Controlling a vacuum system comprising a vacuum generator

A vacuum generator and vacuum system technology, applied in the field of vacuum systems, can solve complex data management and other problems, and achieve the effect of data management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

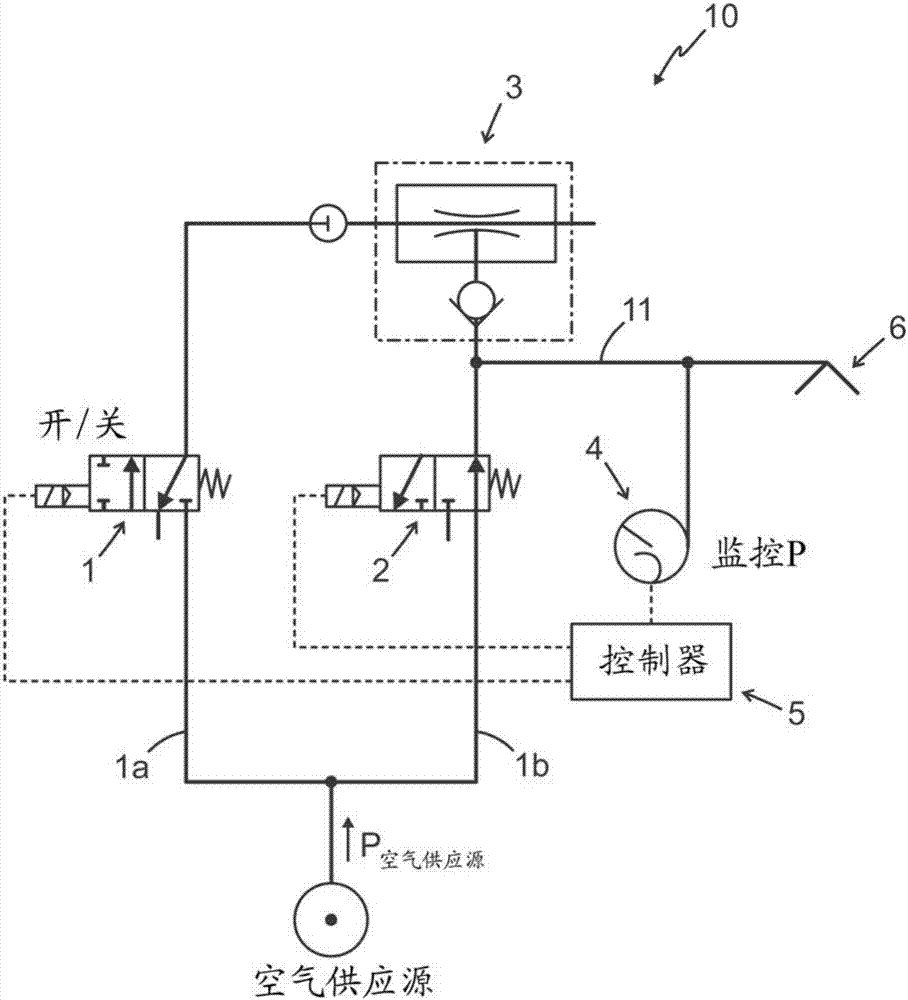

[0025] For a general description of an embodiment of a vacuum system 10 for transporting objects, reference is initially made to figure 1 .

[0026] will now refer to figure 1 An embodiment of the invention is described, wherein details of the embodiment corresponding to the above description of the vacuum system will be given by the previous figure 1 The corresponding reference numerals used in .

[0027] The vacuum system 10 comprises a vacuum generator 3 driven by a flow of compressed air via a first on / off valve 1 or other mechanism for controlling the flow of compressed air, wherein the vacuum generator 3 being part of the vacuum system 10 is arranged in conjunction with One or more vacuum grippers 6 also included in the vacuum system 10 are fluidly connected to supply vacuum to the vacuum grippers 6 due to the flow of compressed air to the vacuum generator 3 . The vacuum system 10 comprises a second valve 2 arranged to be activated (normally opened) and supply compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com