Device for simulating reasonable drainage speed in single-phase flow stage during vertical-well coalbed methane drainage

A speed simulation and single-phase flow technology, applied in the direction of measuring devices, mining fluids, earthwork drilling and production, etc., can solve the problems of scientific limitation, improve the drainage efficiency of coalbed methane vertical wells and its gas production, and achieve the goal of improving Drainage efficiency, strong pertinence and on-site guidance, and solve the effect of insufficient range and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

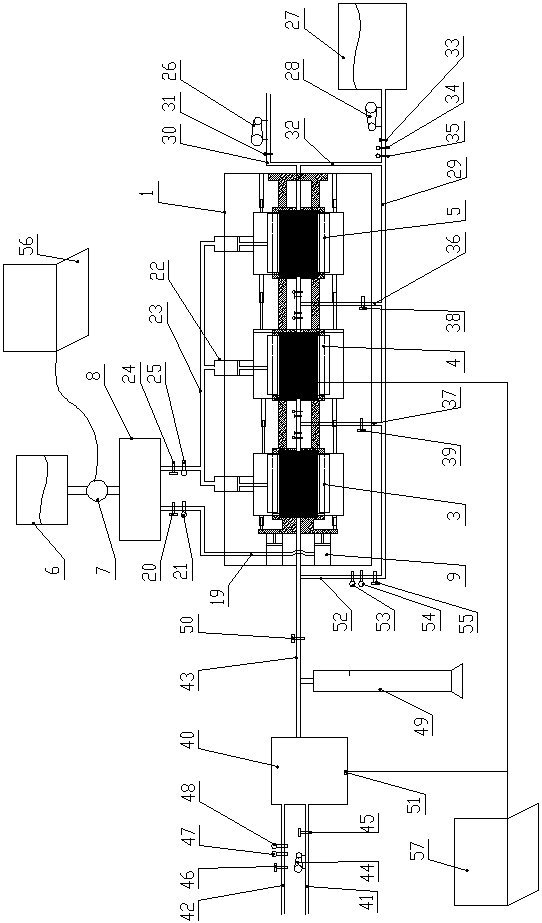

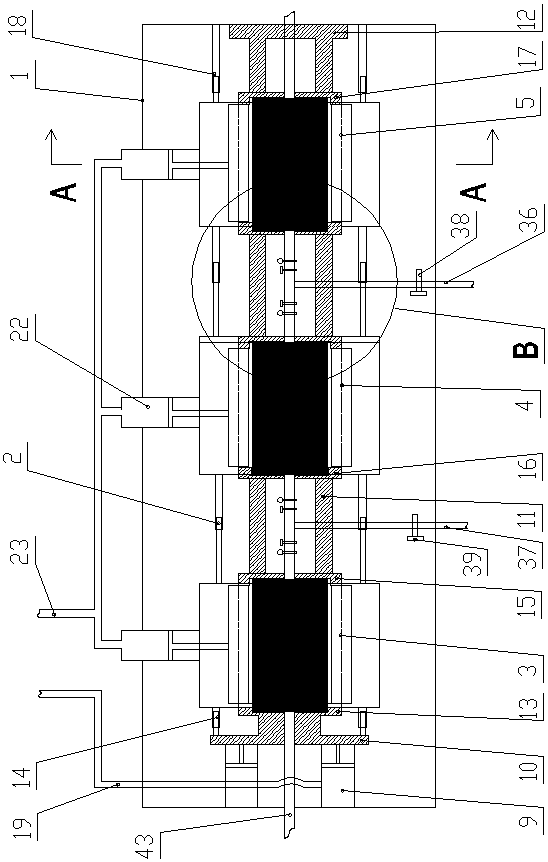

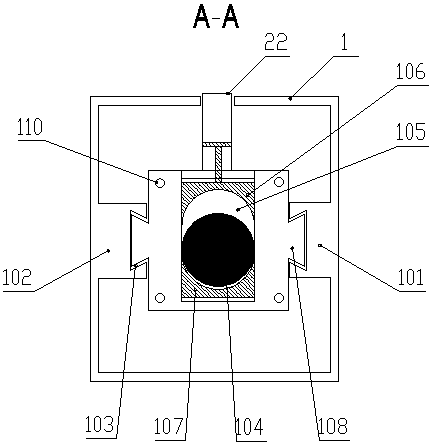

[0027] like Figure 1 to Figure 4 shown in figure 1 The left side of the present invention is the left direction of the present invention. The reasonable drainage speed simulation device of the coalbed methane vertical well single-phase flow stage of the present invention includes a coal sample clamping system and formation pressure simulation for providing the pressure of the coal sample in the axial and lateral directions. system, a liquid supply system for simulating the liquid state in the coal seam, a drainage control simulation system for simulating the pressure drop during the drainage process and testing the liquid production rate, and a fluid for simulating the pressure propagation of the fluid in the coal seam The pressure propagation simulation system and the information collection analysis and control system for collecting and analyzing data and controlling valves, the coal sample clamping system and the formation pressure simulation system, liquid supply system, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com