Diaphragm apparatus production method, diaphragm apparatus and diaphragm type pressure meter

A manufacturing method and diaphragm-type technology, which is applied in the direction of elastic deformation gauge-type fluid pressure measurement, etc., can solve the problem of low coincidence of function surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The content of the present invention will be described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

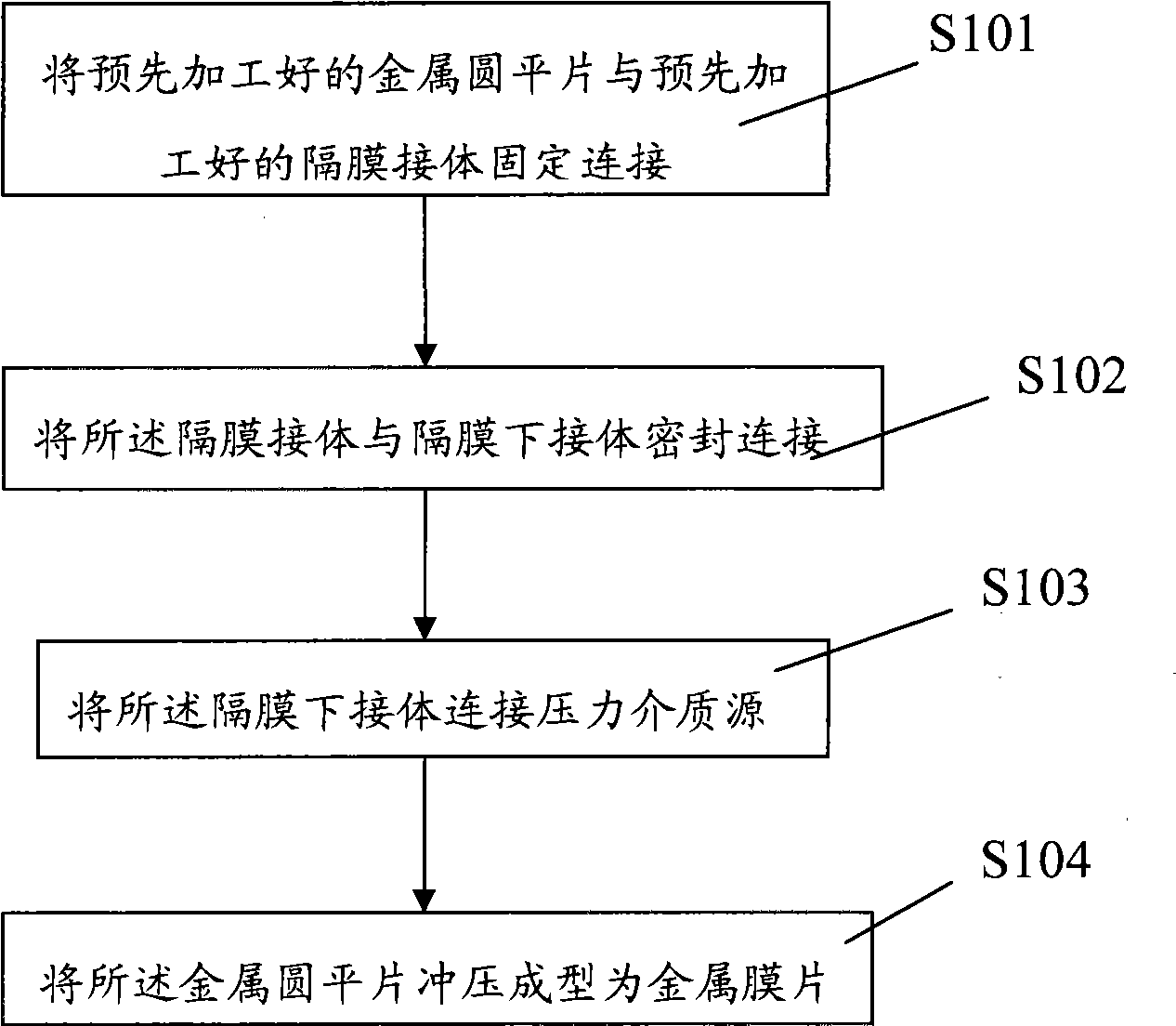

[0034] Please see figure 1 , figure 1 It is a flow chart of the manufacturing method of the diaphragm device provided by the first embodiment of the present invention.

[0035] Such as figure 1 As shown, the manufacturing method of the membrane device comprises the following steps:

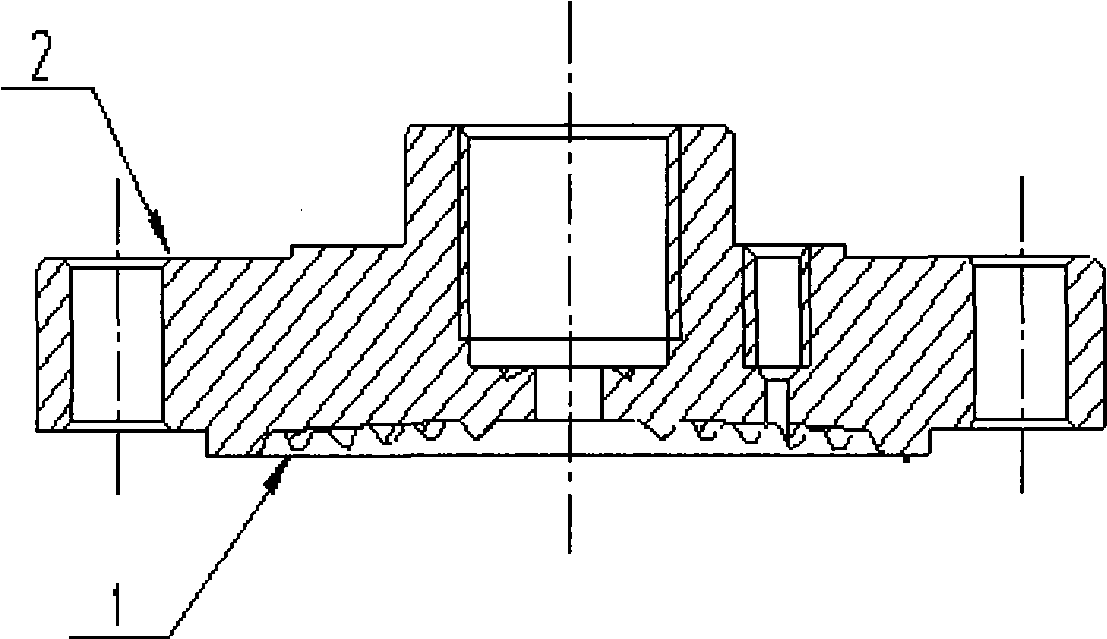

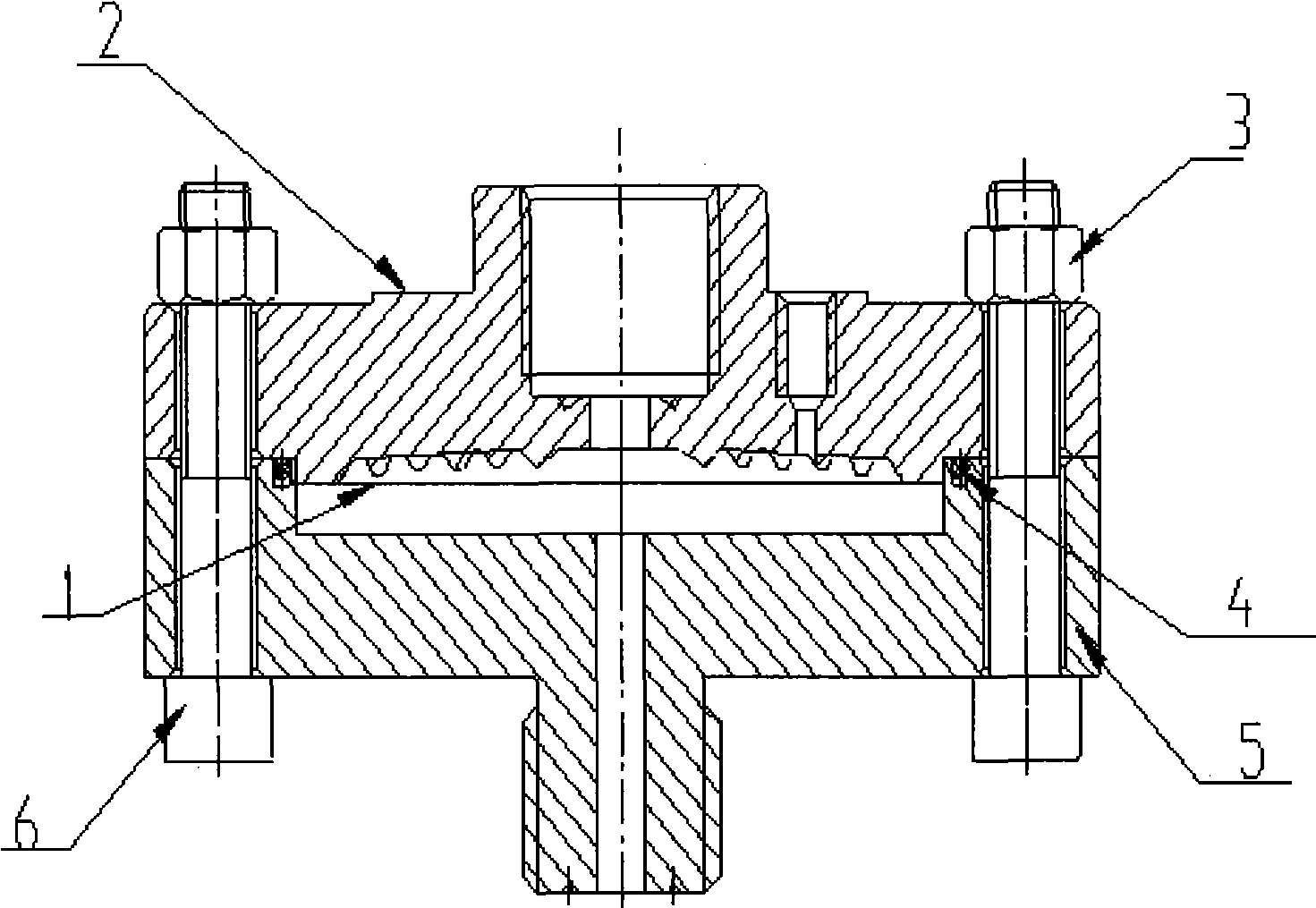

[0036] Step 101, fixedly connect the pre-processed flat metal disc to the pre-processed diaphragm contact body. According to the outer diameter of the drawing, the metal circular flat piece 1 is punched out, and the diaphragm connecting body 2 with a function curved surface is processed with a CNC lathe according to the drawing of the diaphragm connecting body. The outer diameter of the metal round flat piece 1 and the outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com