Strain gauge pressure test tight oil imbibition experimental device

A technology of pressure testing and experimental equipment, which is applied in the direction of measurement, wellbore/well components, production fluid, etc., and can solve the problems of difficult measurement of produced crude oil, inability to measure fluid, capillary force offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

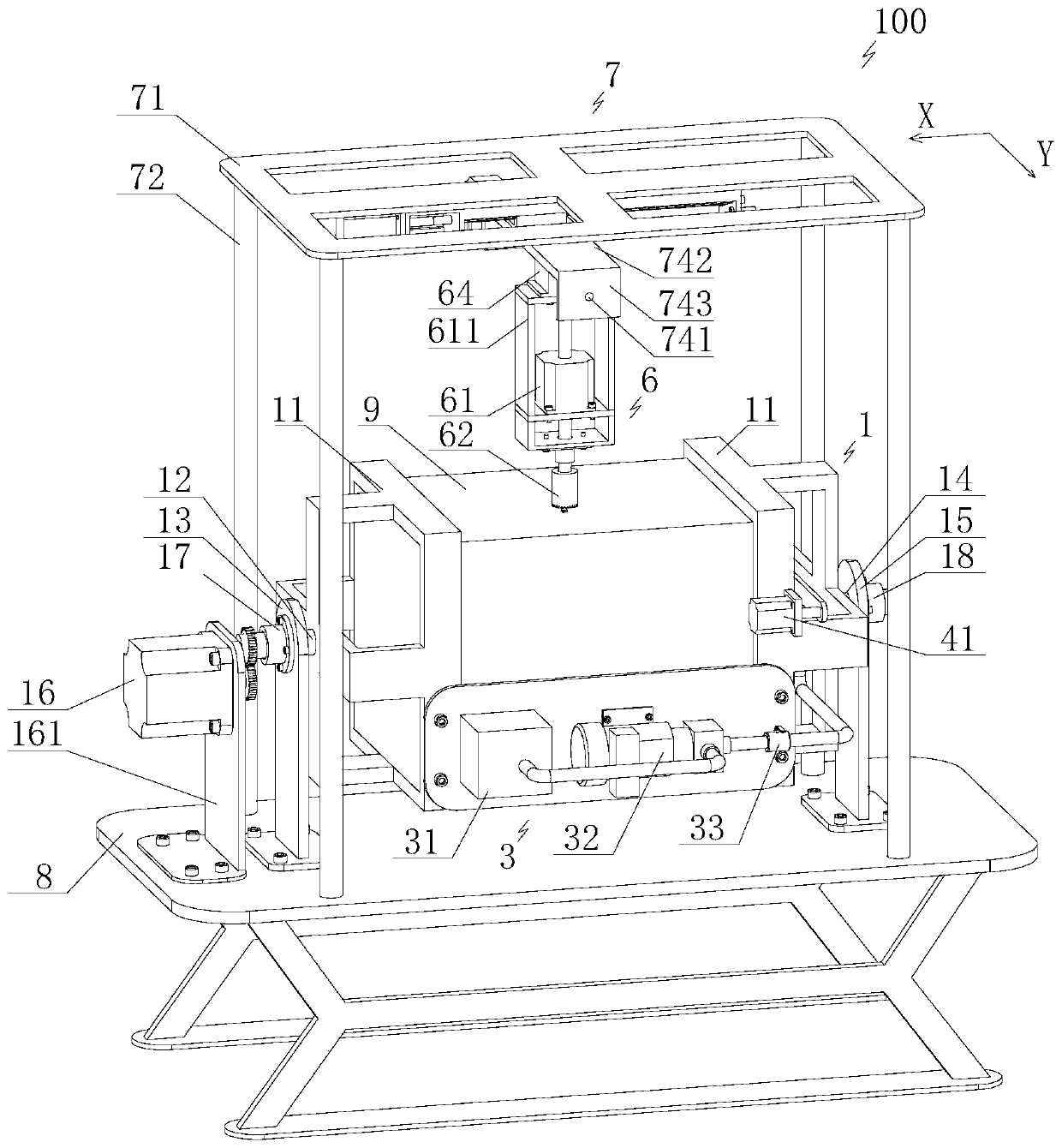

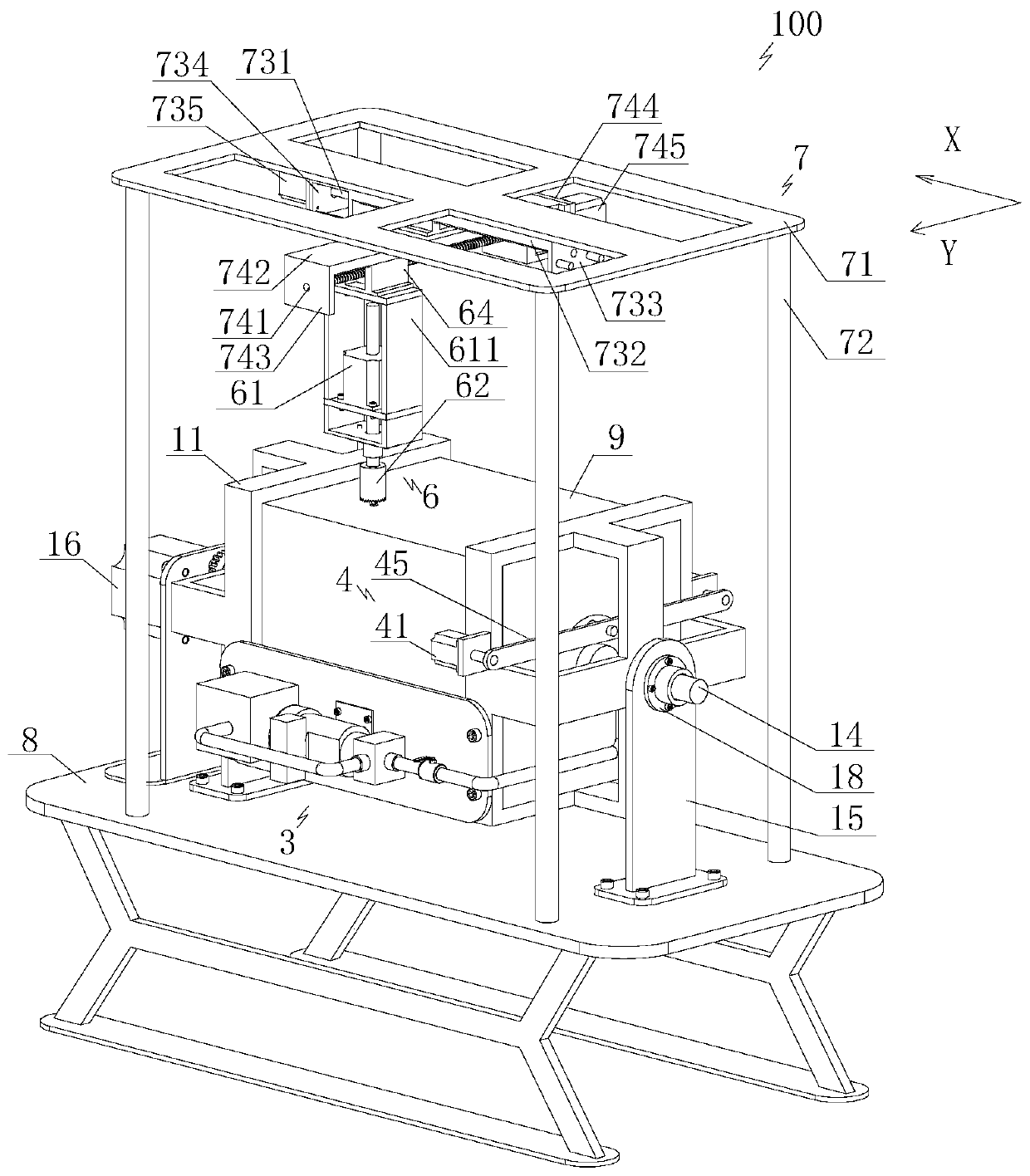

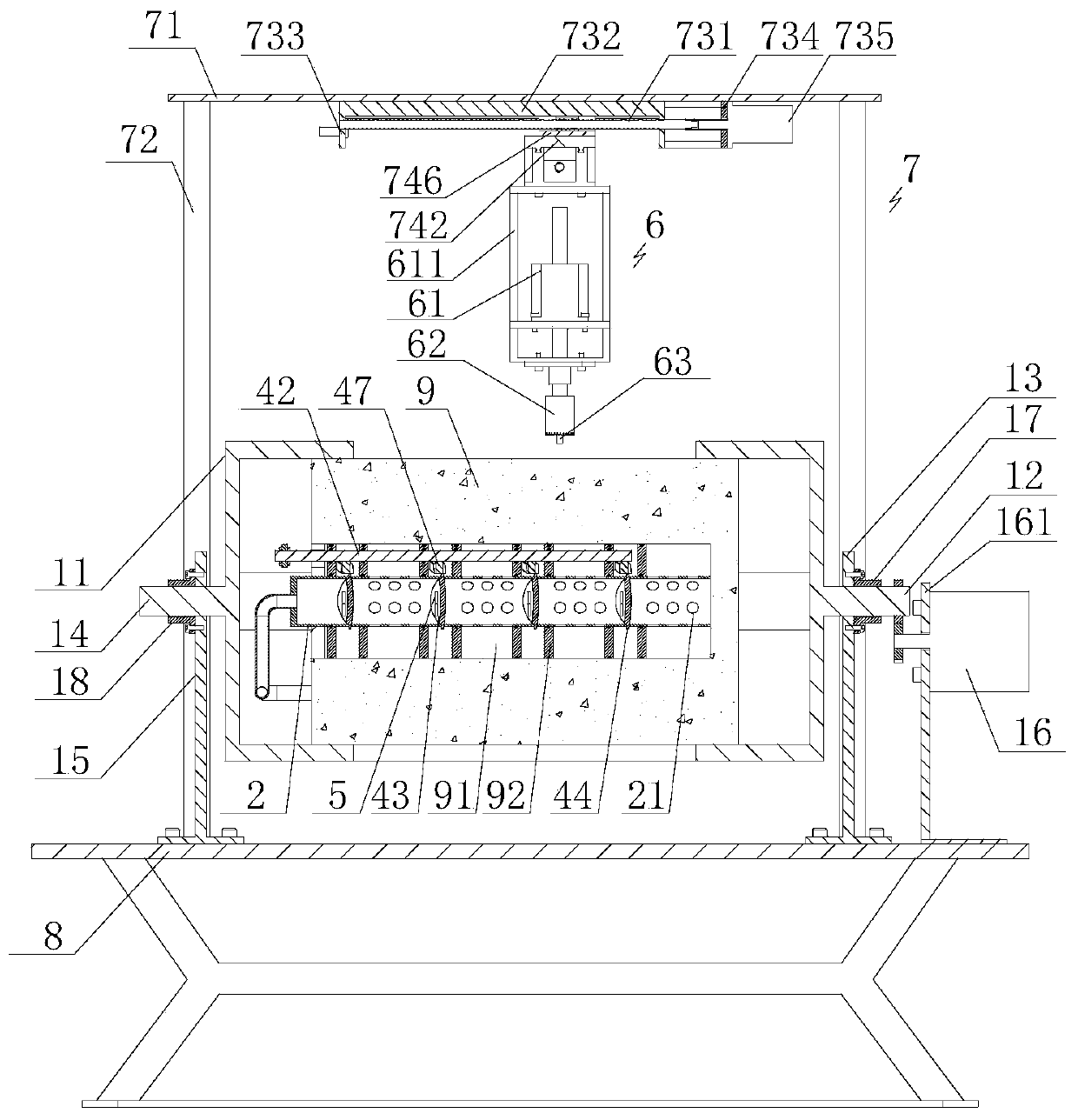

[0050] Such as Figure 1 to Figure 4 As shown, the present invention provides a strain gauge type pressure test tight oil imbibition experimental device 100, which includes a rock clamping structure 1 capable of clamping tight oil rock 9 and rotating around a horizontal axis, and a horizontal shaft containing tight oil rock 9. The cross section is arranged in a rectangular shape; a horizontal fracturing pipe 2 is pierced inward from the side containing the tight oil rock 9, and a horizontal central hole 91 is drilled on the tight oil rock 9, and the fracturing pipe 2 is pierced through the central hole 91; one end of the fracturing pipe 2 can be opened and closed connected to the fracturing fluid injection structure 3, and the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com