Discrete element method for simulating roadway surrounding rock fracture evolution

A fracture evolution, discrete element technology, applied in design optimization/simulation, CAD numerical modeling, testing material strength using applied stable tension/pressure, etc. Guiding on-site construction, deviation and other issues to achieve the effect of strong on-site guiding significance and real and reliable simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the following examples are only used to illustrate the present invention, and do not limit the present invention.

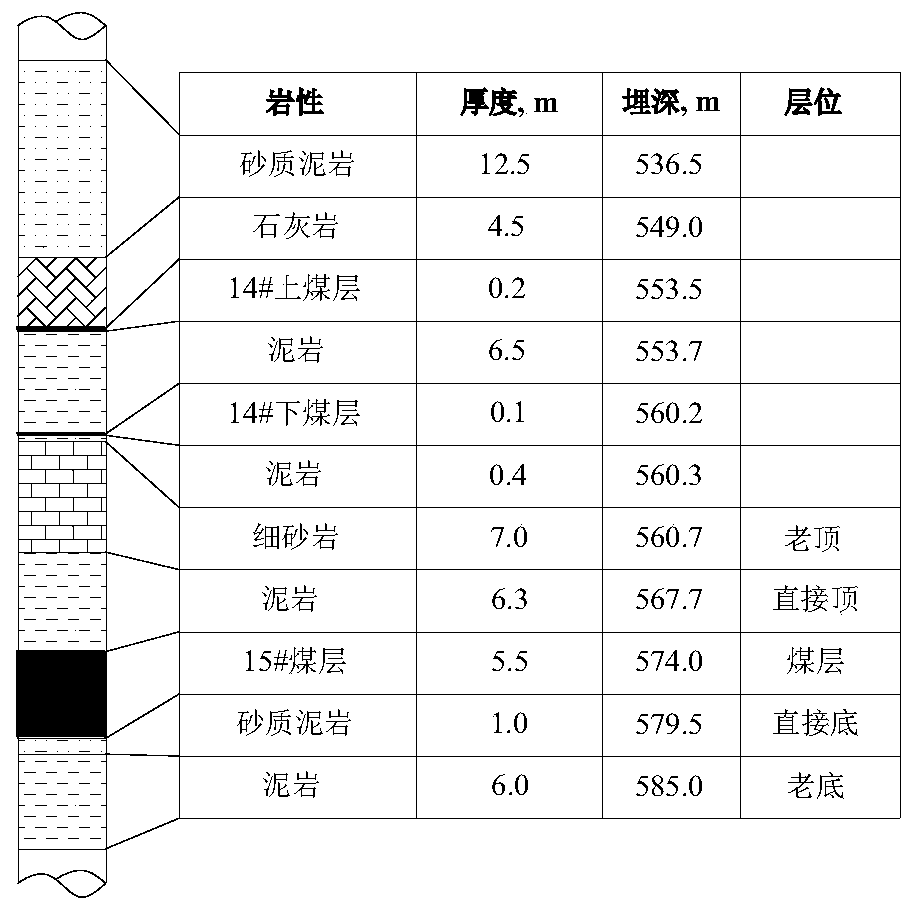

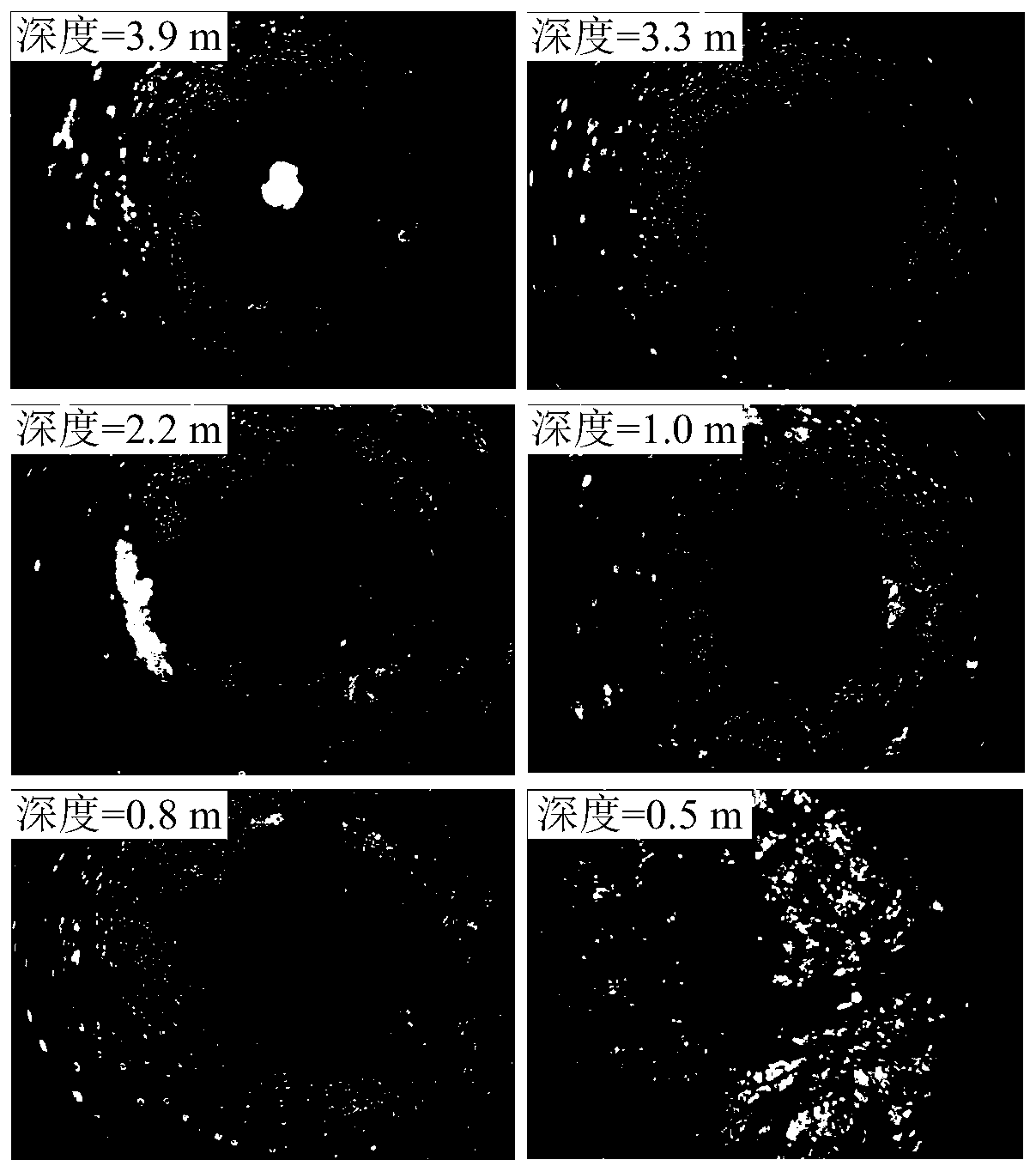

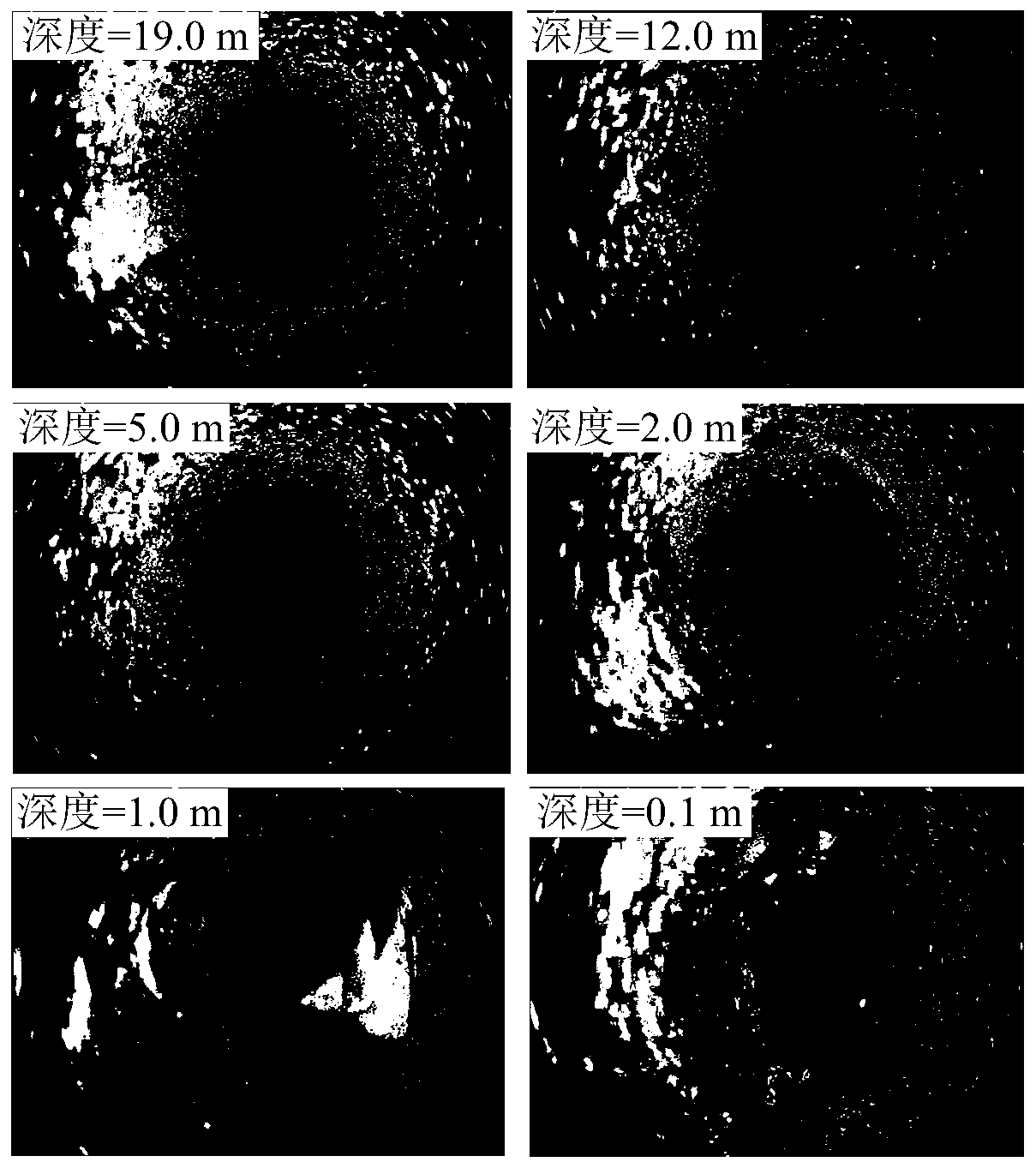

[0043] Example Taking the gob-side excavation of the 7m narrow coal pillar in the 15106 return airway of Sijiazhuang Mine of Yangmei Group as the engineering background, the average buried depth of the coal seam is 574m, the average thickness is 5.5m, and the joints and fissures are developed. The total length of the 15106 return airway is 1700m. The roadway is excavated along the roof of the coal seam, and the excavation section is rectangular width × height: 4.8m × 4.0m. The columnar diagram of the coal seam is as follows figure 1 shown. The method of the present invention is now used to correct the parameters of the numerical model for simulating deformation along the roadway. In this example, the discr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com