Simulation acquisition method for friction coefficient of friction plate

A technology of friction coefficient and acquisition method, applied in the field of brake friction coefficient measurement and tracked vehicle transmission, can solve the problems of low precision and high labor intensity, and achieve the effect of high precision, low labor and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

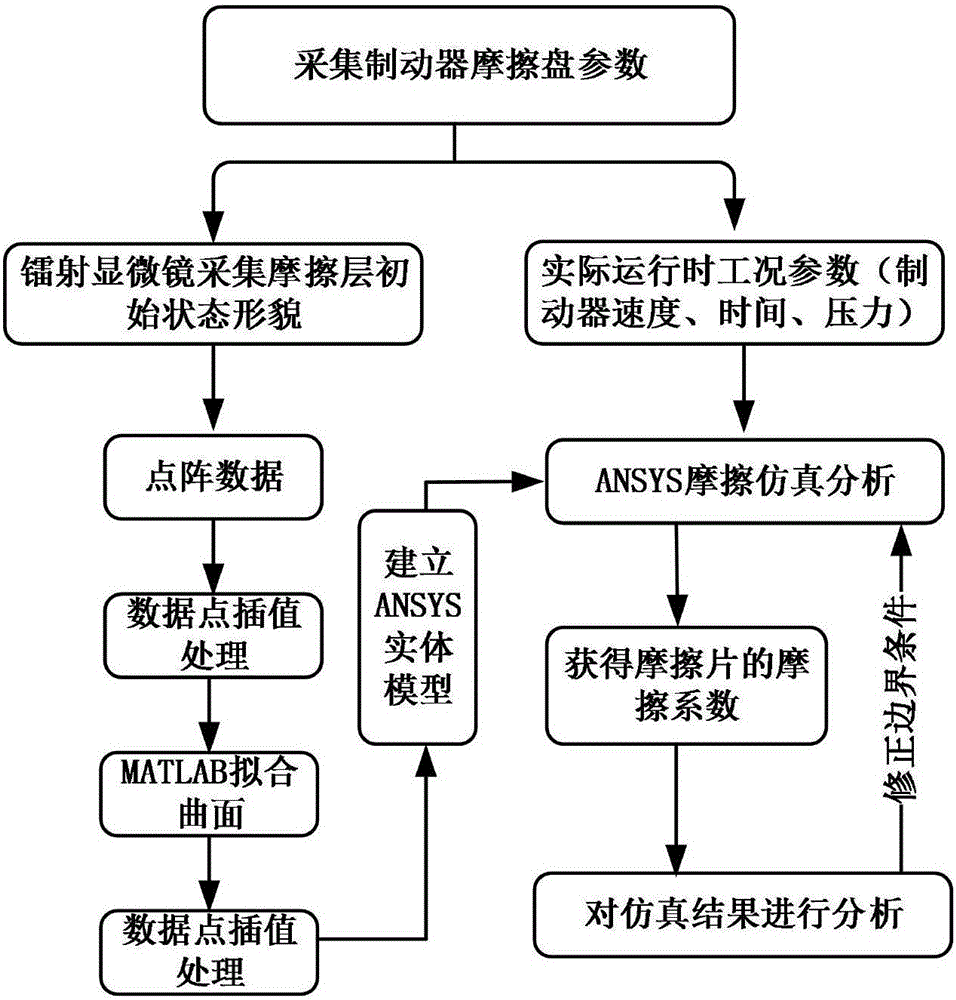

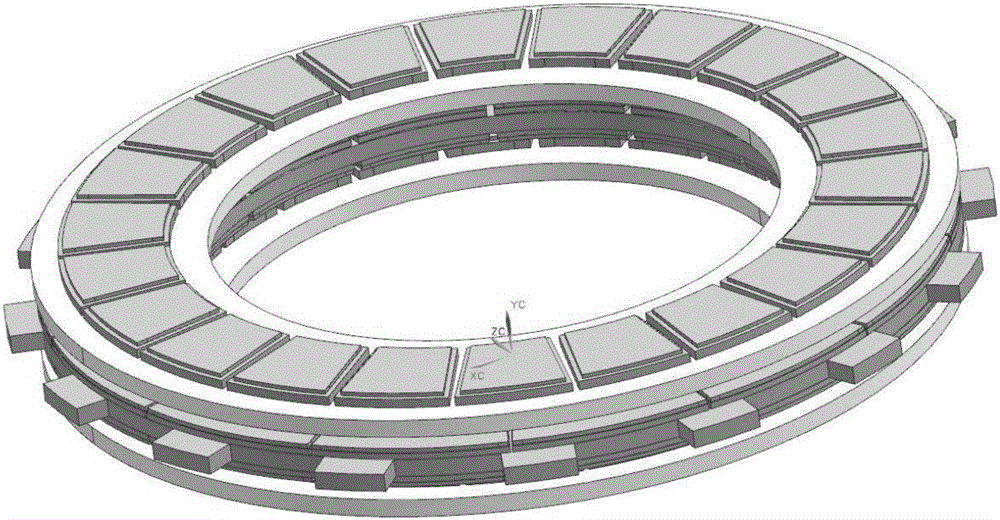

[0019] Such as figure 1 As shown, a simulation acquisition method for the friction coefficient of the friction plate, the implementation steps are as follows:

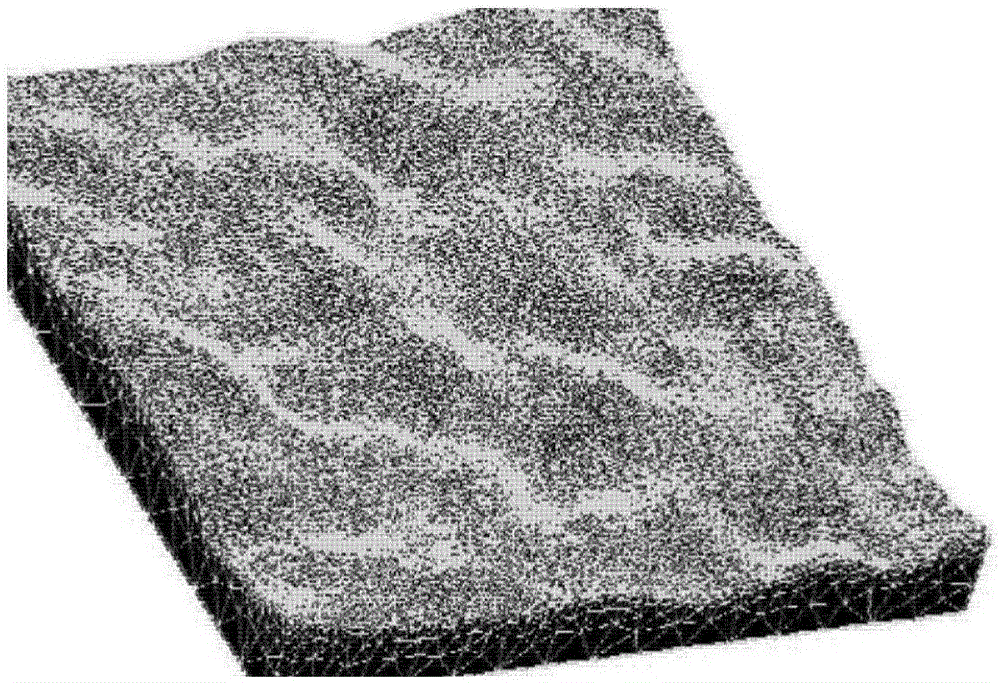

[0020] Step 1. First, wipe the surface to be analyzed with 95% alcohol to remove oil stains on the friction surface, so as to avoid the accuracy of data collection and reduce error points. Place the friction sheet under a laser microscope, select a 3mm×3mm area as the research object, use the laser microscope to perform surface imaging processing on the sample to be studied, and obtain the micro-morphological characteristics of the friction sheet through a computer acquisition system, as shown in figure 2 shown;

[0021] Step 2. Set the sampling lattice density on the computer. The lattice density will affect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com