Ring body for suppressing propagation of earth pressure, its mounting structure, disc cutter and roller device

A technology of earth pressure and ring body, which is applied in the field of disc-shaped hob and roller device, and earth pressure propagation suppression ring body, can solve the problems of increasing production cost and achieve the effect of increasing rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

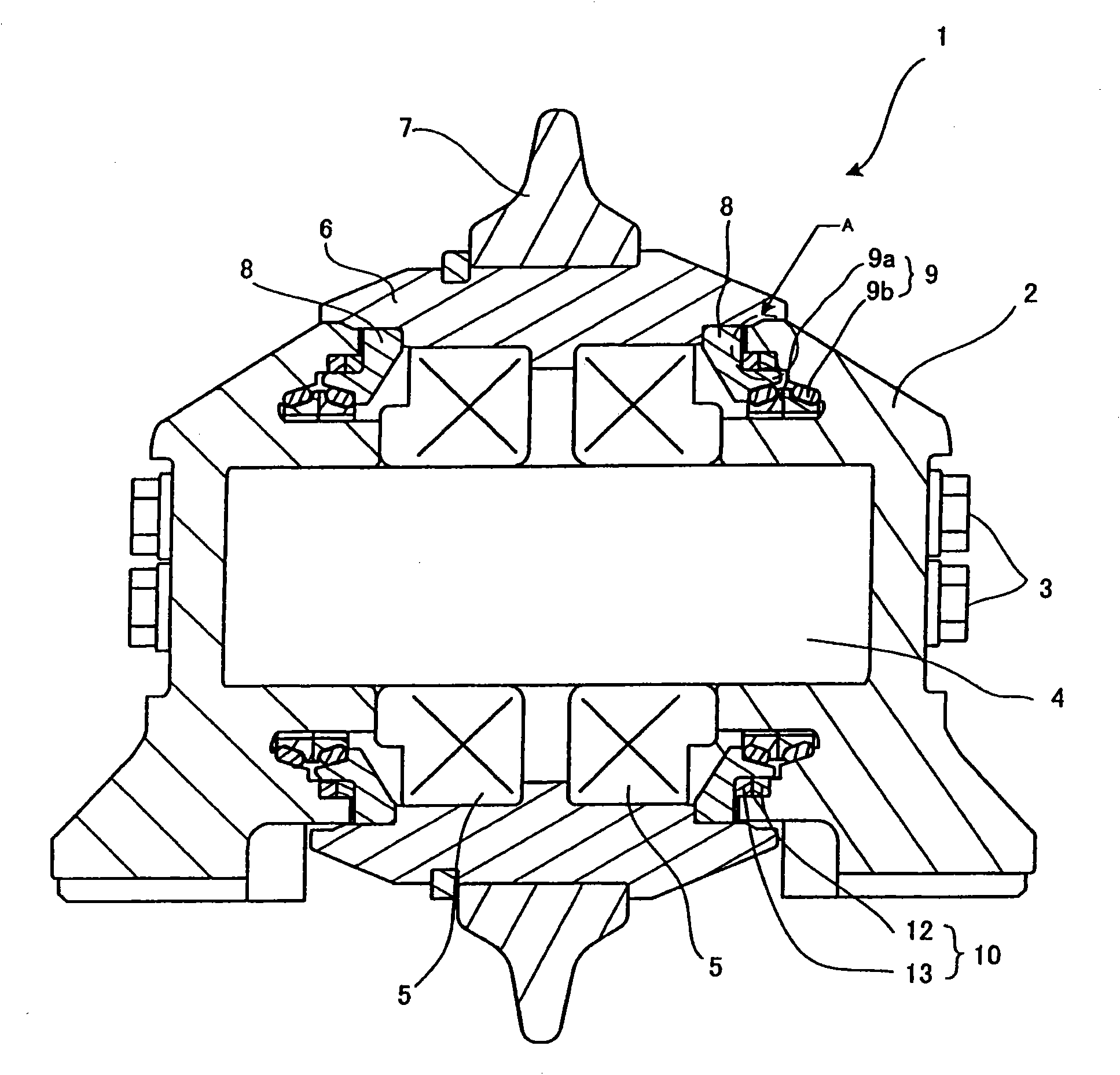

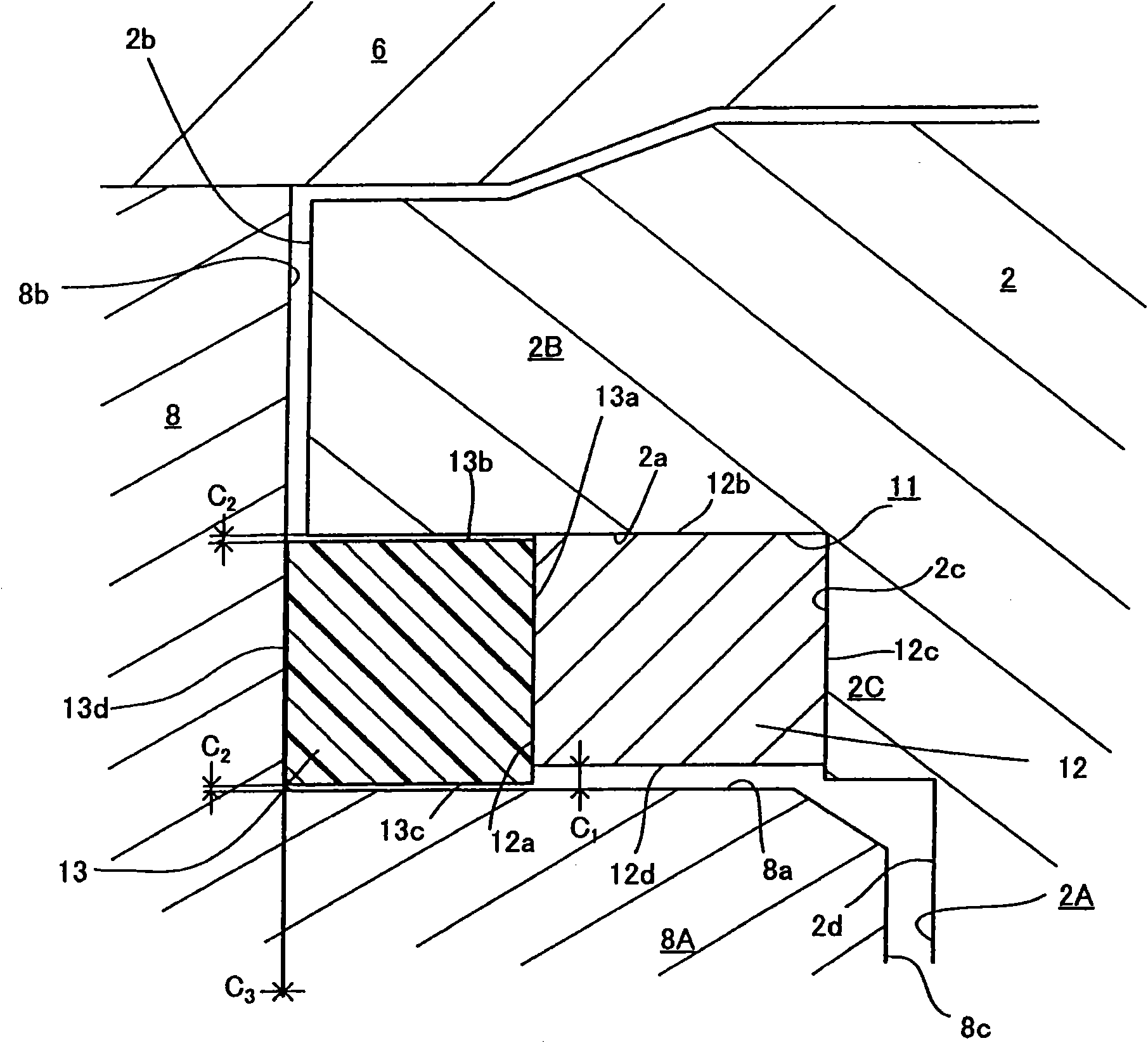

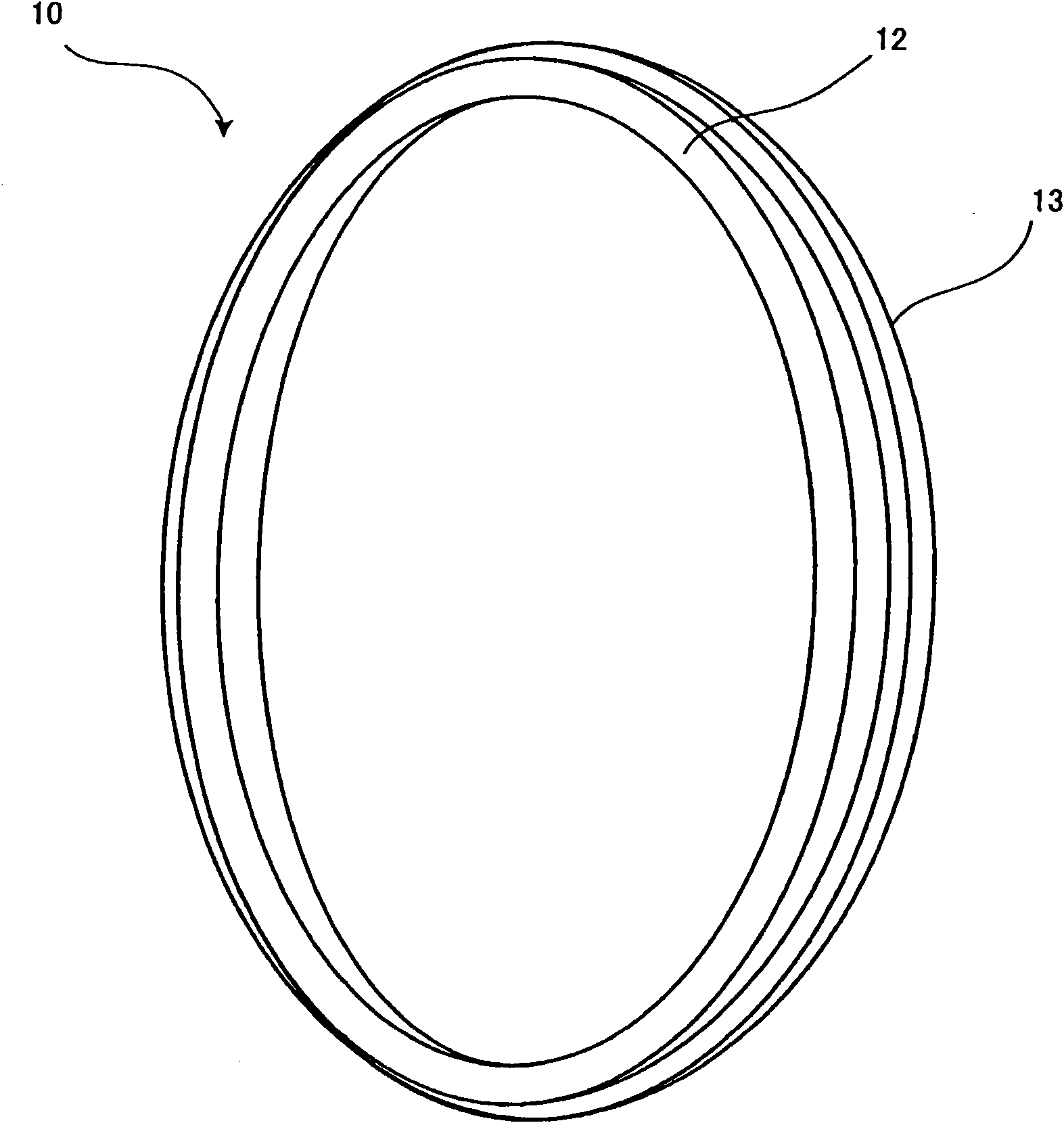

[0037] exist figure 1 shows a sectional view of a disc hob according to the first embodiment of the present invention, in figure 2 shown in figure 1 Enlarged view of part A. Moreover, in image 3 A perspective view of the ring body in this embodiment is shown in .

[0038] This embodiment shows an example applied to a disc hob mounted on a cutter head of a tunnel excavator. The disc hob 1 of the present embodiment includes a pair of holders 2, 2 attached to a not-shown cutter head, and a shaft 4 fixed to the holders 2, 2 with bolts 3. As shown in FIG. A hub 6 is rotatably supported by bearings 5 and 5 on the outer periphery of the shaft 4 , and a cutter ring 7 is non-rotatably supported on the outer periphery of the hub 6 . Furthermore, it is also possible to integrally form the hub with the cutter ring.

[0039] Ring-shaped washers 8 , 8 are fitted into outer ends on the inner peripheral side of the hub 6 , and are fixed to the hub 6 in a non-rotatable and water-tigh...

no. 2 approach

[0051] exist Figure 5 , shows a cross-sectional view of a roller device according to a second embodiment of the present invention. This embodiment shows an example of a roller device applied to a construction machine such as a bulldozer.

[0052] The roller device 20 of the present embodiment includes: a bracket 21 provided on the vehicle body side so as to be non-rotatable; a shaft 22 supported by the bracket 21 so as to be non-rotatable; and a roller 24 supported by a bearing 23 on the shaft 22 In order to be rotatable, the roller device 20 is configured so that a crawler belt (not shown) is guided by the roller 24 . Between the bracket 21 and the roller 24 is installed a floating seal 25 for preventing the intrusion of earth and sand and preventing the leakage of oil filled around the shaft.

[0053] A labyrinth is formed on the outer peripheral side of the floating seal 25, and the ring body 10 of the present invention is attached to the labyrinth. The structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com