Patents

Literature

33 results about "Pressure propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

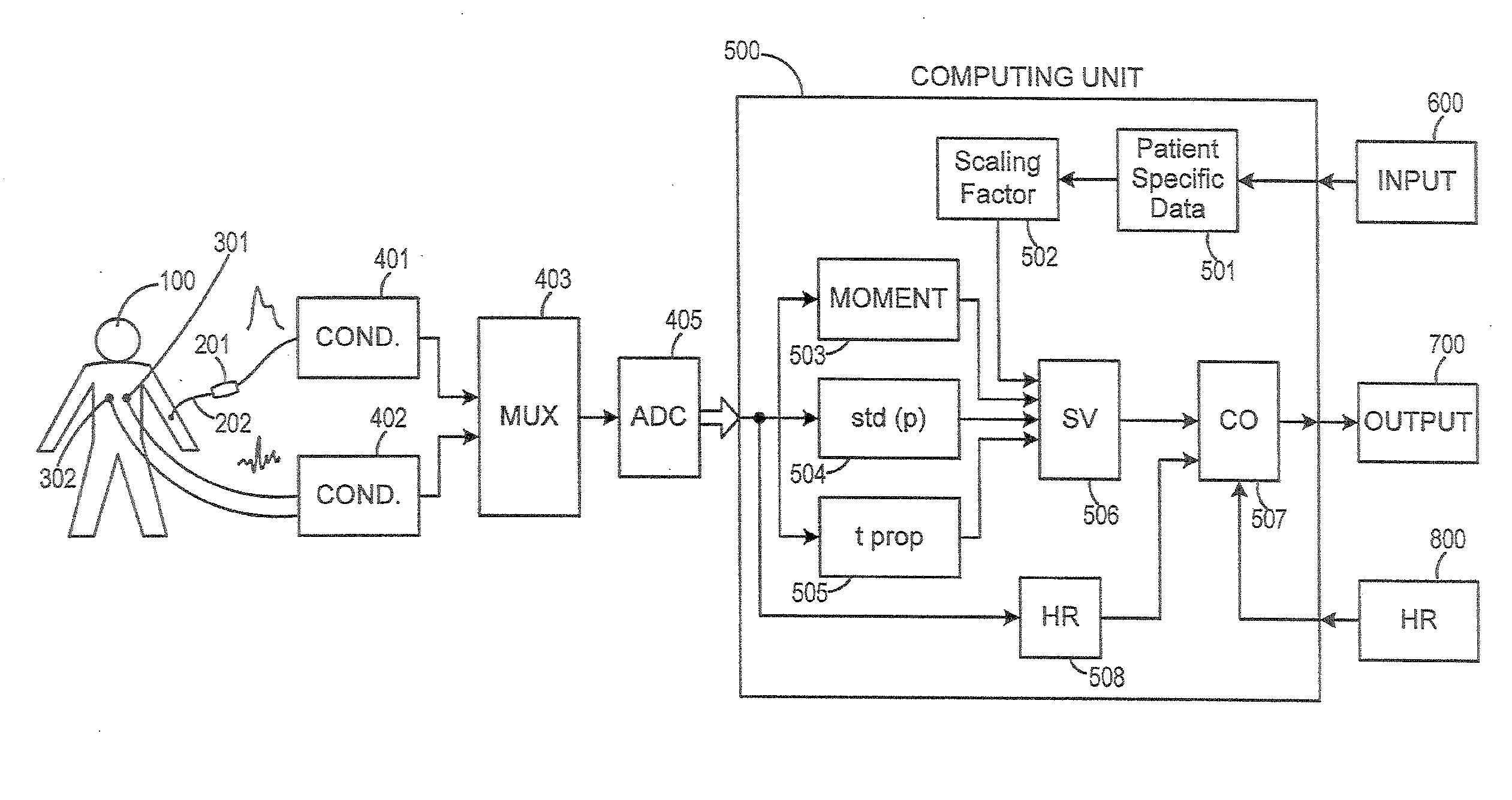

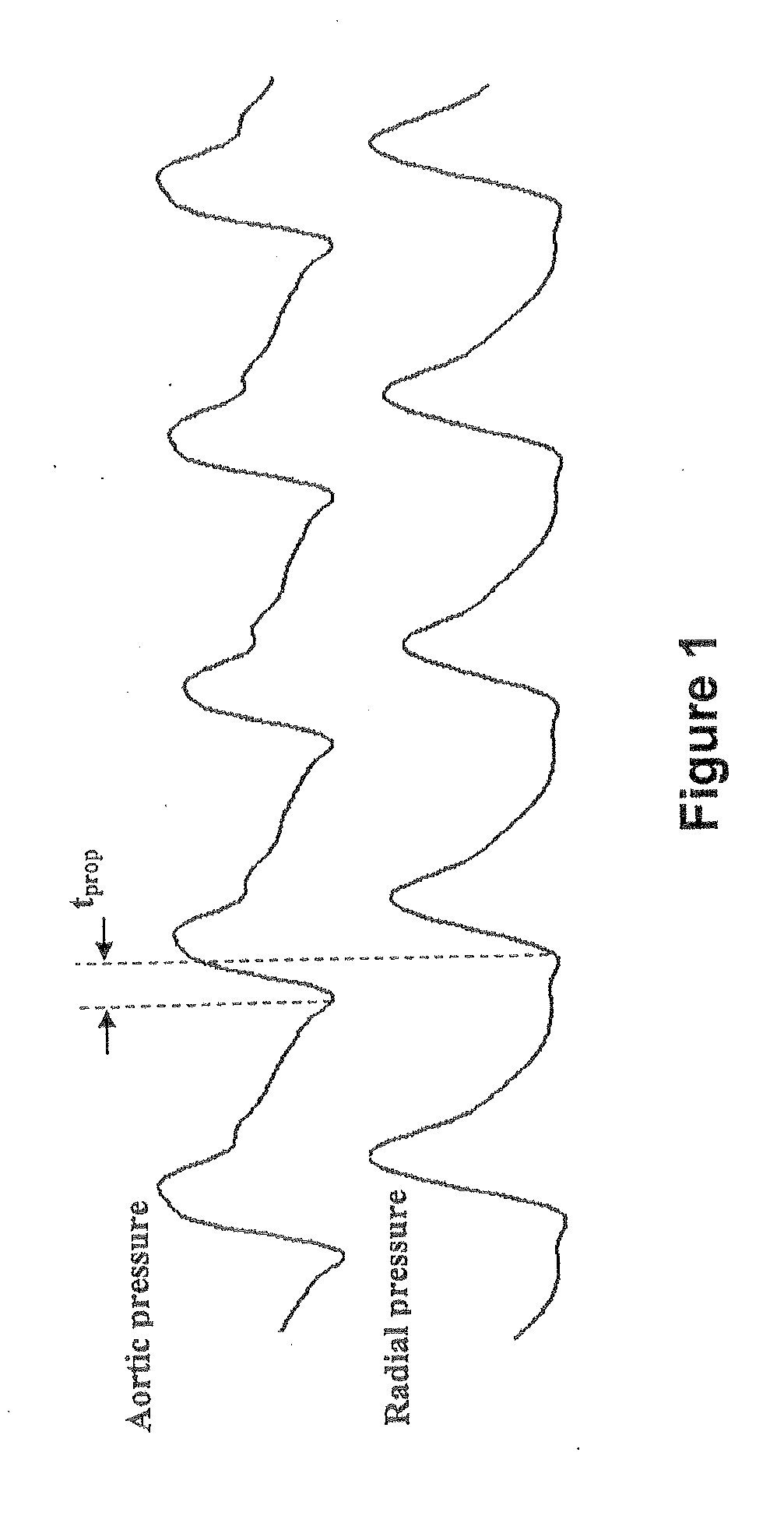

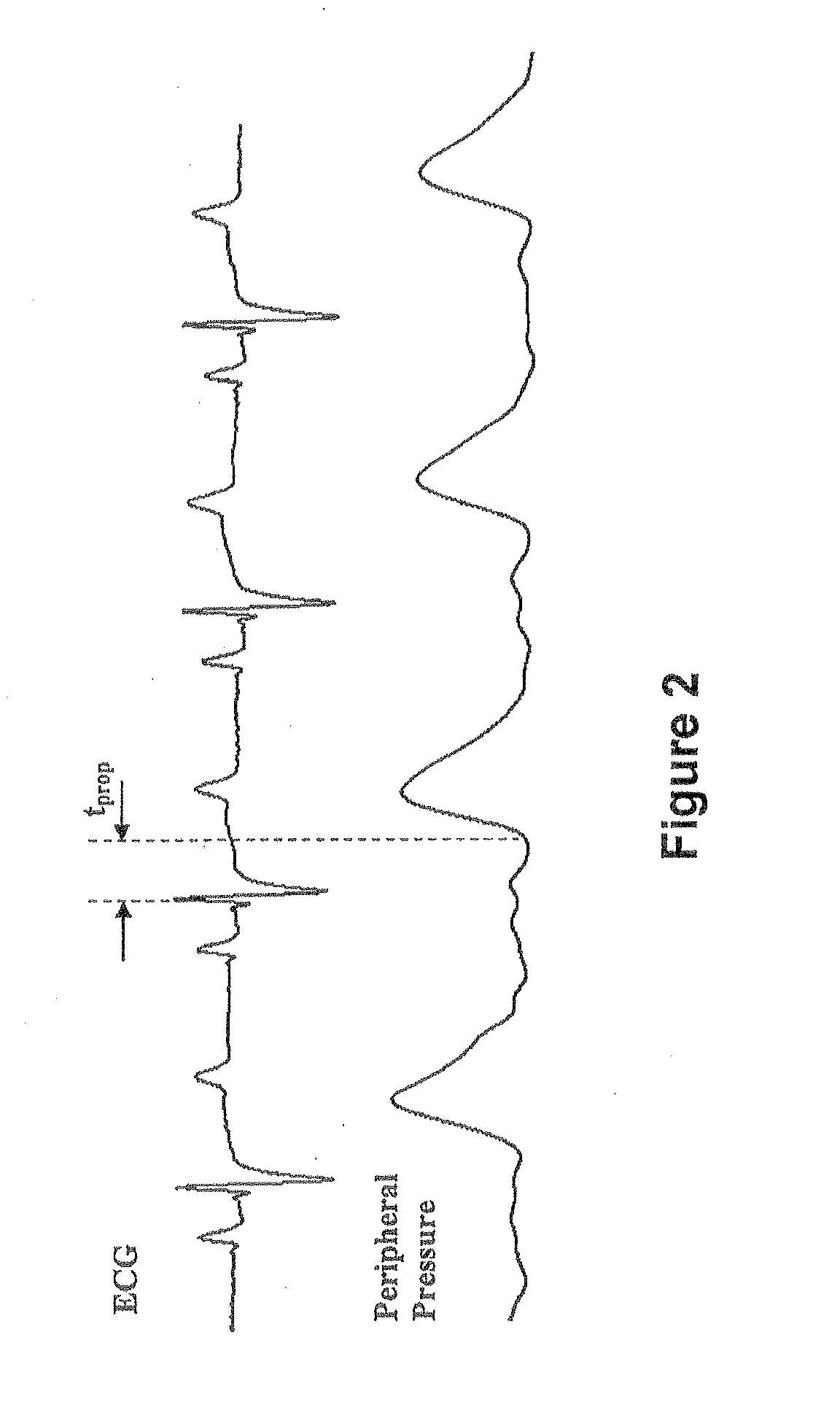

Method and Apparatus for Continuous Assessment of a Cardiovascular Parameter Using the Arterial Pulse Pressure Propagation Time and Waveform

InactiveUS20080015451A1ElectrocardiographyBlood flow measurement devicesCardiac cycleArterial pulse pressure

A method and apparatus for determining a cardiovascular parameter including receiving an input signal corresponding to an arterial blood pressure measurement over an interval that covers at least one cardiac cycle, determining a propagation time of the input signal, determining at least one statistical moment of the input signal, and determining an estimate of the cardiovascular parameter using the propagation time and the at least one statistical moment.

Owner:EDWARDS LIFESCIENCES CORP

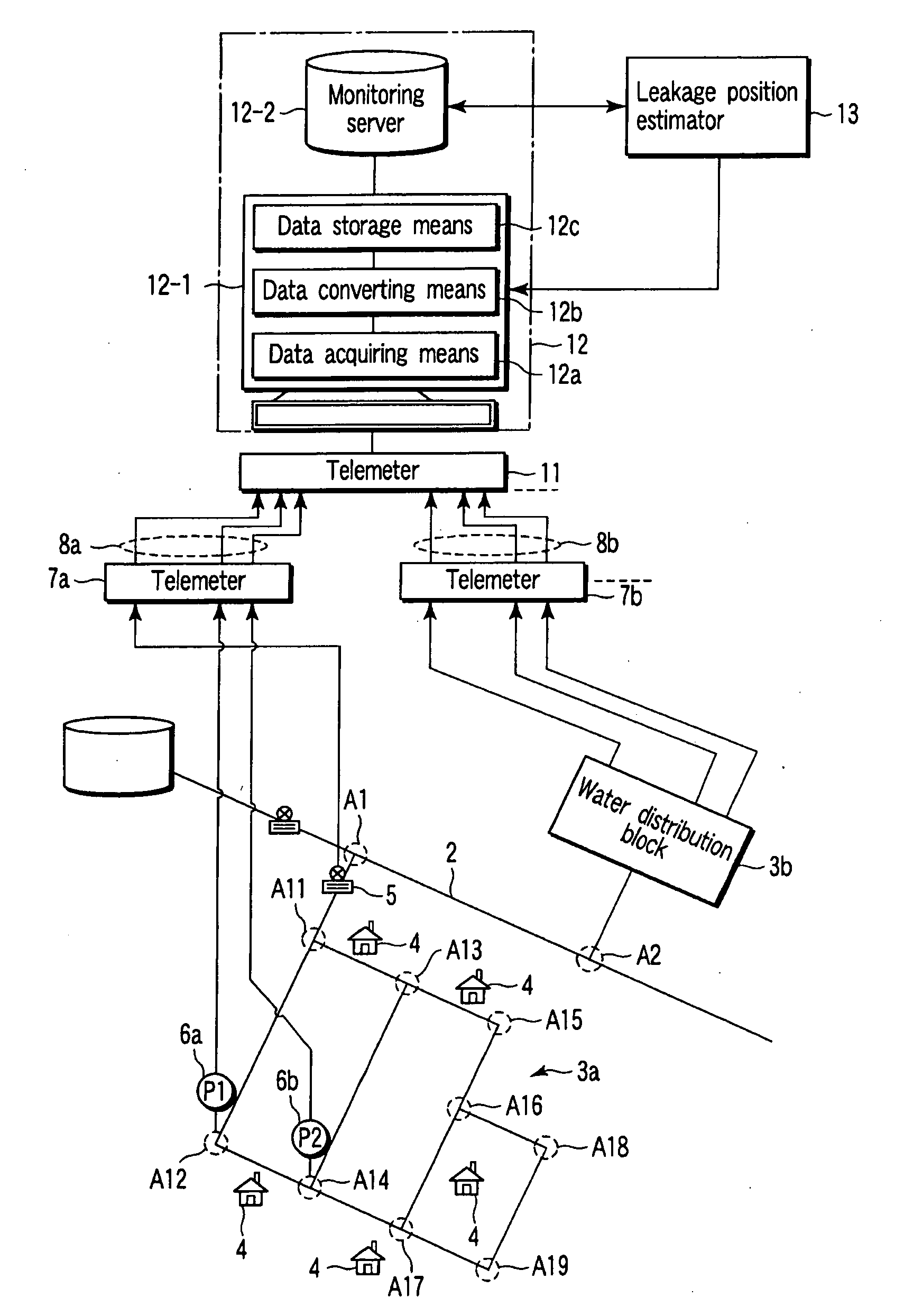

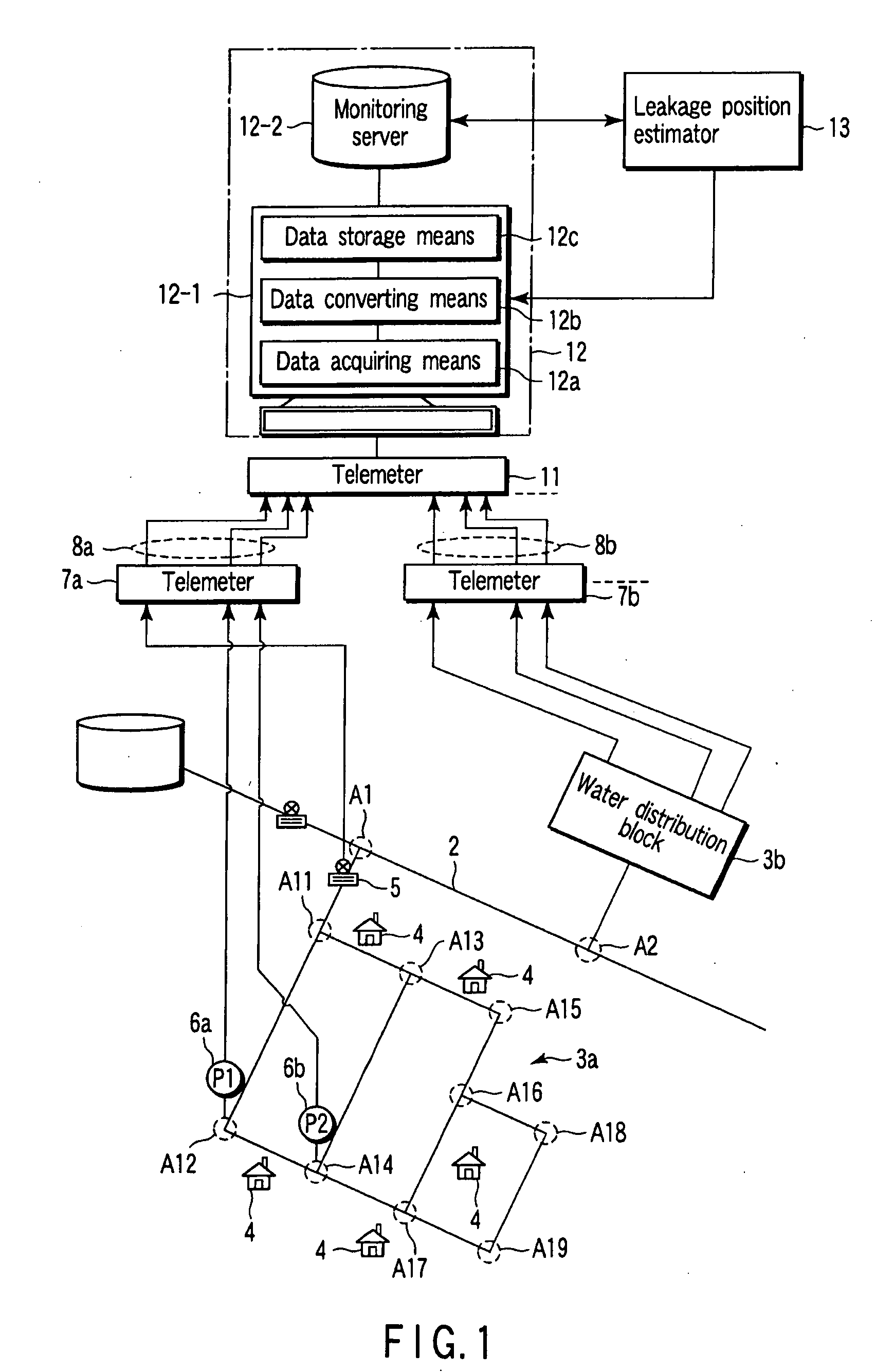

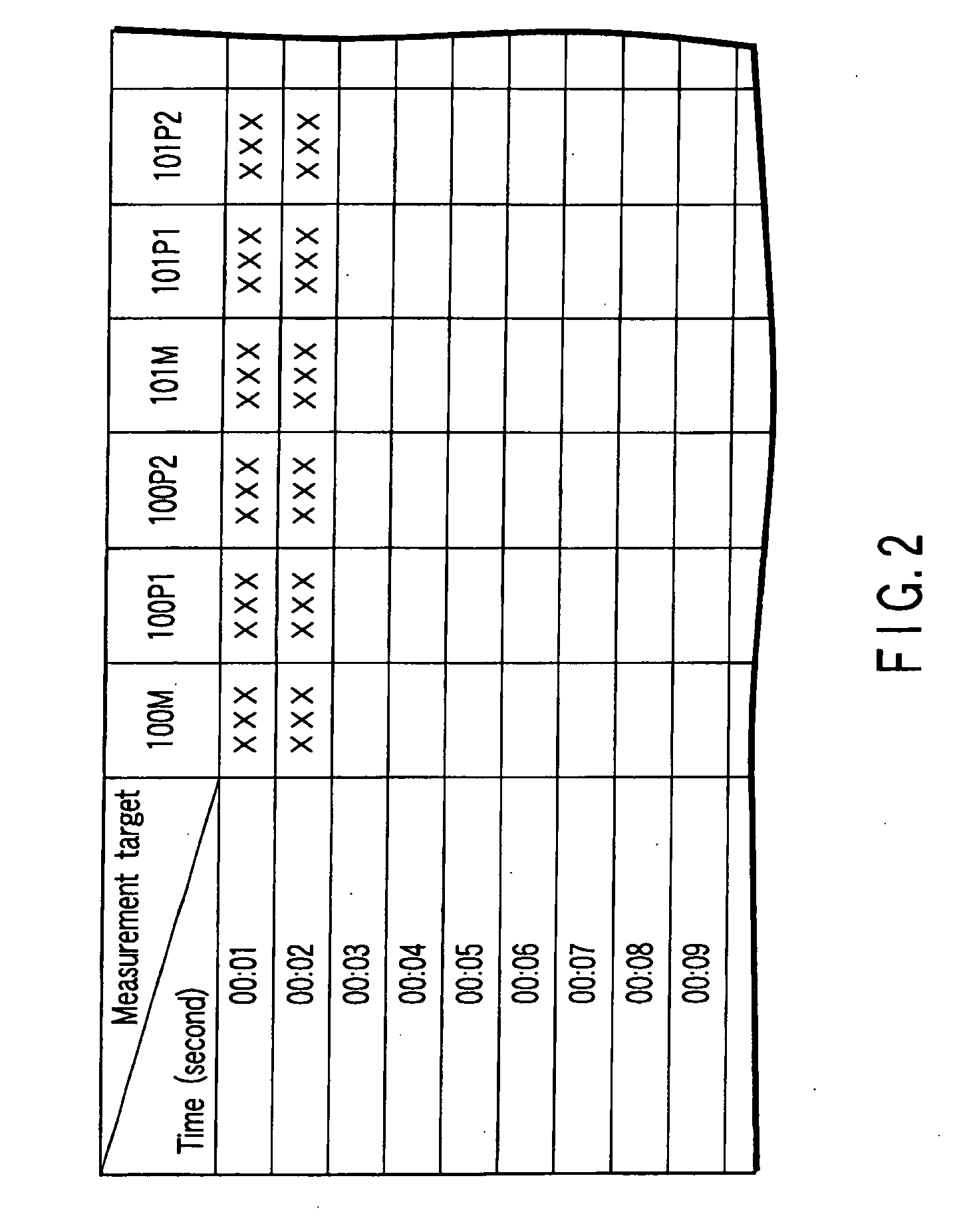

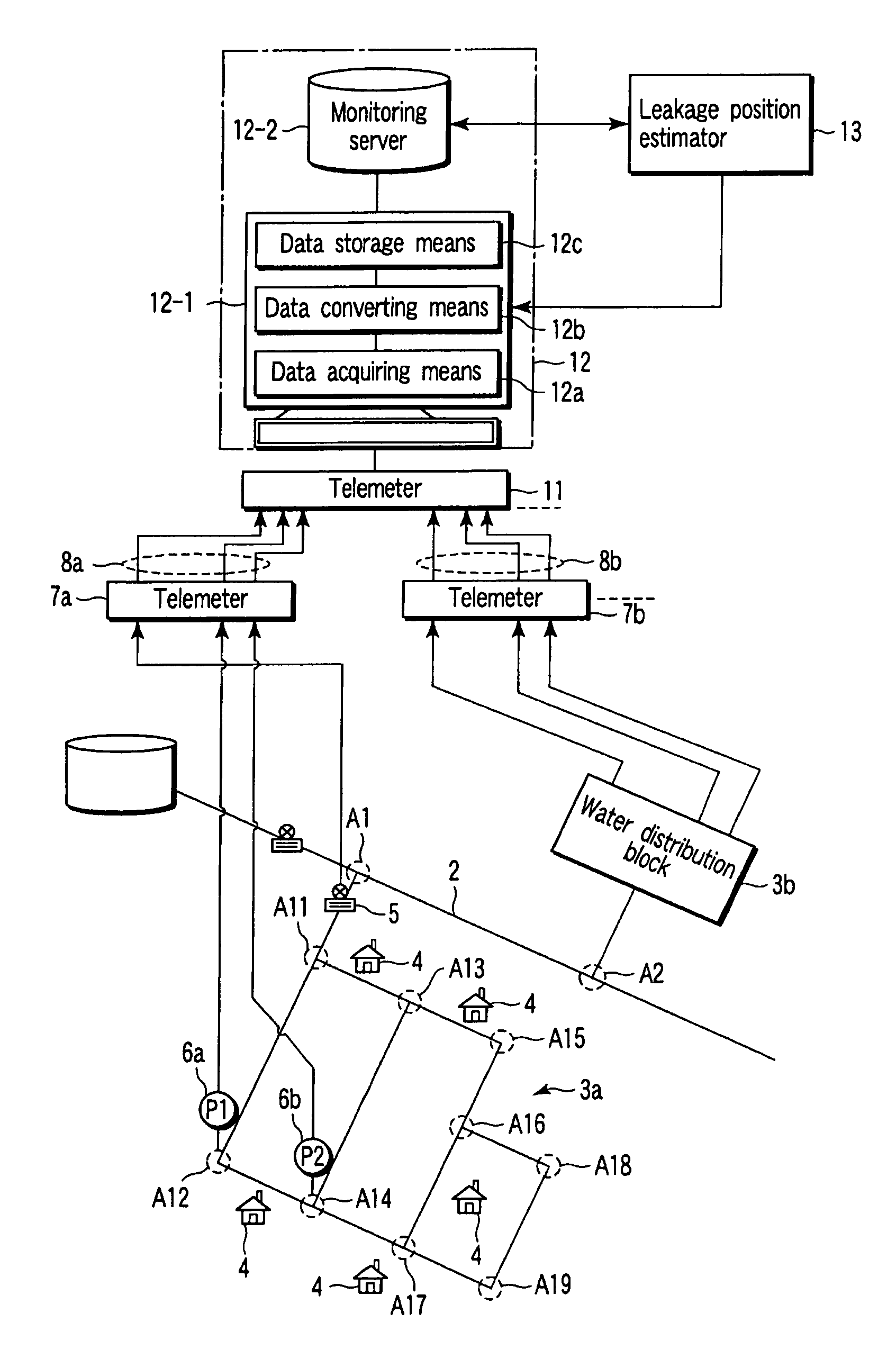

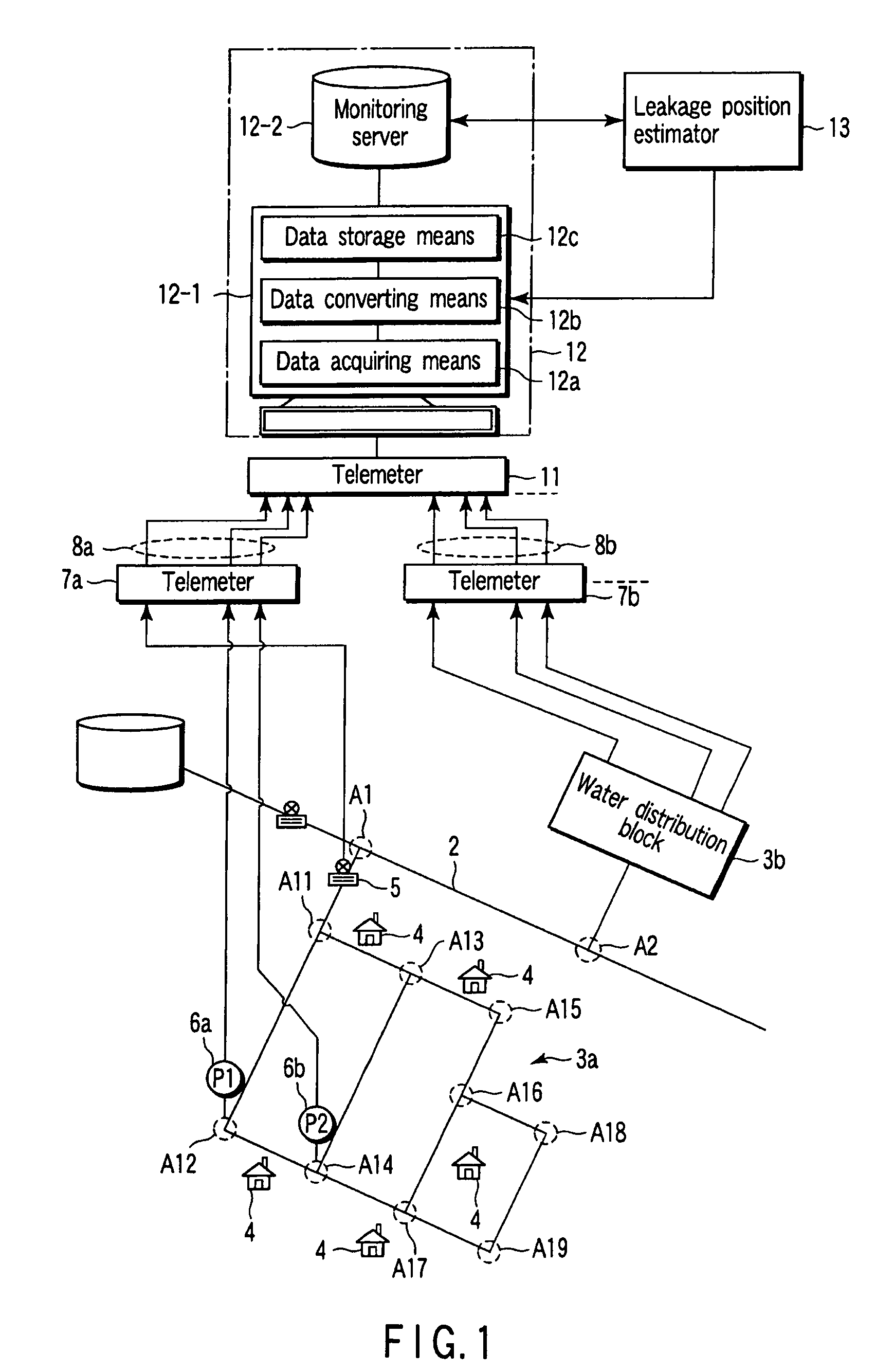

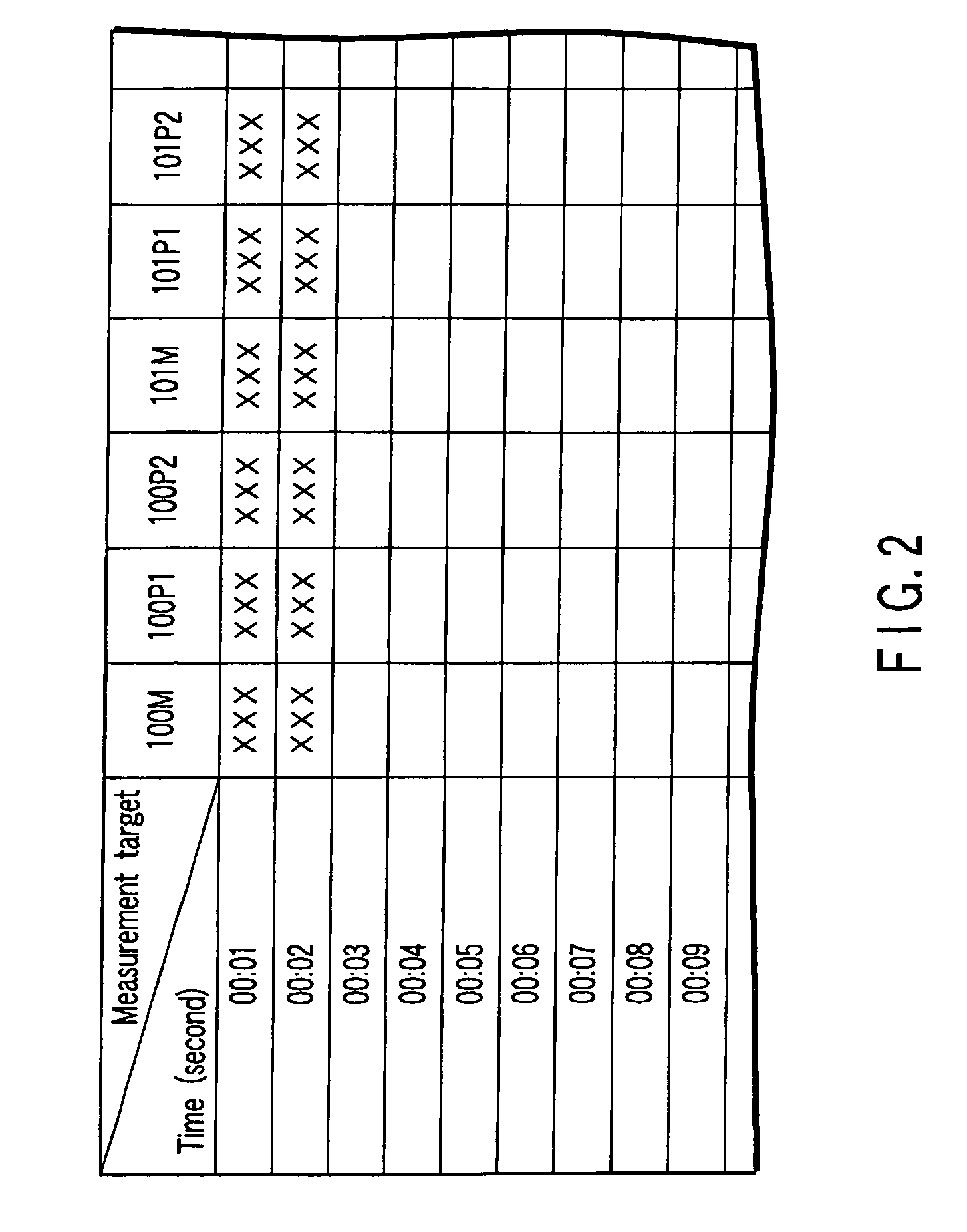

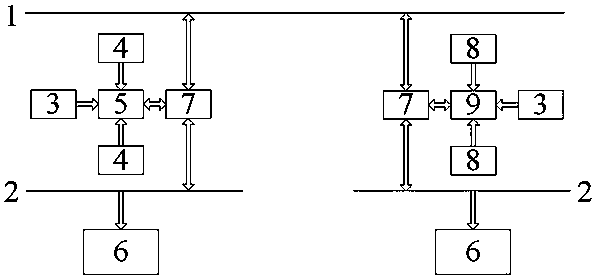

Water leakage monitoring system

ActiveUS20090066524A1Good estimateImprove leakageDetection of fluid at leakage pointFlow propertiesWater leakageTime lag

A water leakage monitoring system including a water leakage position estimator which includes a periodic data acquiring unit for fetching predetermined-period flow rate pressure data stored in a monitoring device, and for fetching a signal related to a flow rate change and pressure changes expecting a water leakage reaction time calculating unit for calculating a pressure reaction time lag between two pressure changes, a pressure propagation velocity estimating unit for estimating a pressure propagation velocity using the pressure reaction time lag and a distance between two pressure gauges located in a water distribution block stored in a pipeline network map data, and a flow rate change position estimating unit for receiving a signal related to the flow rate change, and estimating a flow rate change position using pressure propagation velocity and a flow meter and pressure gauge locating positions of the pipeline network map data.

Owner:TOSHIBA INFRASTRUCTURE SYST & SOLUTIONS CORP +1

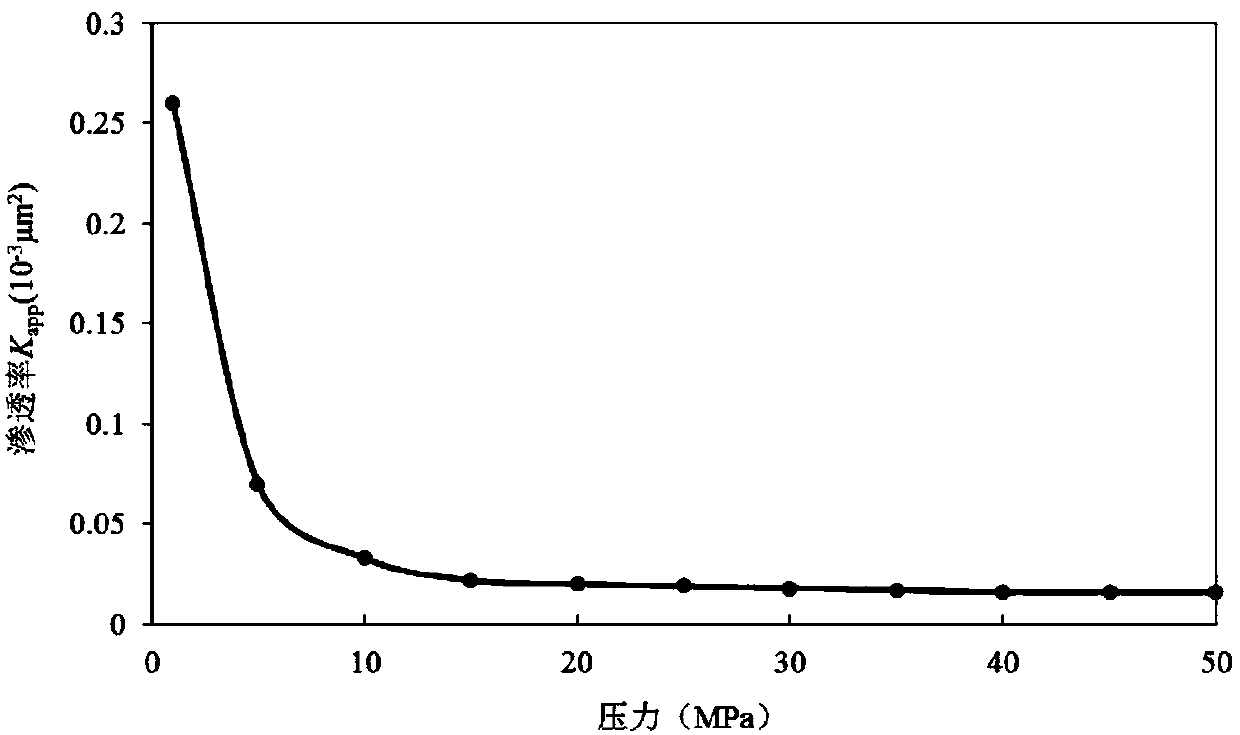

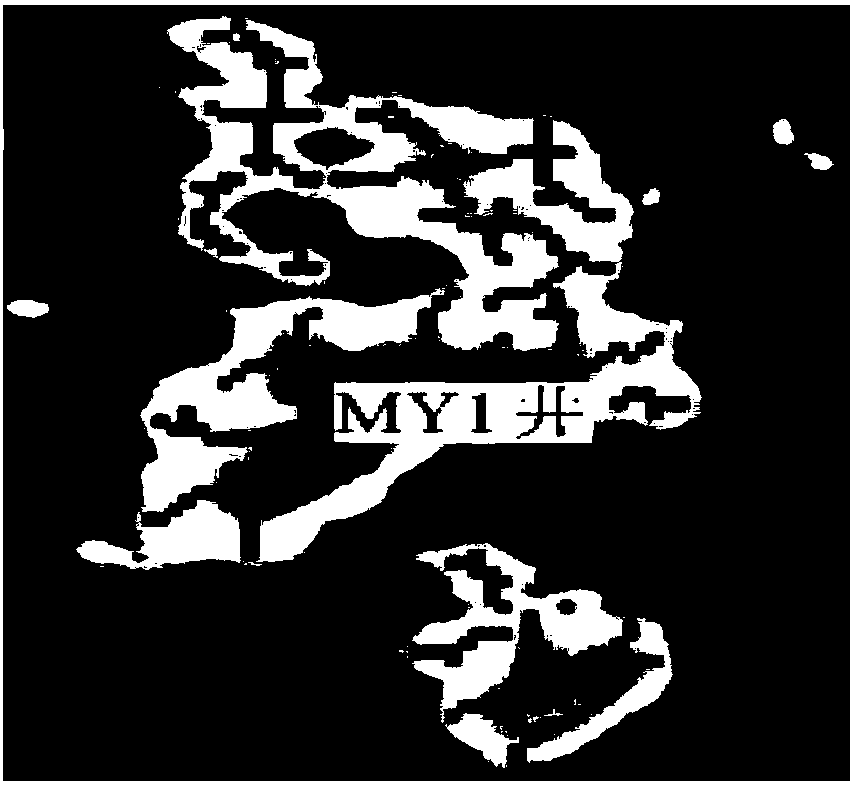

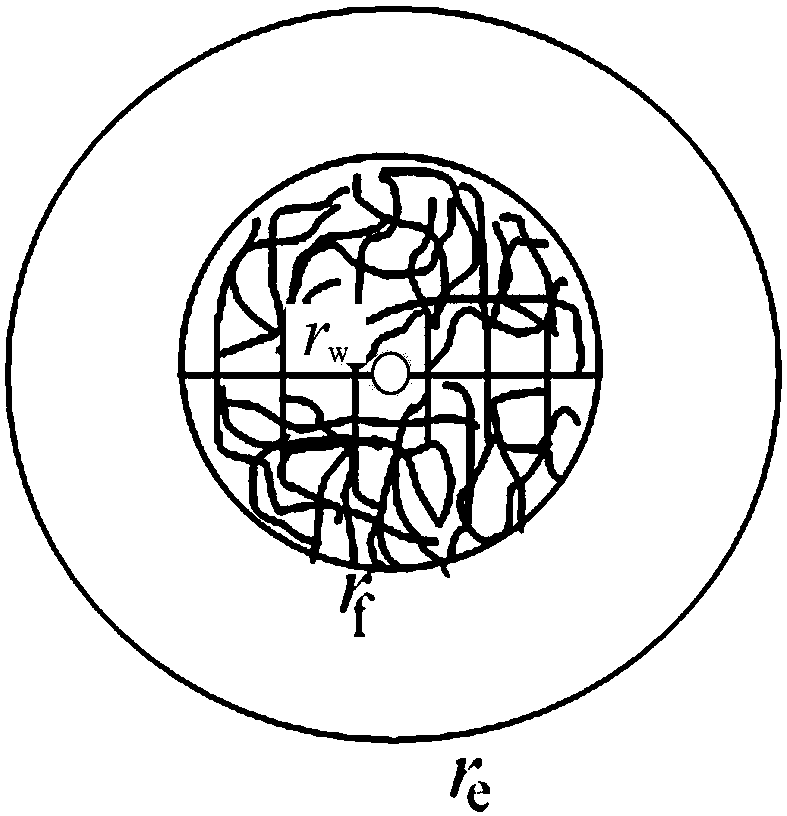

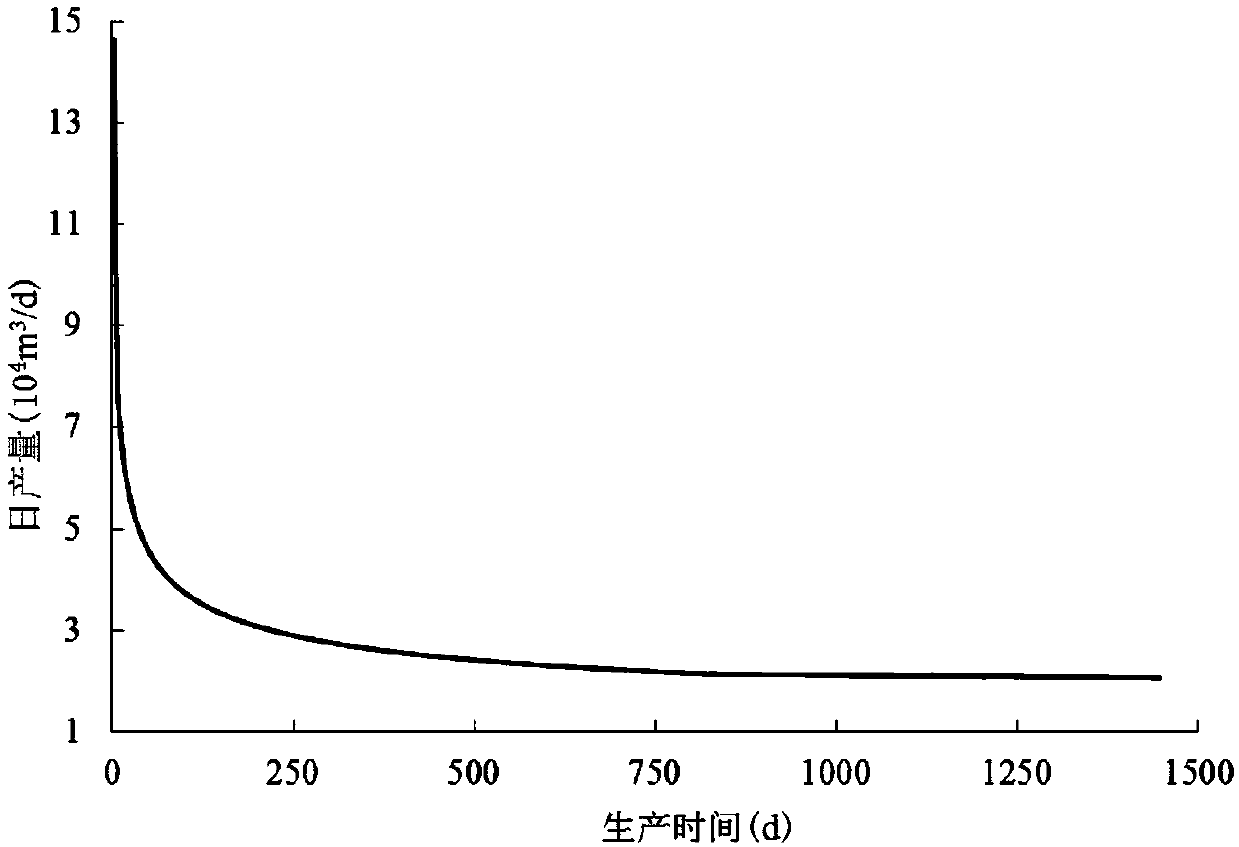

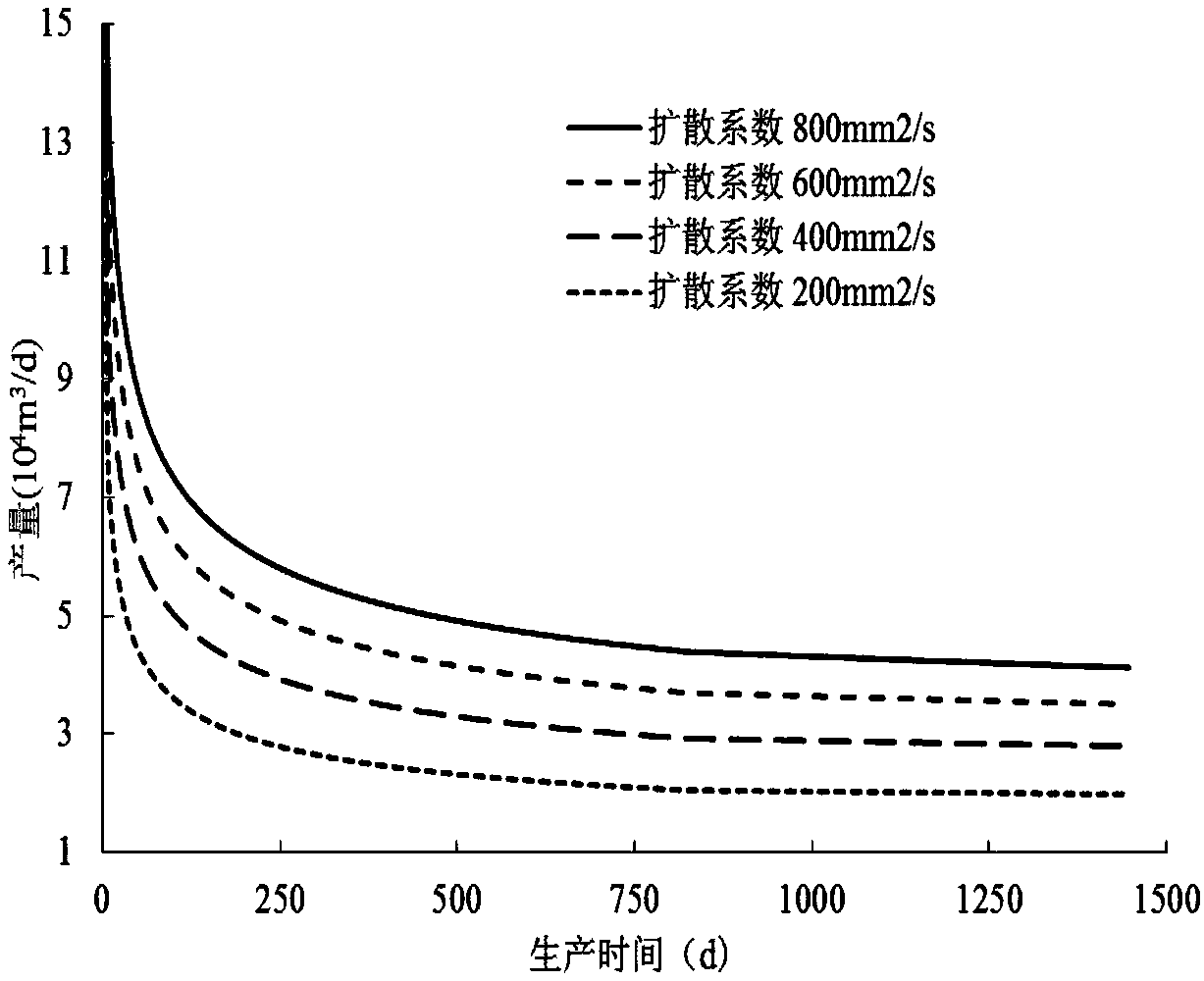

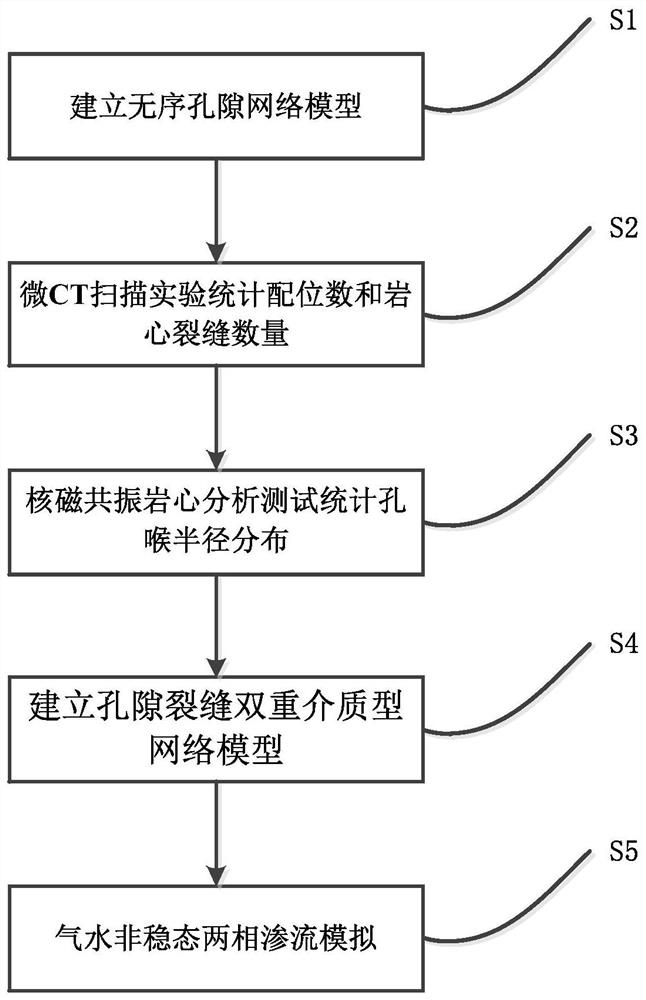

Method for computing unsteady state output of shale gas reservoir complex fracture network

ActiveCN108518212ASimple calculationCalculation of non-steady-state output is simpleSurveyData processing applicationsPorous mediumNetwork model

The invention belongs to the technical field of mineral resources, and particularly relates to a method for computing unsteady state output of a shale gas reservoir complex fracture network. The method comprises the following steps that S1, basic parameters of shale gas reservoir strata and shale gas are collected, and a shale substrate porous media capillary tube permeability model is established; S2, shale gas reservoir microseism fracture imaging data is collected, a box method is applied to acquire fractal dimensions, a two-dimensional discrete fracture network model is established, and animproved cubic law is adopted to calculate the complex fracture network permeability; S3, it is considered that a shale gas reservoir fracturing horizontal well outer region is a substrate area infiltration area and a shale gas reservoir fracturing horizontal well inner region is a complex fracture network area flow area, and a shale gas reservoir fracturing horizontal well steady-state productivity model is established; according to a shale gas pressure propagation radius equation and a shale gas reservoir material balance equation, a continuous quasi-steady method is applied to establish ashale gas reservoir fracturing horizontal well unsteady state model. The method for the computing unsteady state output of the shale gas reservoir complex fracture network has the advantages that theconsideration factors are close to the actual conditions of strata, and computed results are more accurate.

Owner:SOUTHWEST PETROLEUM UNIV

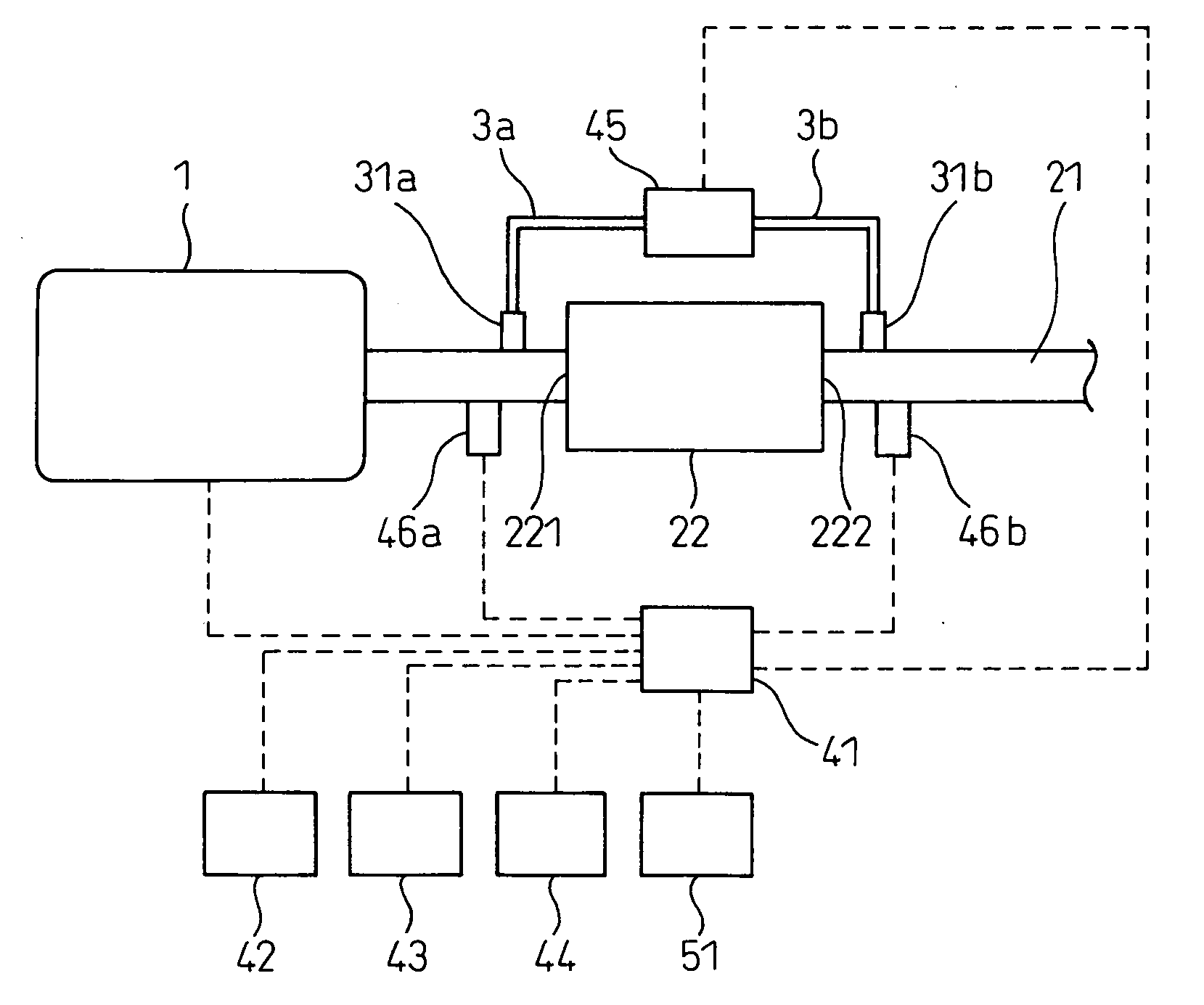

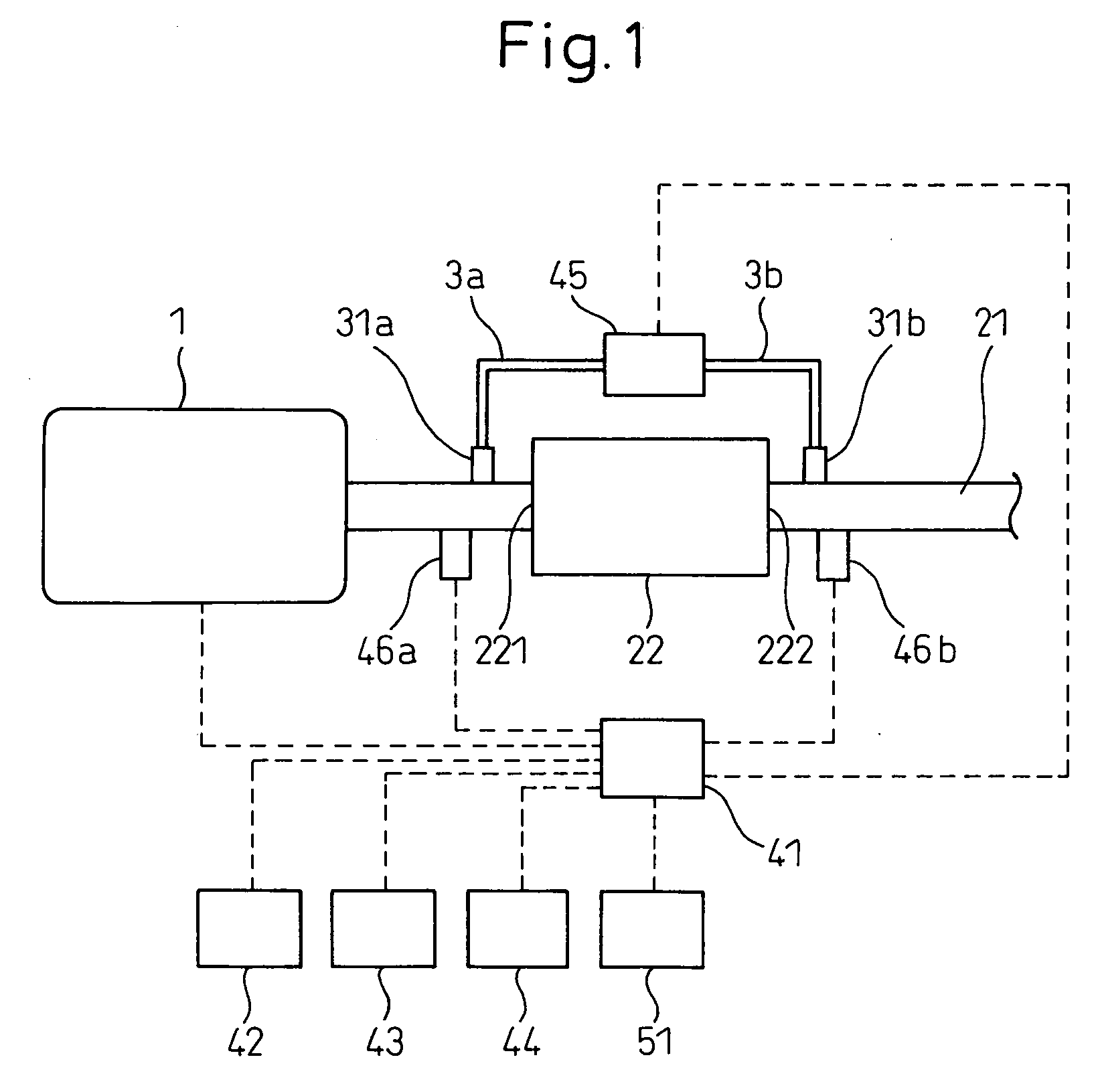

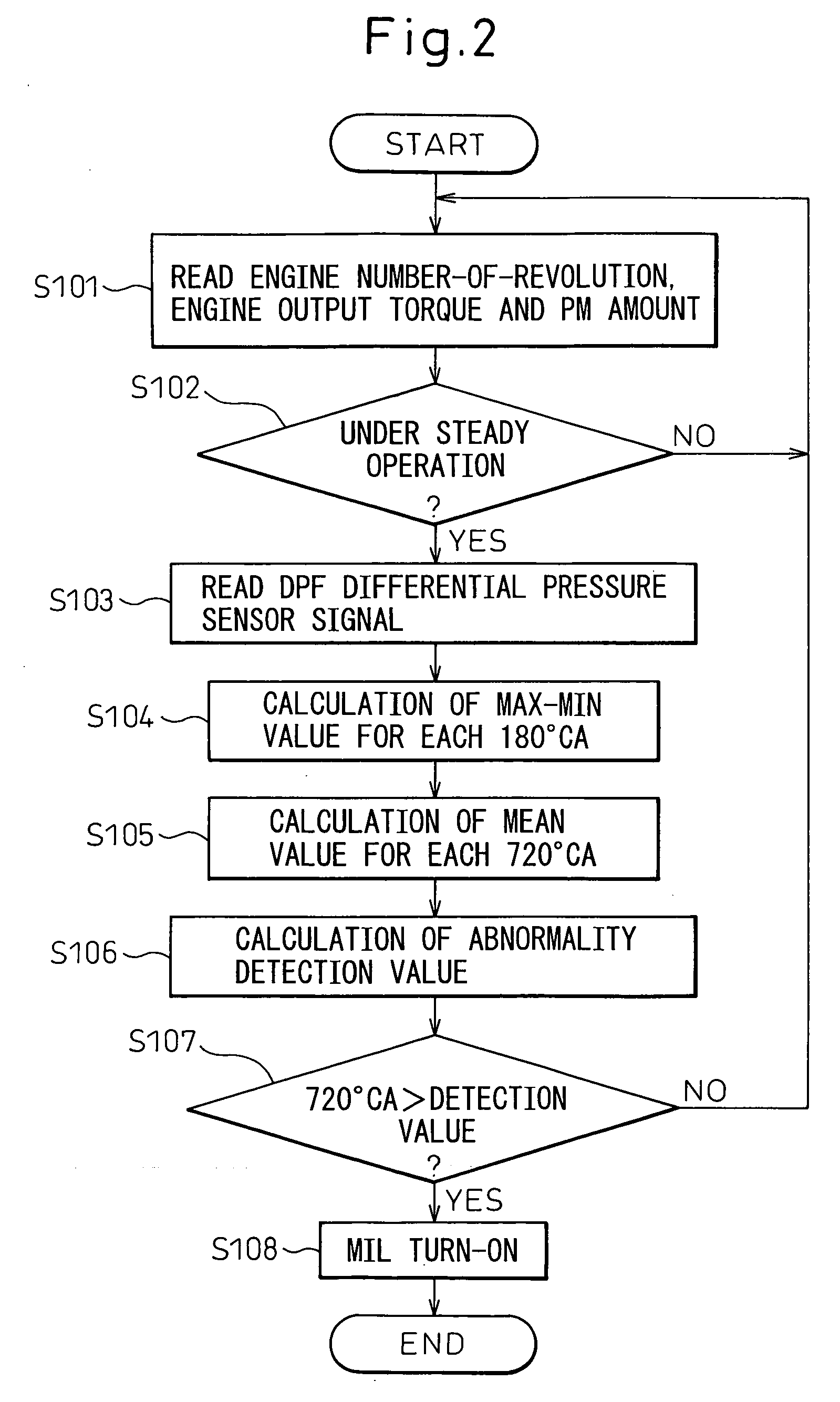

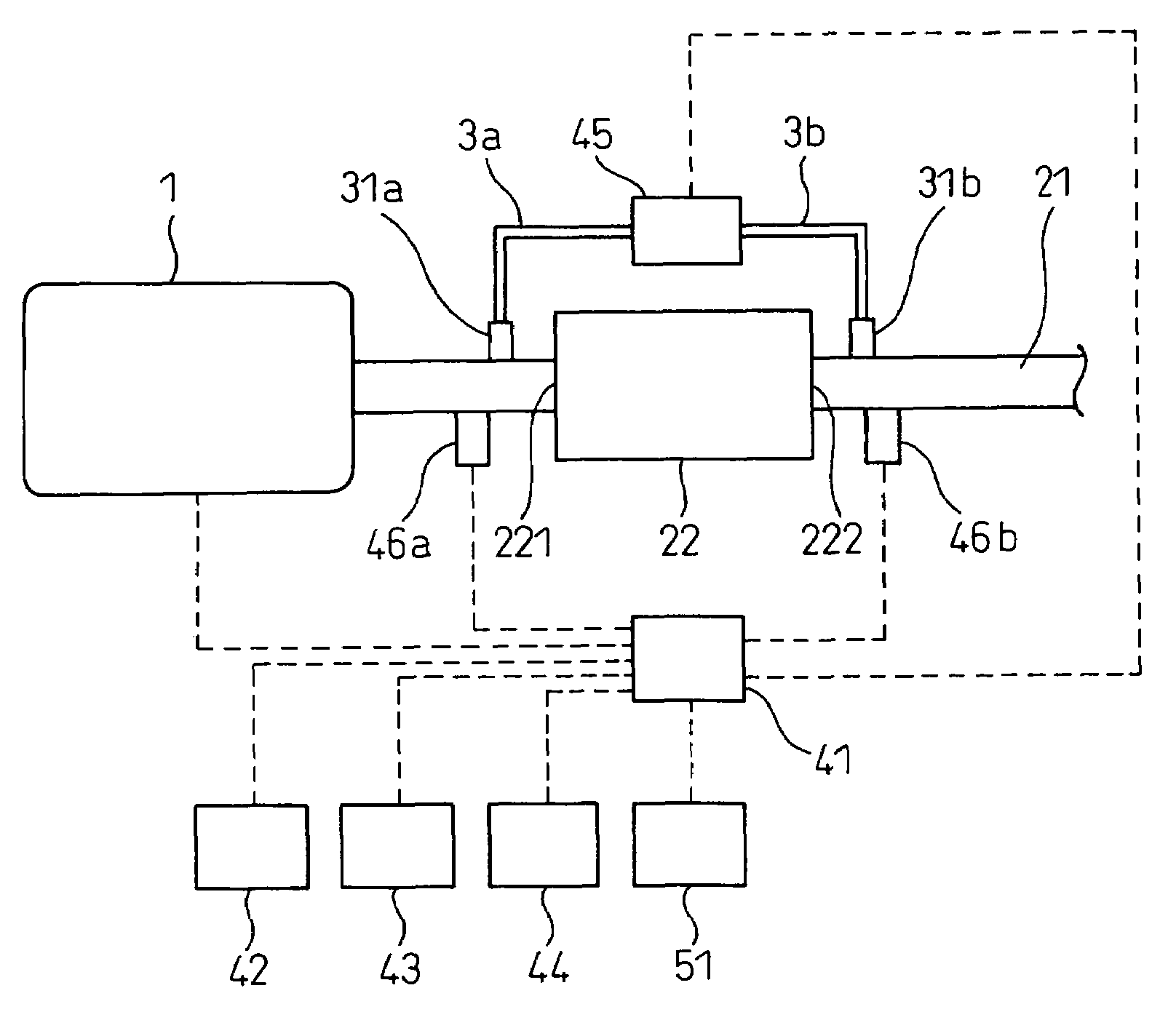

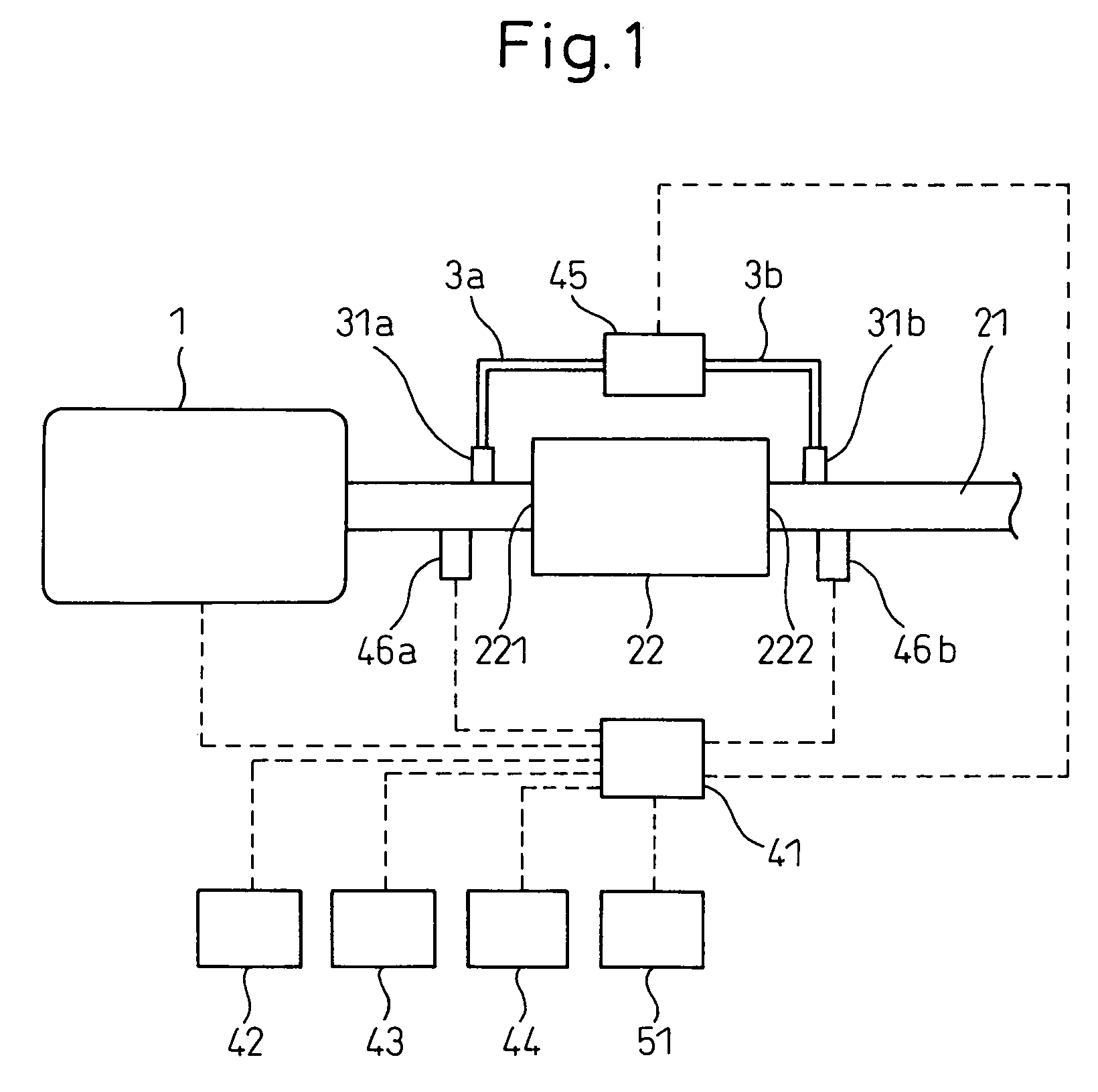

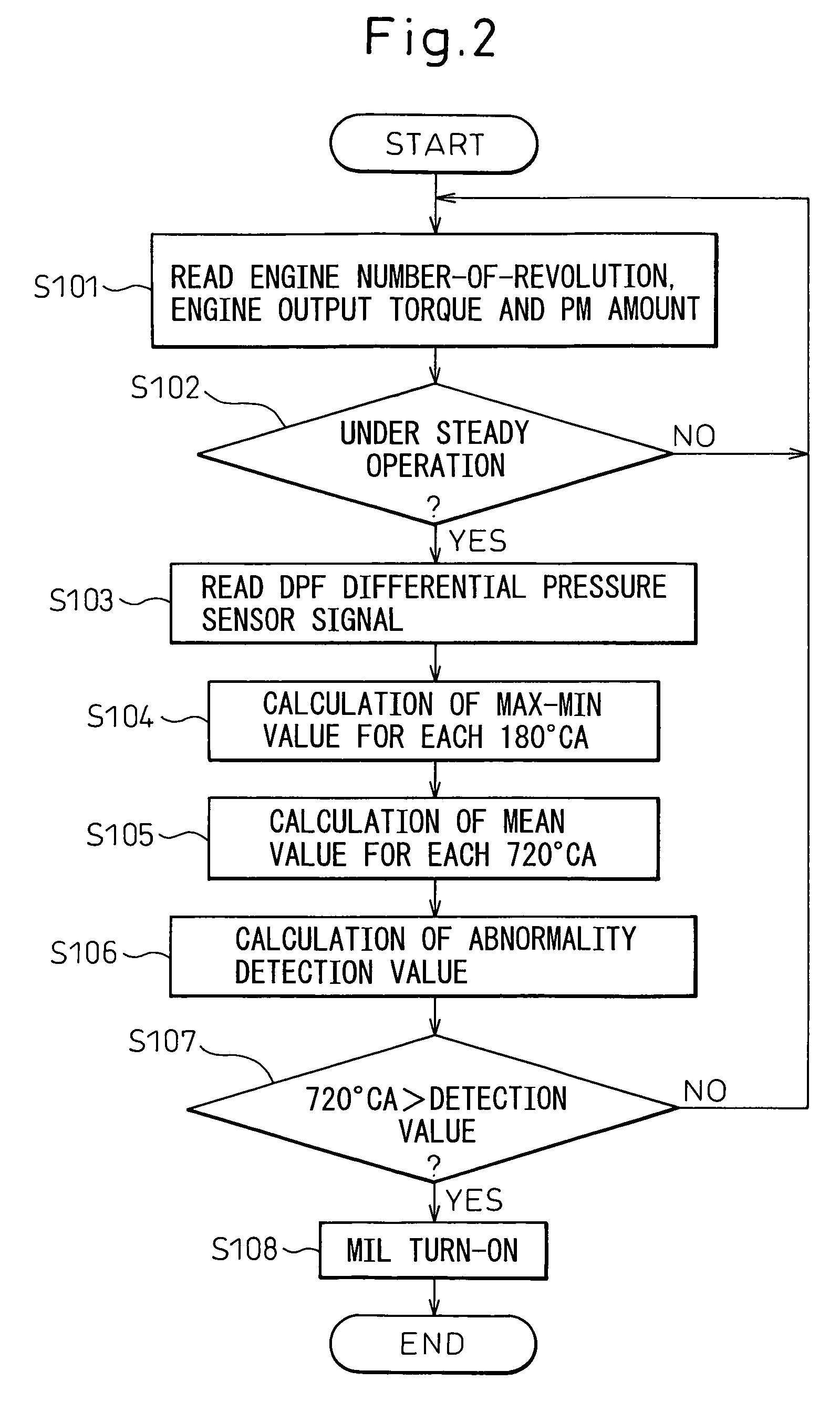

Abnormality detection apparatus for exhaust gas purification apparatus for internal combustion engine

ActiveUS20050178272A1Easily detecting abnormalityEasy to detectDetection of fluid at leakage pointCombination devicesPressure propagationEngineering

Unless an abnormality exists in piping introducing a pressure from front and rear of DPF 22 into a differential pressure sensor 45, pulsations of pressure propagation through an exhaust passage 21 is offset in a detection value of a pressure difference of the differential pressure sensor 45, and an amplitude of the detection value of the DPF pressure difference resulting from pulsation of the pressure becomes small. If a crack exists in one of the piping 3a and 3b, the influence of a pulsation of the pressure appears in the DPF pressure difference and the amplitude of the detection value of the DPF pressure difference becomes large. The amplitude of the detection value of the DPF pressure difference is compared with the reference value and is detected as being abnormal when it is large, utilizing the phenomenon described above.

Owner:DENSO CORP

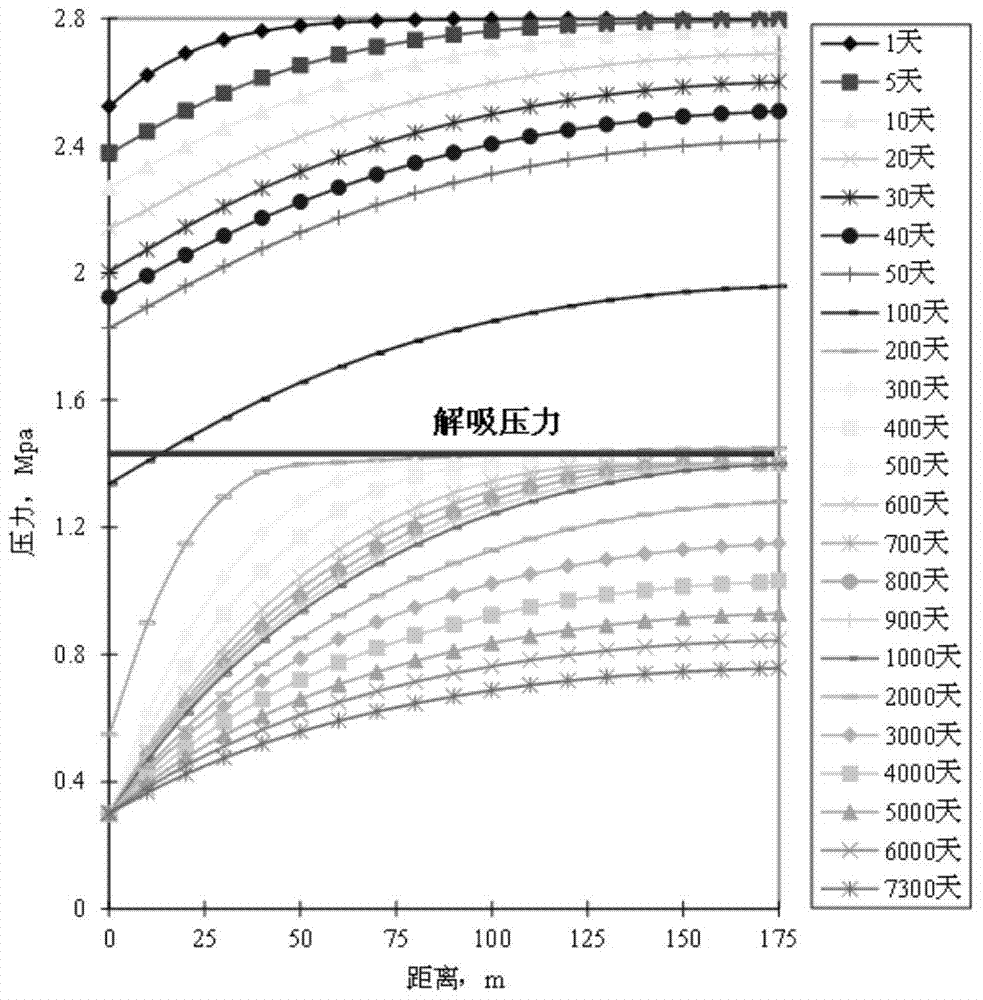

Method for calculating non-steady state yield of volume fractured horizontal well of shale gas reservoir

The invention discloses a method for calculating a non-steady state yield of a volume fractured horizontal well of a shale gas reservoir. The method comprises the following steps of dividing the reservoir into a volume fractured region and a non-transformed matrix region, and collecting basic parameters of the volume fractured region, the non-transformed matrix region and the horizontal well, wherein the volume fractured region is Darcy flow, and the non-transformed matrix region is Knudson flow; according to a mass conservation law, establishing a steady-state yield formula of the volume fractured horizontal well of the shale gas reservoir; based on a pressure propagation formula, the steady-state yield formula and a matter balance equation, calculating the non-steady state yield of the volume fractured horizontal well of the shale gas reservoir by applying a continuous quasi-steady method; and repeating the previous step, and performing calculation to obtain the non-steady state yield of the volume fractured horizontal well of the shale gas reservoir. The method fully considers a process that a pressure is propagated to a boundary gradually in a production process of the volume fractured horizontal well of the shale gas reservoir, different seepage laws of shale gas in a volume transformation region and the non-transformed matrix region, and adsorption and desorption effects of the shale gas, so that actual conditions are better met.

Owner:SOUTHWEST PETROLEUM UNIV

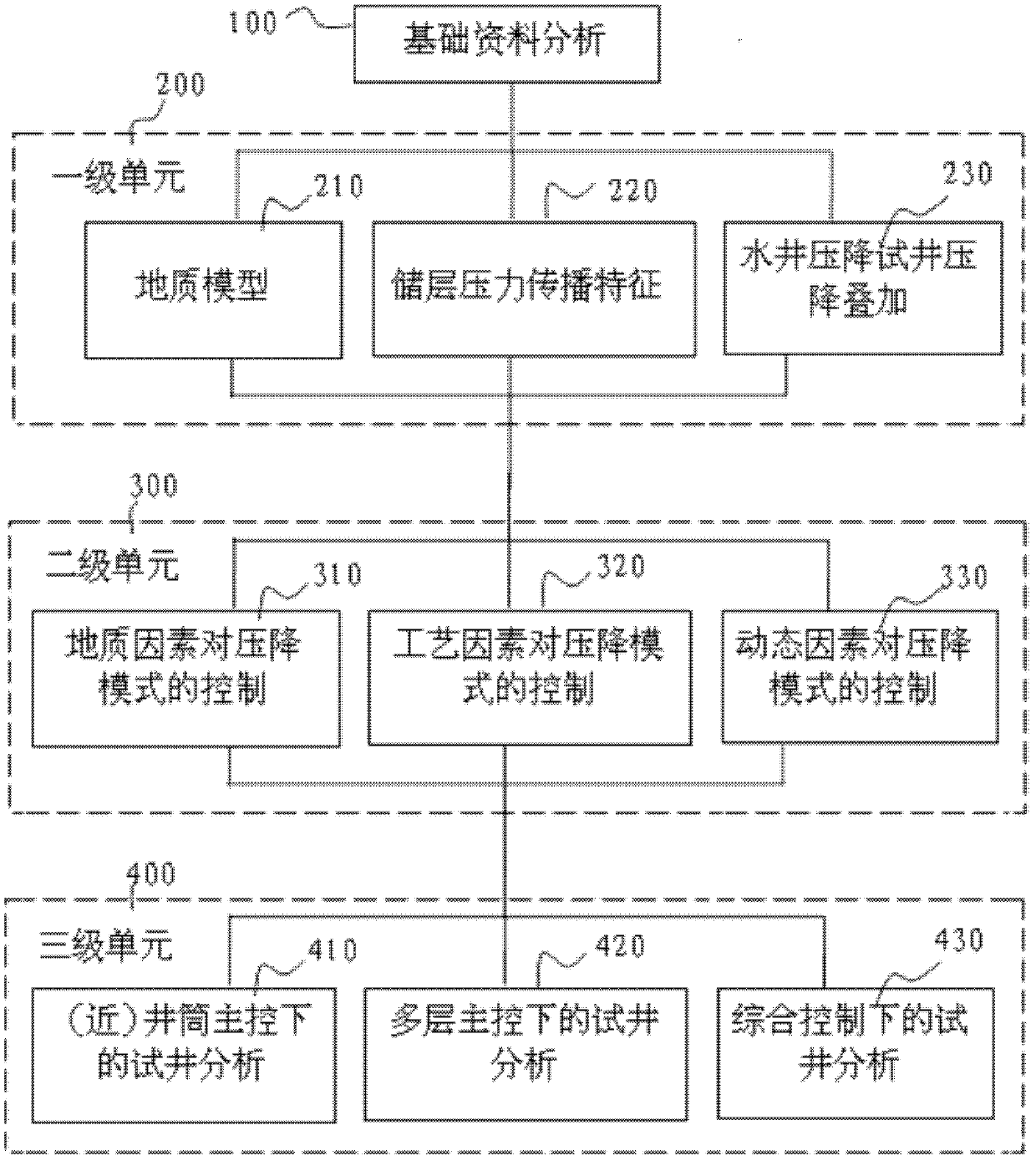

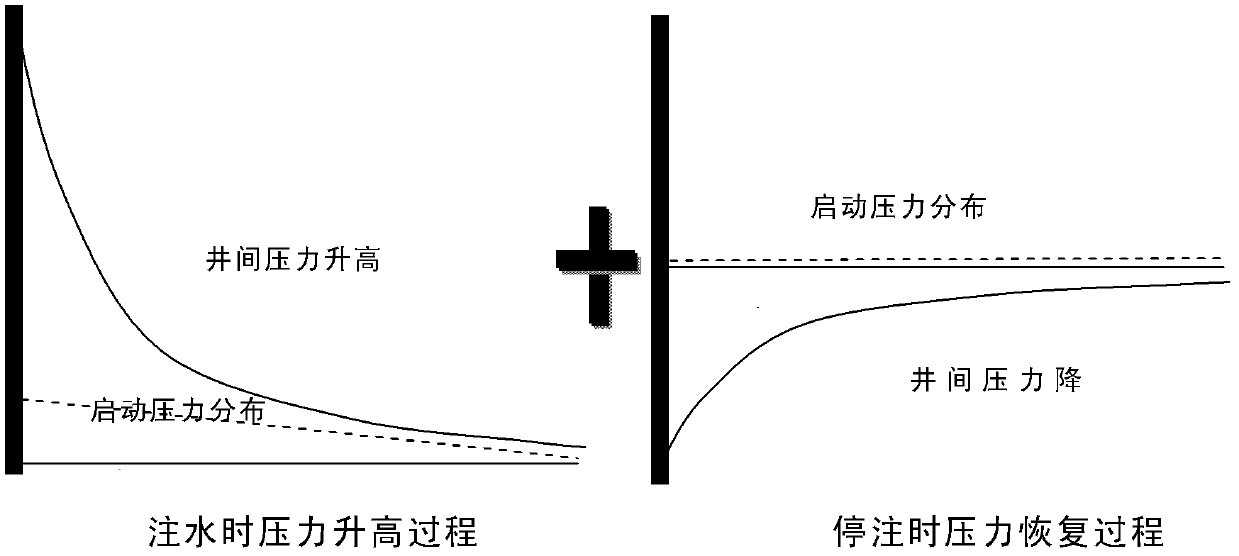

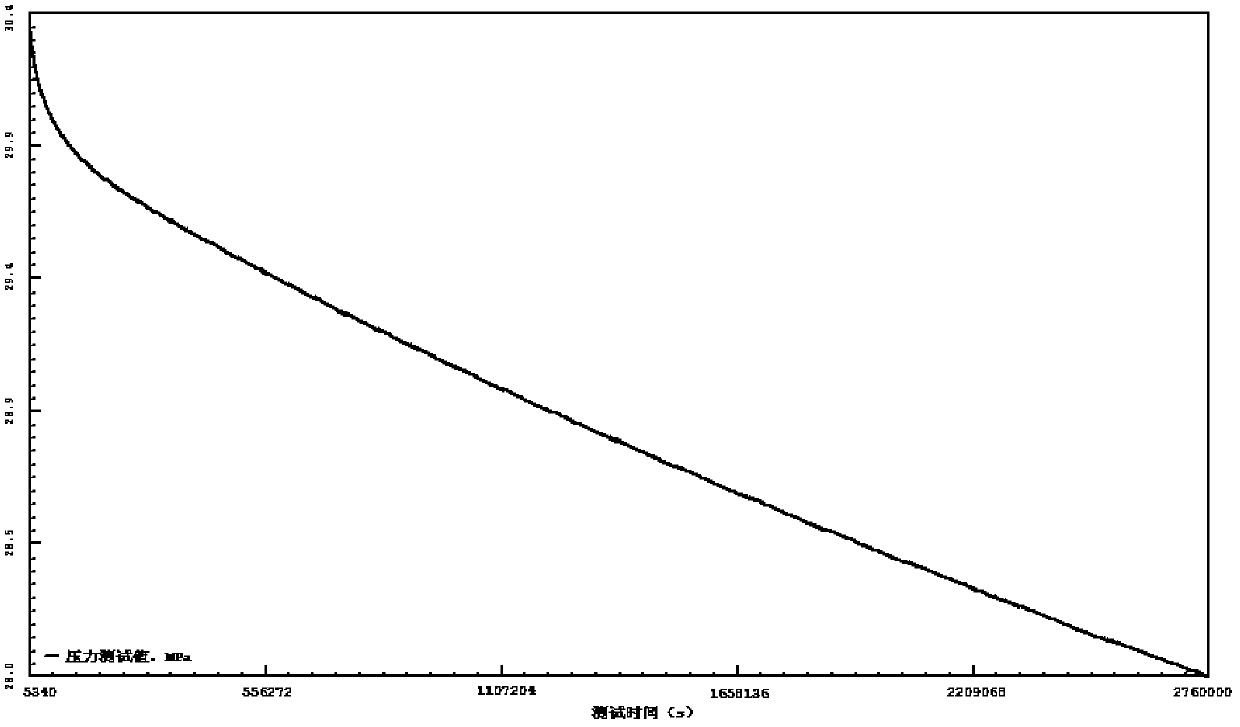

Draw-down test analysis method for underground shut-in water well with low-permeability storage layer

The invention provides a draw-down test analysis method for an underground shut-in water well with a low-permeability storage layer, and the method is applied to the technical field of oil well tests in oil fields. In the method, a base data analysis unit, a primary base feature analysis unit, a secondary main control factor analysis unit and a tertiary data analysis model unit are utilized, wherein the primary base feature analysis unit is used for utilizing the base data of the base data analysis unit to determine a geologic model for detection and analysis, judging the pressure propagation characteristic of the low-permeability storage layer and forming the superposition mode of bottomhole pressure drawdown in a drawn-down test; the secondary main control factor analysis unit is used for carrying out diagnostic analysis on the control degree of a geologic factor, a process factor and a dynamic factor on the pressure drawdown mode of the drawn-down test and determining main control factors according to the conclusion of the primary base feature analysis unit; and the tertiary data analysis model unit is used for selecting the draw-down test analysis method according to the conclusions of the primary base feature analysis unit and the secondary main control factor analysis unit and adopting different well test interpretation models according to the main control factors.

Owner:PETROCHINA CO LTD

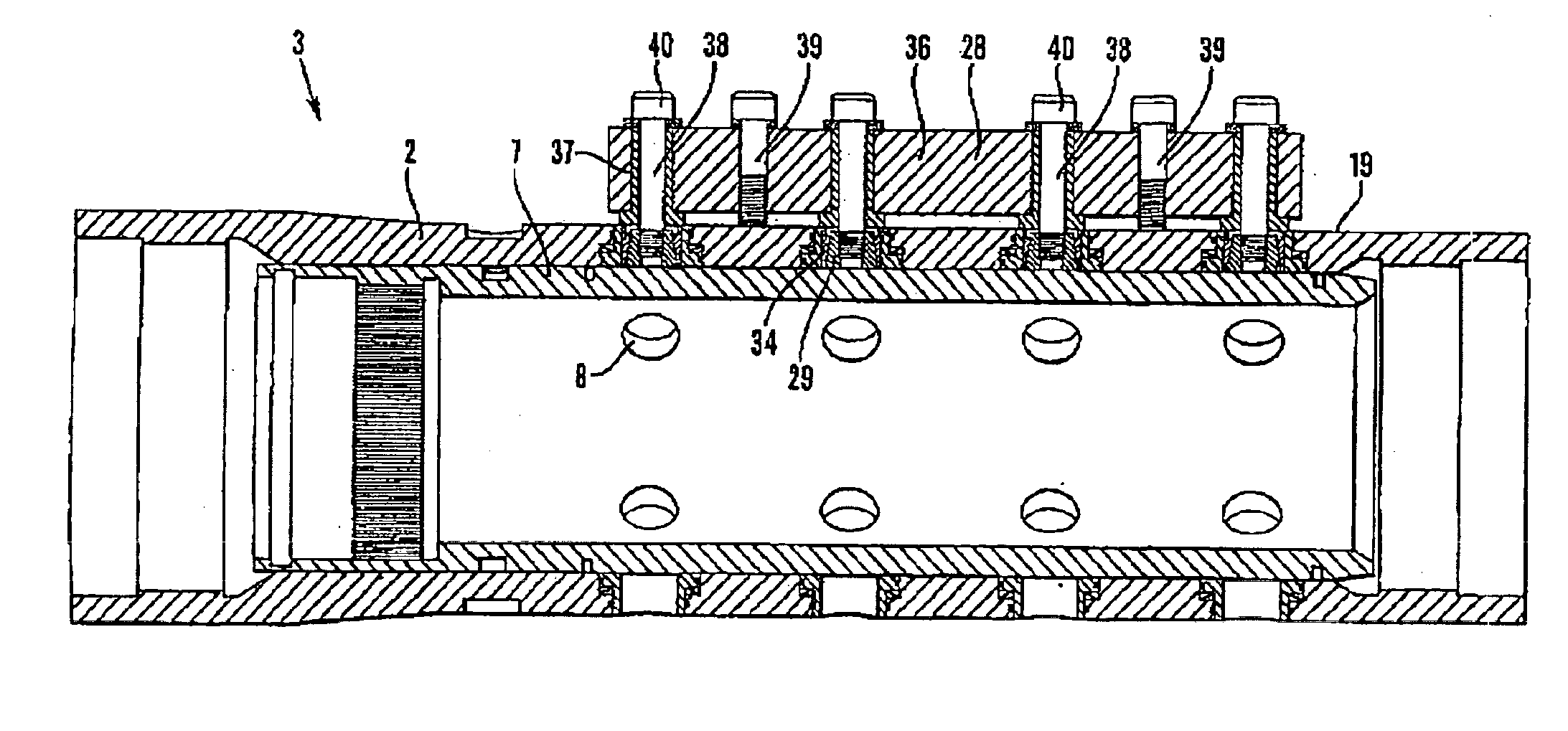

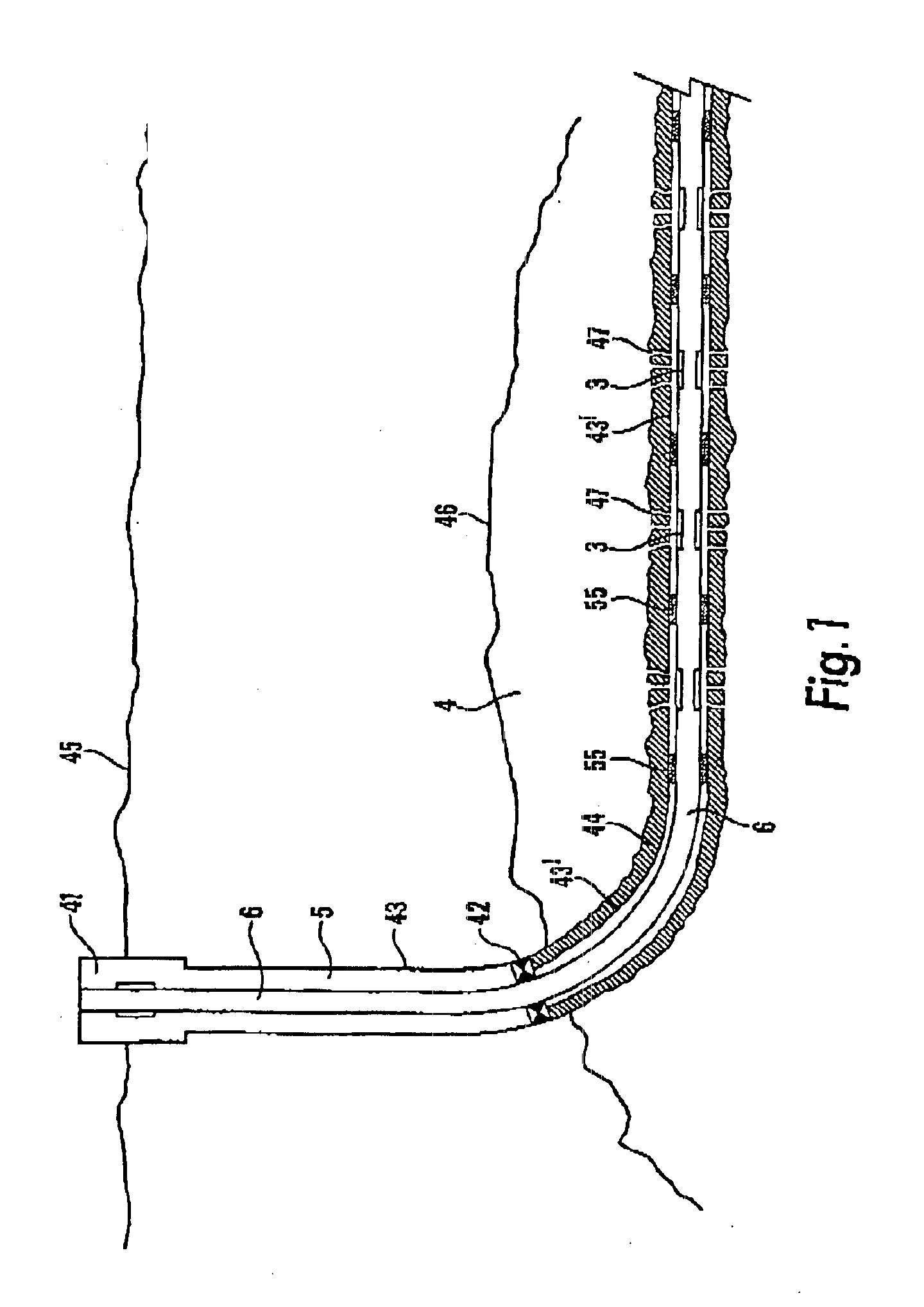

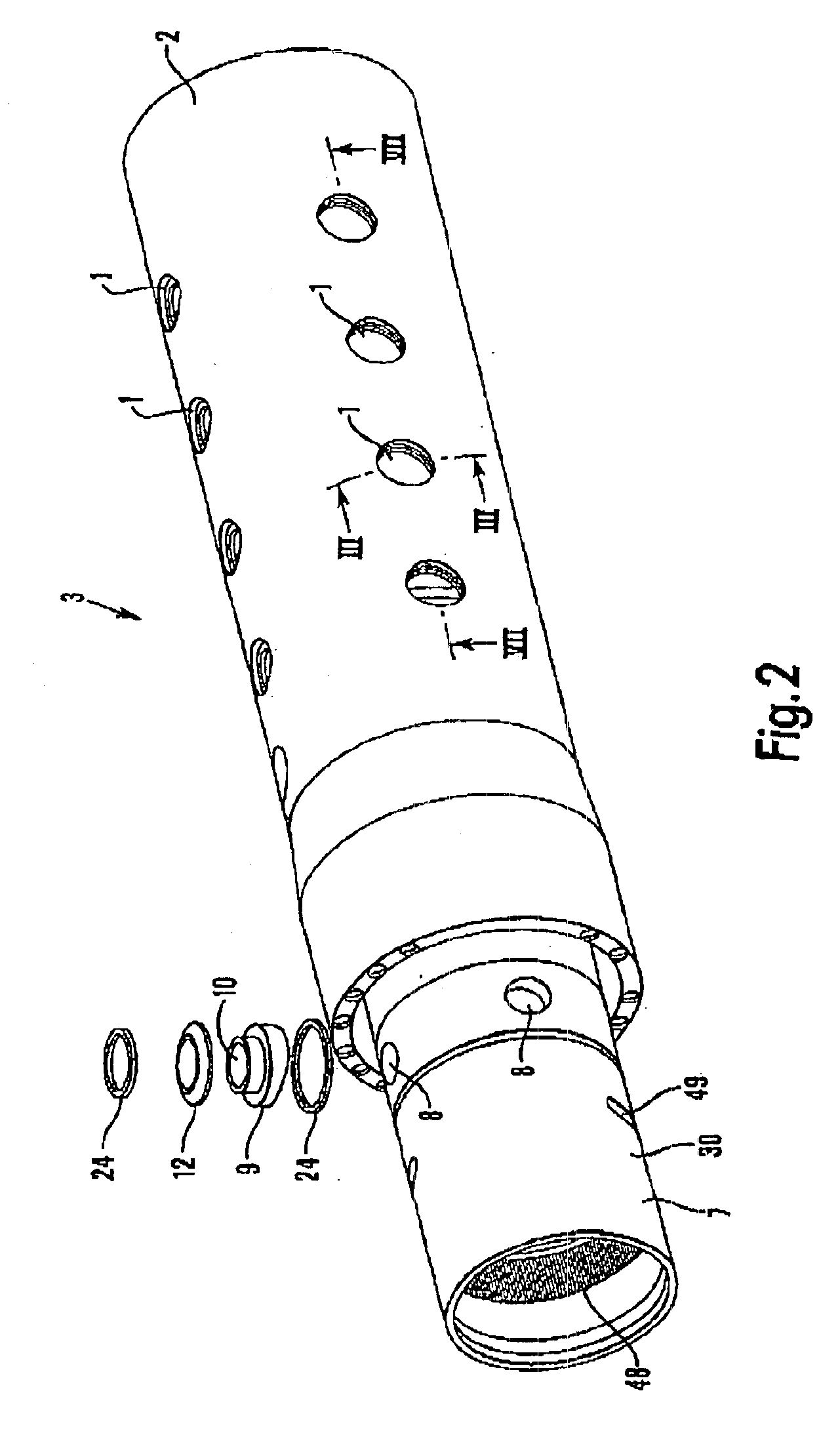

Device for an opening in an outer sleeve of a sleeve valve and a method for the assembly of a sleeve valve

InactiveUS6880638B2Effectively leakagePlug valvesOperating means/releasing devices for valvesSleeve valveEngineering

A sleeve valve for fluid flow between a hydrocarbon reservoir and a well including a fixed outer sleeve with openings and a movable inner sleeve with openings which can be aligned and misaligned with the outer sleeve openings in order to admit or shut off the fluid flow. The outer sleeve opening is provided with a movable sealing element that has a through-going radial opening adapted to rest around the opening in the inner sleeve, and a tension element presses the sealing element against the inner sleeve. A portion of the side face of the sealing element forms a pressure face which under the effect of pressure in a pressure chamber presses the sealing element against the inner sleeve. The pressure chamber is via at least one connection connected to at least one pressure source whereby pressure propagation from the pressure source to the pressure chamber causes the sealing element to be pressed even more against the inner sleeve.

Owner:WELL INNOVATION ENG

Abnormality detection apparatus for exhaust gas purification apparatus for internal combustion engine

ActiveUS7396389B2Easy to detectEasy to practiceCombination devicesAuxillary pretreatmentExhaust fumesEngineering

Unless an abnormality exists in piping introducing a pressure from front and rear of DPF 22 into a differential pressure sensor 45, pulsations of pressure propagation through an exhaust passage 21 is offset in a detection value of a pressure difference of the differential pressure sensor 45, and an amplitude of the detection value of the DPF pressure difference resulting from pulsation of the pressure becomes small. If a crack exists in one of the piping 3a and 3b, the influence of a pulsation of the pressure appears in the DPF pressure difference and the amplitude of the detection value of the DPF pressure difference becomes large. The amplitude of the detection value of the DPF pressure difference is compared with the reference value and is detected as being abnormal when it is large, utilizing the phenomenon described above.

Owner:DENSO CORP

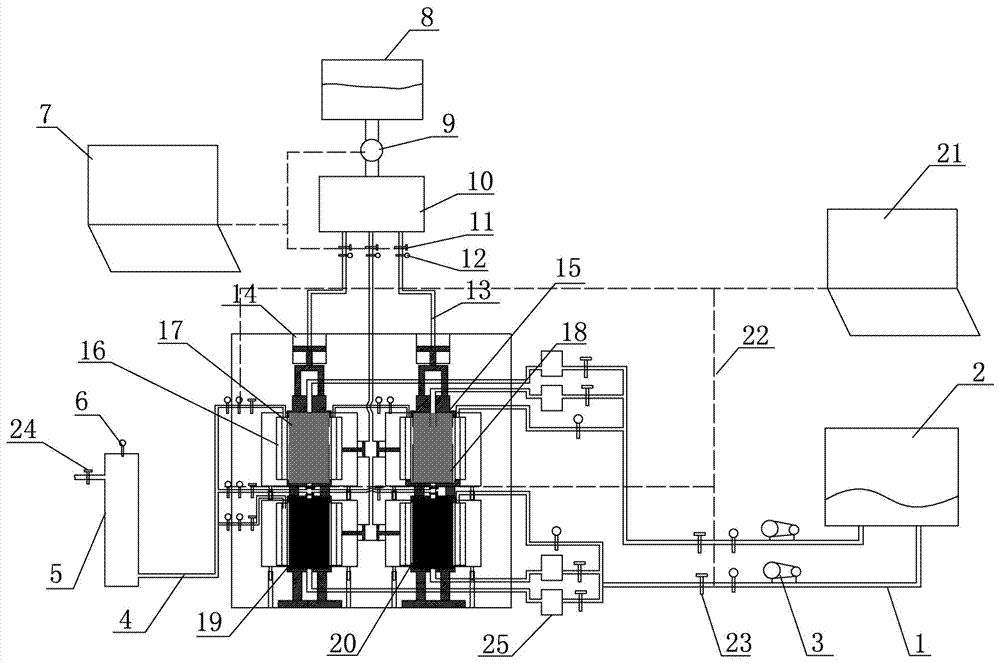

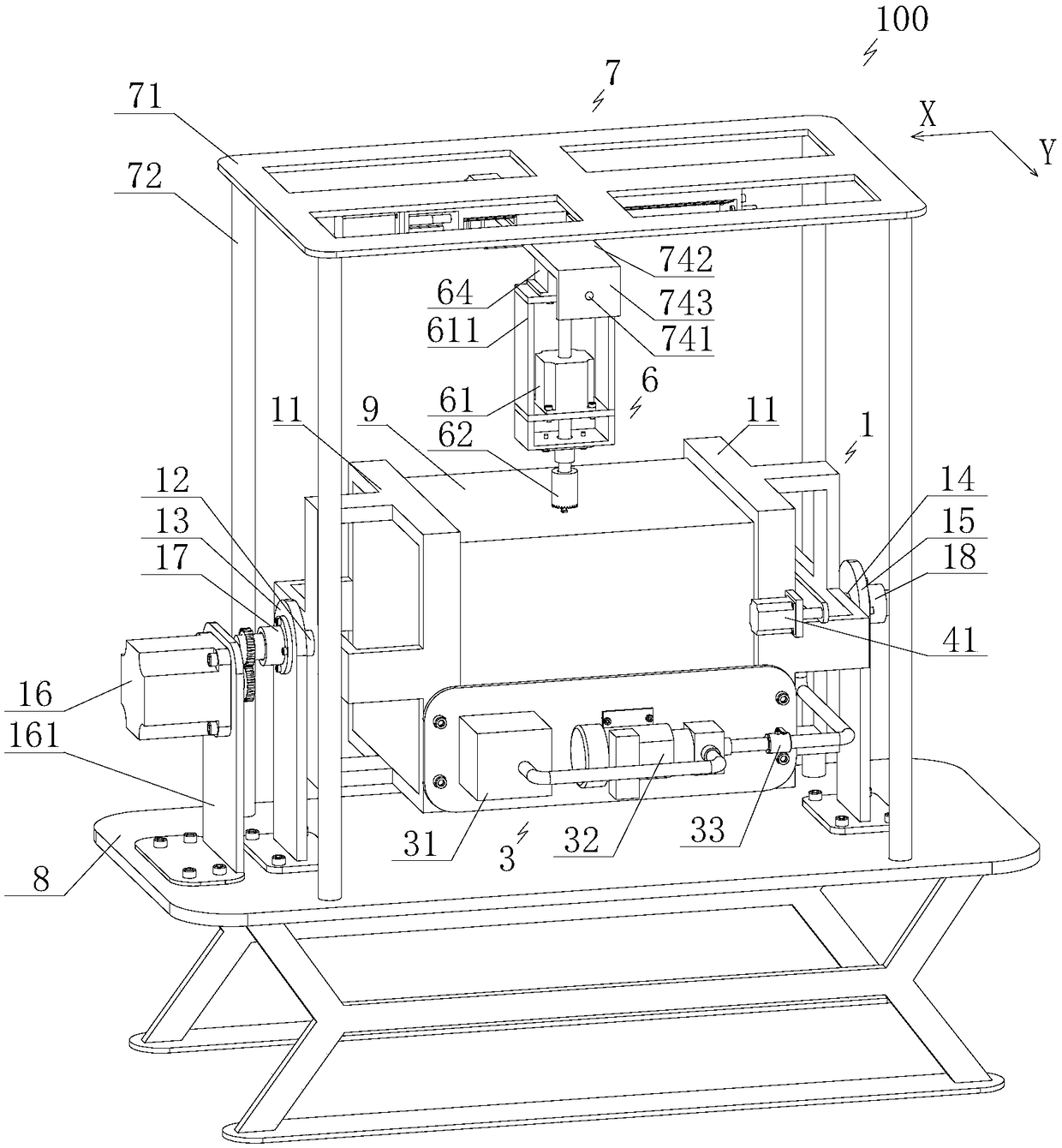

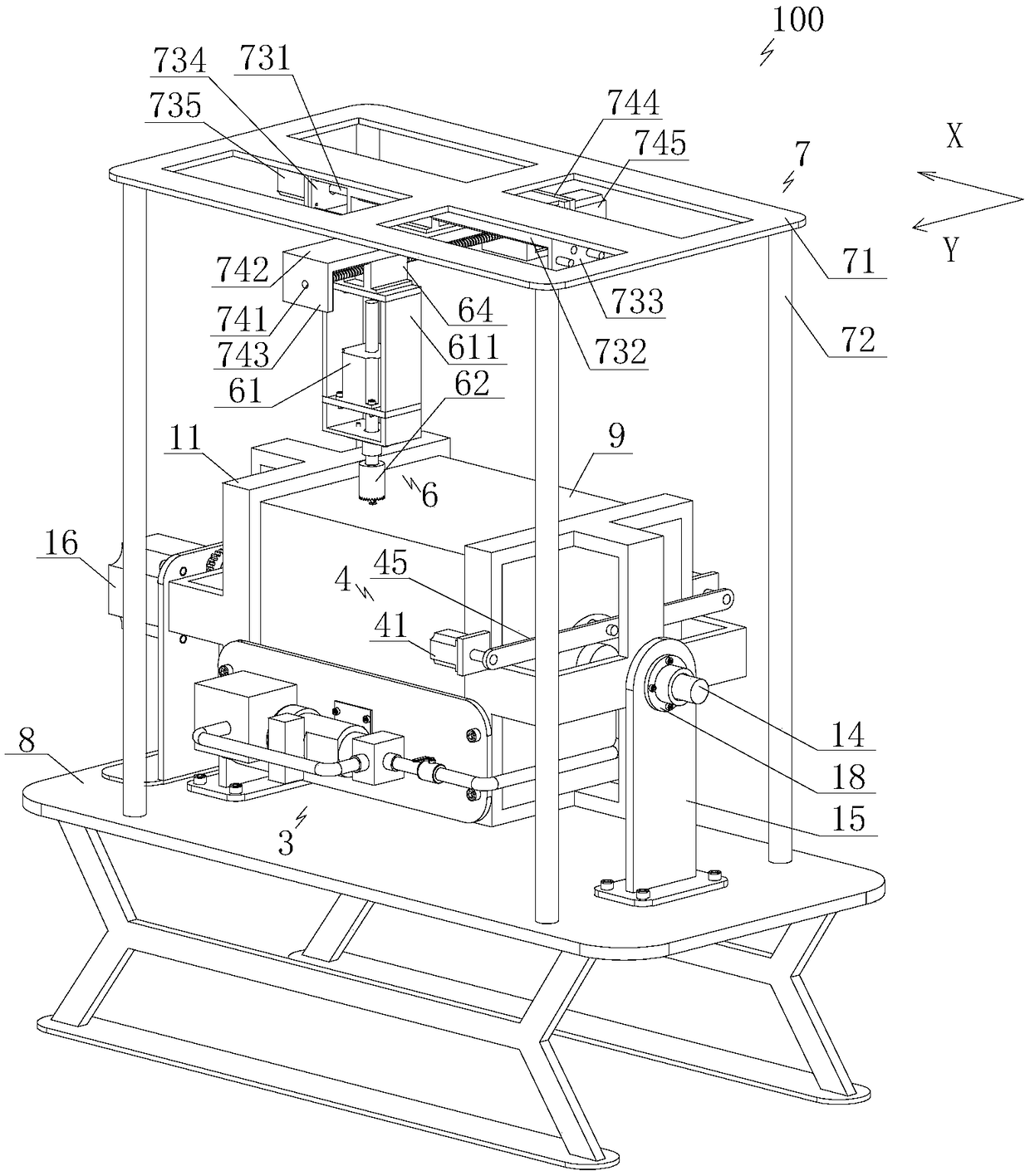

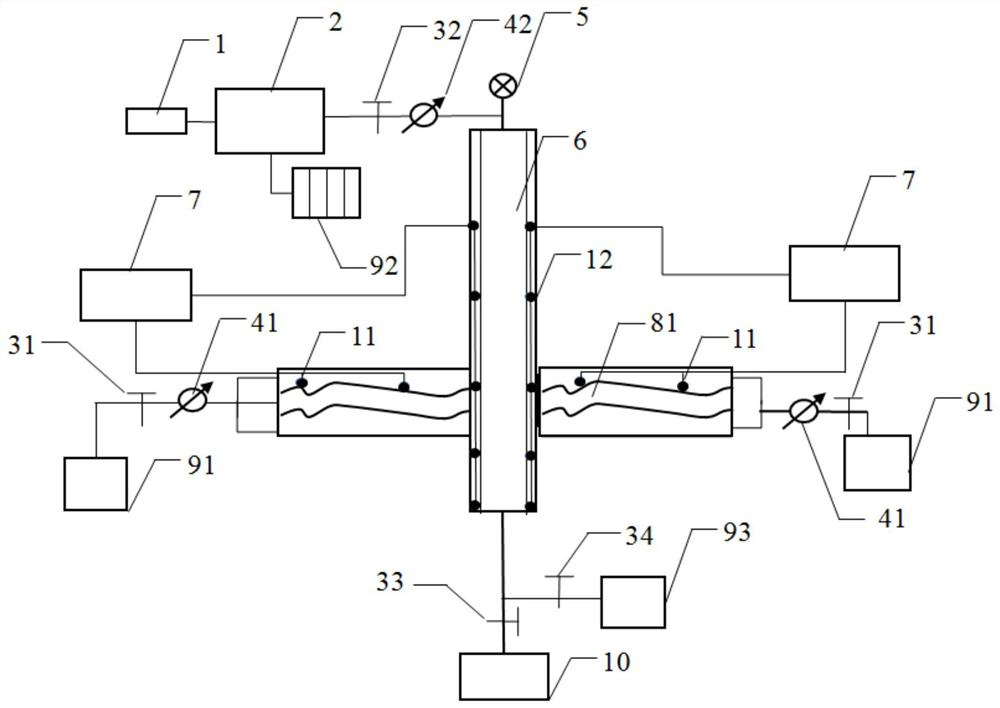

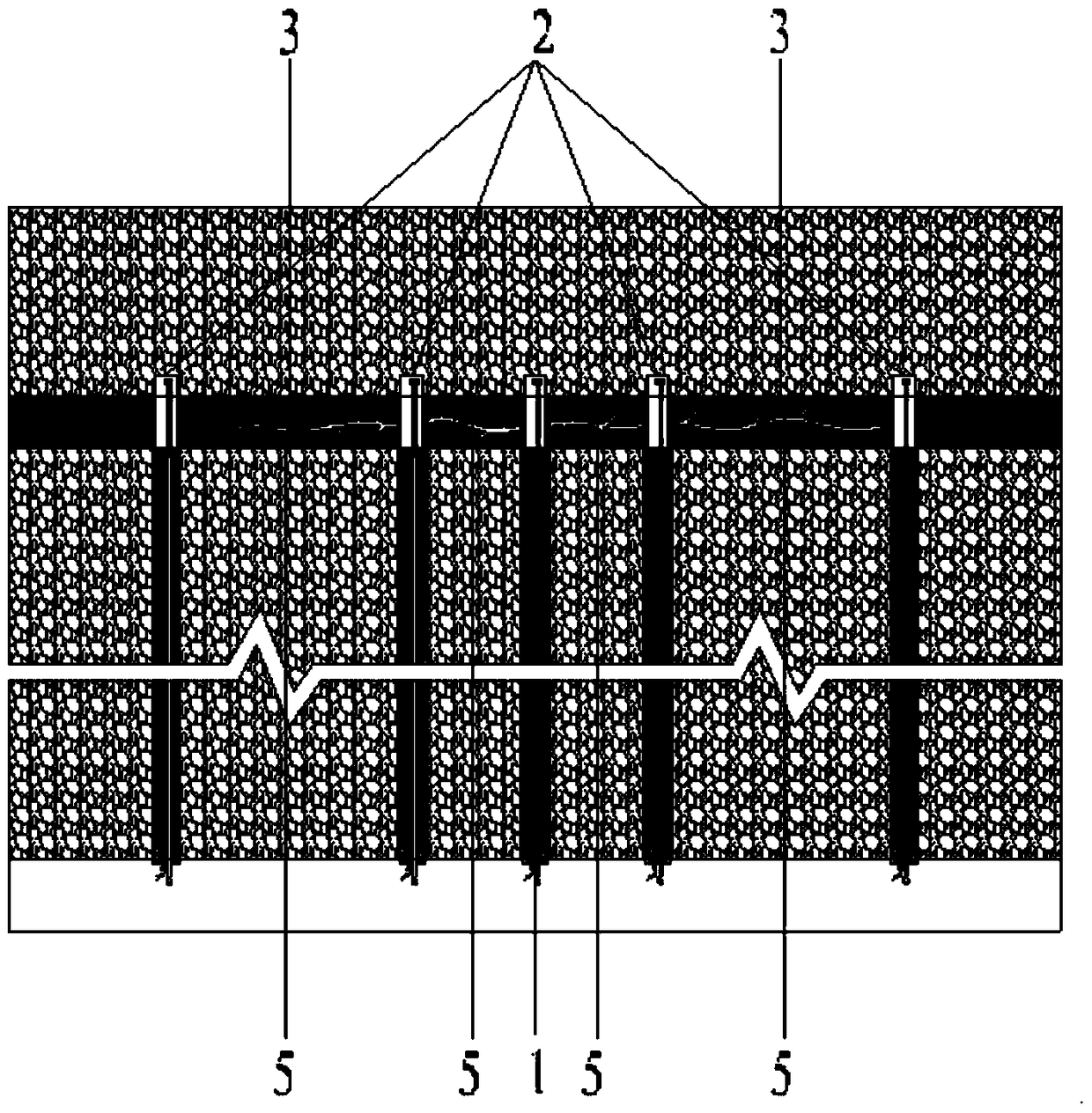

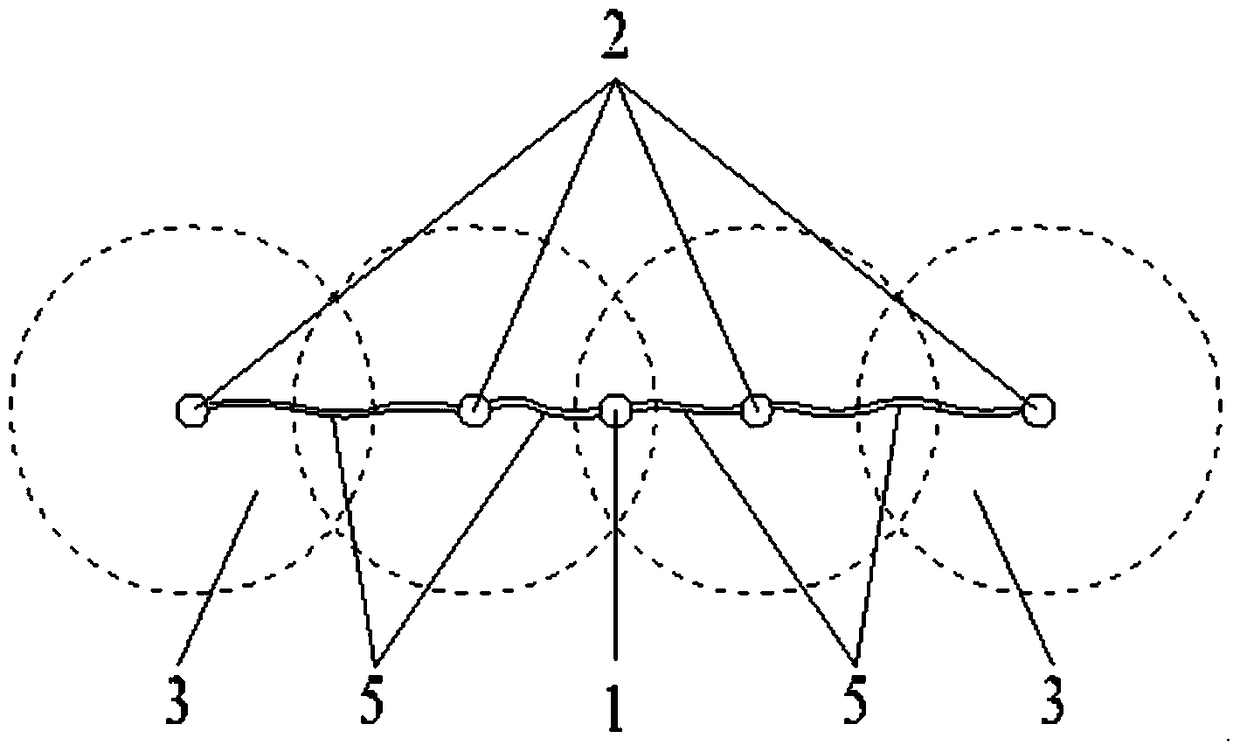

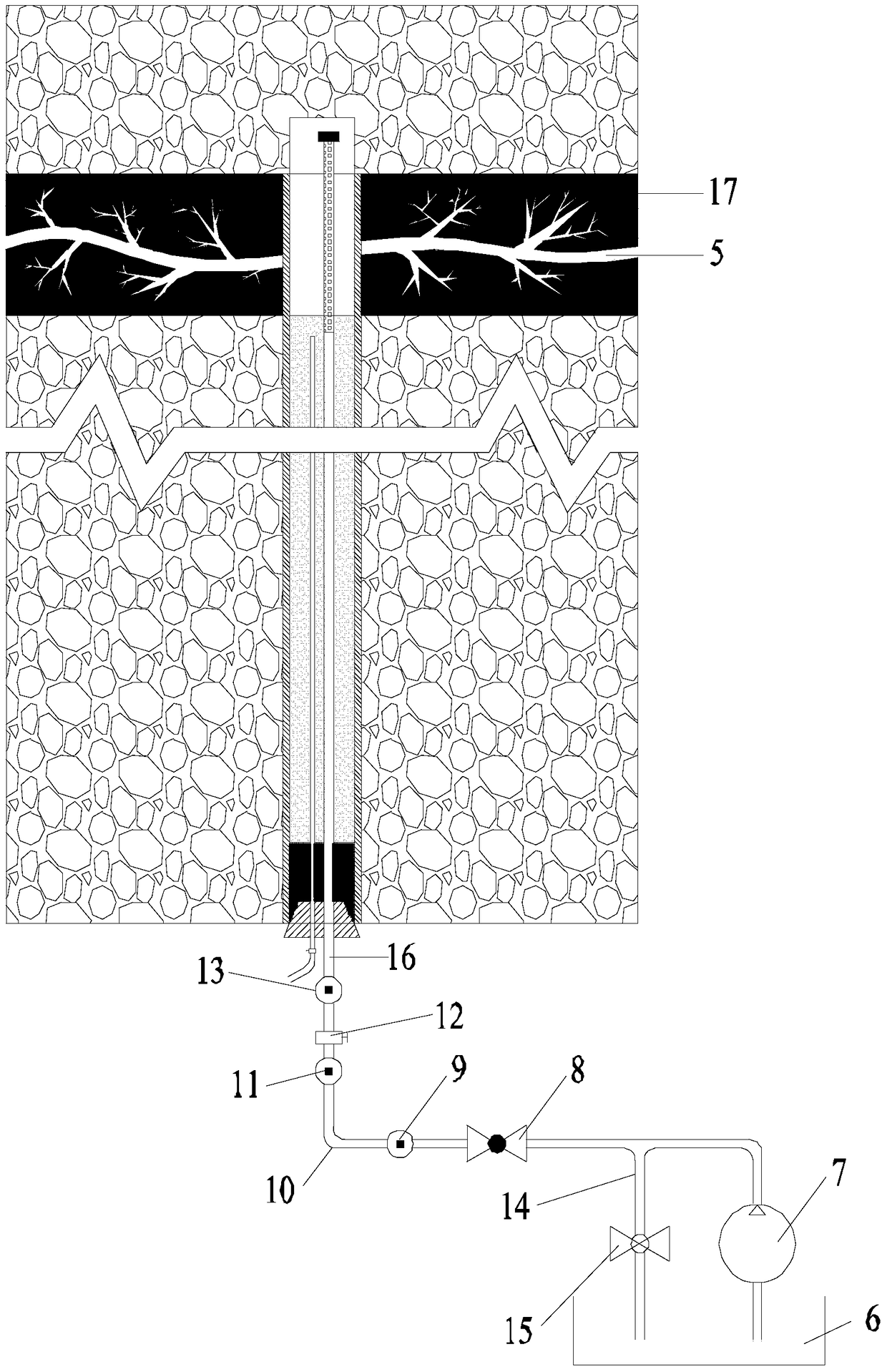

Simulating device and method for water producing source and pressure-dropping path during coal-rock reservoir discharge and recovery

ActiveCN107288632AReduce the difficulty of clampingFluid Flow MonitoringSurveyAxial pressureLiquid storage tank

The invention discloses a simulating device and method for a water producing source and a pressure-dropping path during coal-rock reservoir discharge and recovery. The simulating device comprises a sample clamping assembly, a stratum pressure simulating assembly, a fluid supplying / discharging assembly and an information acquisition and control assembly. The sample clamping assembly comprises at least one clamping device, and each clamping device comprises a coal sample clamping device body and a rock sample clamping device body arranged above the coal sample clamping device body. The stratum pressure simulating assembly comprises an oil tank, an oil pressure pump, a flow divider, an axial pressure loading cylinder and a confining pressure loading cylinder. The fluid supplying / discharging assembly comprises a fluid storage tank, a booster pump, a quantitative fluid storage tank and a simulating shaft. Through the simulating device and method, the developing characteristic, the permeability and the water-bearing property of different fractures and flowing of fluids in and between rock stratums in the coal-rock reservoir discharge and recovery process in a combination mode can be simulated, and scientific bases are provided for judgment of the water producing source and the pressure transmission path under the corresponding geological condition.

Owner:HENAN POLYTECHNIC UNIV

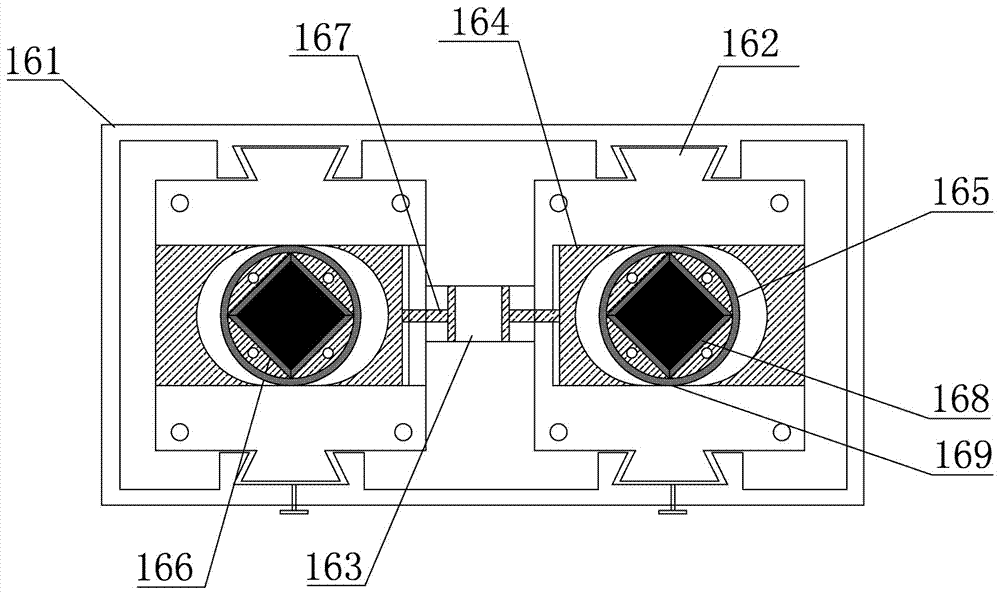

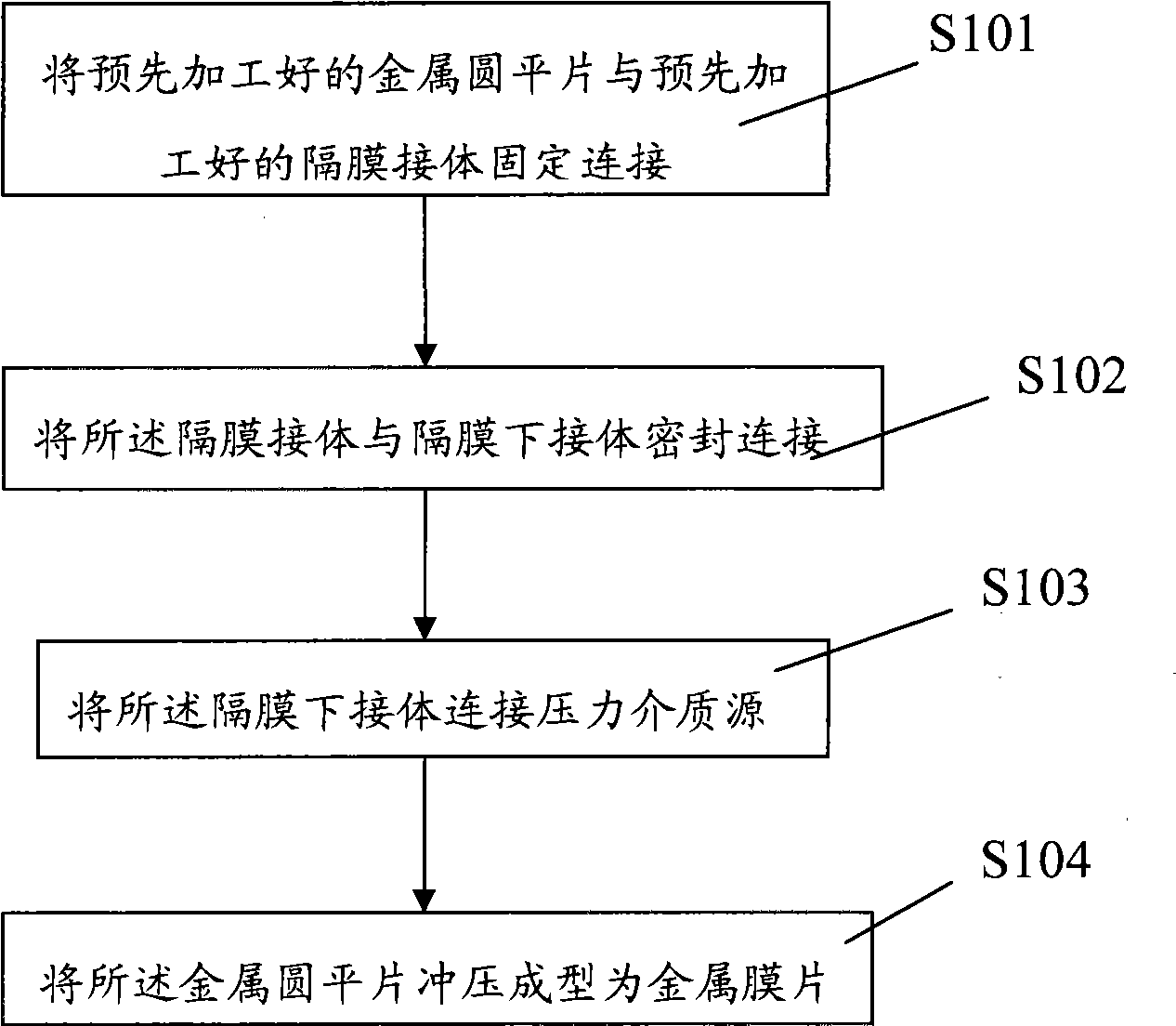

Diaphragm apparatus production method, diaphragm apparatus and diaphragm type pressure meter

InactiveCN101498610AImprove pressure transmission accuracyHigh precisionFluid pressure measurement using elastically-deformable gaugesOvervoltageEngineering

The invention relates to a manufacturing method of a septum device, belonging to the technical field of pressure measuring. The method comprises the following steps: a processed round metal plain film is fixedly connected with a processed septum junctor, an upper septum junctor and a lower septum junctor are connected in a sealing way, the round metal plain film is punched by pressure medium and is jointed with a function surface on the septum junctor under the pressure action of the pressure medium to generate tension set; a function surface completely coinciding with the function surface on the septum junctor is formed on the round metal plain film which is shaped as a metal film with waviness; the metal film is provided with a function surface completely coinciding with the function surface on the septum junctor, the junctor has accurate positioning and accordant die space and especially plays the role of overvoltage protection, so the metal film cannot be damaged in overvoltage, thereby the pressure propagation precision of the septum device is enhanced. The invention also provides a septum device and a septum pressure gauge.

Owner:BEIJING BRIGHTY INSTR

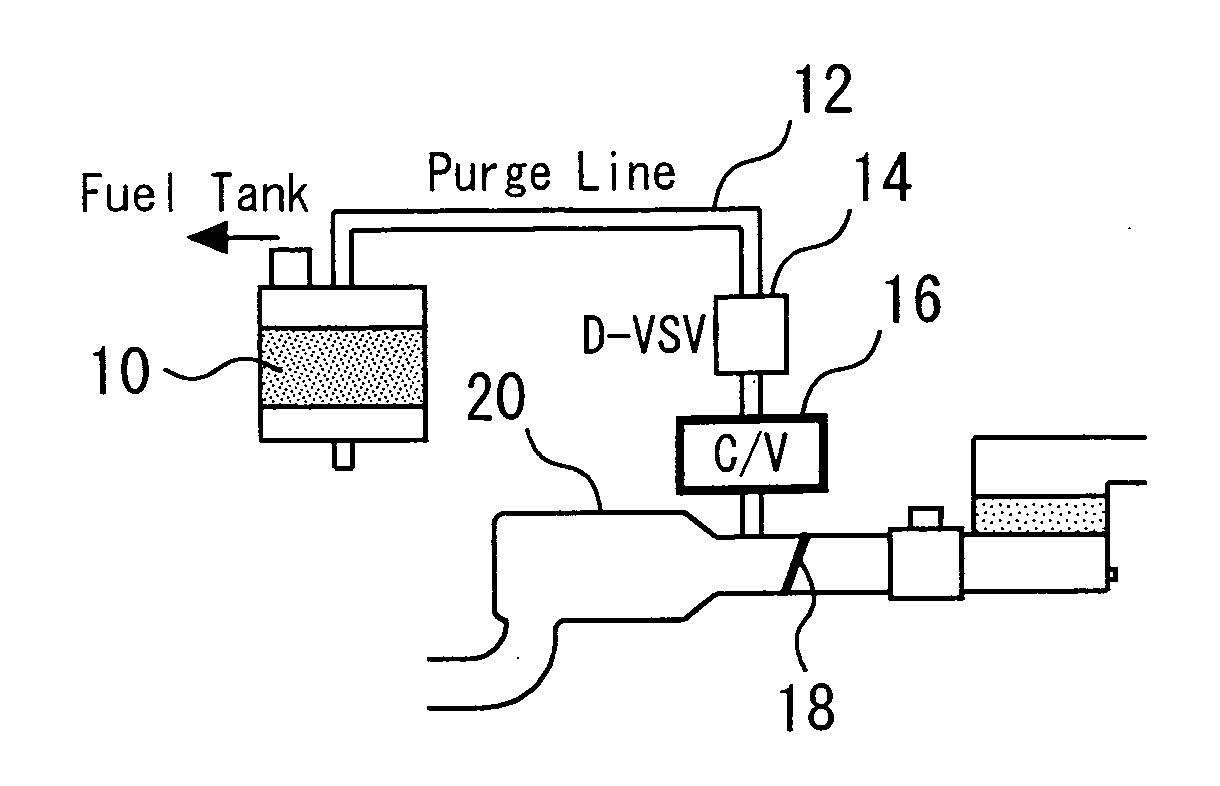

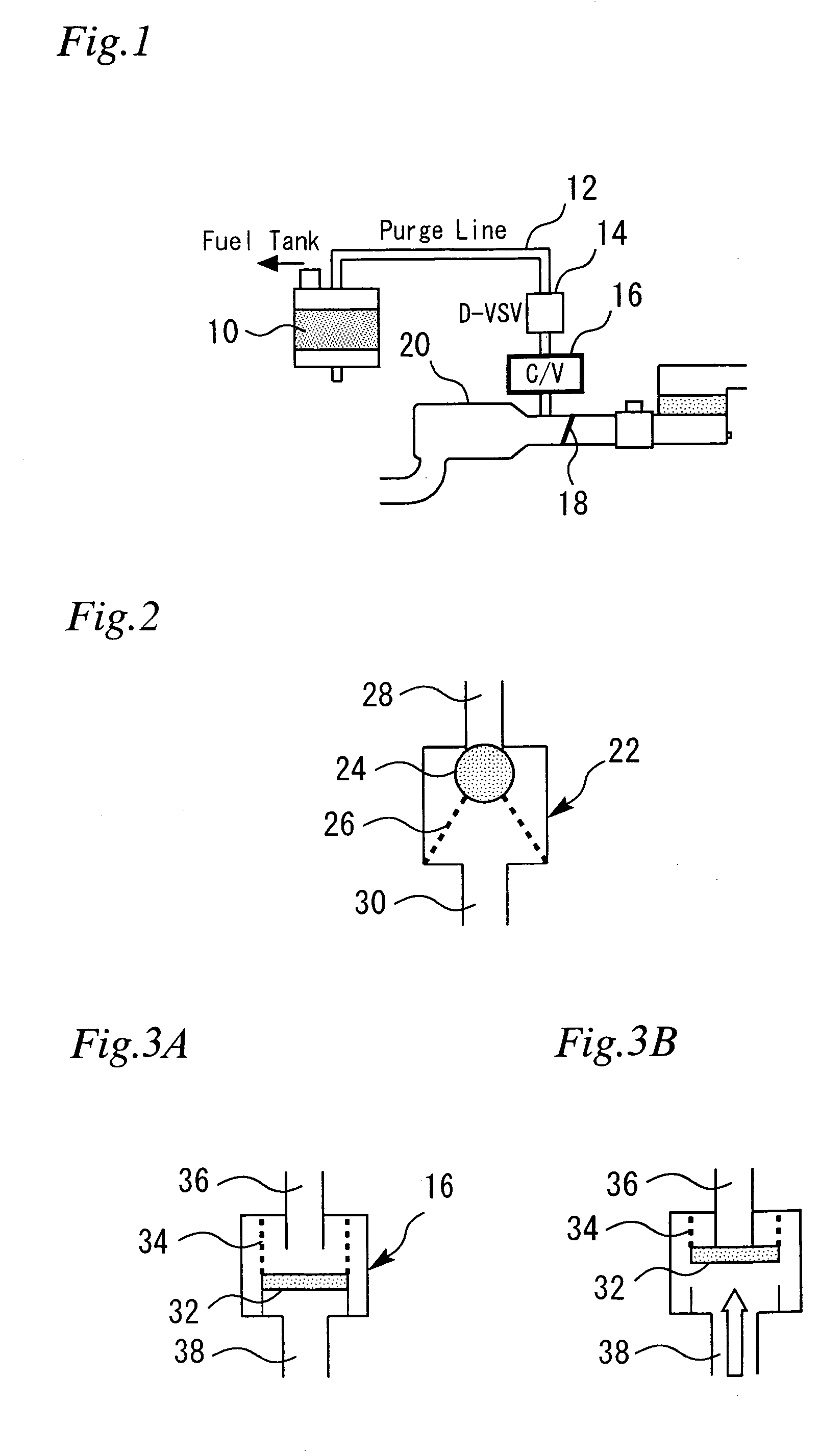

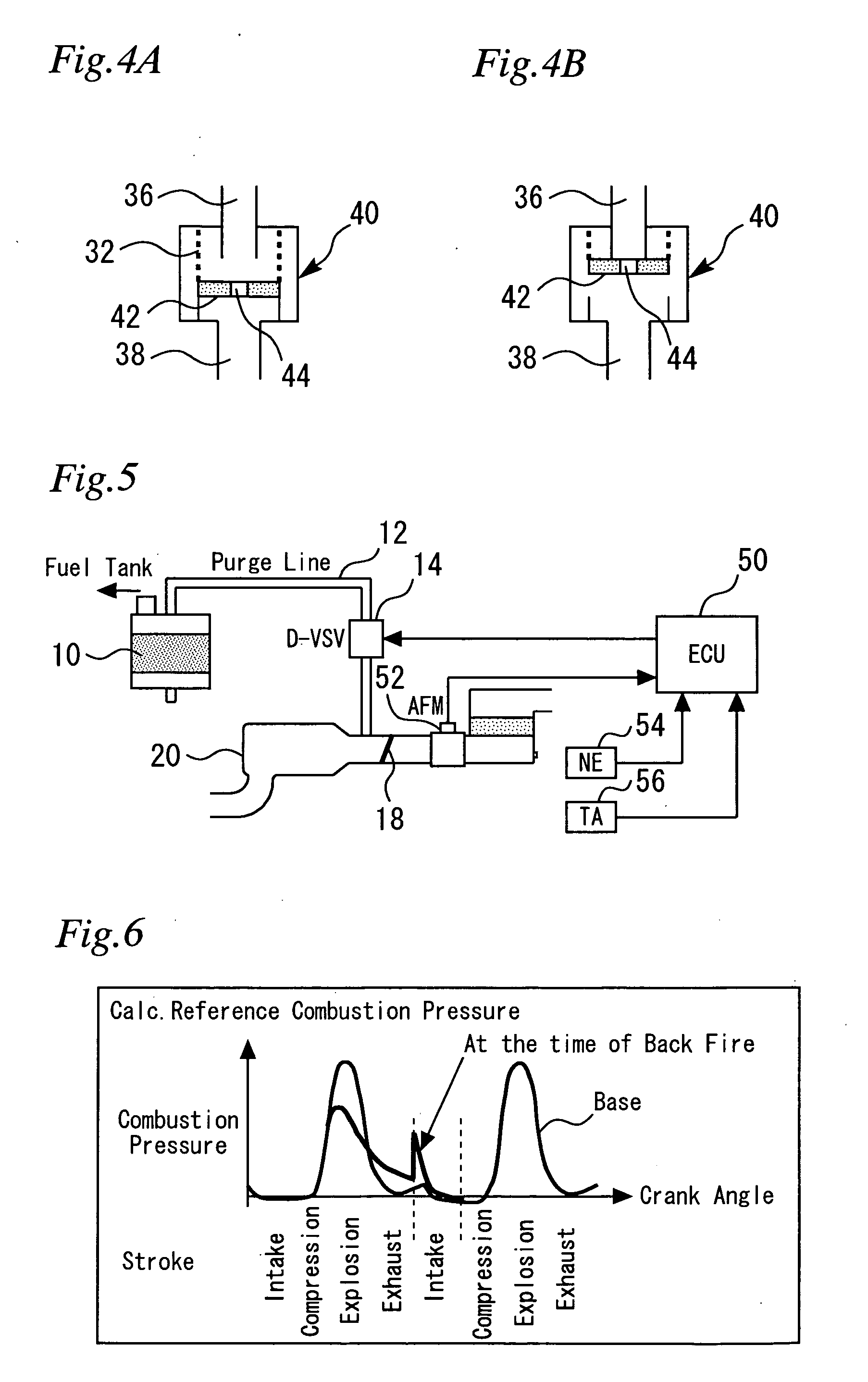

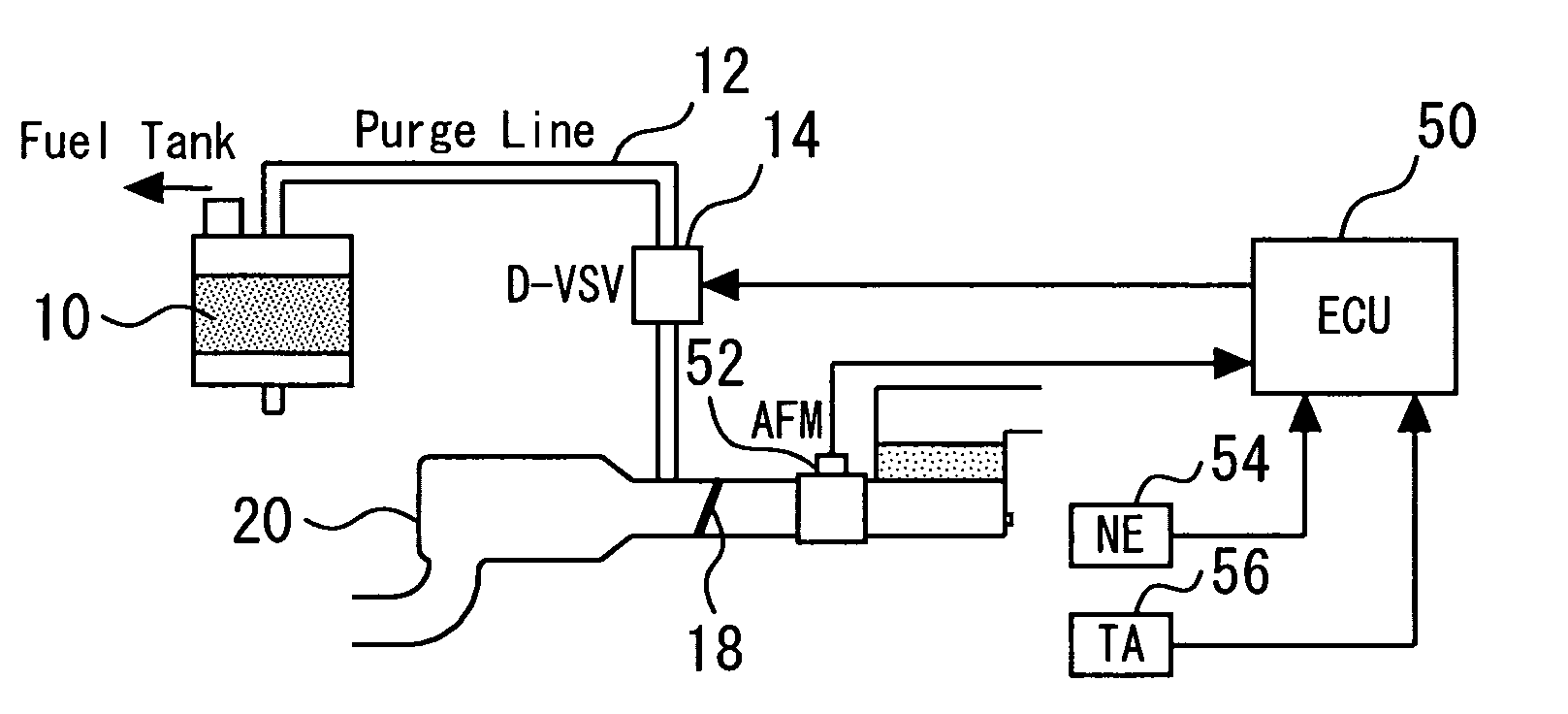

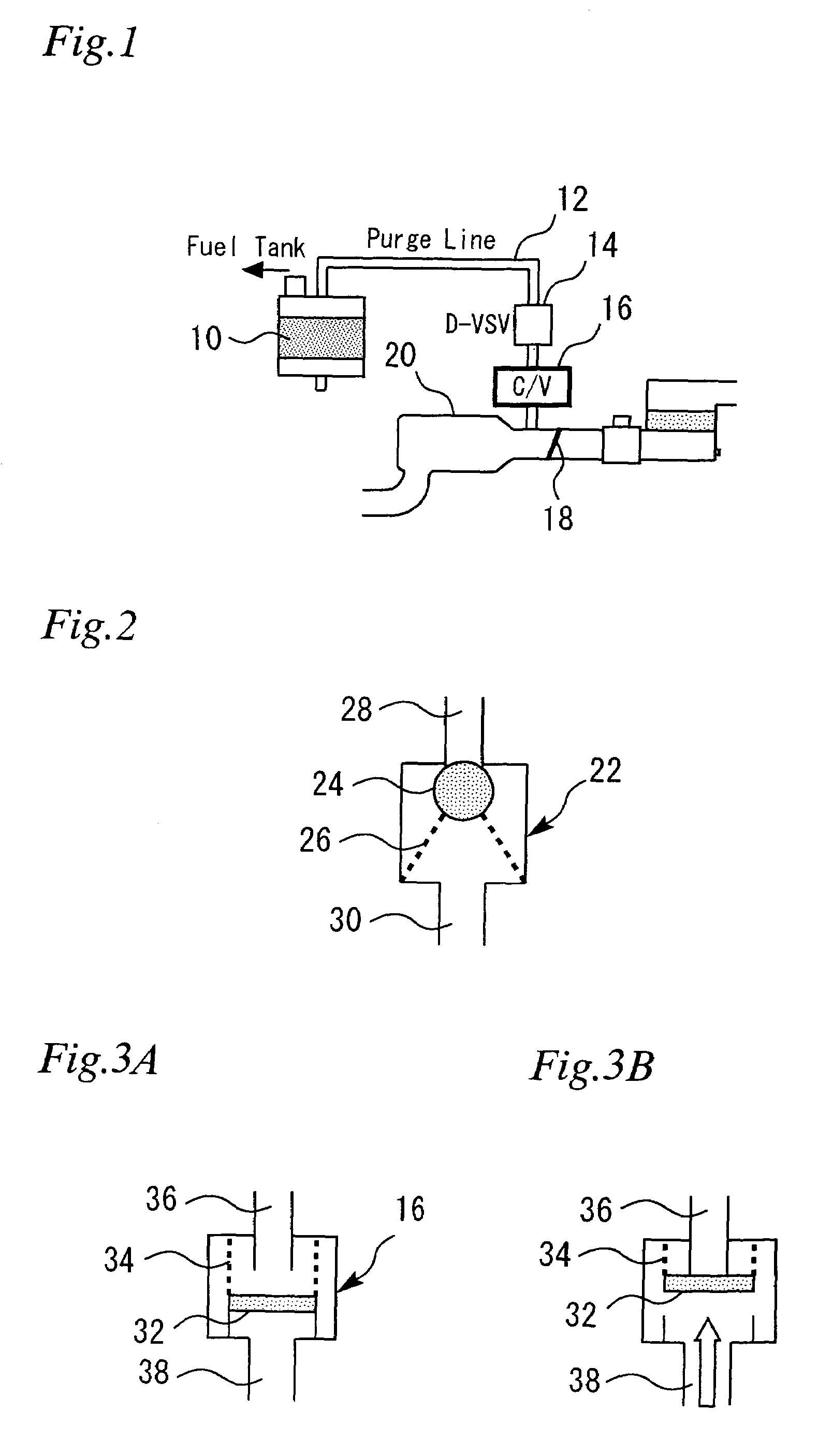

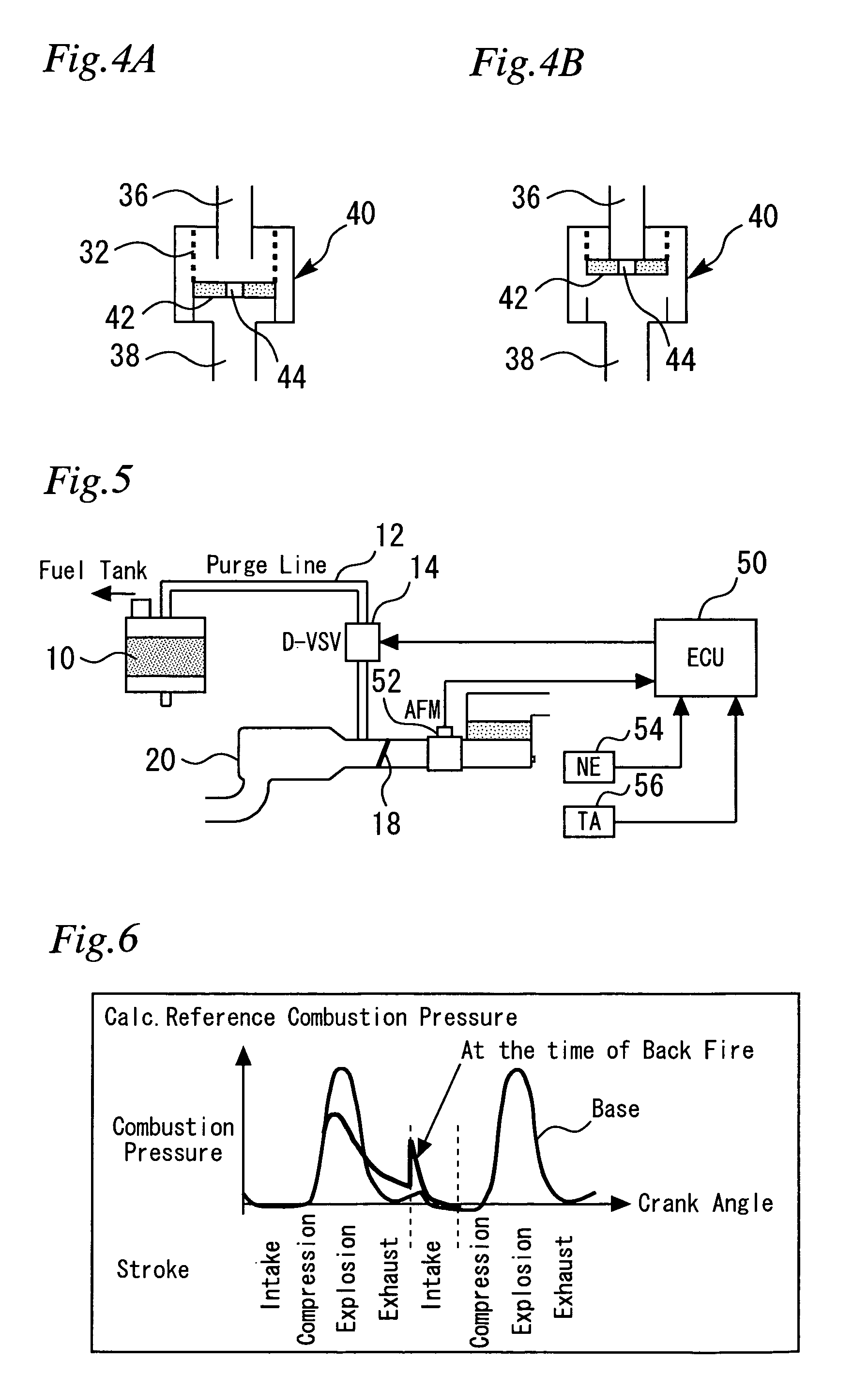

Evaporative fuel supply apparatus

InactiveUS20060037588A1Electrical controlNon-fuel substance addition to fuelEngineeringPressure propagation

A canister is furnished to store evaporative fuel. A purge line is furnished to ensure that the canister communicates with an internal combustion engine intake path. The purge line is provided with a D-VSV (purge control valve) that controls the continuity of the purge line. Further, a check valve is furnished to control the pressure propagation from the intake path to the canister at the time of backfiring.

Owner:TOYOTA JIDOSHA KK

Water leakage monitoring system

ActiveUS8072340B2Good estimateImprove leakageDetection of fluid at leakage pointFlow propertiesWater leakageTime lag

A water leakage monitoring system including a water leakage position estimator which includes a periodic data acquiring unit for fetching predetermined-period flow rate pressure data stored in a monitoring device, and for fetching a signal related to a flow rate change and pressure changes expecting a water leakage reaction time calculating unit for calculating a pressure reaction time lag between two pressure changes, a pressure propagation velocity estimating unit for estimating a pressure propagation velocity using the pressure reaction time lag and a distance between two pressure gauges located in a water distribution block stored in a pipeline network map data, and a flow rate change position estimating unit for receiving a signal related to the flow rate change, and estimating a flow rate change position using pressure propagation velocity and a flow meter and pressure gauge locating positions of the pipeline network map data.

Owner:TOSHIBA INFRASTRUCTURE SYST & SOLUTIONS CORP +1

Evaporative fuel supply apparatus

InactiveUS7334559B2Electrical controlNon-fuel substance addition to fuelPressure propagationControl valves

A canister is furnished to store evaporative fuel. A purge line is furnished to ensure that the canister communicates with an internal combustion engine intake path. The purge line is provided with a D-VSV (purge control valve) that controls the continuity of the purge line. Further, a check valve is furnished to control the pressure propagation from the intake path to the canister at the time of backfiring.

Owner:TOYOTA JIDOSHA KK

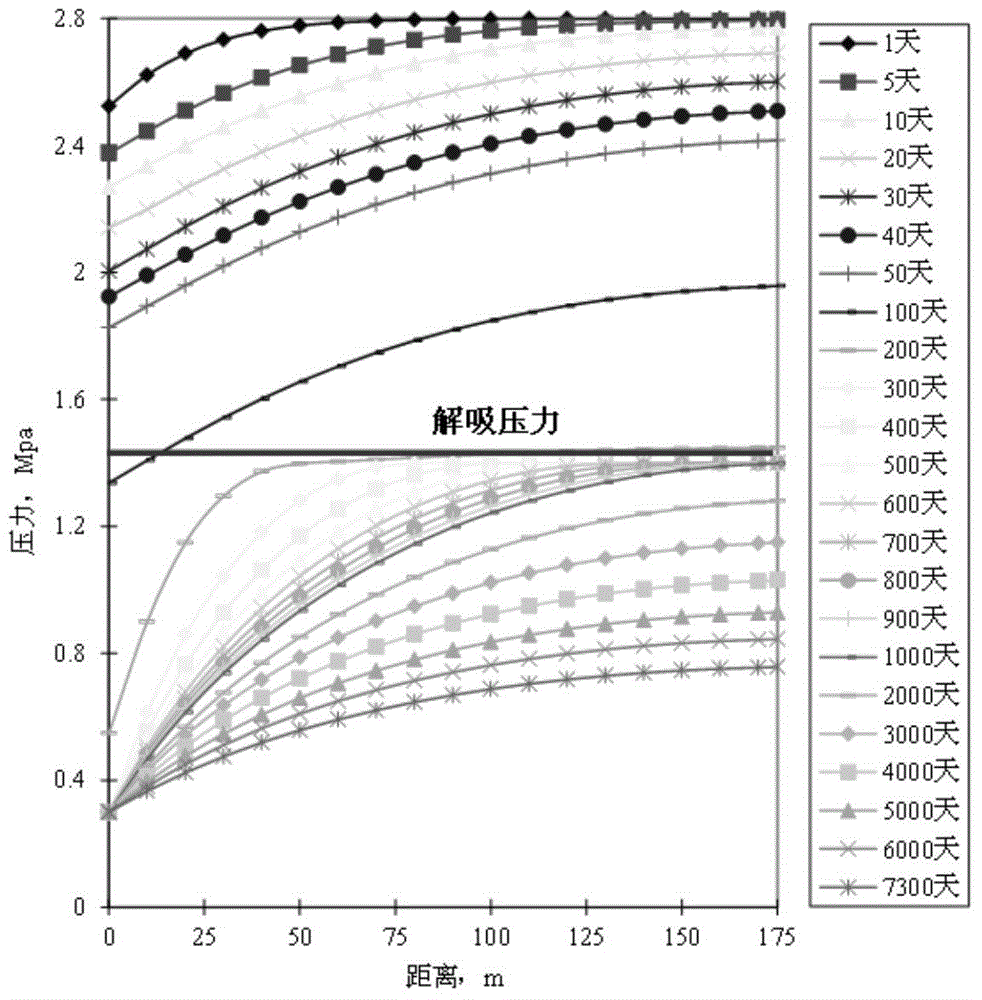

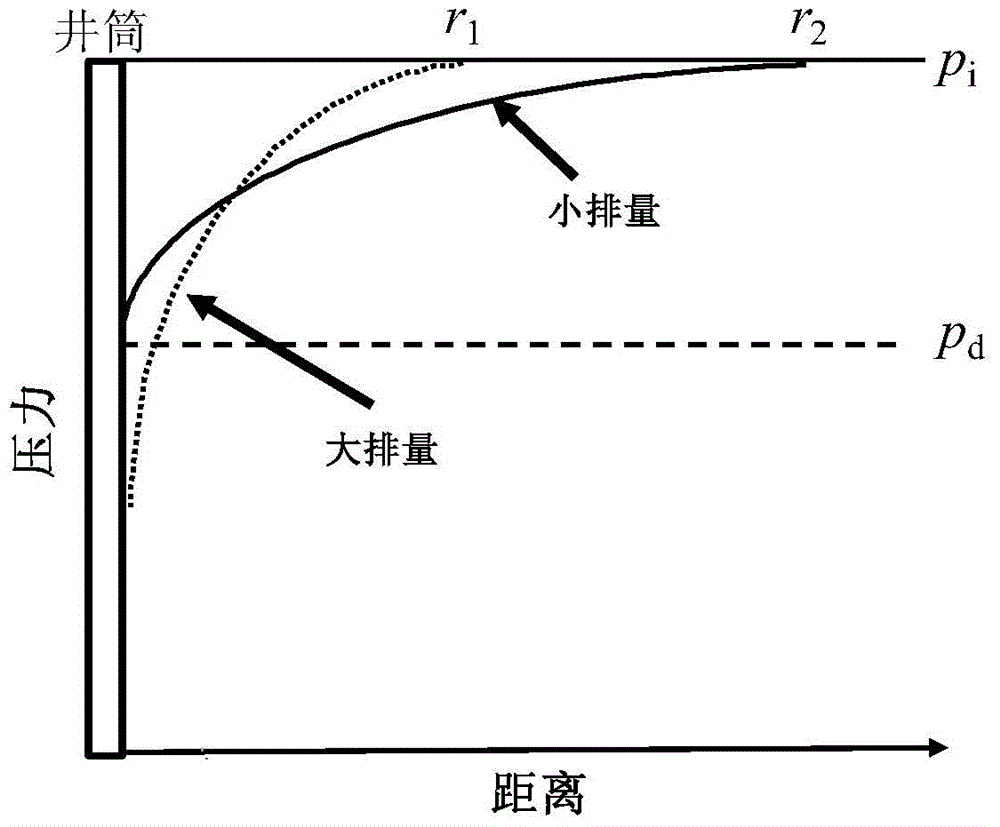

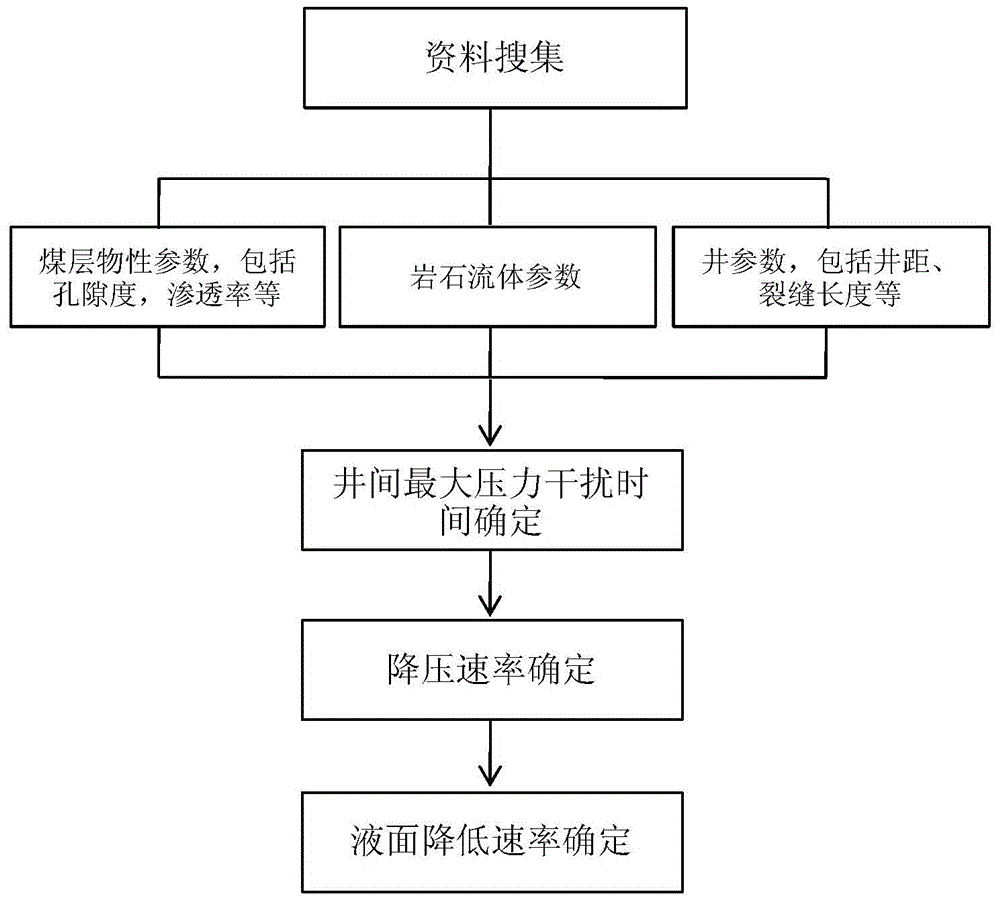

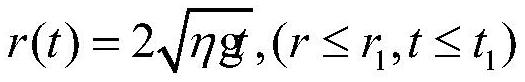

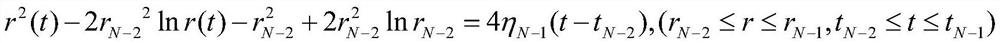

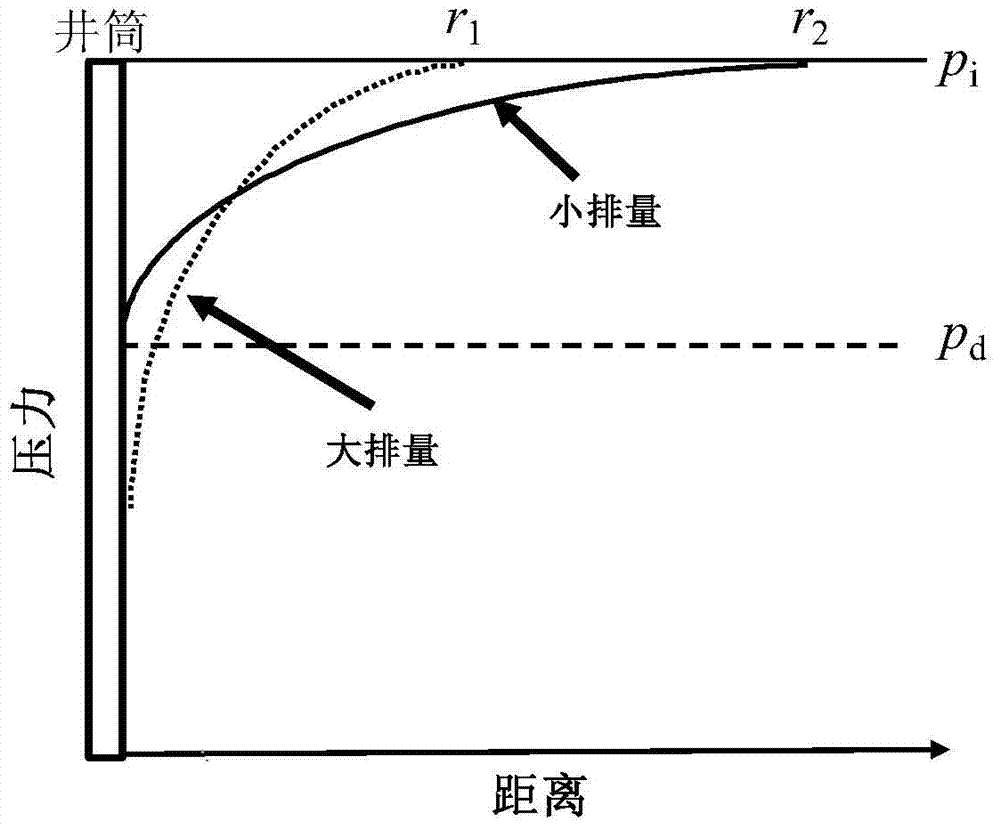

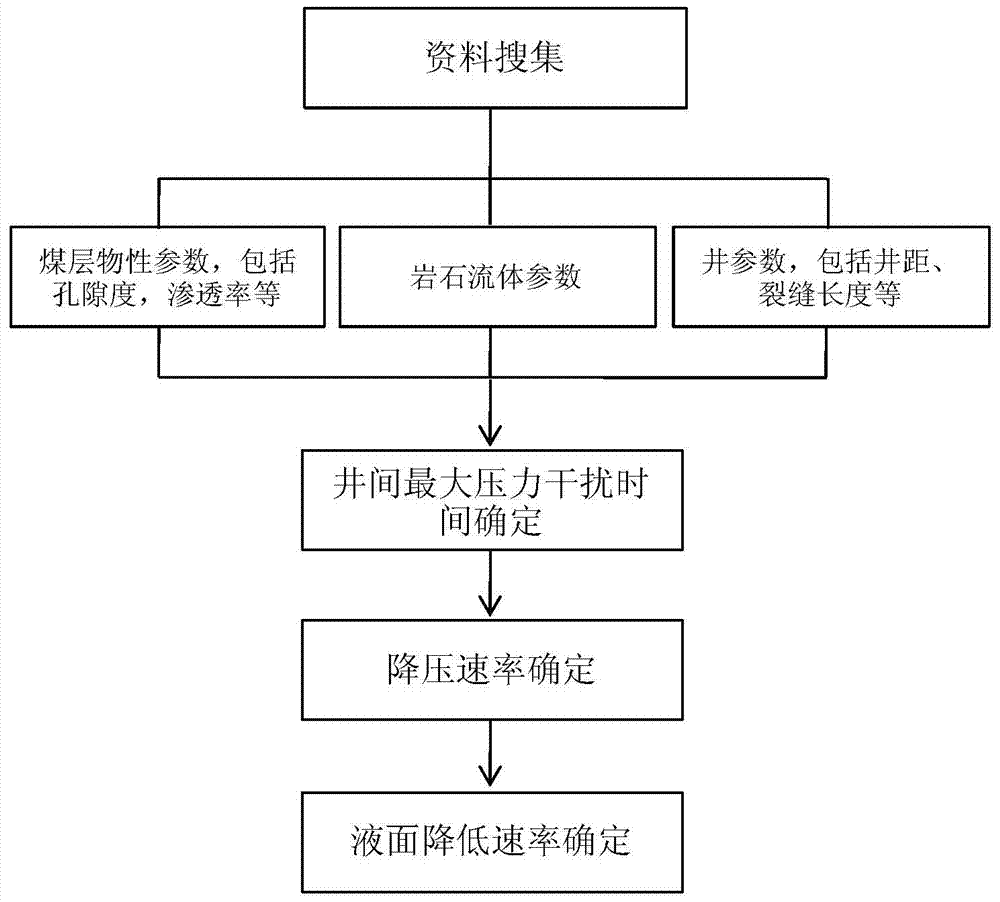

Pressure-propagation-based method for determining discharge and recovery speed at initial stage of coalbed methane exploitation

ActiveCN104863547AFluid removalSpecial data processing applicationsInitial rateQuantitative determination

The invention relates to a pressure-propagation-based method for determining the discharge and recovery speed at the initial stage of coalbed methane exploitation. The method comprises the following steps: (1) according to the pressure propagation distance and time relationship, determining time required for inter-well pressure interference under the conditions of given well patterns and spacing; (2) determining the pressure reduction rate by virtue of the balanced step-down concept according to the inter-well pressure interference required time obtained in the step (1); (3) determining the liquid level descending rate of a shaft according to the pressure reduction rate obtained in the step (2). The pressure-propagation-based method has a strict theoretical basis, realizes quantitative determination of the discharge and recovery speed at the initial stage of coalbed methane exploitation, and can be widely applied to quantitative determination of the discharge and recovery speed at the initial stage of coalbed methane exploitation of coalbed gas fields under different reservoir physical conditions.

Owner:CHINA NAT OFFSHORE OIL CORP +1

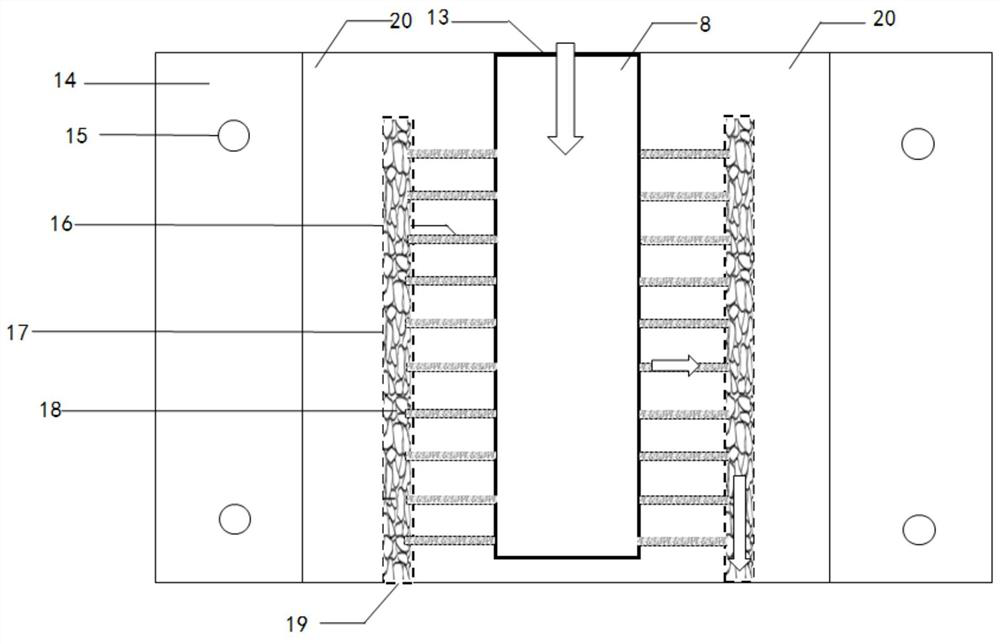

Strain gauge type pressure test tight oil inhibition experimental device

ActiveCN108979630AIntuitive observation of displacement phenomenonSurveyFluid removalLeading edgeElectrical resistance and conductance

The invention relates to a strain gauge type pressure test tight oil inhibition experimental device, comprising a rock fixture structure and further comprising a control unit. The rock fixture structure can clamp rock containing tight oil and rotate around a horizontal shaft; a horizontal fracturing pipe runs from one side of the rock containing tight oil, one end of the fracturing pipe is connected with a fracturing fluid injection structure, and the fracturing pipe is provided with an inhibition cabin linkage sealing structure; the inhibition cabin linkage sealing structure is provided withmultiple resistance strain gauges; besides, a potential and resistance inhibition test structure is arranged above the rock fixture structure; the control unit can control working status of the fracturing fluid injection structure, the inhibition cabin linkage sealing structure and the potential and resistance inhibition test structure. The device can be used for testing oil and water displacement and oil production effect of fracturing fluid prepared based on different formulas, can analyze pressure propagation speed in inhibition process and oil and water displacement leading-edge position,and has a great significance in optimized evaluation on soaking effect of the fracturing fluid of different formulas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

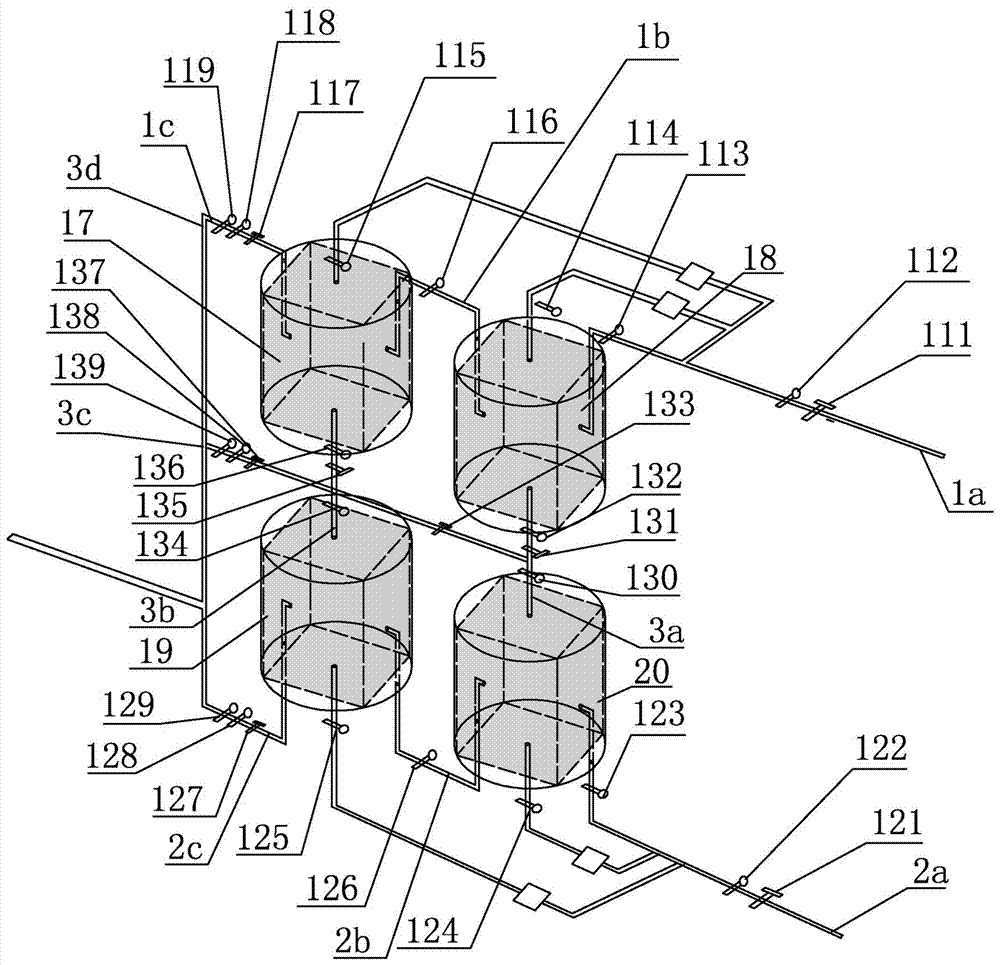

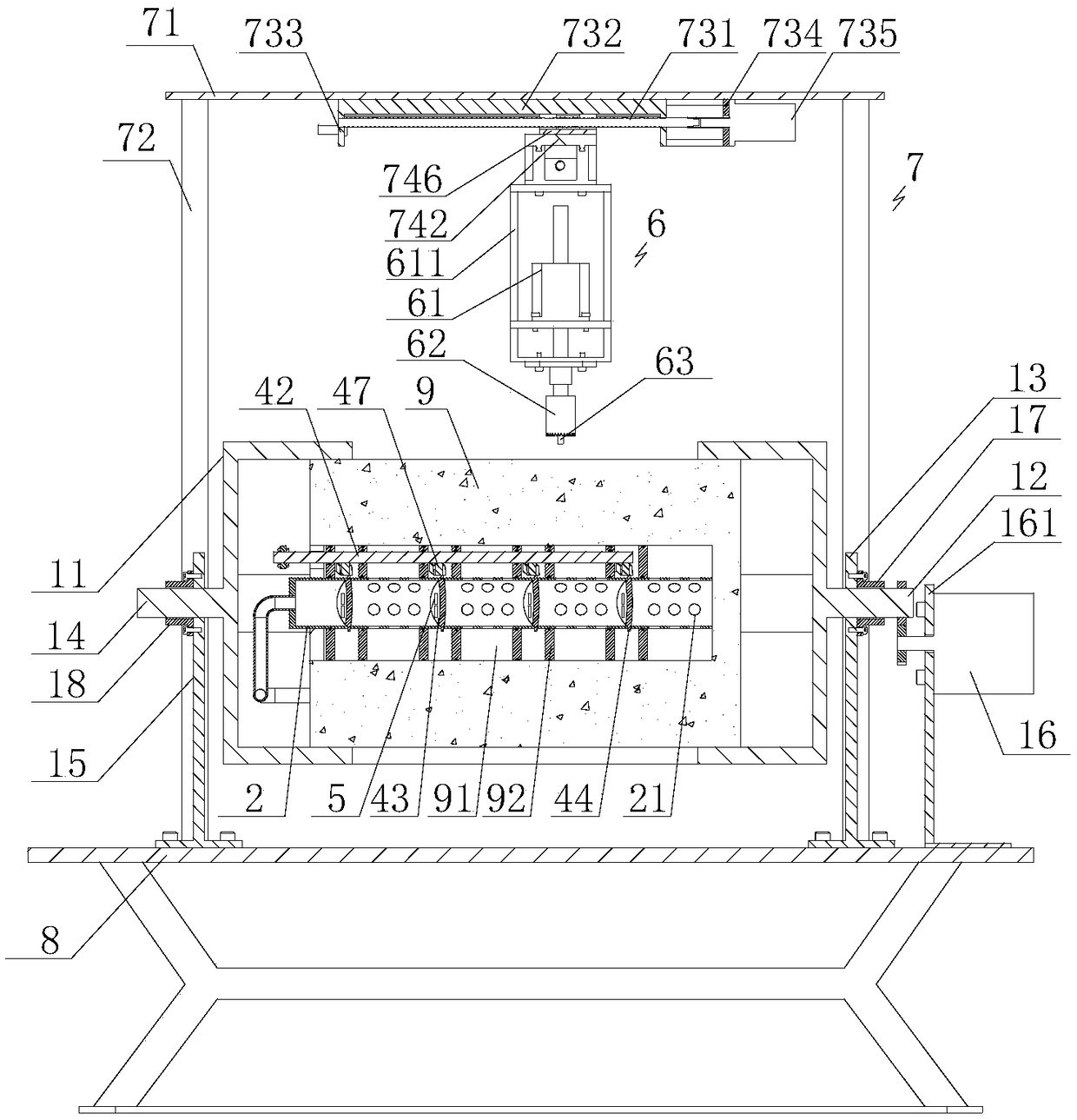

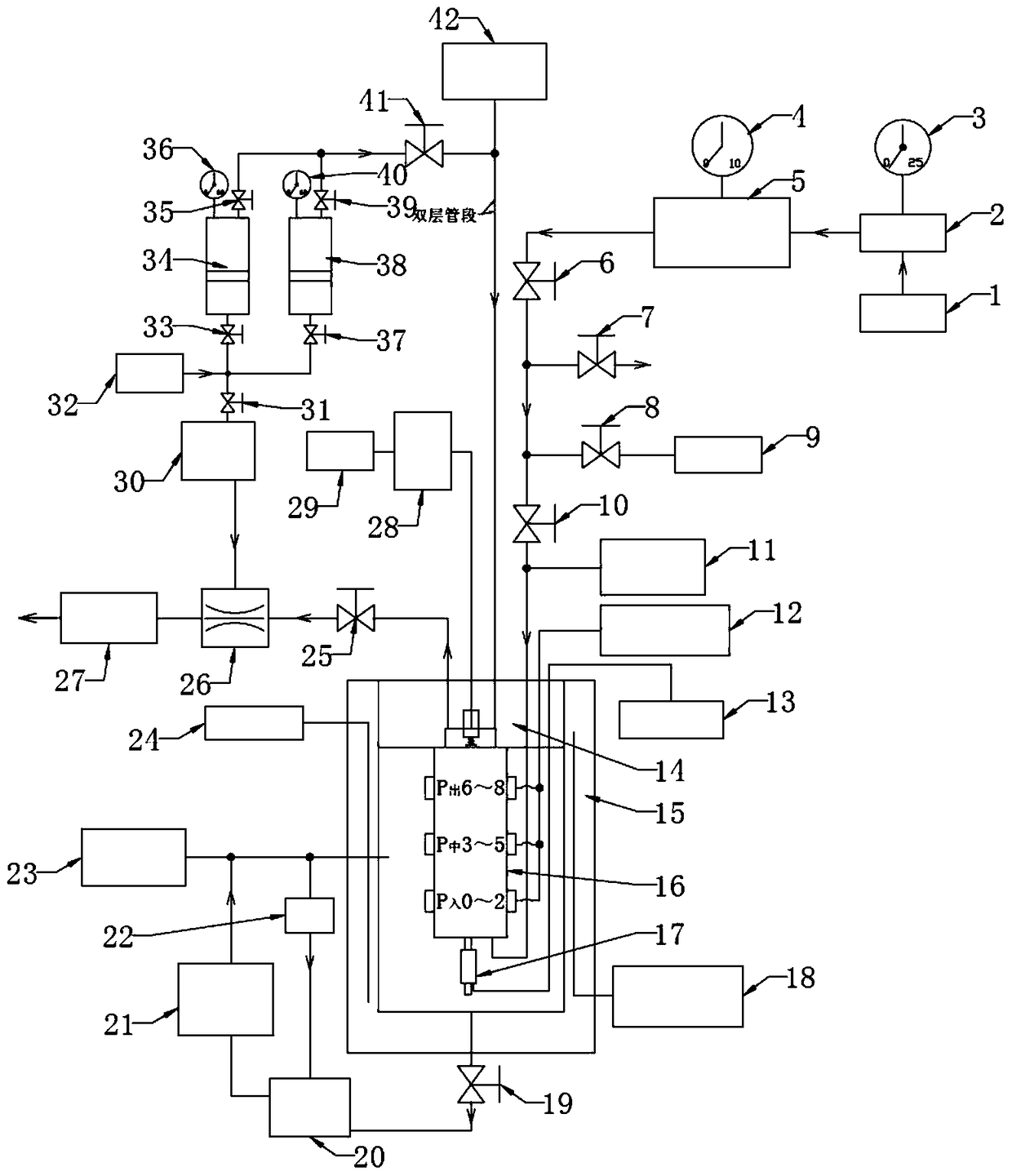

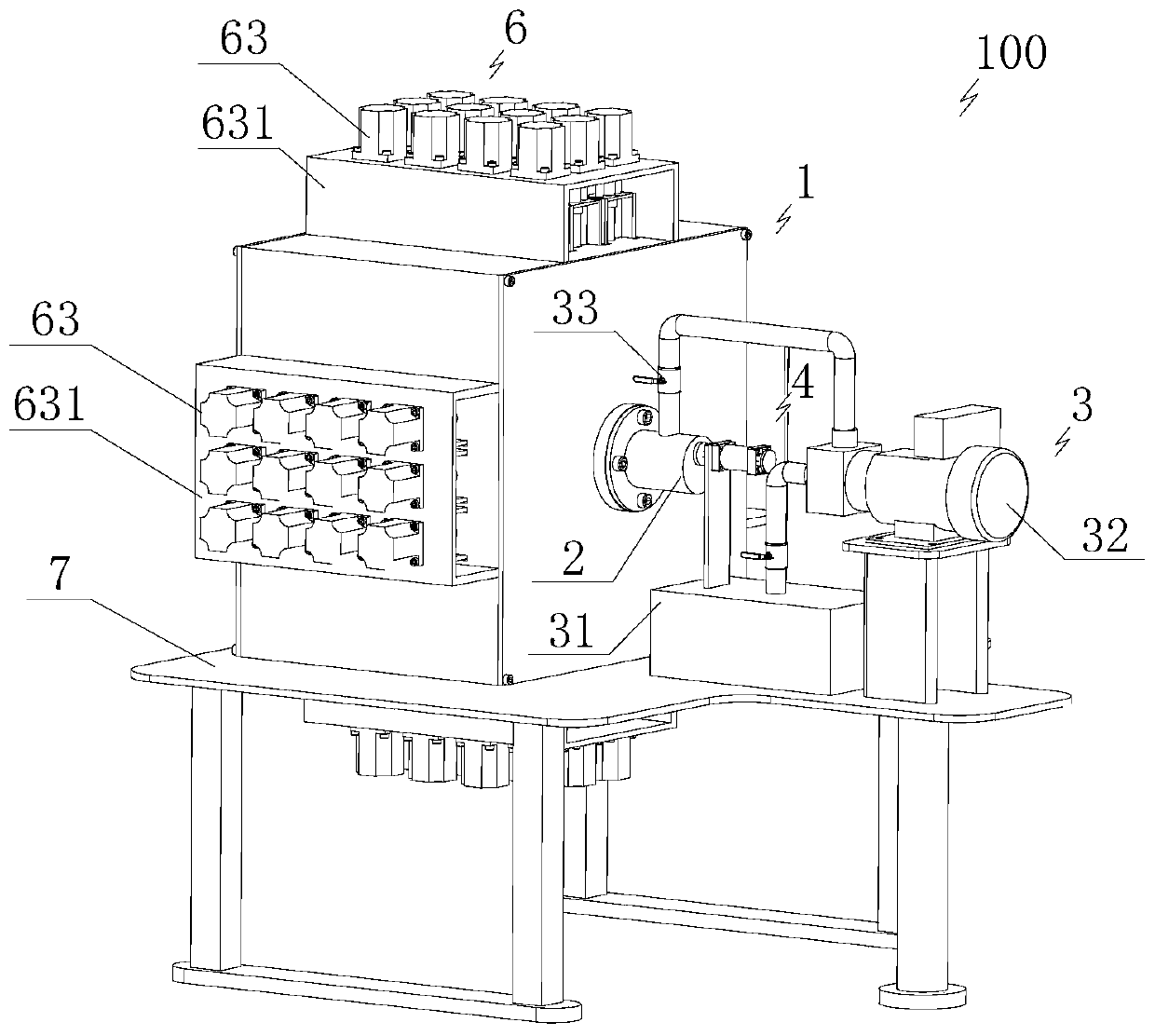

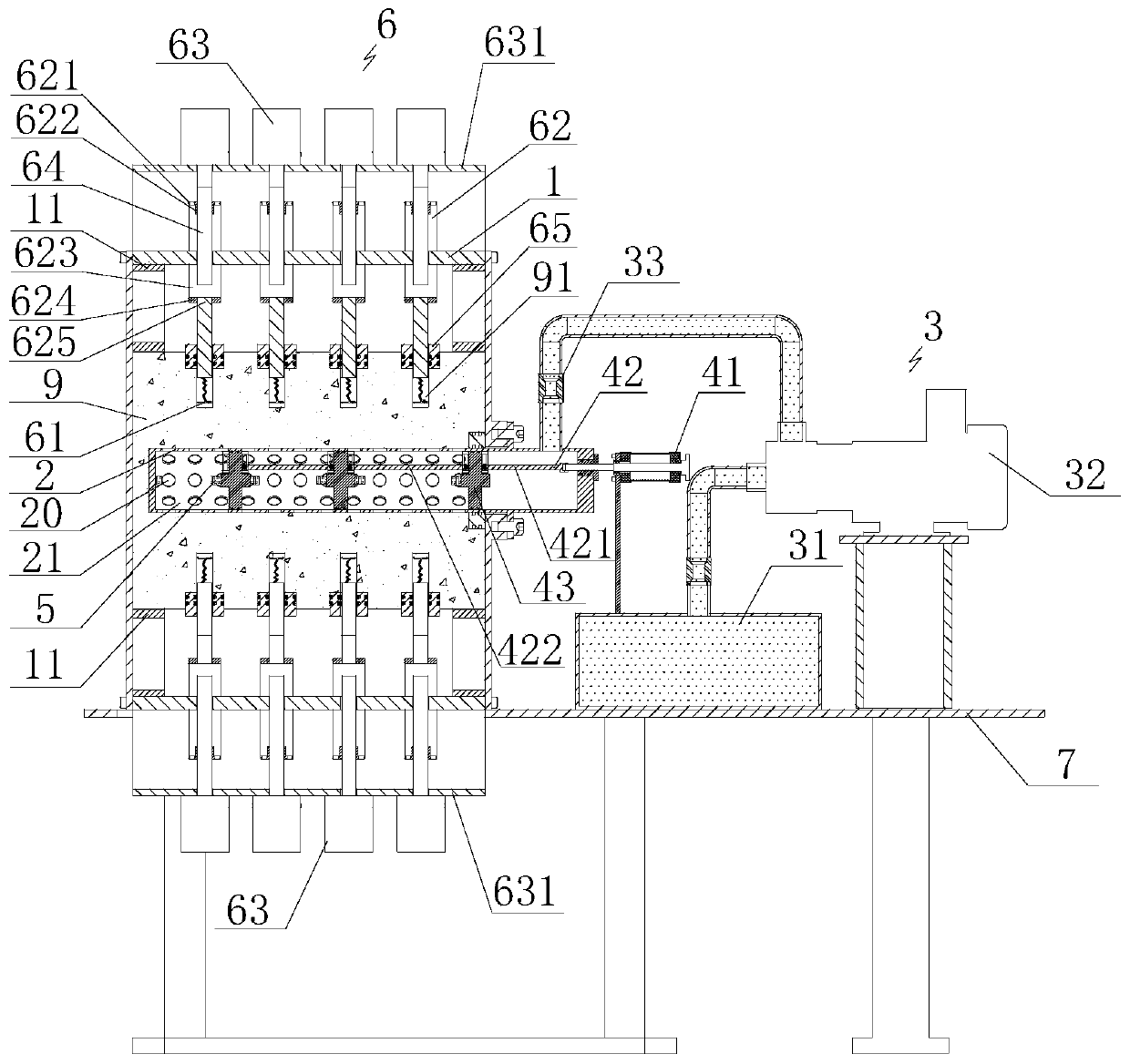

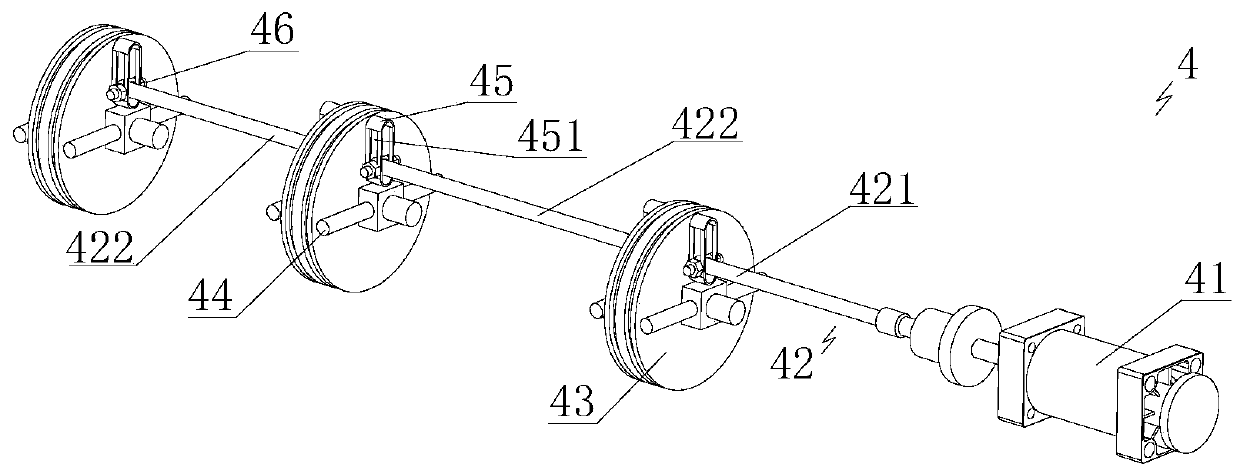

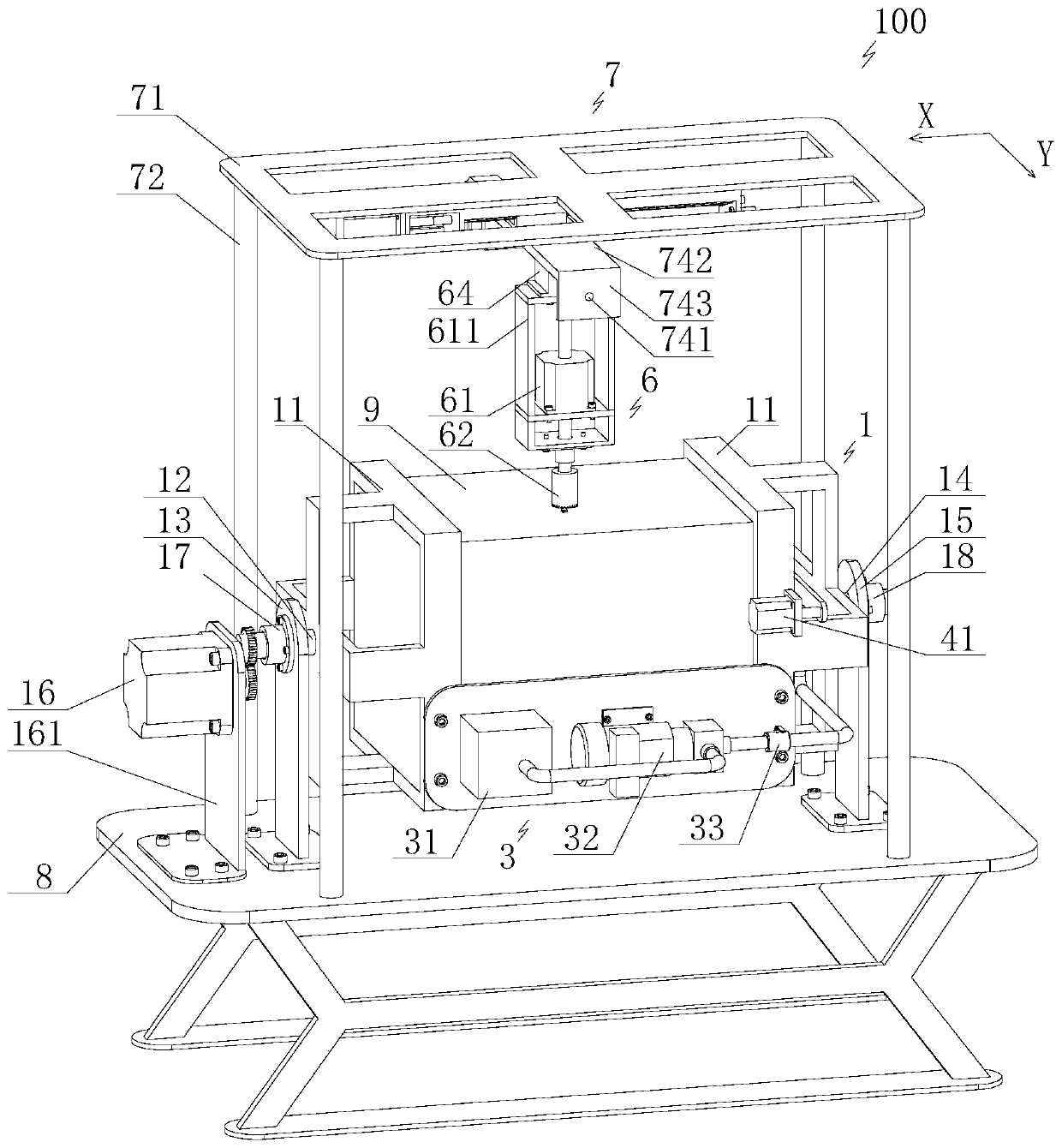

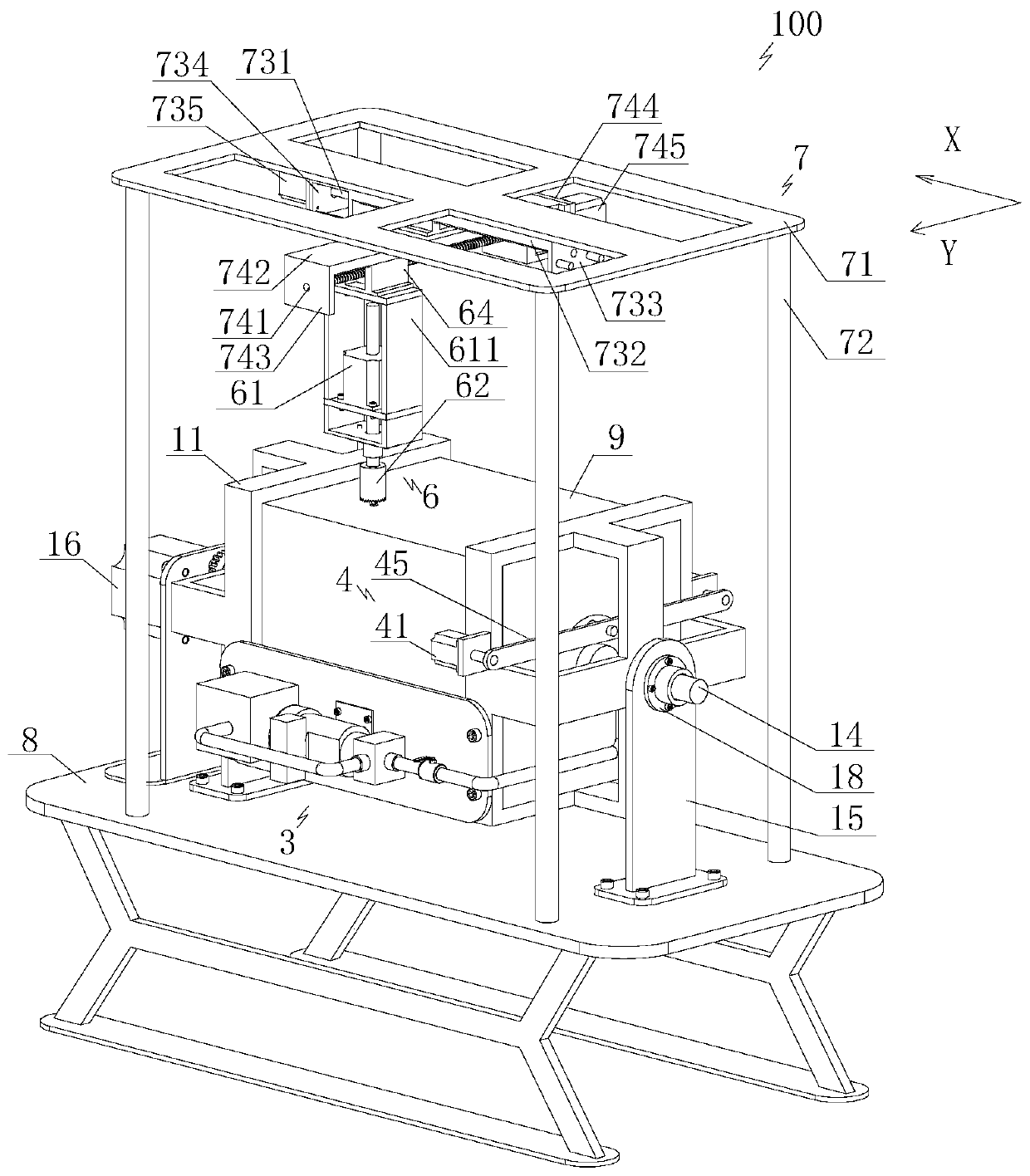

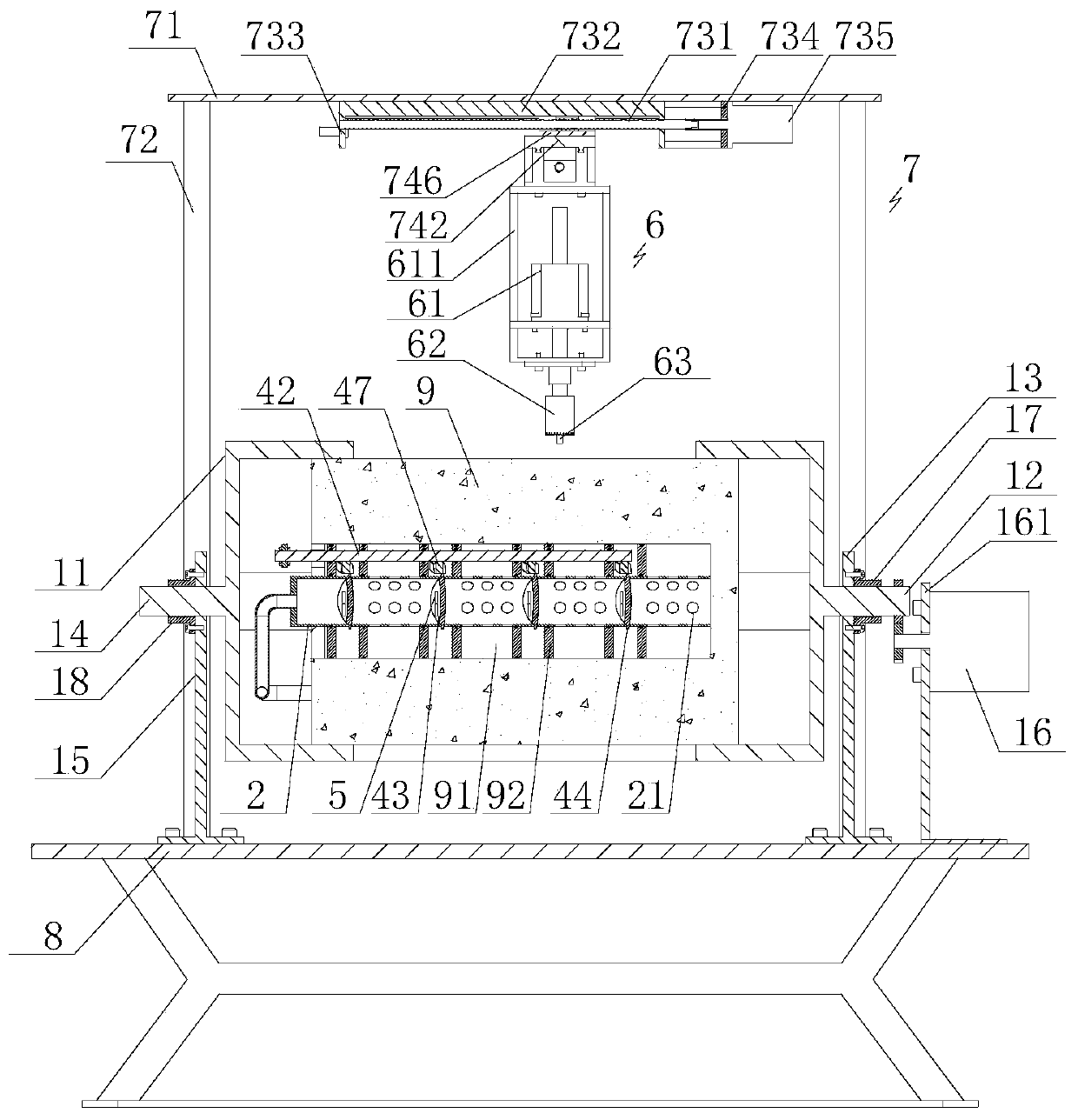

Wellbore-fracture experimental system and experimental method for simulating injection of fracturing fluid

The invention discloses a wellbore-fracture experimental system and experimental method for simulating injection of fracturing fluid. The experimental system comprises a plurality of shells, a simulation wellbore, a data acquisition device and a fluid injection device, wherein each shell is provided with a fluid outlet and a fluid inlet, a first chamber and a second chamber are arranged in each shell, each first chamber is filled with a fracture model, each fracture model comprises a fracture, each fracture has roughness in a fluctuating state relative to the horizontal plane, a plurality of first pressure sensors are arranged in the extending direction of each fracture, each fracture communicates with the corresponding second chamber, and each second chamber is filled with rock for simulating a reservoir matrix; the simulation wellbore is connected with the multiple shells, a drill hole communicating with the fluid inlets of the shells is formed in the side wall of the simulation wellbore, and a plurality of second pressure sensors are arranged in the simulation wellbore; and the fluid injection device is used for injecting the fracturing fluid into the simulation wellbore. The wellbore-fracture experimental system and experimental method can be used for studying the pressure propagation characteristics and the filtration effect in the wellbore and the fractures and the influence of the fracture roughness on pressure propagation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

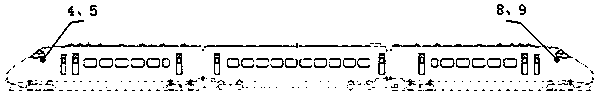

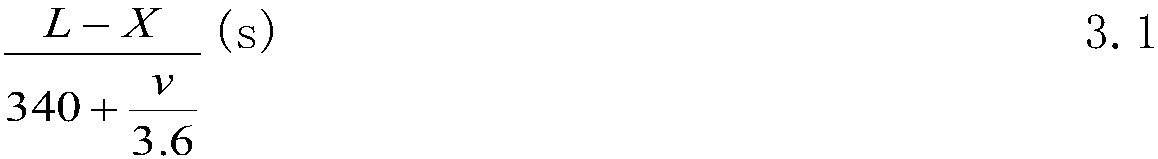

Air tightness detecting device and detecting method for movement process of high speed train

ActiveCN108844694ASimple structureShorten the timeMeasurement of fluid loss/gain rateMicrocontrollerHuman power

The invention provides an air tightness detecting device and detecting method for a movement process of a high speed train. The device includes two air pressure transmitters and one single chip microprocessor disposed on a head locomotive of the high speed train and two air pressure transmitters and one single chip microprocessor disposed on a tail locomotive of the high speed train. The device isadvantaged in that the structure is simple and air pressure leakage information can be displayed in real time. When air pressure leakage occurs, the position of an air pressure leakage point can be calculated; data can be stored in a CCU(Central Control Unit) and can be transmitted to a DMI (Driver-Machine Interface) through an MVB (Multifunction Vehicle Bus) connected with the CCU. The detectionmethod is that when air pressure leakage occurs, the single chip microprocessors on the head locomotive and the tail locomotive send air pressure abnormal values and abnormal moments measured by theair pressure transmitters to the CCU, calculate the air pressure leakage position according to time difference in combination with vehicle speed, vehicle length and air pressure propagation rate and gives real time alarm and display in the DMI. At the same time, the CCU can be started during in-factory maintenance of the high speed train and information of the air pressure leakage position can becalled, so that a large amount of time and labor can be saved in air tightness check.

Owner:LANZHOU JIAOTONG UNIV

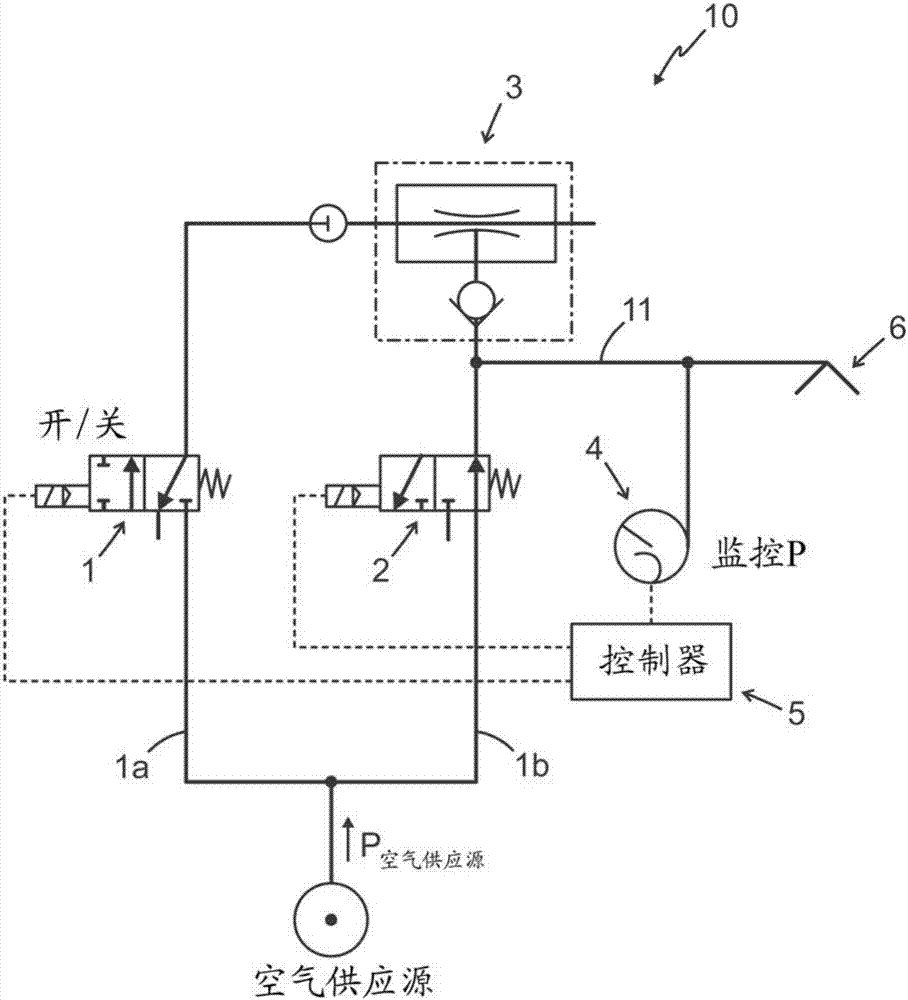

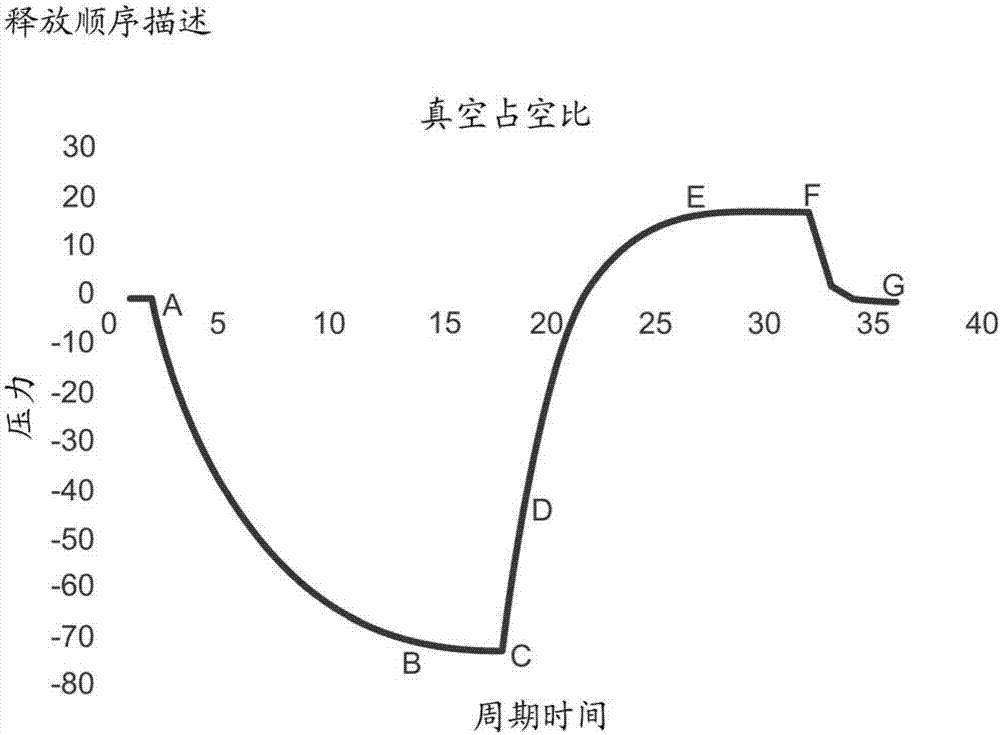

Controlling a vacuum system comprising a vacuum generator

InactiveCN107489661ASolve data management problemsGripping headsJet pumpsSystem pressurePressure propagation

The invention relates to controlling a vacuum system comprising a vacuum generator. A method for controlling a vacuum generator in a vacuum system for transportation of objects, the vacuum system comprises a vacuum generator driven by a compressed air flow via a first on / off valve, a second valve, which is arranged to supply compressed air into the vacuum system, one centralized pressure sensor used for monitoring a system pressure inside the vacuum system and for adaptive blow-off; and a vacuum system controller, wherein if the on / off valve is not flowing air to the vacuum generator, the vacuum system controller indicates a state of no vacuum generation, and the second valve is activated, allowing an amount of compressed air to flow into the vacuum-system for blow-off, blow-off is terminated and excessive air injected into the system is released through the vacuum gripper means, analyzing pressure propagation following blow-off for calculating a duration of when the vacuum system is being fully pressure-equalized in parts of the vacuum gripper means by using a compensation factor.

Owner:ピアブアクチエボラグ

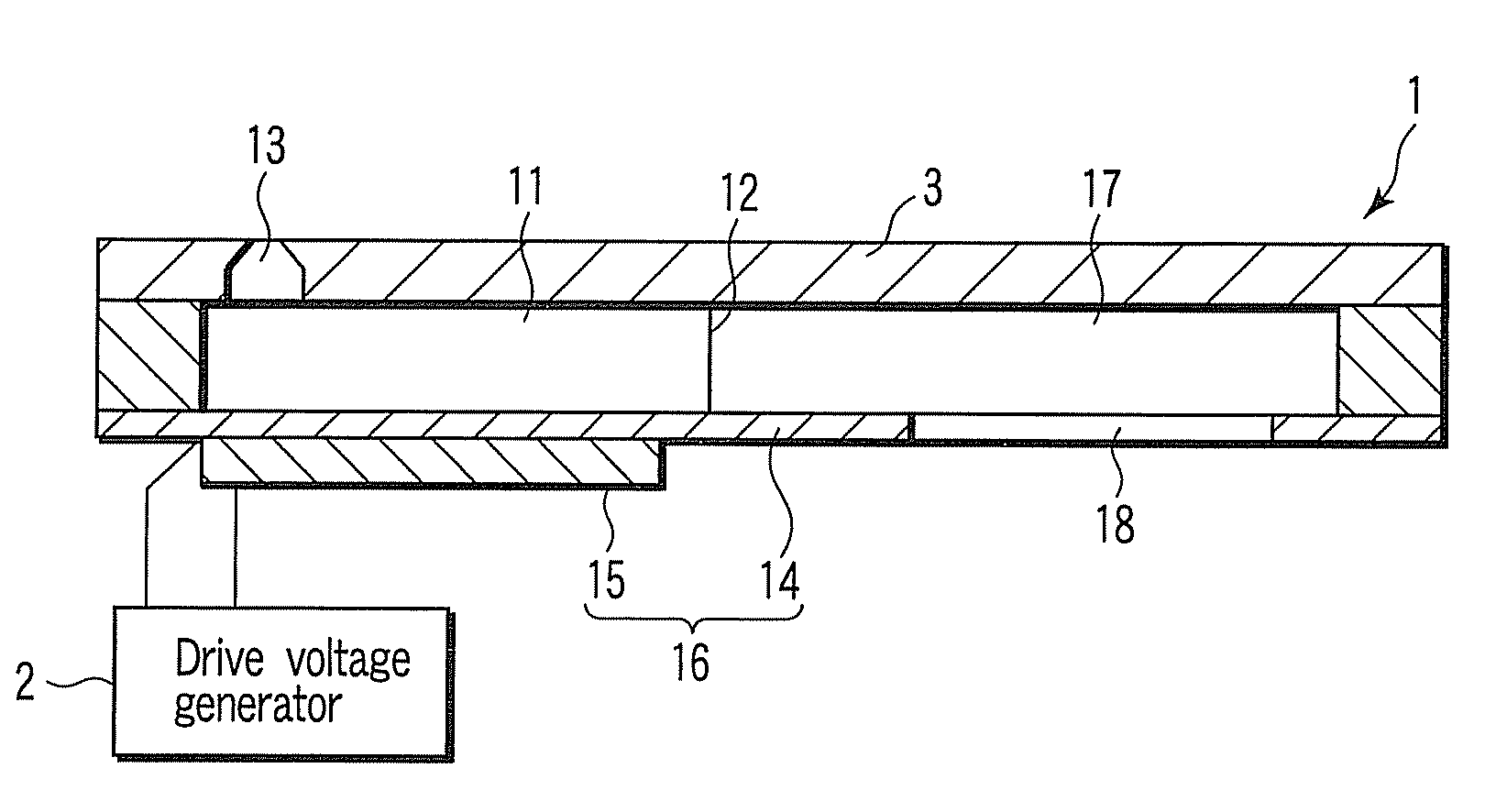

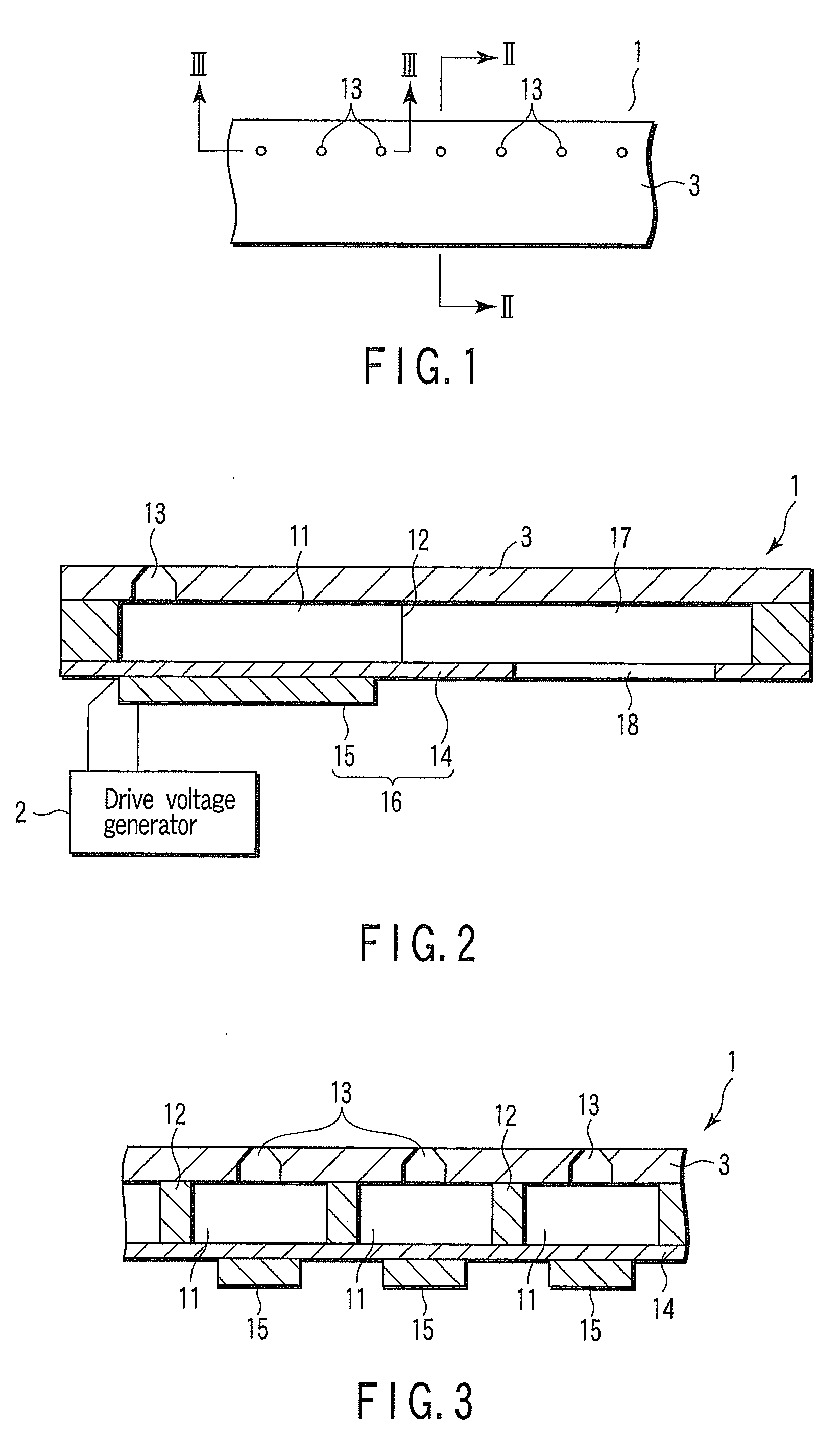

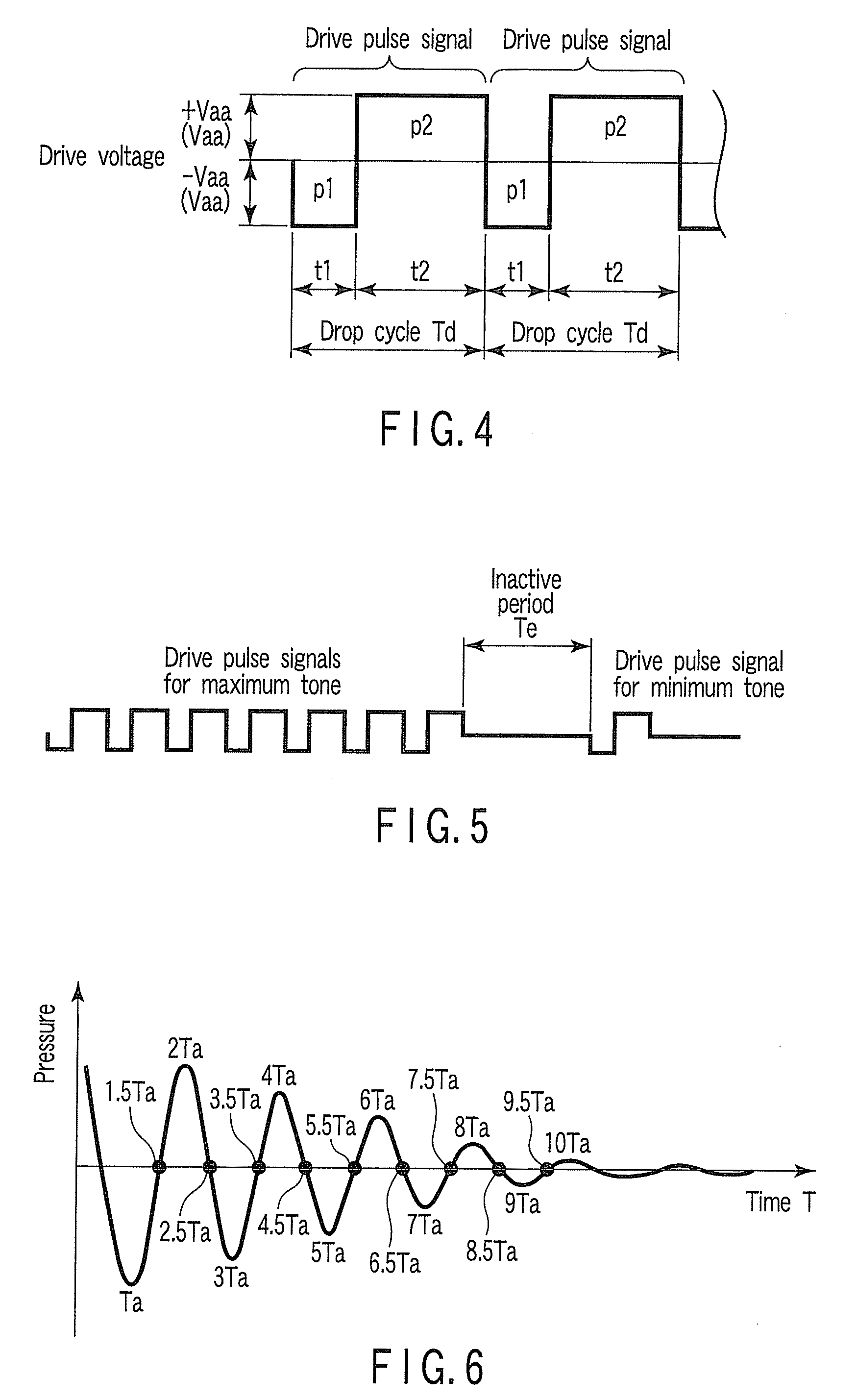

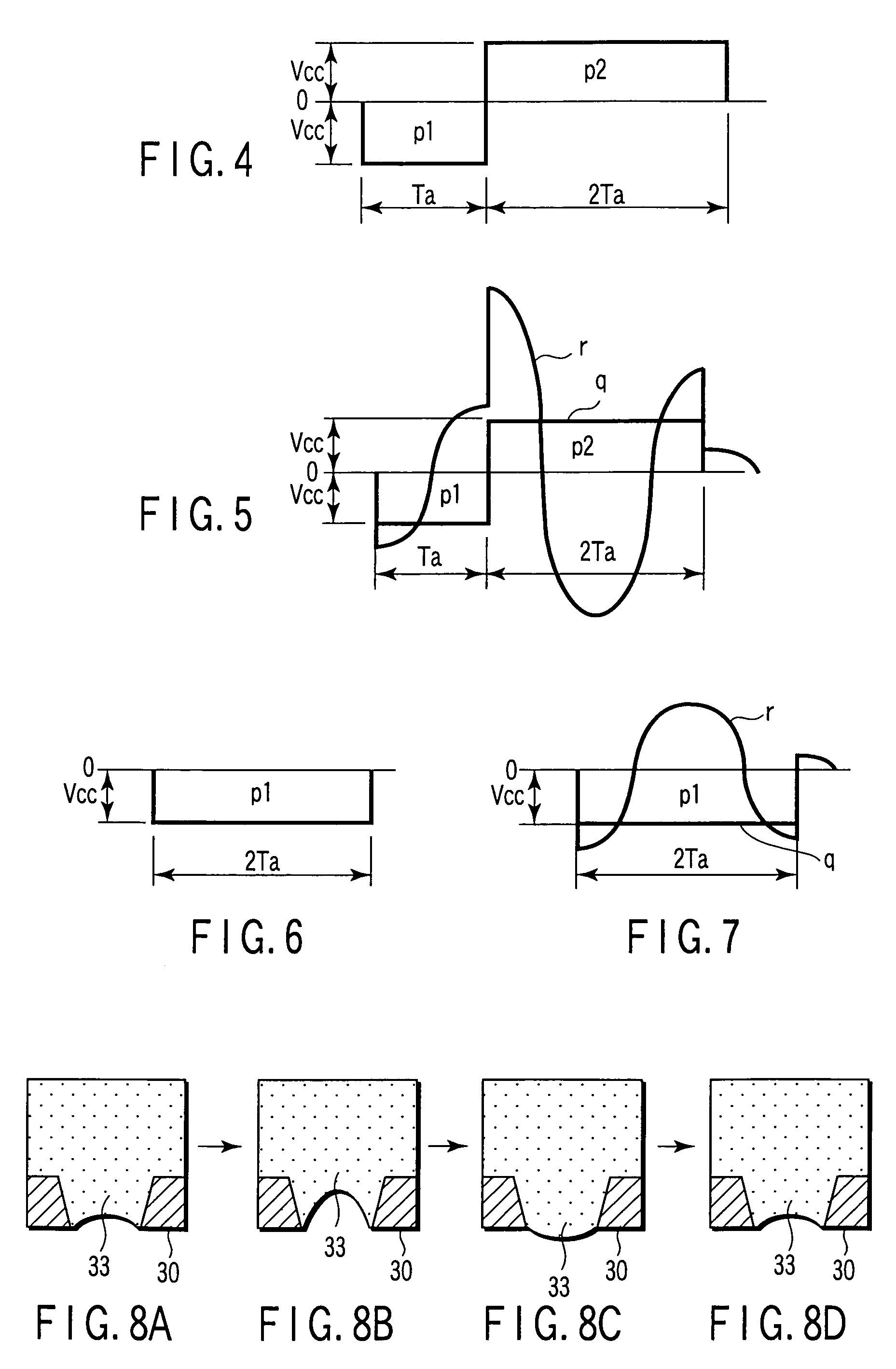

Driving method and driving device of inkjet head

ActiveUS20080088656A1Reduce the impactAvoid print qualityOther printing apparatusVoltage generatorEngineering

An inkjet recording apparatus includes actuators provided in an inkjet head, and a drive voltage generator that drives each actuator. The drive voltage generator is configured to set the cycle time Tc, the drop cycle Td, the number of ink droplets N for a maximum tone, and the inactive period Te in a relationship of Tc=Td×N+Te, set the drop cycle Td and the inactive period Te, by referencing pressure propagation time Ta in relationships of Td=n×Ta (where n=1, 2, 3, . . . ) and Te=(0.5+m)×Ta (where m=1, 2, 3, . . . ), and make an output timing of the final drive pulse signal for a dot of a tone other than the maximum tone coincide with an output timing of the final drive pulse signal for the maximum tone.

Owner:TOSHIBA TEC KK

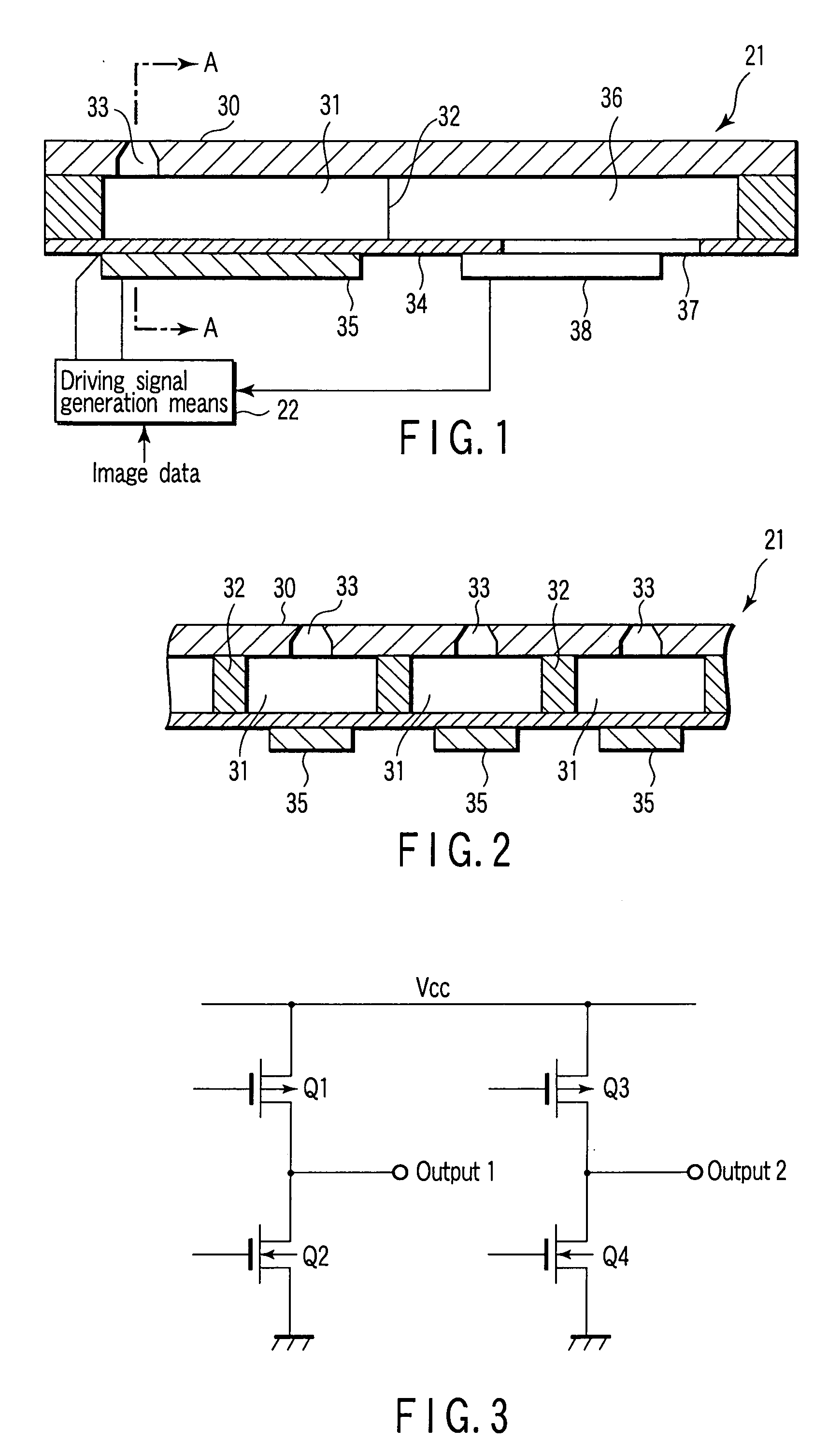

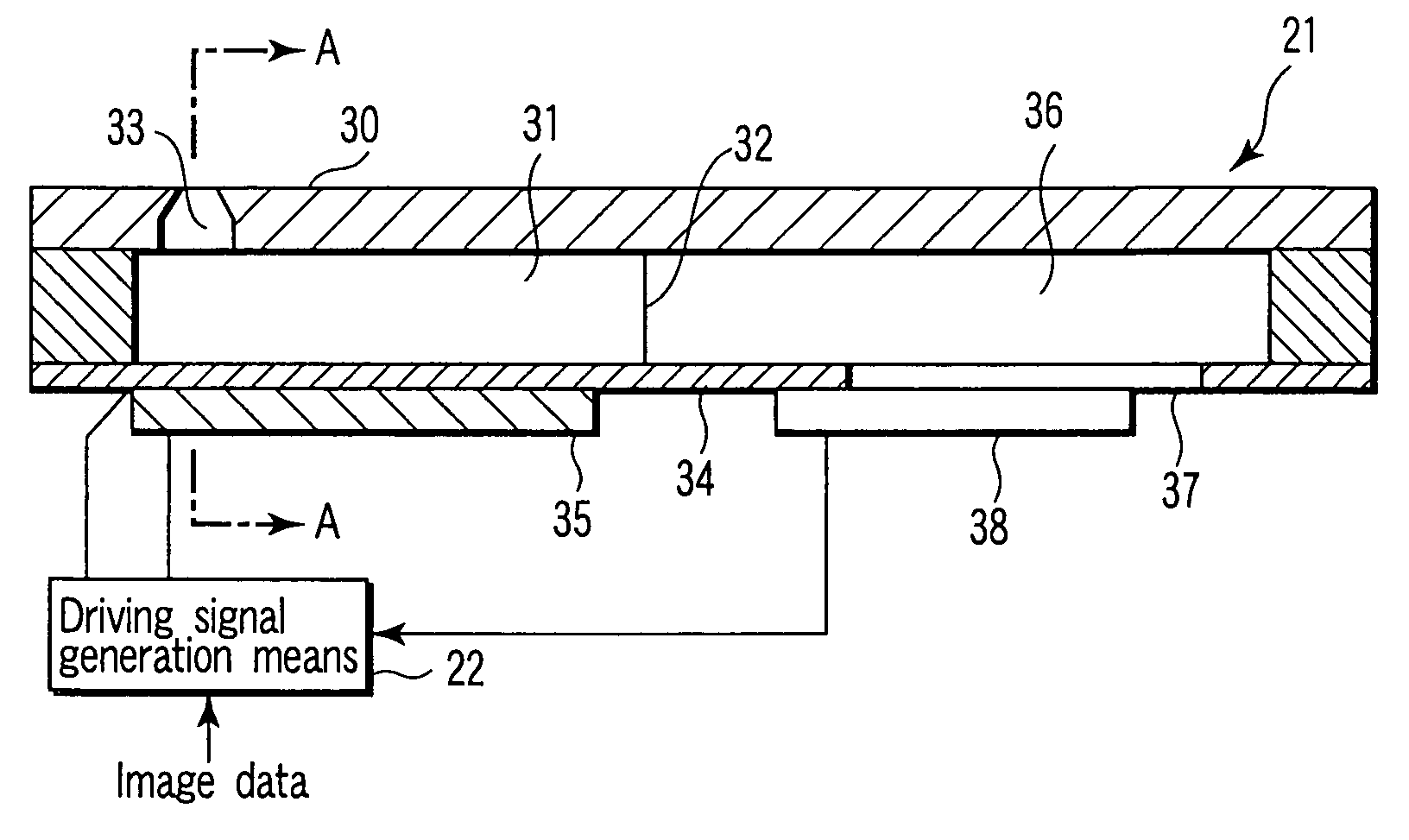

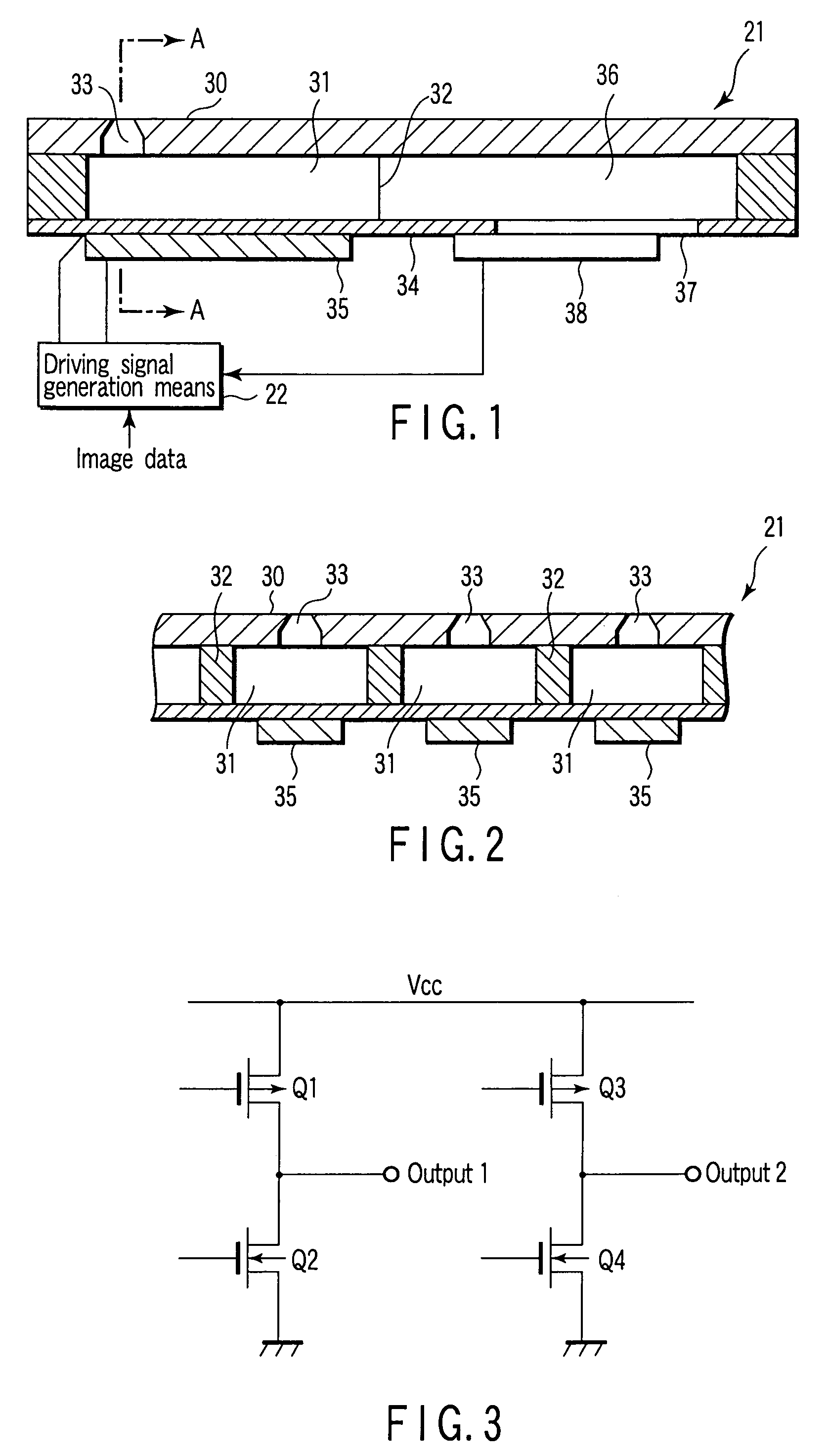

Ink-jet head driving method and ink-jet recording apparatus

ActiveUS20050018003A1Good coagulationHigh viscosityOther printing apparatusPressure propagationActuator

An ink-jet recording apparatus includes a pressure chamber that contains ink, a nozzle communicating with the pressure chamber, which ejects the ink from the pressure chamber, an ink-jet head having an actuator that increases and decreases the capacity of the pressure chamber, and a driving signal generation unit that supplies the actuator with a driving signal to eject an ink drop from the nozzle. When no ink is ejected from the nozzle, the actuator is supplied with a very low pressure driving signal to increase the capacity of the pressure chamber and then return the increased capacity to an original size. The pulse width of the very low pressure driving signal is about twice as long as a pressure propagation time period during which a pressure wave in the ink propagates through the pressure chamber.

Owner:TOSHIBA TEC KK

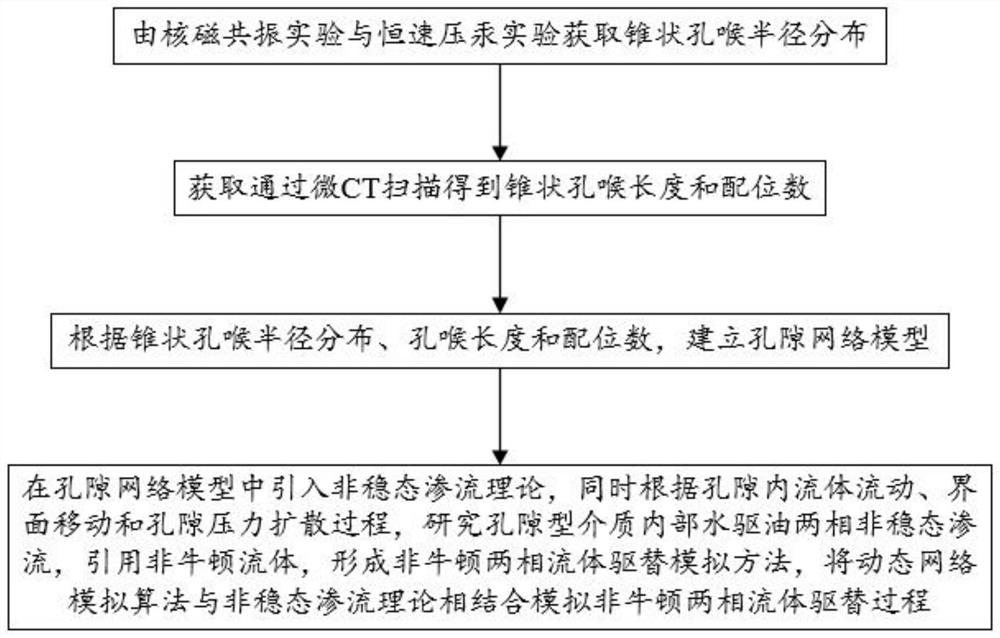

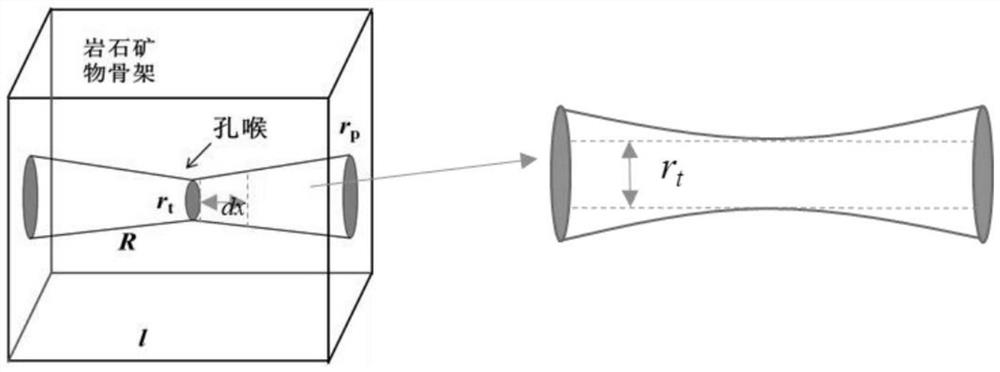

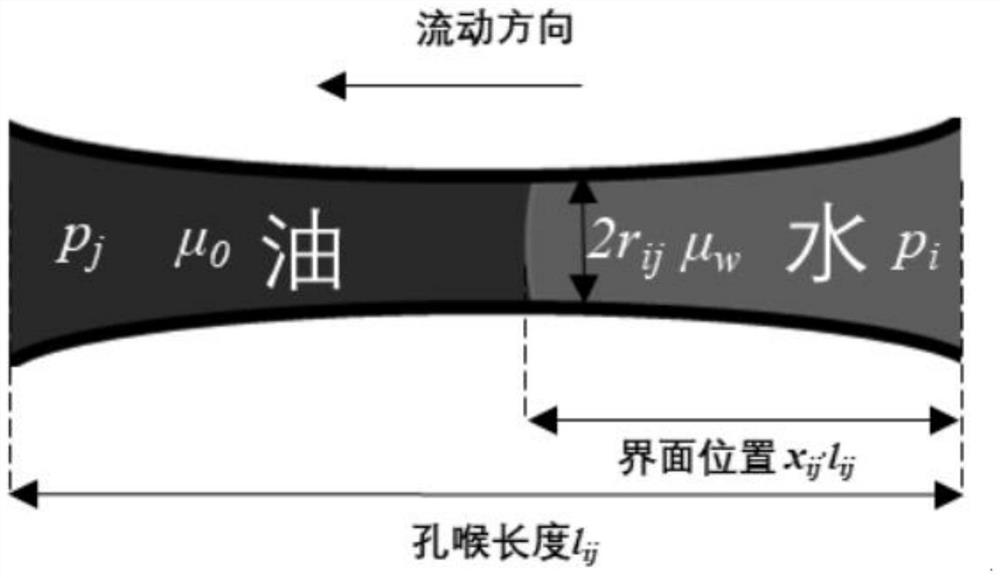

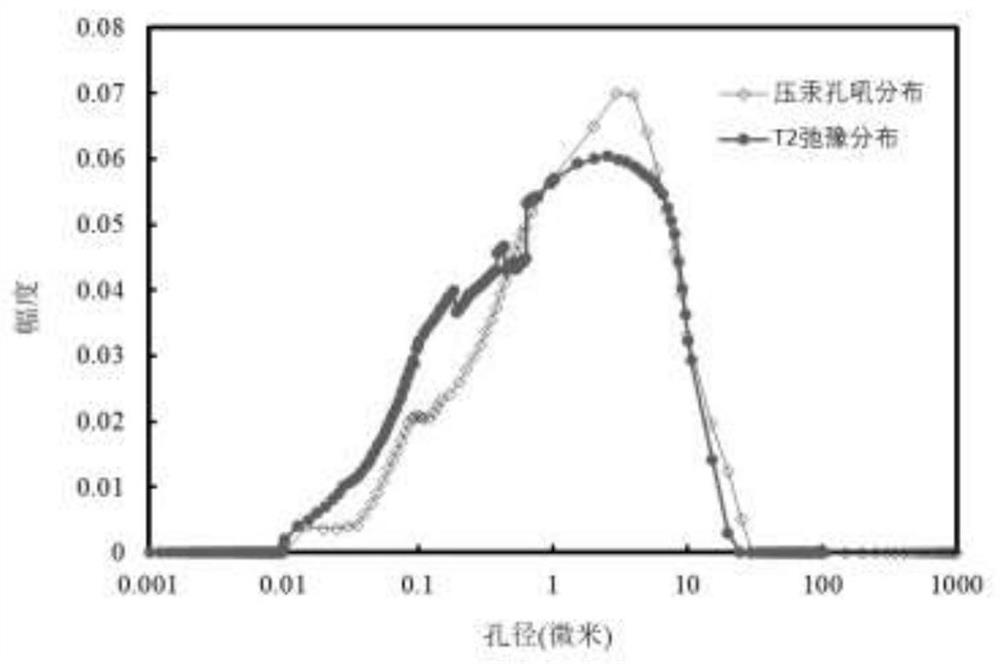

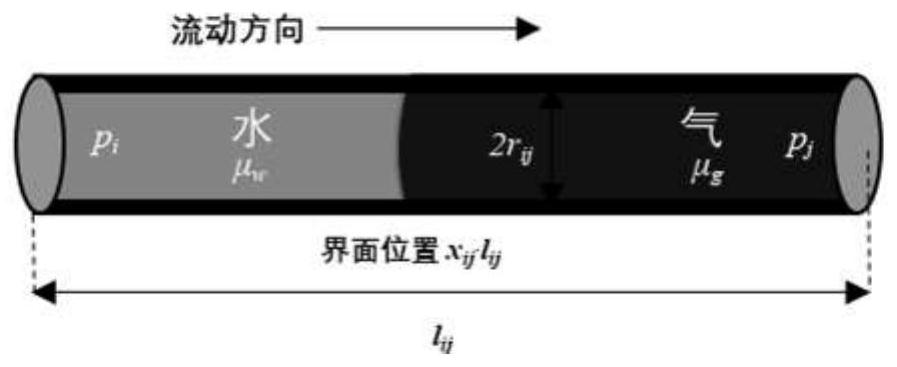

Unstable non-Newtonian two-phase fluid displacement simulation method based on pore network model

PendingCN113468829AAccurately reflect the characteristics of unsteady seepageDesign optimisation/simulationWater resource assessmentNMR - Nuclear magnetic resonancePorous medium

The invention relates to the technical field of oil and gas field development, in particular to an unstable non-Newtonian two-phase fluid displacement simulation method based on a pore network model, which comprises the following steps: 1) acquiring radius distribution of a conical pore throat through a nuclear magnetic resonance experiment and a constant-speed mercury injection experiment; 2) obtaining the length and coordination number of a conical pore throat; 3) establishing a pore network model; and 4) introducing an unsteady-state seepage theory into the pore network model, and meanwhile, researching water-displacing-oil two-phase unsteady-state seepage in the pore type medium according to the process of fluid flow in pores, interface movement and pore pressure diffusion to form a non-Newtonian two-phase fluid displacement simulation method. A dynamic network simulation algorithm and an unsteady-state seepage theory are combined to simulate a non-Newtonian two-phase fluid displacement process. The method can accurately reflect the unstable seepage characteristics of the fluid and pore throat compression coefficient, fluid viscosity and the like which change along with pressure propagation in the process that the non-Newtonian two-phase fluid flows in the porous medium pore throat.

Owner:SOUTHWEST PETROLEUM UNIV

Ink-jet head driving method and ink-jet recording apparatus

ActiveUS7156480B2Good coagulationHigh viscosityOther printing apparatusEngineeringPressure propagation

An ink-jet recording apparatus includes a pressure chamber that contains ink, a nozzle communicating with the pressure chamber, which ejects the ink from the pressure chamber, an ink-jet head having an actuator that increases and decreases the capacity of the pressure chamber, and a driving signal generation unit that supplies the actuator with a driving signal to eject an ink drop from the nozzle. When no ink is ejected from the nozzle, the actuator is supplied with a very low pressure driving signal to increase the capacity of the pressure chamber and then return the increased capacity to an original size. The pulse width of the very low pressure driving signal is about twice as long as a pressure propagation time period during which a pressure wave in the ink propagates through the pressure chamber.

Owner:TOSHIBA TEC KK

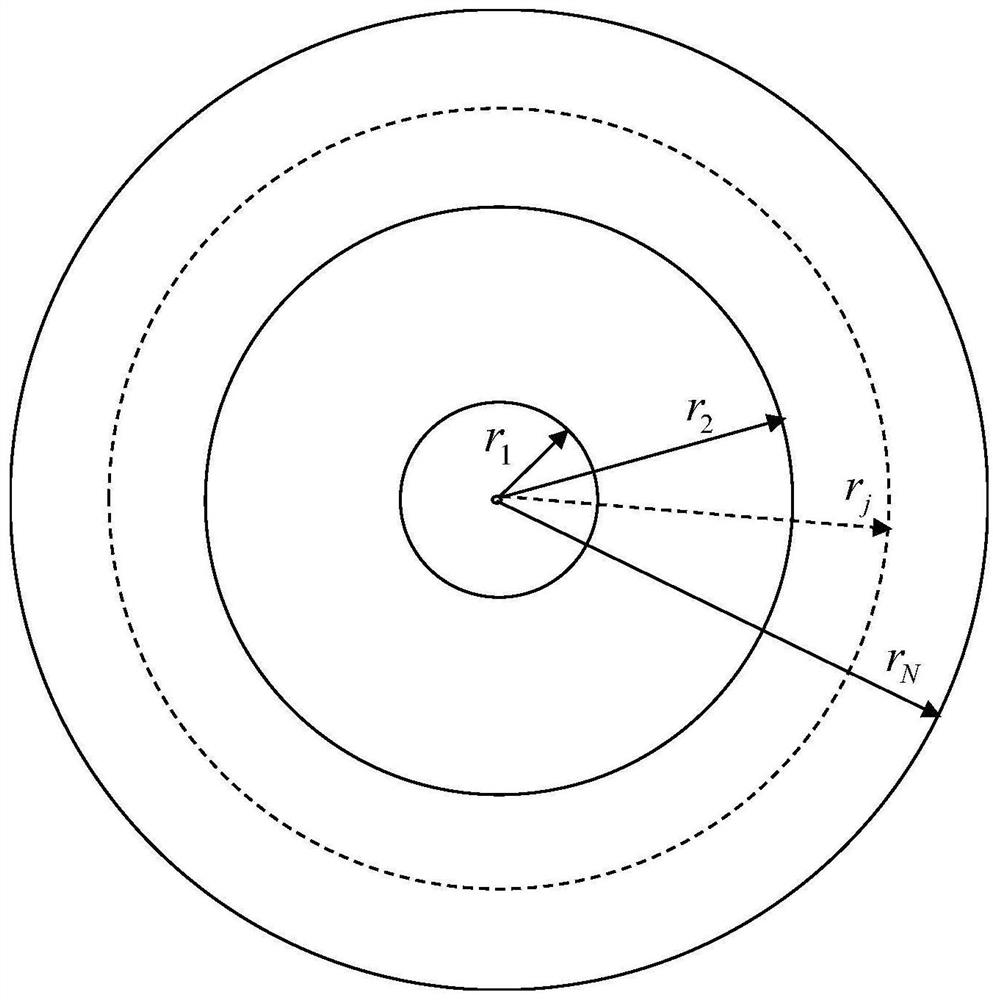

Method and device for predicting well control reserves of heterogeneous buried hill gas reservoir

PendingCN114462197AForecasting helps guideDesign optimisation/simulationSpecial data processing applicationsPredictive methodsPressure propagation

The invention discloses a heterogeneous buried hill gas reservoir well control reserve prediction method and device.The method comprises the steps that a gas reservoir is divided into N seepage areas in the radial direction of a borehole according to the heterogeneous condition, the N seepage areas are distributed in a concentric annulus mode, and basic parameters of the N seepage areas are obtained; a pressure propagation equation of the gas reservoir from the concentric circle center in the radial direction is established, and the gas reservoir well control radius is obtained through the pressure propagation equation; and well control reserves are predicted by using the gas reservoir well control radius. The method can consider the characteristics of heterogeneous distribution of buried hill gas reservoirs, is more consistent with the actual situation, and achieves the accurate prediction of well control reserves.

Owner:中海石油(中国)有限公司海南分公司

Simulation method of unsteady gas-water two-phase seepage in dual-media gas reservoirs based on pores and fractures

ActiveCN112098293BMeet production needsIn line with reservoir characteristicsMaterial analysis using wave/particle radiationSurface/boundary effectSoil sciencePressure propagation

The invention relates to a method for simulating unsteady gas-water two-phase seepage in dual-media gas reservoirs based on pores and fractures. The core pore throat length and coordination number of the pore network model, the number of added fractures; the establishment of a pore-fracture dual-media model; the introduction of unsteady-state seepage theory and the combination of dynamic network simulation algorithm and unsteady-state seepage theory The gas-water two-phase seepage and pressure propagation process are simulated. The present invention simulates the unsteady gas-water two-phase flow on the basis of the pore-fracture dual-media model. In the traditional gas-water two-phase seepage process, the dynamic network simulation considering the fluid compressibility can more accurately describe the pore-level gas-water two-phase flow. Phase flow process; it can analyze the pressure distribution and pressure wave propagation of gas-water two-phase in the dual medium of pores and fractures, and help to study the flow law of fluid in pores and fractures.

Owner:SOUTHWEST PETROLEUM UNIV

A method for determining the initial drainage rate of coalbed methane development based on pressure propagation

ActiveCN104863547BFluid removalSpecial data processing applicationsQuantitative determinationPressure propagation

The invention relates to a pressure propagation-based method for determining the drainage and production speed of coalbed methane at the initial stage of development, which comprises the following steps: 1) according to the relationship between pressure propagation distance and time, the time required for interwell pressure interference under a given well pattern and well spacing condition is determined; 2) According to the time required for interwell pressure interference obtained in step 1), the depressurization rate is determined according to the concept of balanced depressurization; 3) The depressurization rate of the wellbore liquid level is determined according to the depressurization rate obtained in step 2). The invention has a strict theoretical basis and realizes the quantitative determination of the coal bed methane drainage rate at the initial stage of development. The invention can be widely applied to the quantitative determination of the coal bed methane drainage rate at the initial stage of coal bed methane development in different reservoir physical property conditions.

Owner:CHINA NAT OFFSHORE OIL CORP +1

A method for controlling the expansion of coal mine fracturing cracks

ActiveCN105239984BAvoid damageIncrease the effective fracturing rangeFluid removalGas removalInjection pressureHydraulic fracturing

The invention discloses a method for controlling the expansion of hydraulic fracturing cracks in underground coal mines. Arrangement of the expansion direction of the fracturing, (2) Grouting and sealing of the fracturing drilling and pressure-holding water injection drilling, (3) According to the calculated pressure-holding hole water injection pressure and single-hole pressure-holding water injection time, the pressure-holding water injection drilling (4) Hydraulic fracturing of the fracturing borehole. In the present invention, a number of boreholes are preset on both sides of the fracturing borehole according to the artificially expected expansion direction of hydraulic cracks, and pressure-maintaining water injection is performed on them before formal fracturing, so that a continuous band is formed around the fracturing borehole. In the high pore pressure area, hydraulic fractures can be induced to expand along the high pore pressure area, increasing the effective fracturing range; at the same time, reducing the crack initiation and expansion pressure of the fracturing drilling hole, reducing the damage to the coal seam roof and floor strata.

Owner:CHONGQING JIAOTONG UNIVERSITY

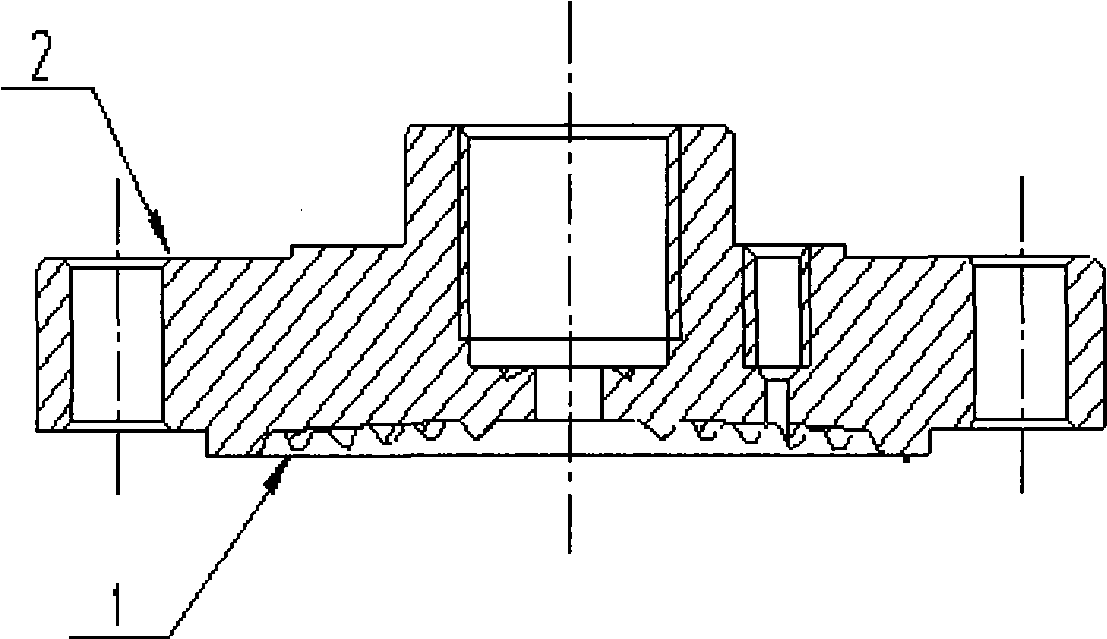

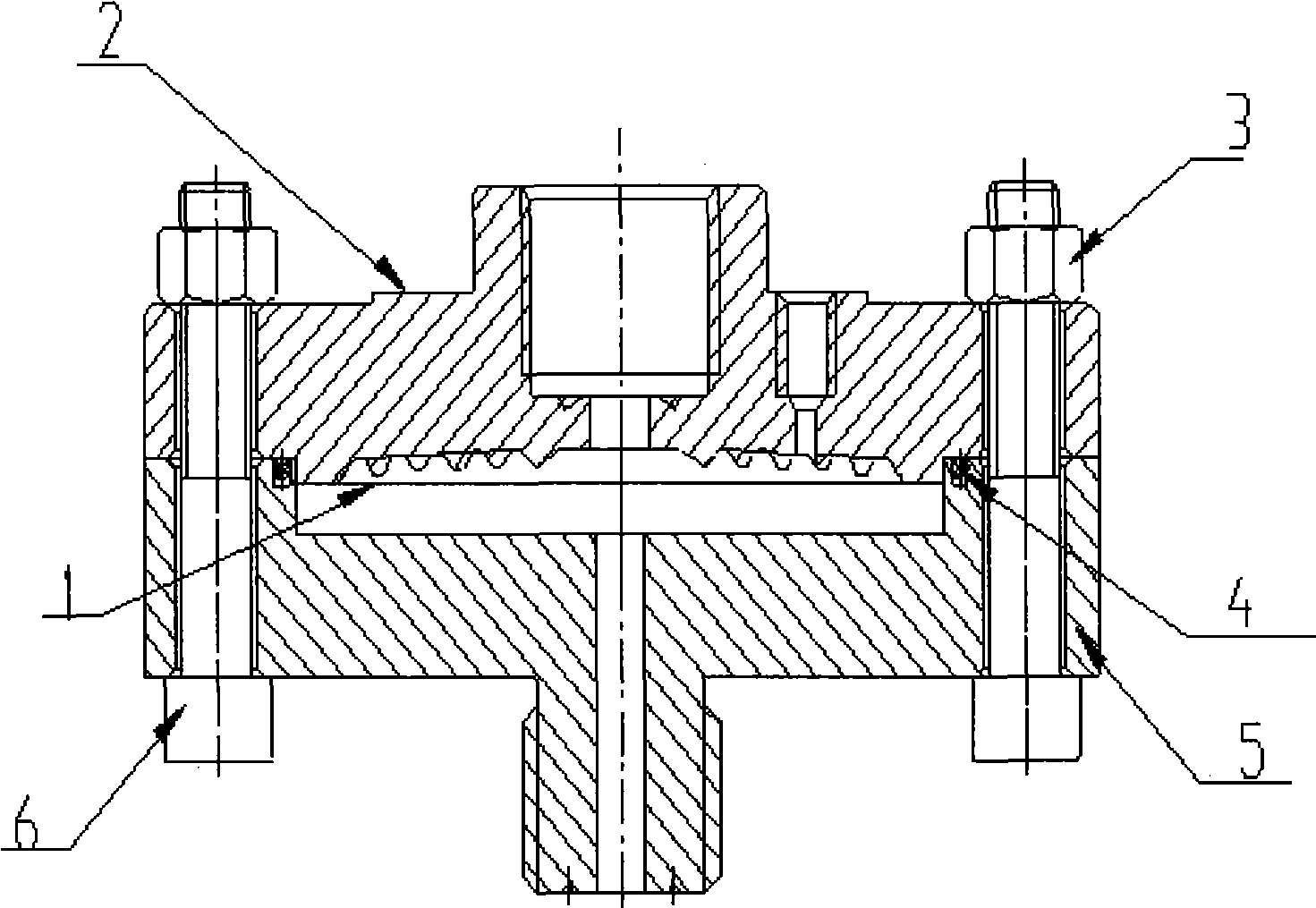

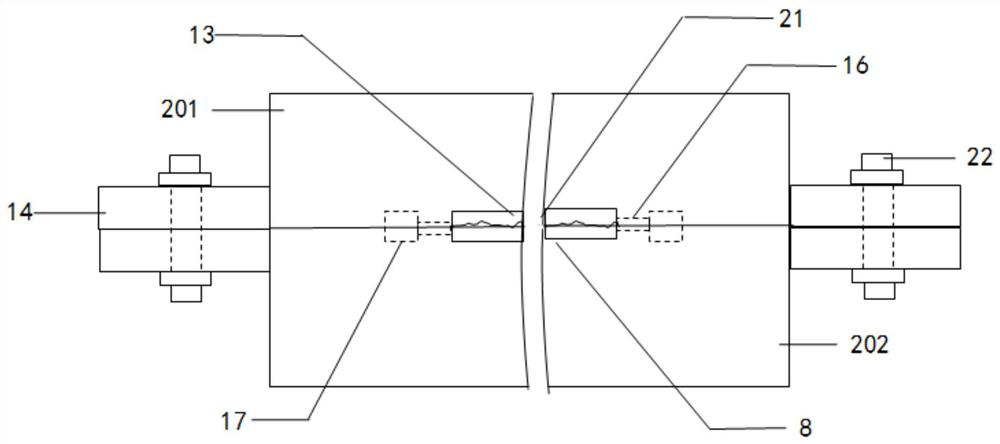

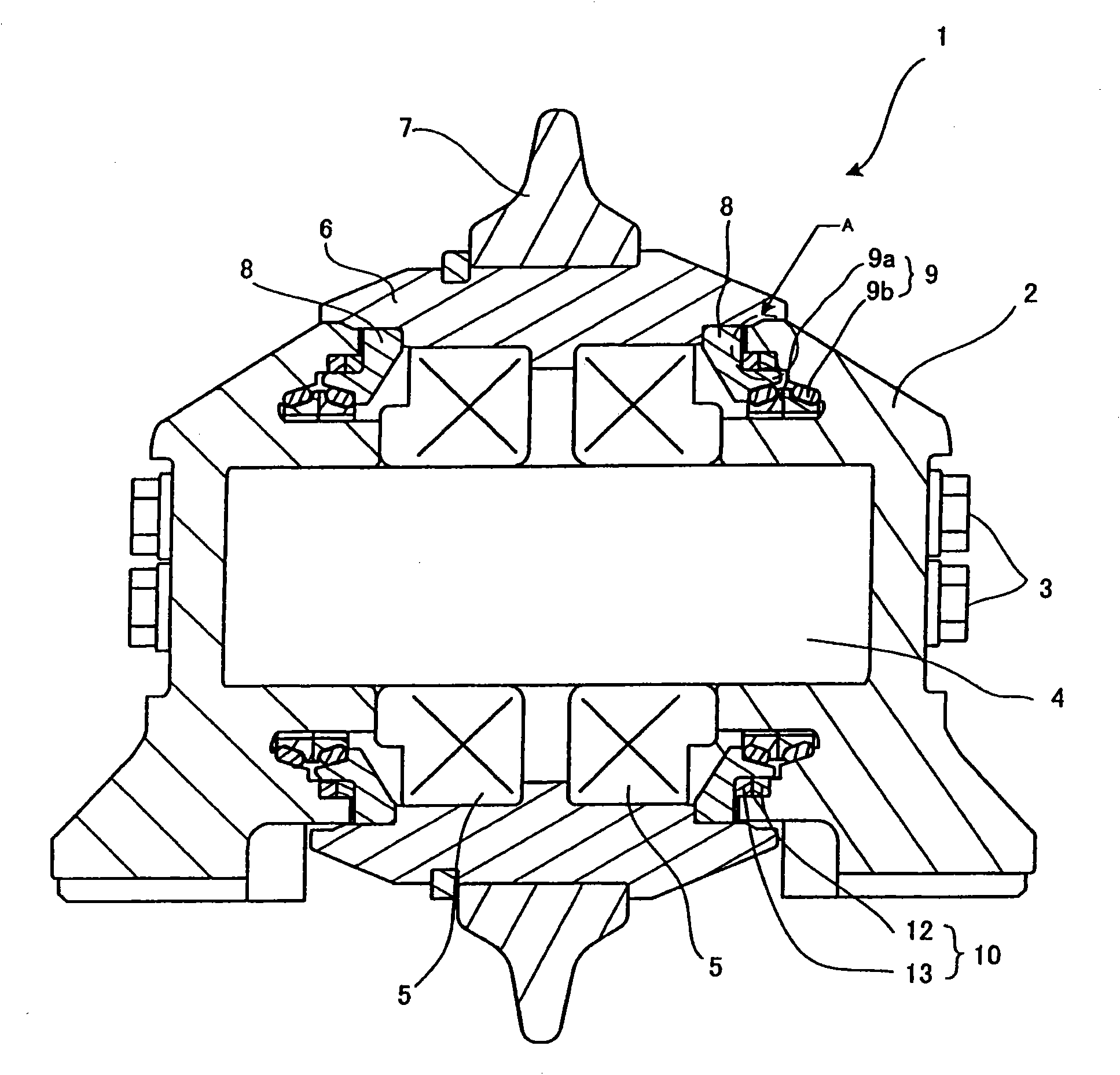

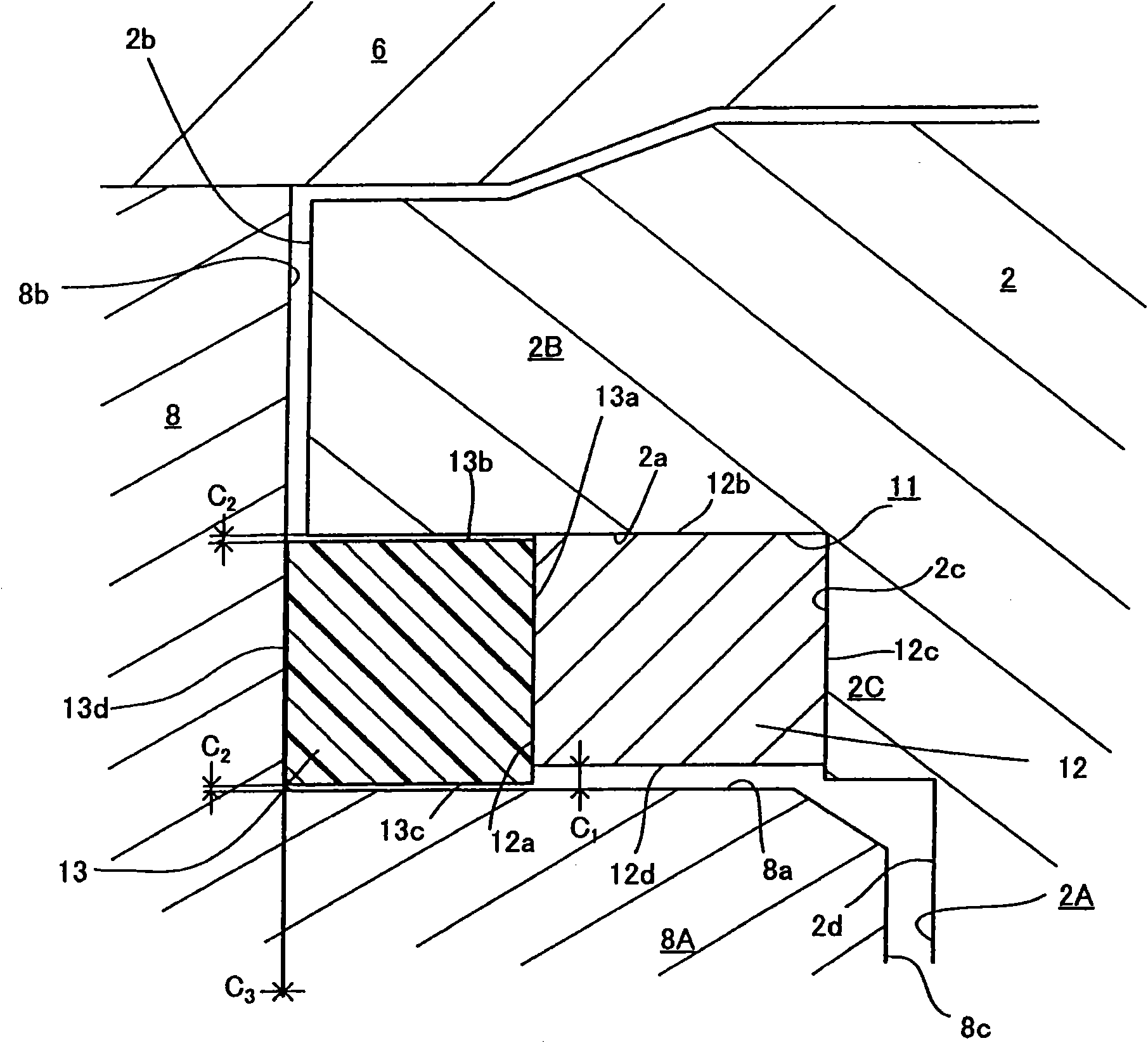

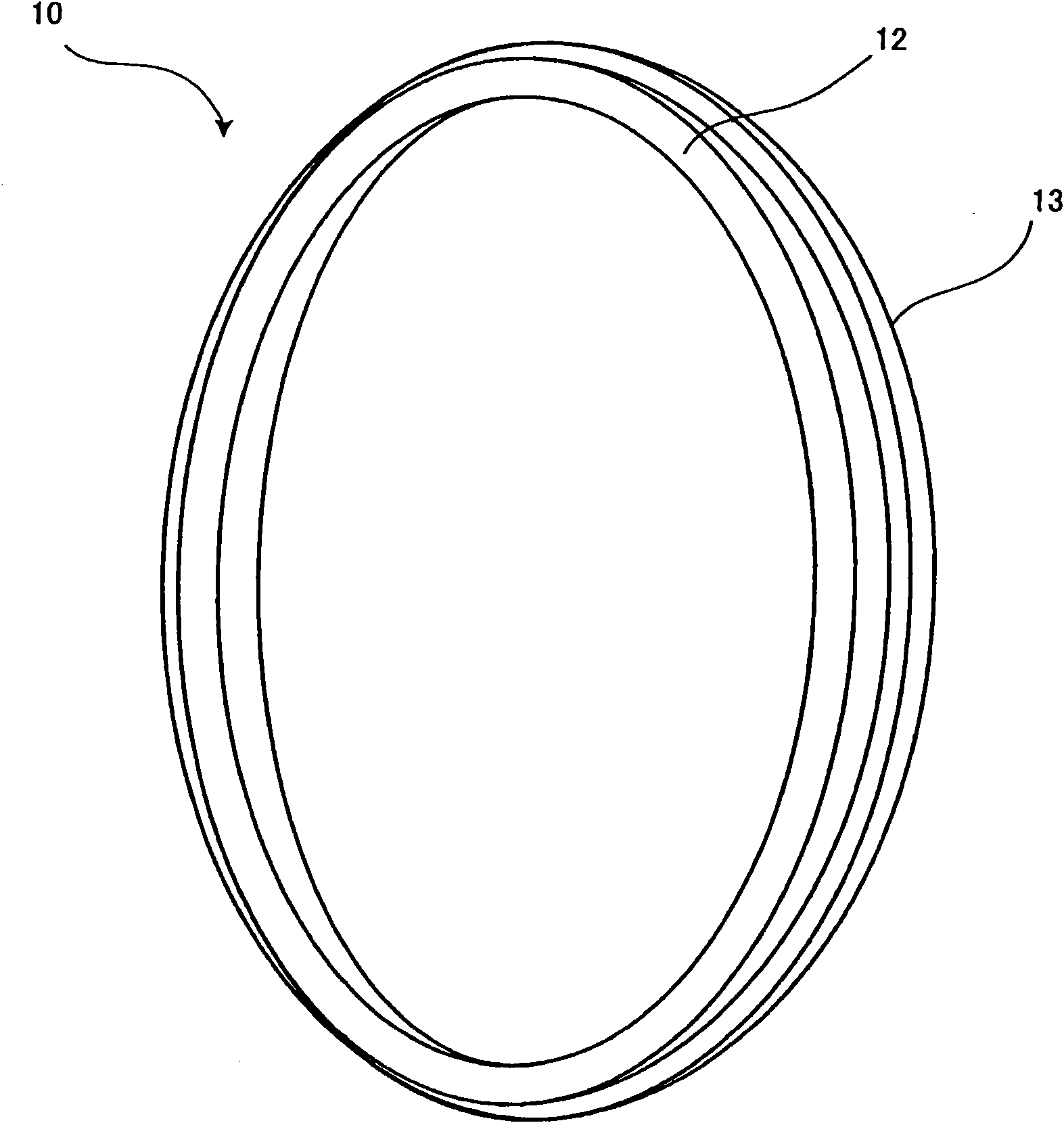

Ring body for suppressing propagation of earth pressure, its mounting structure, disc cutter and roller device

ActiveCN101749029BDoes not increase rotational resistanceEasy to processEngine sealsDrill bitsSurface roughnessEngineering

PURPOSE: A ring body for suppressing the propagation of earth pressure, an installation structure thereof, a disc cutter, and a front wheel device are provided to suppress the propagation of earth pressure to a rotation sliding part arranged inside the ring body. CONSTITUTION: A ring body(10) for suppressing the propagation of earth pressure comprises a first ring part(12) and a second ring part(13). The first ring part is composed of an elastic body. The second ring part is fixed to the side surface of the first ring part, and is composed of rotatable metal. The surface roughness of the second ring part is more than 12.5S.

Owner:KOMATSU LTD +1

A device and method for evaluating the stability of shale with fractures

ActiveCN106153856BRealize stability evaluationRealize evaluationEarth material testingTemperature controlLiquid medium

A crack-containing shale stability evaluation device mainly comprises a kettle, a temperature control assembly connected with the kettle, a pressure assembly connected with the kettle, a back pressure control assembly, a gas source supply control assembly, a liquid medium assembly connected with the kettle, a core deformation measuring assembly connected with the kettle, and a data measuring and collecting assembly, wherein the kettle is used for fixing a core and simulating the environment around the core; the temperature control assembly is controlled to heat the core, control the temperature and simulate the actual temperature of a stratum; the pressure assembly is used for exerting confining pressure, required by experiments, on the core to simulate stratum burden pressure; the back pressure control assembly is used for back pressure control of the core; the gas source supply control assembly is used for providing a constant-pressure gas source on a core inlet end; the liquid medium assembly is used for providing clean water or slurry for the core and simulating the pressure action of drilling fluid circulation; the core deformation measuring assembly is used for measuring core deformation; the data measuring and collecting assembly is connected with the assemblies and used for obtaining expansion strain, the crack core pore pressure propagation rule and pressure penetration period monitoring results.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultrasonic tight oil imbibition experimental device

ActiveCN109025939BIntuitive observation of displacement phenomenonConstructionsFluid removalLeading edgeElectrical resistance and conductance

The invention relates to an ultrasonic tight oil imbibition experiment device comprising a rock fixed box; a fracture pipe capable of penetrating a tight coil rock penetrates one side of the rock fixed box in a sealed manner, and the other end of the fracture pipe is connected with a fracture liquid injection structure in a foldable manner; a push structure penetrates the fracture pipe in a sealedand slide manner, and provided with a plurality of ultrasonic probes; the side wall, on which the fracture pipe penetrates, of the rock fixed box is the first fixed box side wall; each side wall adjacent to the first fixed box side wall on the rock fixed box is provided with a telescopic potential resistance imbibition test structure; the ultrasonic tight oil imbibition experiment device also comprises a control portion; the control portion can control the work states of the fracture liquid injection structure, the push structure and the potential resistance imbibition test structure. The device can test oil-water replacement rate and oil extraction effects of fracture liquids of different formulas, can analyze the pressure propagation speed and oil-water replacement leading edge positionin the imbibition process, thus providing important meanings for selecting and optimizing and evaluating soak effects of fracture liquids of different formulas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Strain gauge pressure test tight oil imbibition experimental device

ActiveCN108979630BIntuitive observation of displacement phenomenonSurveyFluid removalClassical mechanicsFracturing fluid

The invention relates to a strain gauge type pressure test tight oil inhibition experimental device, comprising a rock fixture structure and further comprising a control unit. The rock fixture structure can clamp rock containing tight oil and rotate around a horizontal shaft; a horizontal fracturing pipe runs from one side of the rock containing tight oil, one end of the fracturing pipe is connected with a fracturing fluid injection structure, and the fracturing pipe is provided with an inhibition cabin linkage sealing structure; the inhibition cabin linkage sealing structure is provided withmultiple resistance strain gauges; besides, a potential and resistance inhibition test structure is arranged above the rock fixture structure; the control unit can control working status of the fracturing fluid injection structure, the inhibition cabin linkage sealing structure and the potential and resistance inhibition test structure. The device can be used for testing oil and water displacement and oil production effect of fracturing fluid prepared based on different formulas, can analyze pressure propagation speed in inhibition process and oil and water displacement leading-edge position,and has a great significance in optimized evaluation on soaking effect of the fracturing fluid of different formulas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com