An in-plane thermoelectric device structure design method based on COMSOL software

A technology for thermoelectric device and structural design, applied in design optimization/simulation, instrumentation, calculation, etc., can solve problems such as multi-cost, long cycle, heavy workload, etc., and achieve the effect of reducing experimental cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

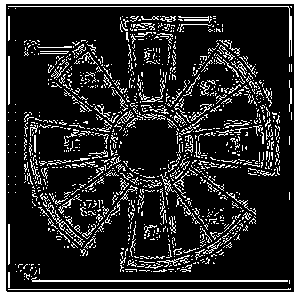

[0059] According to the single-stage thermoelectric device design method in the present invention, the temperature distribution of the annular series thermoelectric device under the optimum working current is simulated. Including the following steps:

[0060] (1) Select the physical field:

[0061] Enter the main interface of the software, select "Model Wizard", select "3D" in "Spatial Dimension", select "Thermoelectric Effect" under the sub-module of the solid heat transfer module of the physics field, and select "Steady State" in "Research" .

[0062] (2) Establish a geometric physical model:

[0063] Select "Working Plane" in the main geometry window to enter the 2D graphics construction interface. Use the two-dimensional drawing tool to draw concentric circles with radii of 3.5mm and 4.5mm respectively, set the fan angle to 78°, and use the "Difference" tool under "Boolean operation and segmentation" to subtract the 4.5mm circle from the 3.5mm circle , to obtain a part...

Embodiment 2

[0074] According to the single-stage thermoelectric device design method in the present invention, the temperature distribution of the ring thermoelectric device under the optimum working current is simulated. Including the following steps:

[0075] (1) Select the physical field:

[0076] Enter the main interface of the software, select "Model Wizard", select "3D" in "Spatial Dimension", select "Thermoelectric Effect" under the sub-module of the solid heat transfer module of the physics field, and select "Steady State" in "Research" .

[0077] (2) Establish a geometric physical model:

[0078] Select "Working Plane" in the main geometry window to enter the 2D graphics construction interface. Use the two-dimensional drawing tool to draw concentric circles with radii of 3.5mm and 4.5mm, and use the "Difference" tool under "Boolean Operations and Segmentation" to subtract the 3.5mm circle from the 4.5mm circle to get the first circular pattern . In the same way, the circle w...

Embodiment 3

[0089] According to the multi-stage thermoelectric device design method in the present invention, the temperature distribution of the two-stage annular thermoelectric device under the optimum working current is simulated. Including the following steps:

[0090] (1) Select the physical field:

[0091] Enter the main interface of the software, select "Model Wizard", select "3D" in "Spatial Dimension", select "Thermoelectric Effect" under the sub-module of the solid heat transfer module of the physics field, and select "Steady State" in "Research" .

[0092] (2) Establish a geometric physical model:

[0093] Select "Working Plane" in the main geometry window to enter the 2D graphics construction interface. Use the two-dimensional drawing tool to draw concentric circles with radii of 3.5mm and 4.5mm, and use the "Difference" tool under "Boolean Operations and Segmentation" to subtract the 3.5mm circle from the 4.5mm circle to get the first circular pattern . In the same way, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com