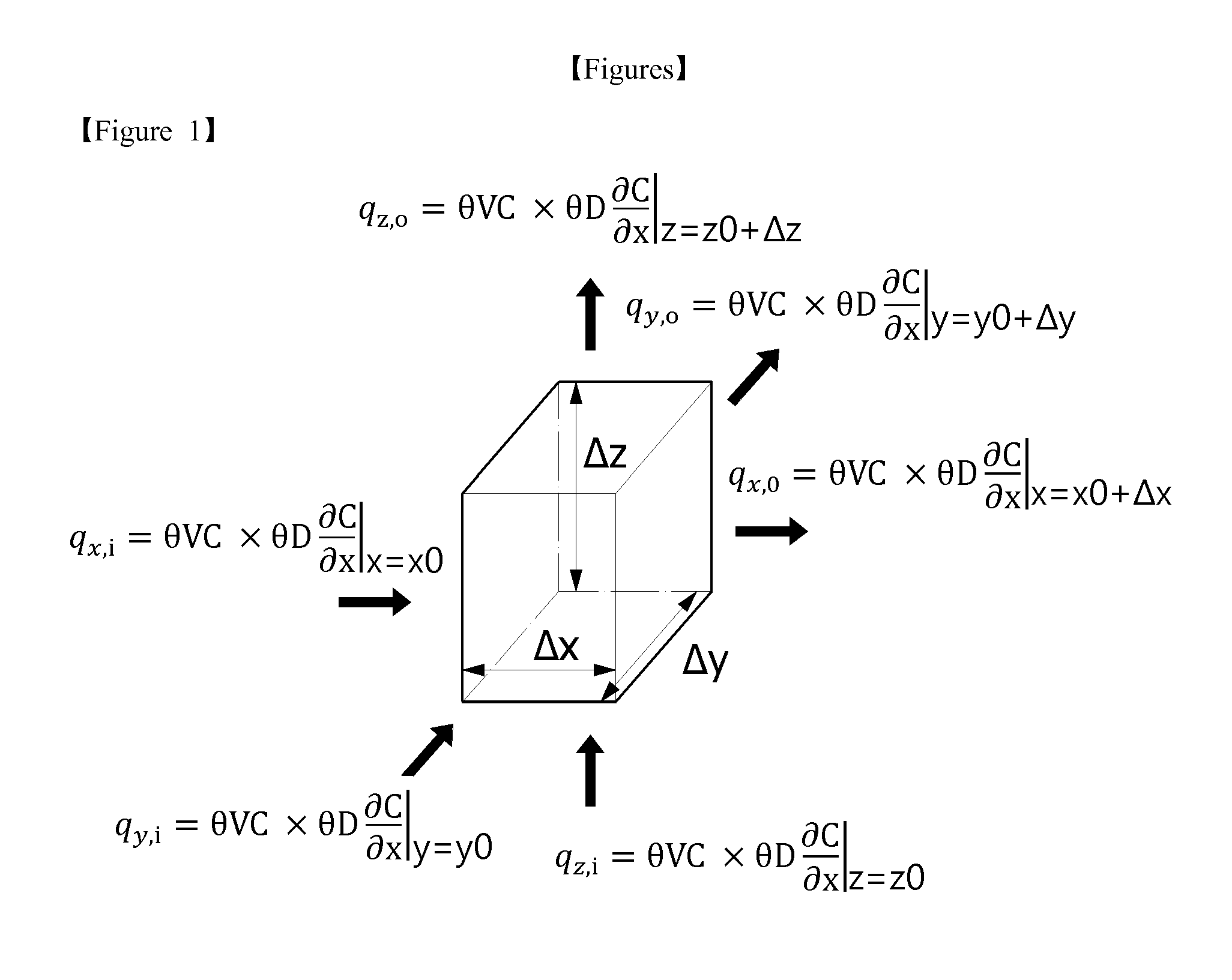

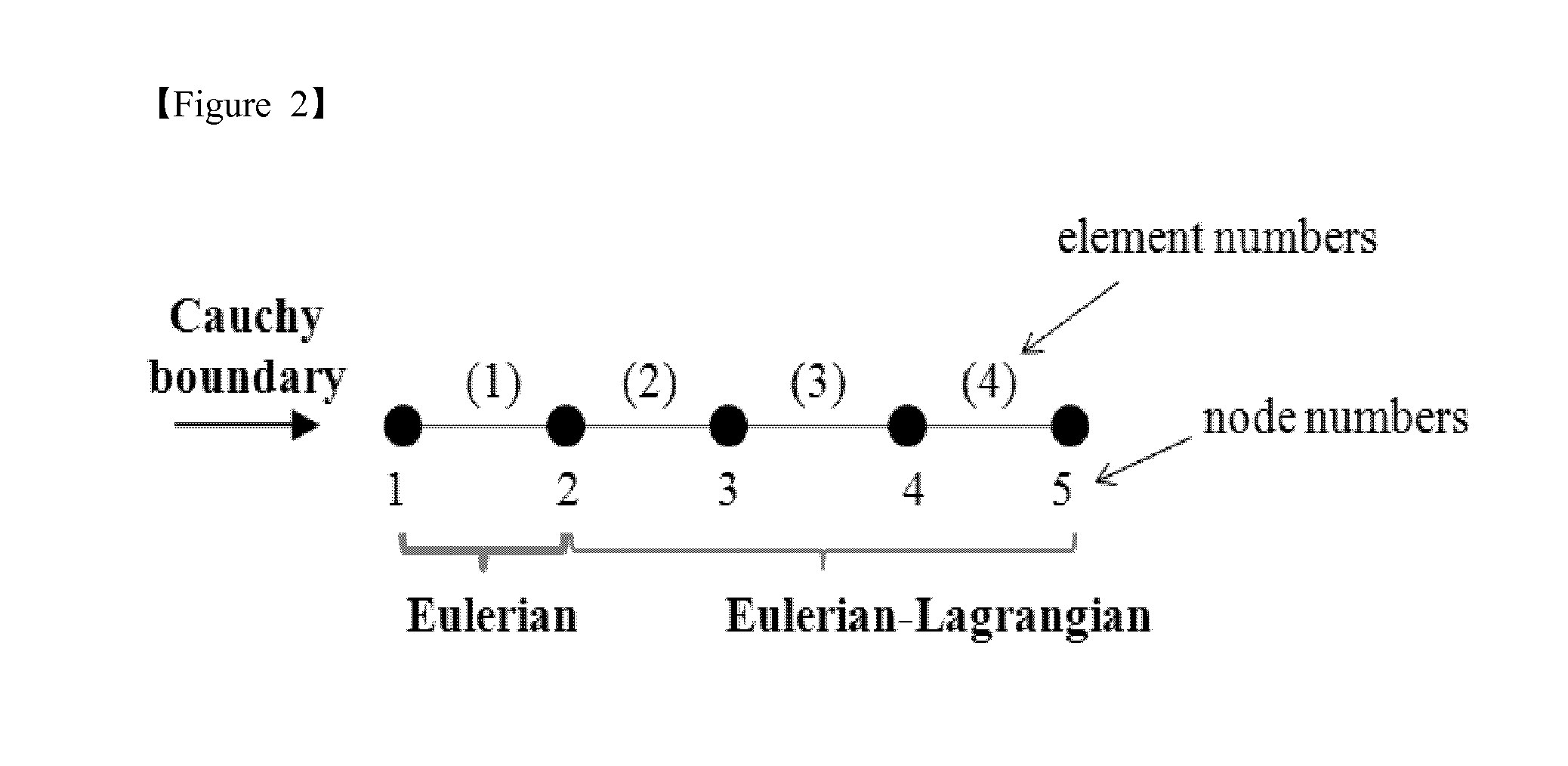

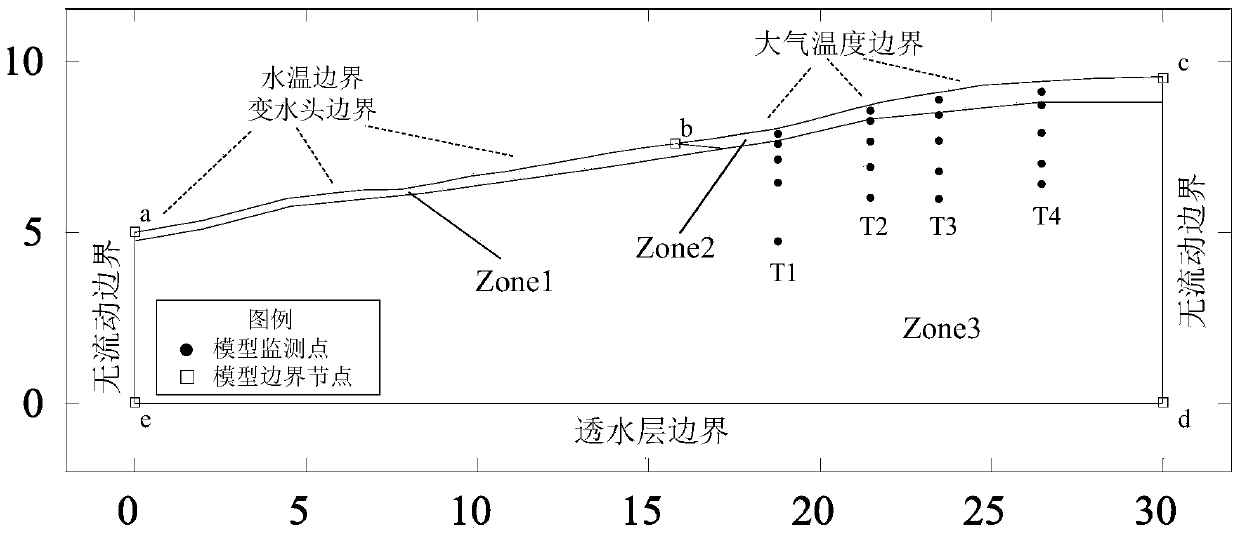

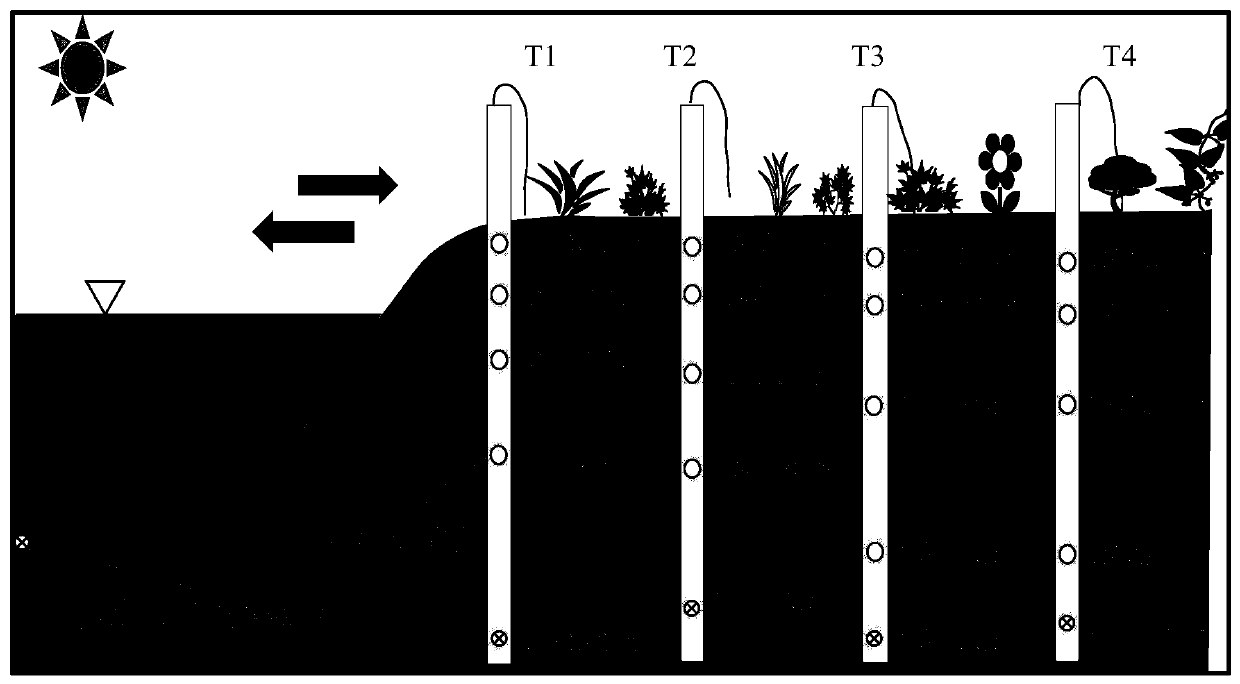

Method of analyzing contaminant transport under cauchy boundary conditions using improved lagrangian-eulerian method

InactiveUS20140372088A1Accurate numerical analysisAccurate analysisComputation using non-denominational number representationDesign optimisation/simulationEulerian methodComputer science

This invention relates to, in order to numerically analyze contaminant transport in groundwater, a method of analyzing contaminant transport under Cauchy boundary conditions using an improved Lagrangian-Eulerian method, wherein problems of a conventional Lagrangian-Eulerian method able to analyze only high Peclet numbers are solved, and which is configured to analyze a new numerical matrix constructed in such a manner that a Eulerian method is applied to an element adjacent to Cauchy boundary conditions and a conventional Lagrangian-Eulerian method is applied to an internal element, thereby enabling accurate numerical analysis of contaminant transport at various Peclet numbers including not only high Peclet numbers but also particularly low Peclet numbers under Cauchy boundary conditions.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

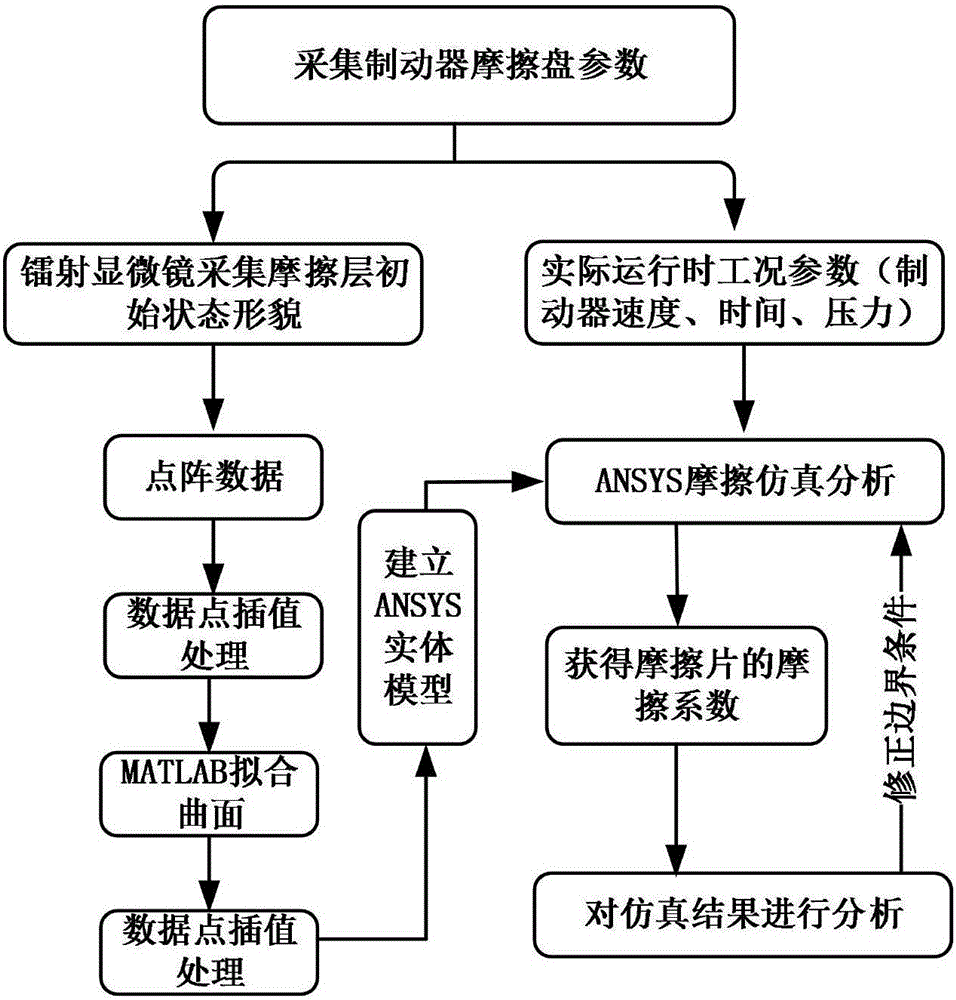

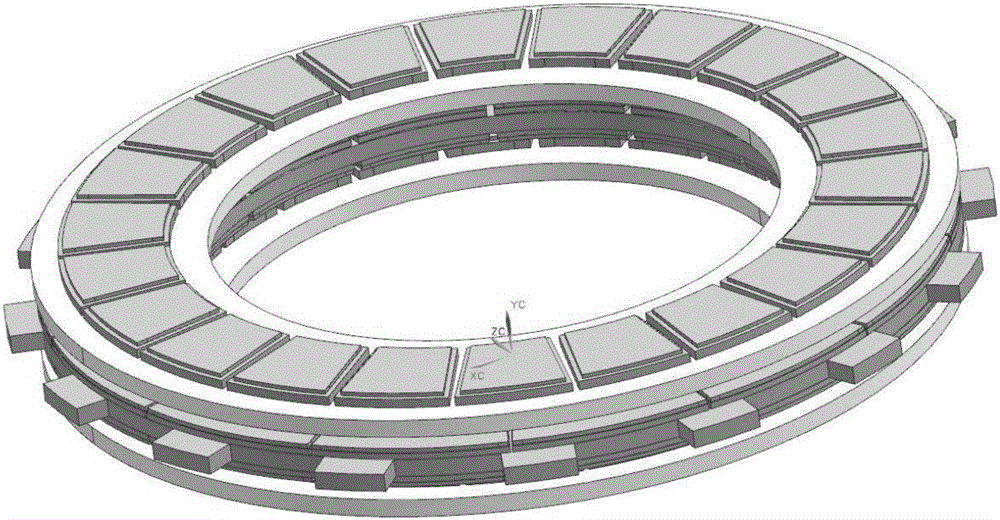

Simulation acquisition method for friction coefficient of friction plate

InactiveCN106354914AHigh precisionLow costGeometric CADSustainable transportationImaging processingModel reconstruction

The invention discloses a simulation acquisition method for friction coefficient of friction plate, comprising the steps ofstep 1) the surface of the new friction plate is subjected to image processing to obtain the micro-topographic features of the friction plate; step 2) set the lattice density of sampling, output the lattice data that describes the characteristic of the surface of the friction layer and perform the interpolation processing to obtain the fitting surface;step 3) three - dimensional model reconstruction is performed on the fitting surface basis; step 4) the imported entities are meshed to obtain the finite element analysis model; step 5) the initial speed, the stop speed, the braking time and the pressure of the friction plate in the actual work is obtained;step 6) the boundary condition of the actual working condition is applied and the friction simulation analysis is carried out and step 7) compare with the actual measured values, constantly correct the simulation boundary conditions. The method can effectively and accurately obtain the friction coefficient of the friction plate, which is simple and has long-term development prospect compared with the physical mapping.

Owner:LIAONING INST OF SCI & TECH +1

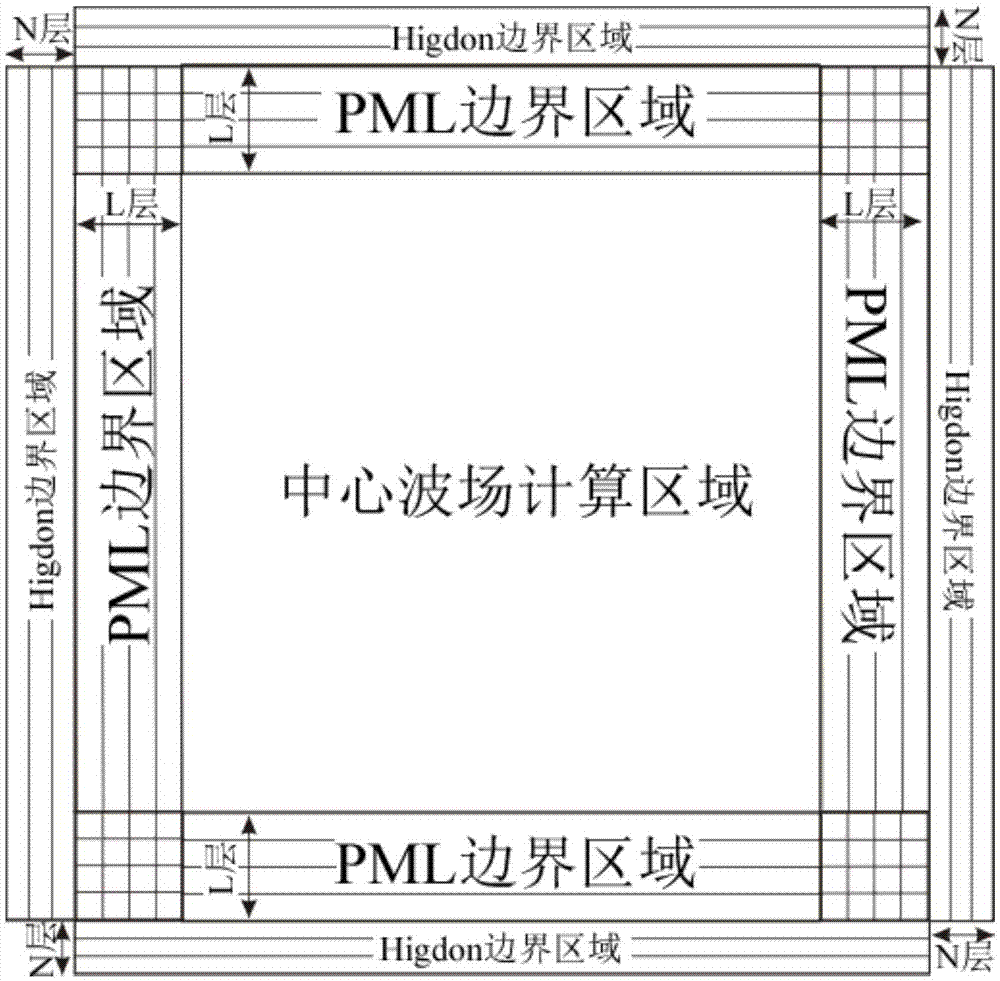

Combined absorbing boundary condition applied to sound wave finite difference numerical simulation

ActiveCN105447225AHigh precisionReduce memory consumptionDesign optimisation/simulationSpecial data processing applicationsReflexPerfectly matched layer

The invention discloses a combined absorbing boundary condition applied to sound wave finite difference numerical simulation, and belongs to the field of seismic exploration numerical simulation. The combined absorbing boundary condition applied to the sound wave finite difference numerical simulation specifically comprises the following steps of: when sound wave equation numerical simulation is performed based on a 2N-order (N>0) accuracy staggered-mesh finite difference scheme, at first, setting L (L>N) perfectly matched layers (PML) at an artificial truncated boundary, and absorbing boundary reflected waves from a central wave field by using a PML boundary condition; and then, for N layers of boundaries outside the PML, by using an Higdon three-order absorbing boundary condition, absorbing outer boundary reflexes of the PML. According to the method provided by the present invention, by fully utilizing the advantages of both the PML boundary condition and the Higdon three-order absorbing boundary condition are fully utilized, the boundary reflexes of inner layers and outer layers of artificial boundaries can be effectively absorbed, thereby achieving high-accuracy finite difference numerical simulation.

Owner:OCEAN UNIV OF CHINA

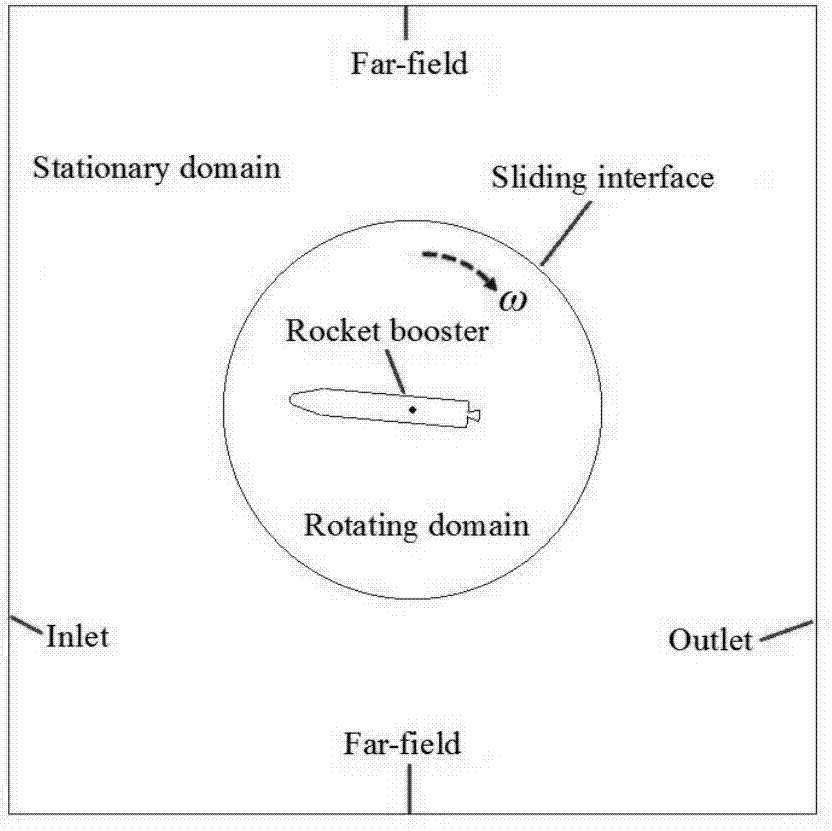

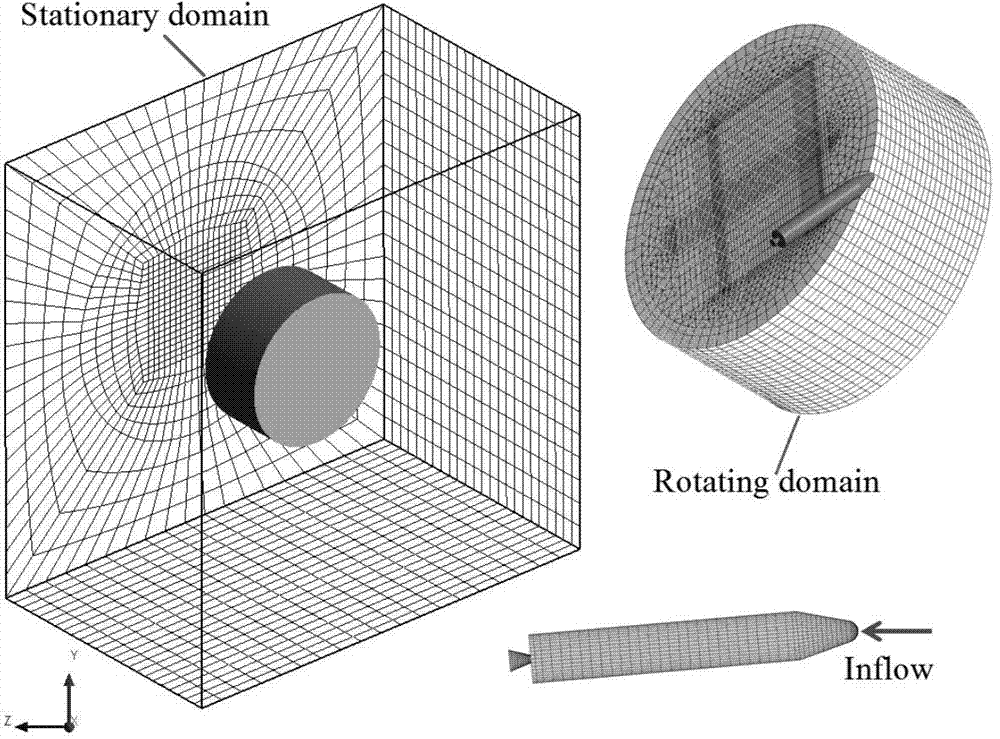

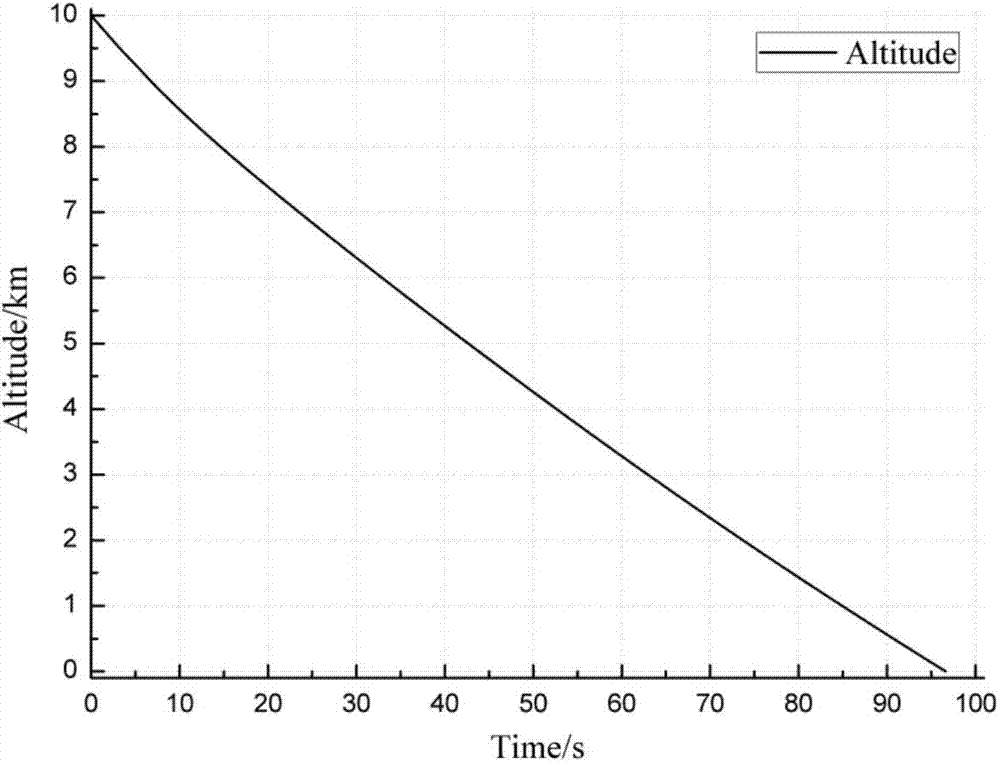

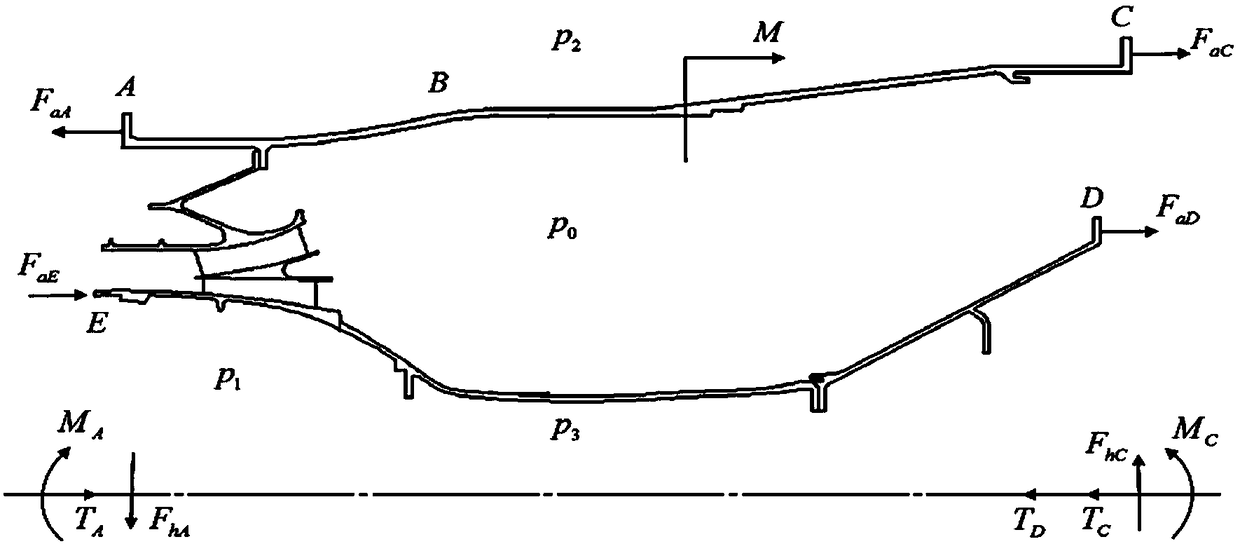

Booster reentry motion analysis method based on dynamic boundary condition

The invention provides an analysis method for predicting pneumatic load and movement rules of a reentry process of a booster. According to the method, a three-dimensional unsteady flow field of the reentry process of the booster is carried out, on the basis of a multiple reference coordinate system principle and a sliding mesh technique, a dynamic boundary condition is combined, and analysis of the reentry motion of the booster is carried out. According to the Newton's laws of motion and a theorem of moment of momentum, and user programs used for calculating height, speed, pitch angle speed and other parameters of the reentry process of the booster are written. The user programs can control rotation of a rotation field to achieve pitching motions of the booster, and the physical environment in the reentry process of the booster is simulated through changes of inlet, outlet and far field boundary condition parameters of a static field. In the process that time advance is used for solving the unsteady flow field, a solver calls the user programs in real time, real-time updating of boundary conditions and the rotation speed of the rotation field is achieved, calculation is never stopped until the booster arrives at the ground, and accordingly the transient pneumatic load and the motion parameters of the booster are obtained.

Owner:BEIHANG UNIV

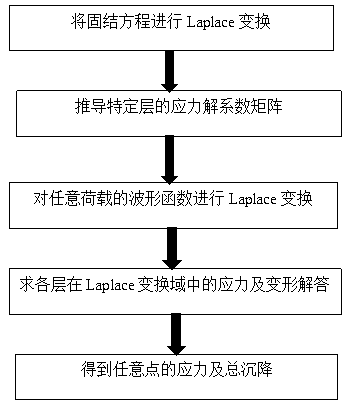

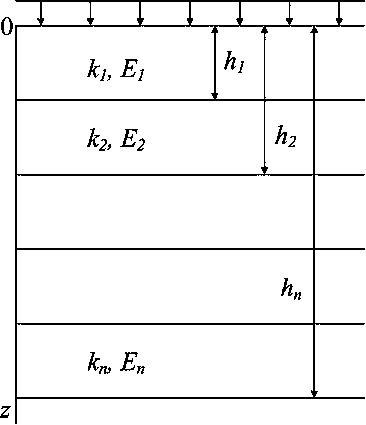

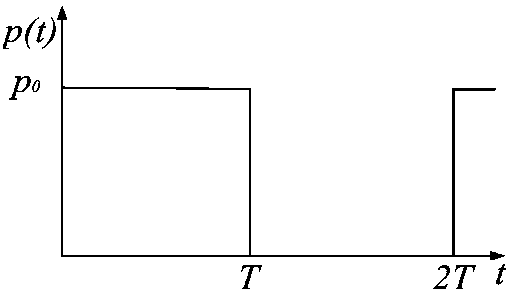

Settlement calculation method of multilayer foundation under any load effect

The invention provides a settlement calculation method of a multilayer foundation under any load effect. The method includes the steps that 1, a consolidation equation is subjected to Laplace transformation, and an initial boundary value condition and an interlayer continuity condition between multiple layers of the foundation are subjected to Laplace transformation; 2, according to a formula obtained after transformation in the first step, a stress solution coefficient matrix of a specific layer is deduced; 3, a waveform function of any load is subjected to Laplace transformation to serve asa boundary condition in a transformation domain; 4, according to the stress solution coefficient matrix and the boundary condition, a matrix transfer method is adopted, and stress and deformation solutions of all the layers in the Laplace transformation domain are obtained; and 5, the stress and the total settlement of any point can be obtained through a Laplace inverse transformation method. Quantitative calculation and predictive analysis of the settlement rule of the layered foundation under any load effect are achieved, and a scientific and effective basis is provided for design and construction of the foundation under the variable-load effect in engineering.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Simulation method, simulation program, and semiconductor device manufacturing method each employing boundary conditions

InactiveUS7162400B2Analogue computers for electric apparatusSemiconductor/solid-state device manufacturingParallel computingCauchy boundary condition

An aspect of the present invention provides a method of carrying out a simulation with simulation data, including, determining whether or not the simulation data includes boundary conditions set for a boundary of a calculation area set for the simulation, computing the influence of the boundary conditions on the inside of the calculation area if the simulation data includes the boundary conditions, displaying the influence of the boundary conditions on the inside of the calculation area, prompting to enter an instruction whether or not the boundary conditions are changed, and if an instruction to make no change in the boundary conditions is entered, carrying out the simulation with the simulation data.

Owner:KK TOSHIBA

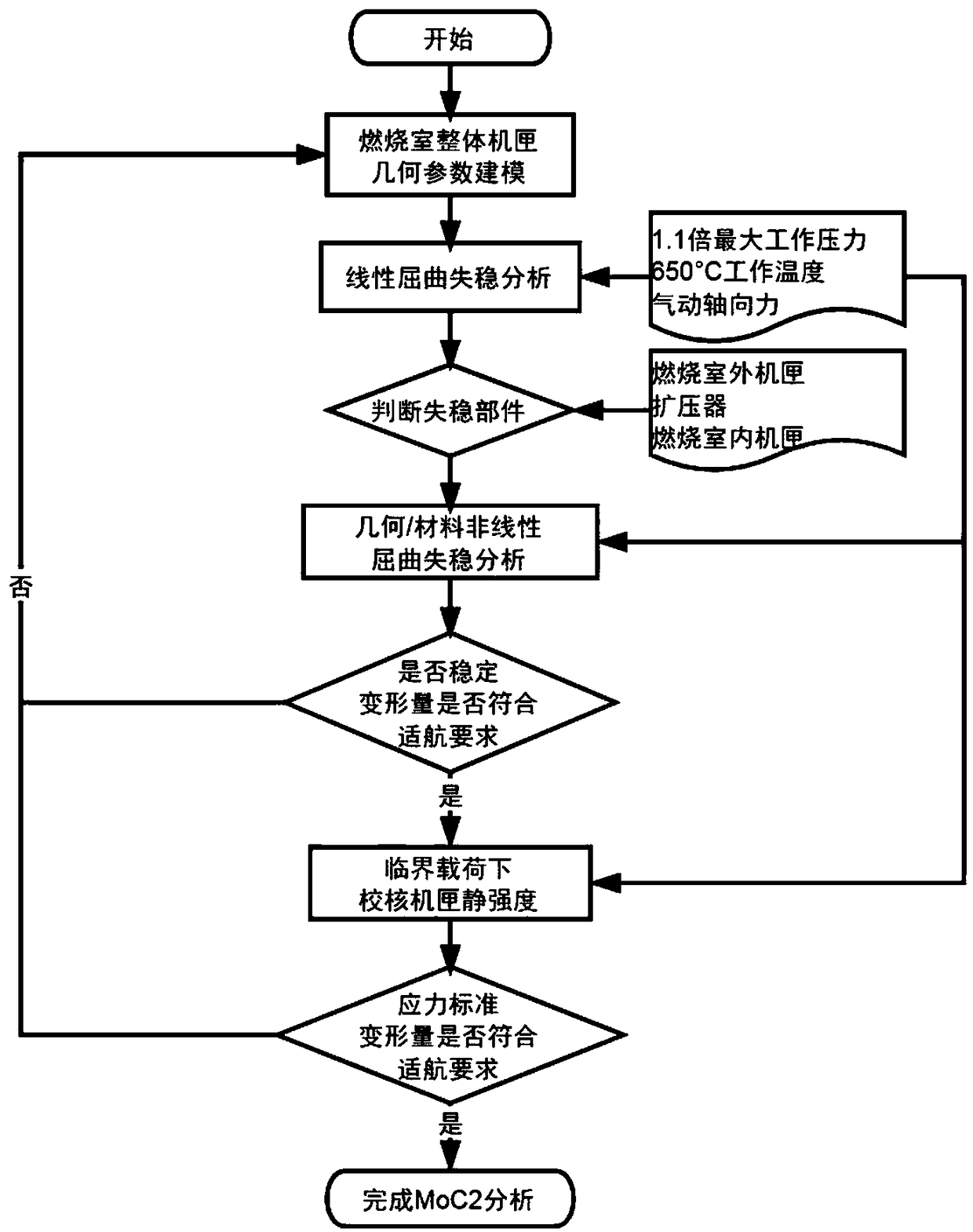

Airworthiness compliance verification method for combustion chamber casing

ActiveCN108897959AGeometric CADDesign optimisation/simulationStatic timing analysisCombustion chamber

The invention discloses an airworthiness compliance verification method for a combustion chamber casing. The method comprises the steps of (1) determining a load boundary condition of the combustion chamber casing according to clauses and requirements of CCAR 33.64, and determining a displacement boundary condition according to a constraint situation under an actual working condition; (2) conducting an eigenvalue buckling analysis on the combustion chamber casing, and obtaining eigenvalues and eigenvalue buckling modes under different orders; (3) selecting a first-order buckling instability portion of the casing as analysis focus, and performing a geometrical and material double nonlinear buckling analysis under a condition (1); (4) calculating a stability safety factor as the condition for determining the stability of the casing; (5) using a nonlinear buckling critical load obtained in (3) through analysis as an internal and external gas pressure difference, loading the boundary condition in (1) for a static strength analysis, and determining the compliance of the combustion chamber casing with the airworthiness clauses. The method simultaneously considers the stability and staticstrength of the combustion chamber casing, proposes a targeted verification analysis method, and indicates the airworthiness compliance of the combustion chamber casing.

Owner:BEIHANG UNIV

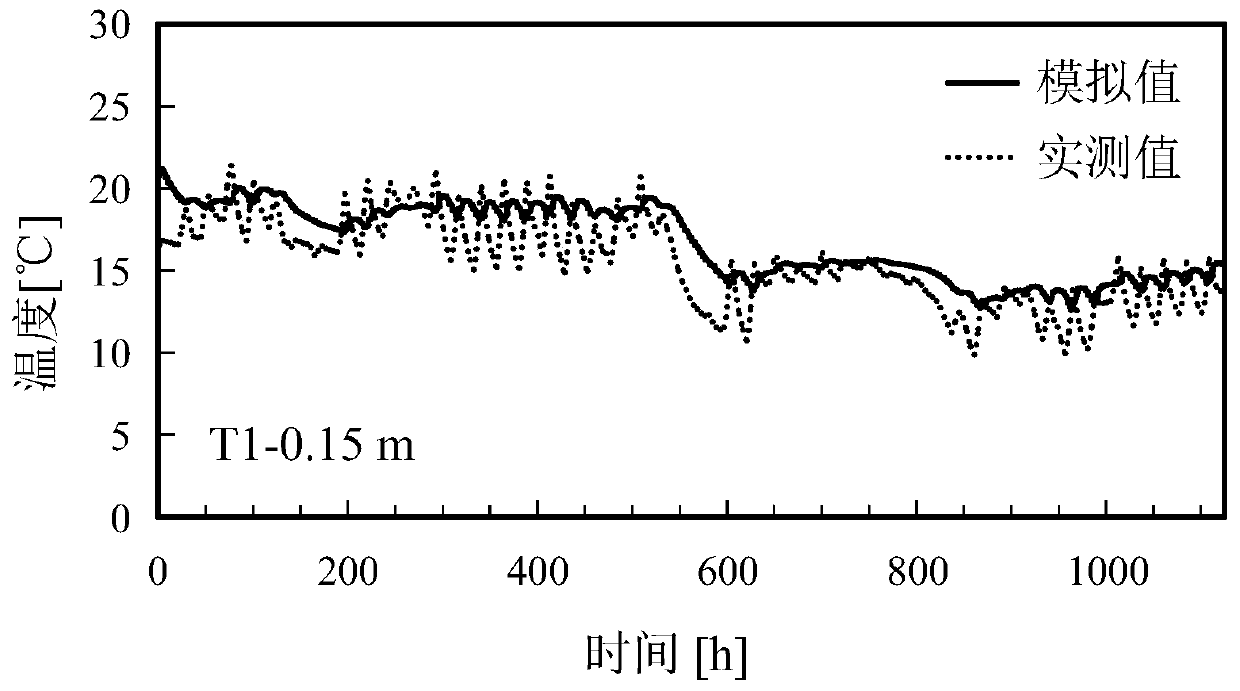

Reservoir area beach hydrothermal migration model construction method based on Ren model

InactiveCN110598287AFit closelyStrong temperature fluctuationsSpecial data processing applicationsGeomorphologyRichards equation

The invention discloses a reservoir area beach hydrothermal migration model construction method based on a Ren model, and the method comprises the steps: firstly constructing a reservoir area beach hydrothermal migration mathematic model based on a Richards equation and a thermal convection-diffusion equation, and describing the relation between a temperature field and a seepage field; setting boundary conditions for the reservoir area beach hydrothermal migration model, wherein the boundary conditions comprise boundary conditions of a seepage field and boundary conditions of a temperature field; and finally, solving the reservoir area beach hydrothermal migration model, and describing the relationship among the equivalent heat conductivity coefficient of the soil body, the water content and each physical parameter of the soil body by adopting a Ren model in the solving process, so as to obtain the space-time change characteristics of the temperature field in the reservoir area beach under the change condition. The problem that in the prior art, the influence mechanism of reservoir area beach hydrothermal migration under the changing condition cannot be accurately simulated due tothe factors that model parameters are difficult to determine, errors are large and the like is solved.

Owner:XIAN UNIV OF TECH

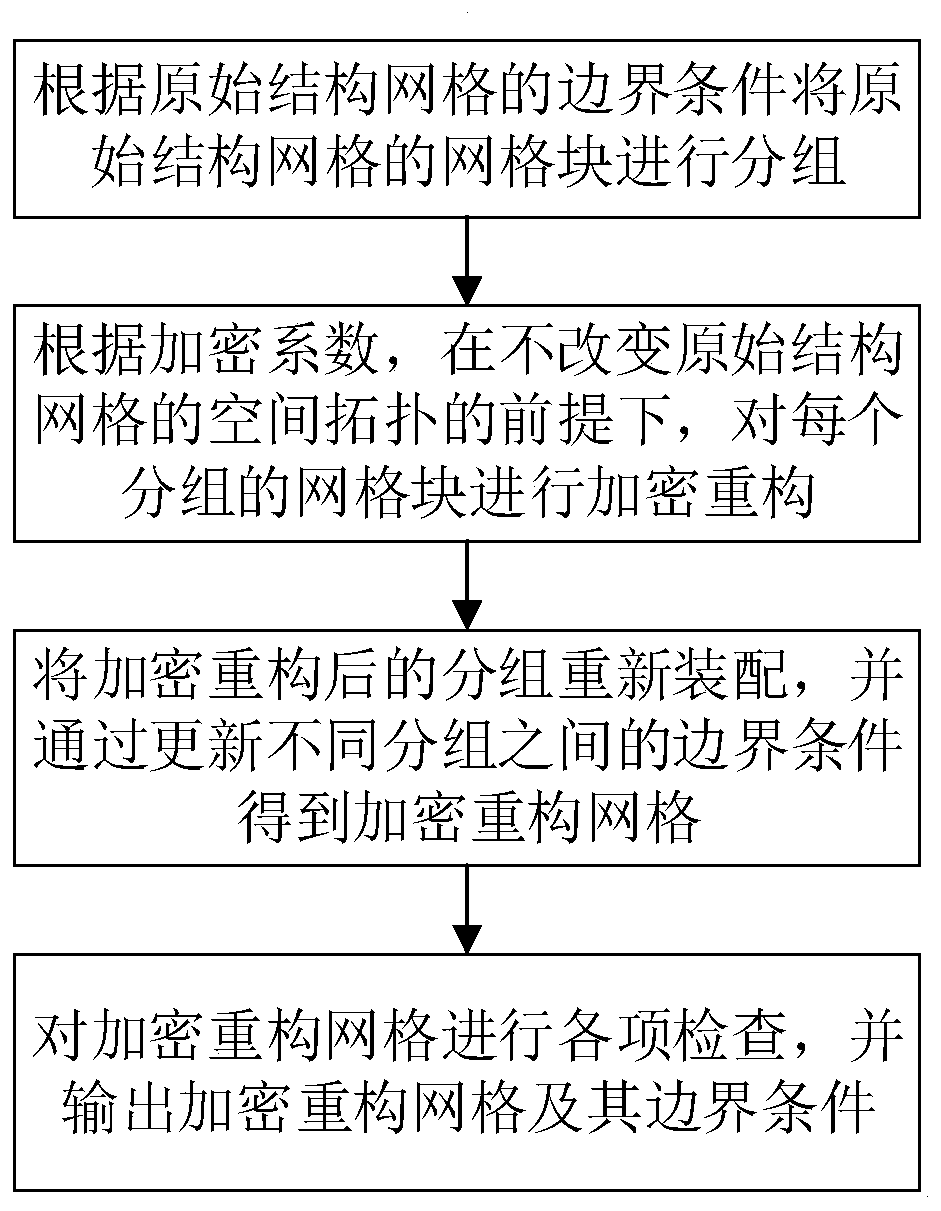

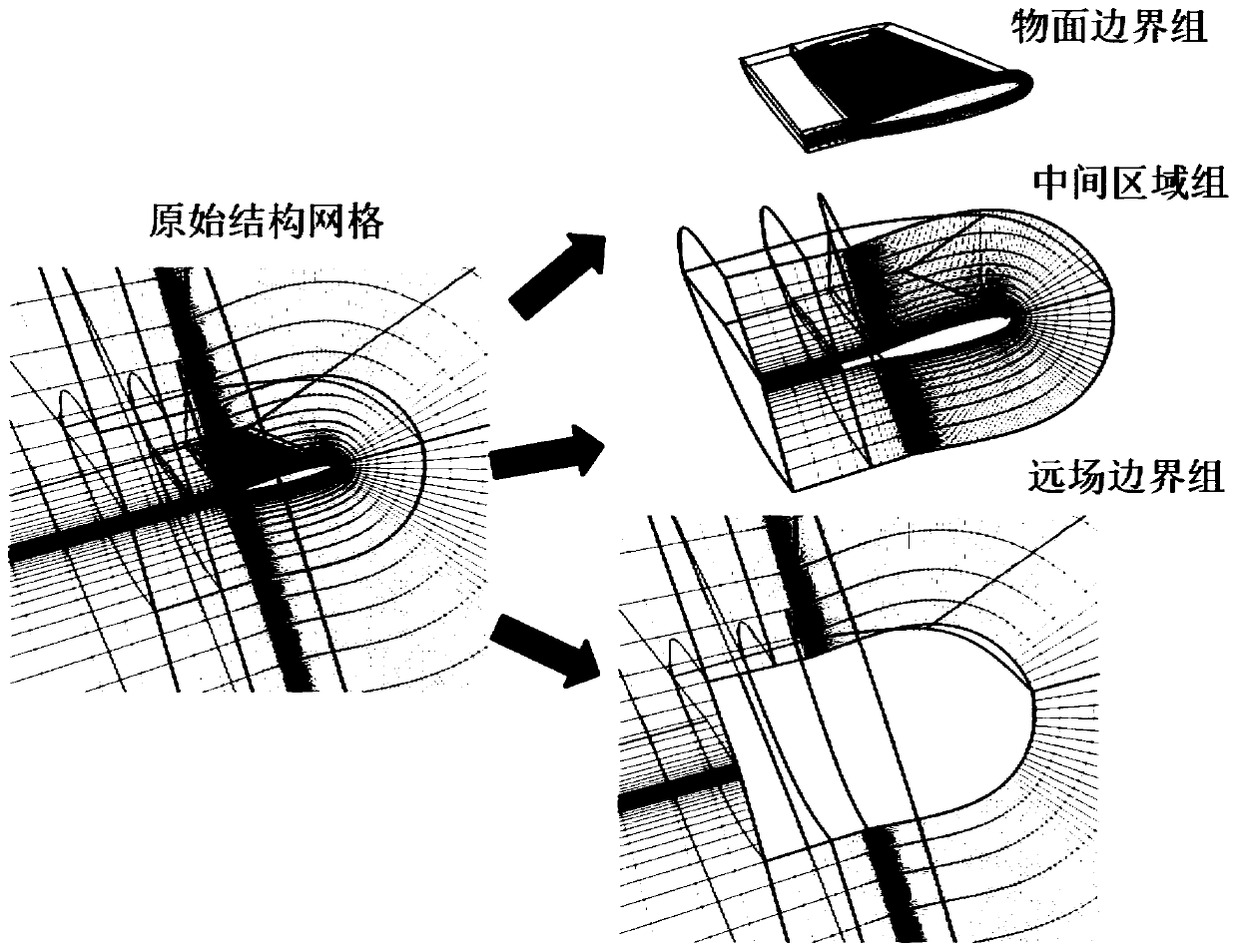

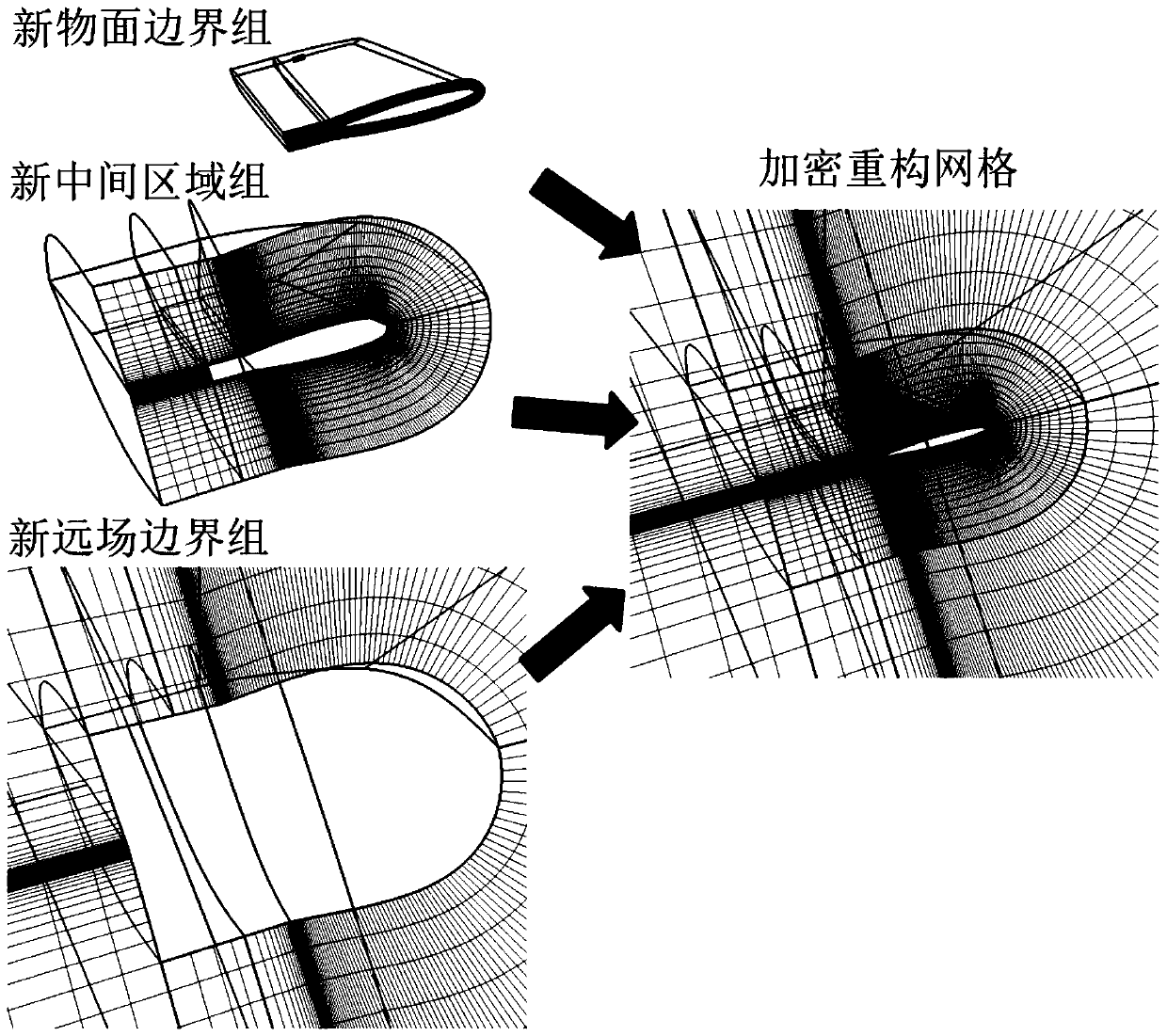

Automatic partitioning and encryption method for structural grid

ActiveCN109783965AImplement automatic block encryptionNo human intervention requiredSpecial data processing applicationsComputer hardwareCauchy boundary condition

The invention discloses an automatic partitioning and encryption method for a structural grid. The method comprises the following steps: step 1, grouping grid blocks of an original structural grid according to boundary conditions of the original structural grid; step 2, according to the encryption coefficient, on the premise that the space topology of the original structure grid is not changed, performing encryption reconstruction on the grid block of each group; step 3, reassembling the encrypted and reconstructed groups, and updating boundary conditions among different groups to obtain an encrypted and reconstructed grid; and step 4, checking each item of the encrypted reconstructed grid, and outputting the encrypted reconstructed grid and boundary conditions thereof. According to the boundary conditions of the original structural grid, grouping is automatically carried out, encryption reconstruction is automatically carried out, and the encryption reconstruction grid and the boundary conditions of the encryption reconstruction grid are automatically output, so that automatic block encryption of the structural grid is realized, manual intervention is completely not needed, high efficiency and stability are realized, and errors possibly caused by manual operation are completely eradicated.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

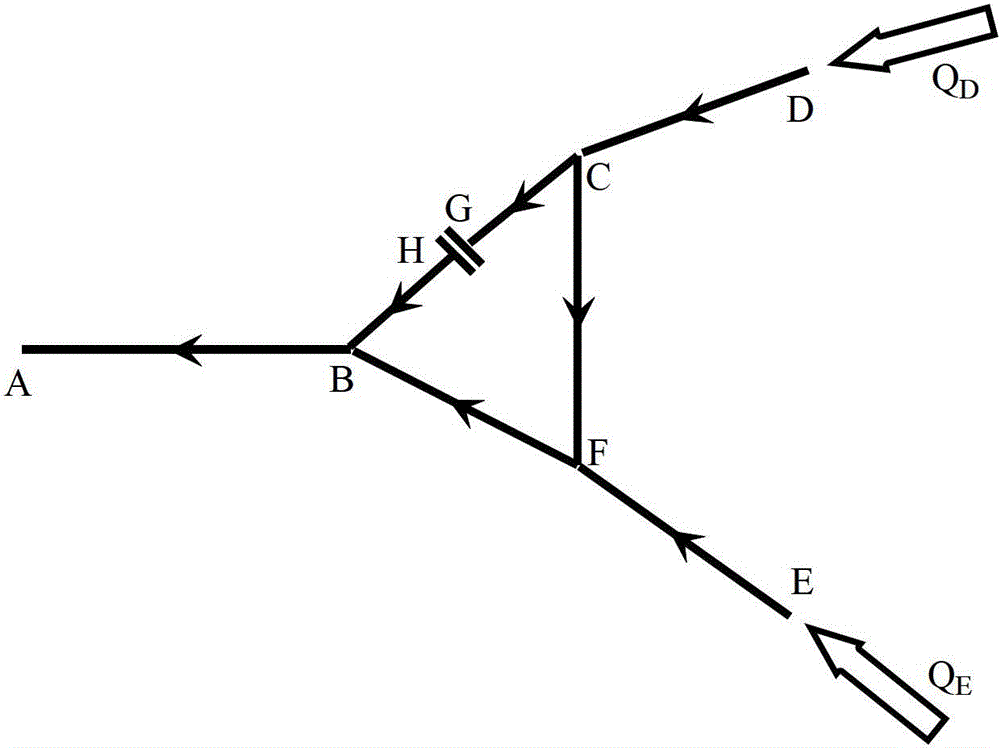

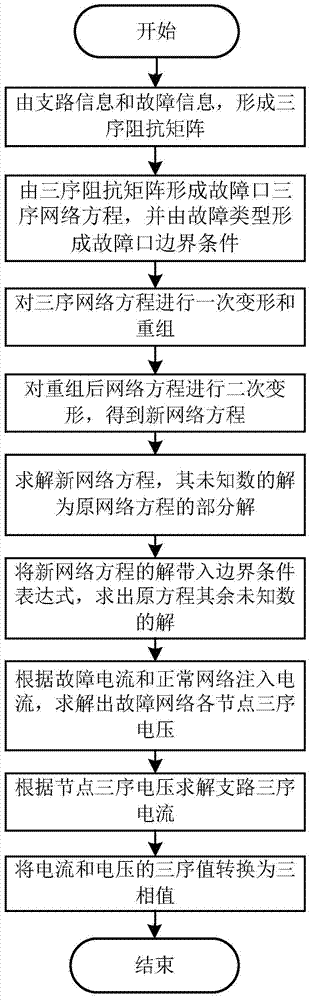

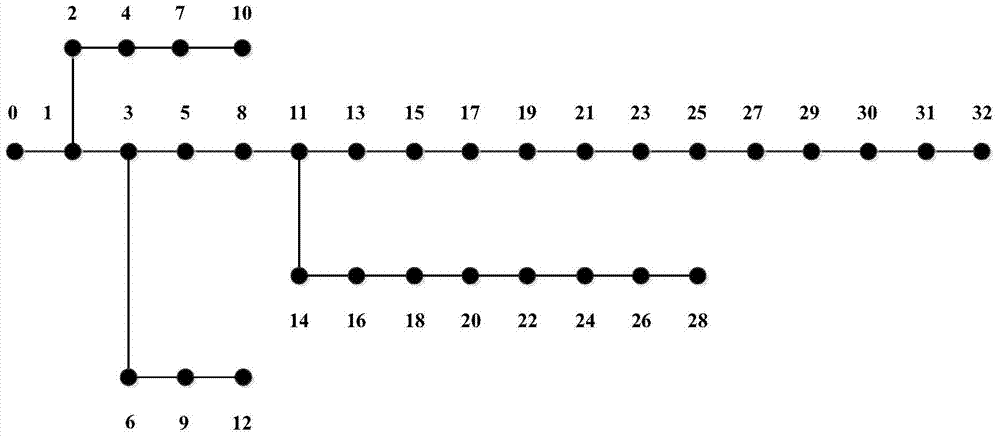

Boundary condition classification based multiple fault calculation method

InactiveCN104504269AAvoid combiningEasy to implementSpecial data processing applicationsNetwork equationElectric power system

The invention discloses a boundary condition classification based multiple fault calculation method, and relates to the technical field of power system fault analysis and calculation. The calculation method comprises the following steps: transforming and recombining original network equations; classifying boundary condition expressions to generalize five transformation rules; adopting the dynamic of the transformation rules to transform the network equations again in order to realize the united solution of complex faults under the condition of fault combination in different multiple numbers and different types. The calculation method is based on the idea of boundary condition classification, carries out classification on boundary conditions of multiple faults in arbitrary multiple numbers, summarizes the transformation rule of each classification of boundary conditions, carries out united transformation on various fault port network equations, solves the combination of various fault boundary conditions and the network equations, realizes unification of the solution process of the complex faults under the condition of fault combination in different multiple numbers and different types, and is easy for computer realization.

Owner:STATE GRID SHANDONG ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com