Formwork support system derivative design method

A design method and a derivative technology, applied in the field of design and optimization of the formwork support system, can solve the problems of waste of engineering materials, difficulty in ensuring the optimization space of the design plan, etc., and achieve the effect of saving engineering costs and improving calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

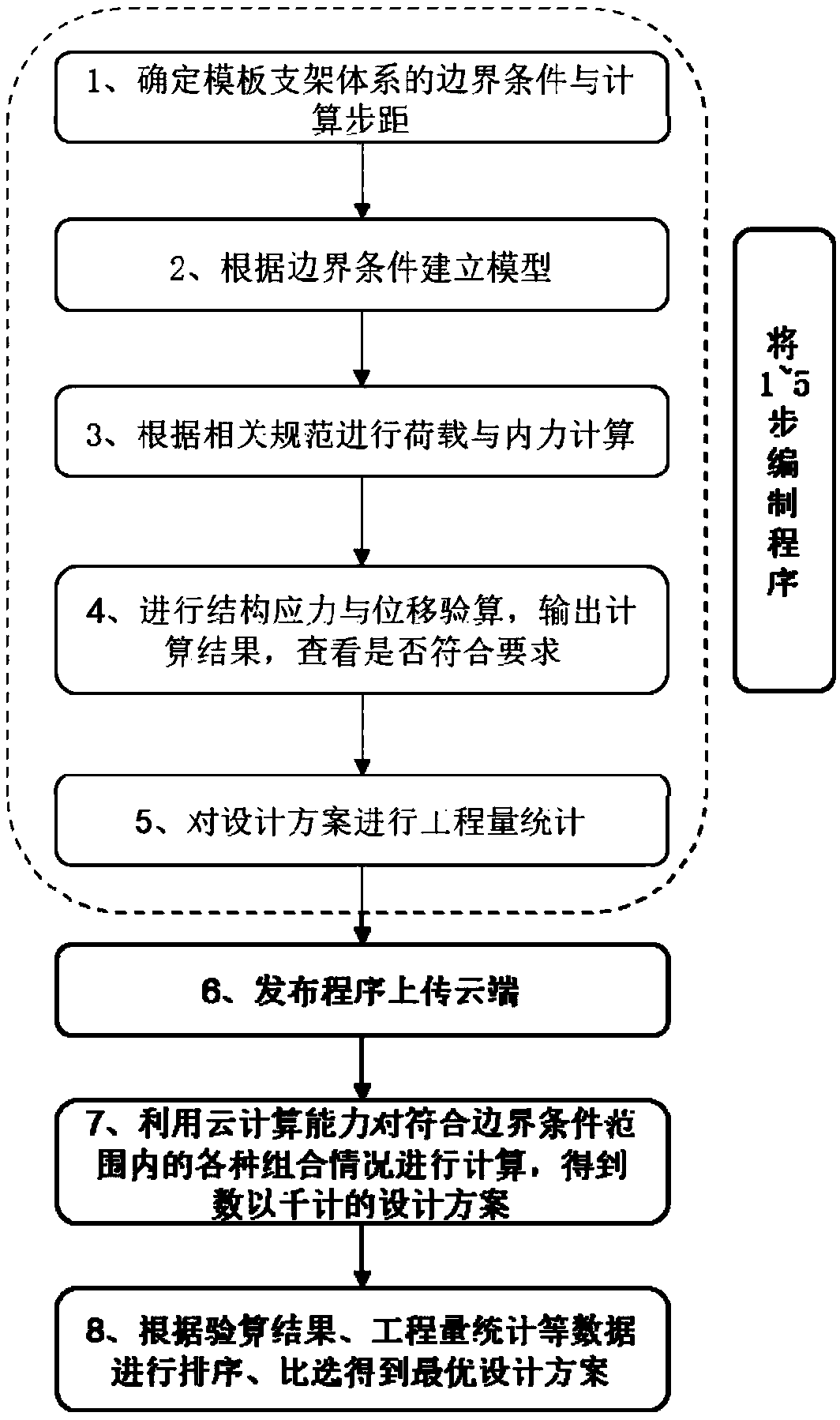

[0020] A generative design method for the formwork support system, which needs to parameterize all the geometric parameters of the components contained in the formwork support system according to the geometric dimensions of the formwork support system, the structural force, and the characteristics of the support system, and give the minimum boundary conditions Value, maximum value and change step distance, realizing the association between model establishment, structural calculation analysis and engineering quantity statistics. Compile the program and release it to the cloud. Within the scope of boundary conditions, calculation and analysis are performed according to the requirements of the variable step setting, thereby generating thousands of design schemes, and finally comparing and screening the calculation results to obtain the optimal solution. Contains the following implementation steps:

[0021] Step 1: Determine the boundary conditions and calculation steps of the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com