Simulating device and method for water producing source and pressure-dropping path during coal-rock reservoir discharge and recovery

A simulation device and reservoir technology, which are applied in the field of coal-rock reservoir drainage and production water production sources and pressure drop path simulation devices, and can solve problems such as unclear pressure propagation distance, unknown water production sources, and influence on accurate prediction of gas production. , to achieve the effect of reducing the difficulty of clamping and the difficulty of confining pressure loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

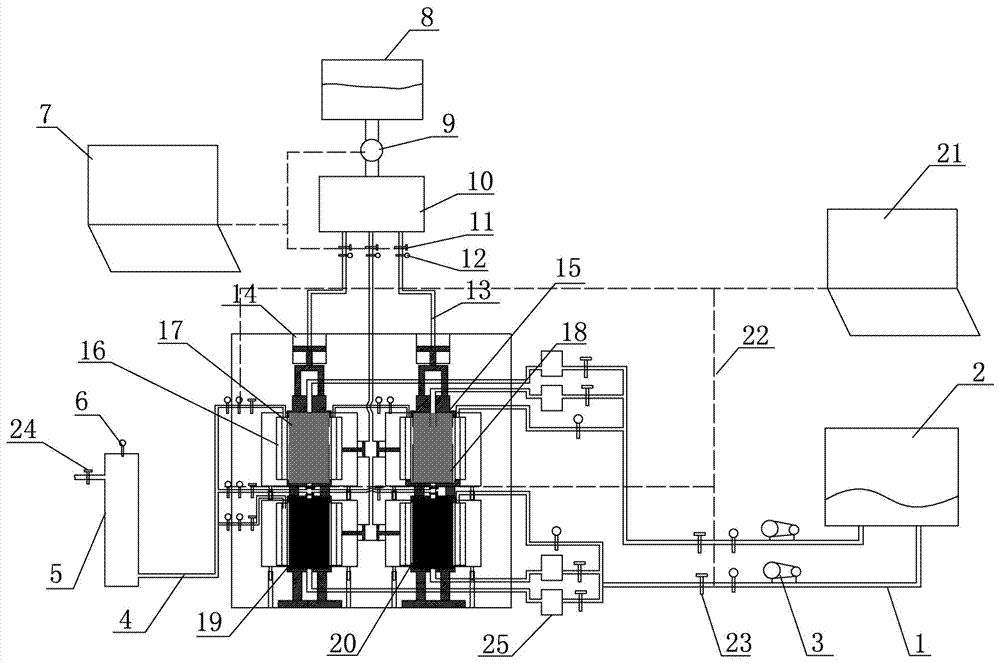

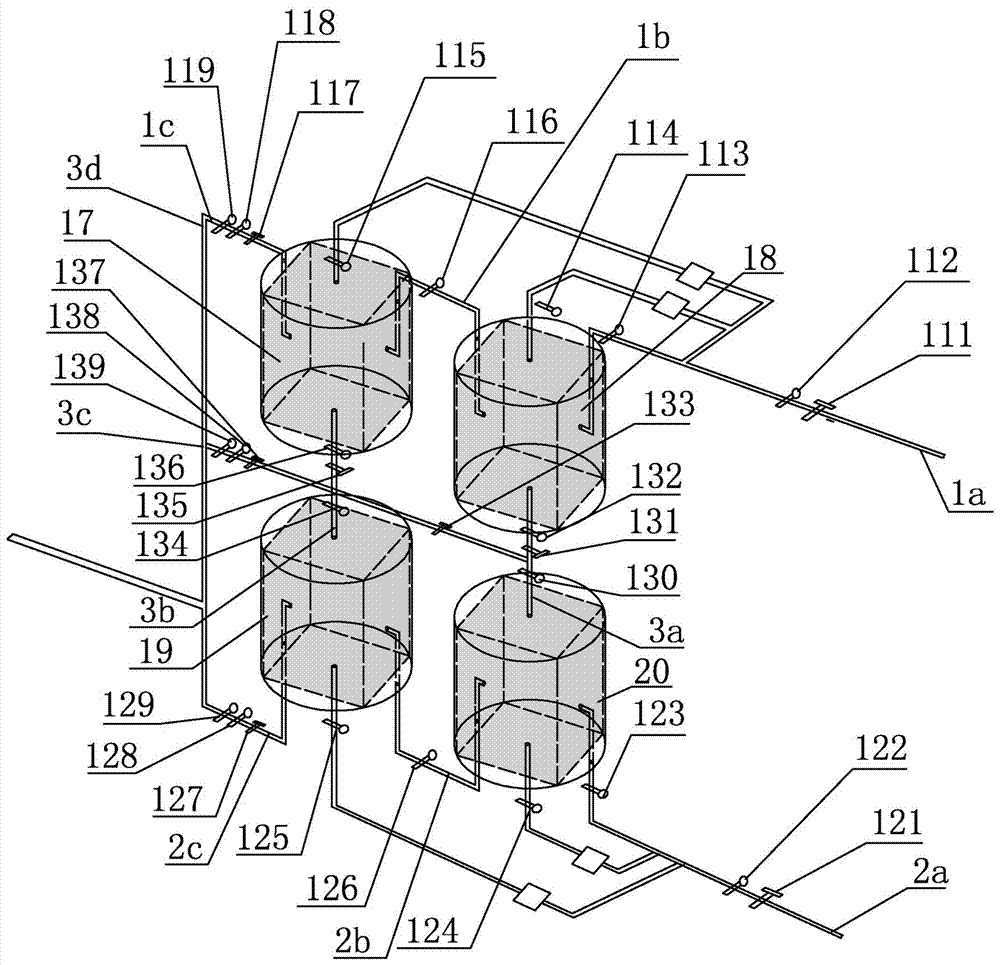

[0034] Embodiment one: see Figure 1-4 A coal-rock reservoir water production source and pressure drop path simulation device includes a sample clamping component, a formation pressure simulation component, a fluid supply / drainage component, and an information collection and control component.

[0035] The sample holding assembly comprises two groups of holders 16, and the first group of holders 16 includes the No. 1 rock sample holder and the No. 1 coal sample holder arranged below the No. 1 rock sample holder, and the second The set of holders 16 includes No. 2 rock sample holder and No. 2 coal sample holder located below the No. 2 rock sample holder.

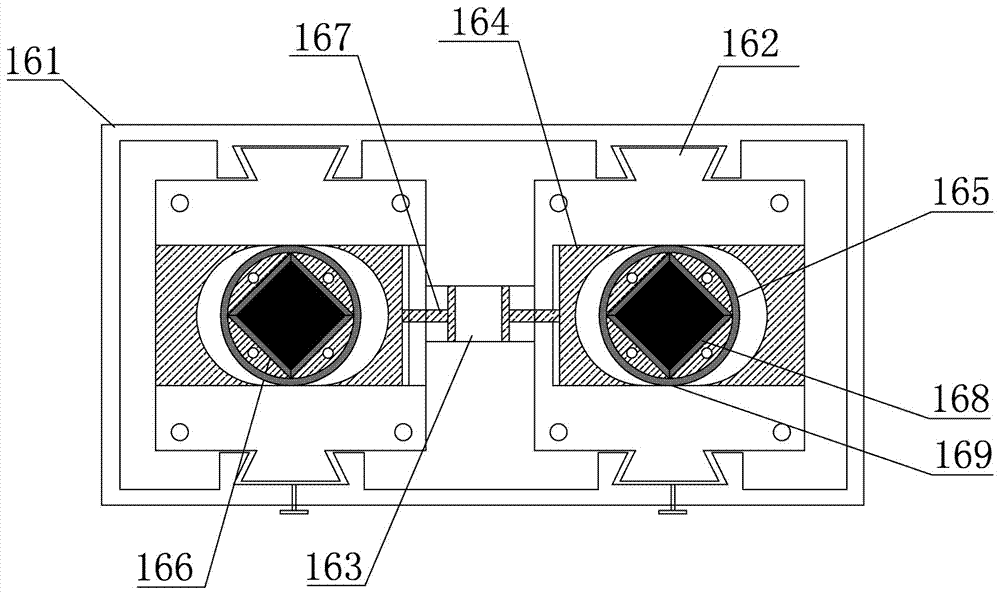

[0036] The formation pressure simulation component includes an oil tank 8 , an oil pressure pump 9 , a flow divider 10 , an axial pressure loading cylinder 14 and a confining pressure loading cylinder 163 . One side of the coal sample holder and the rock sample holder is respectively provided with a confining pressure loadin...

Embodiment 2

[0040] Embodiment 2: A method based on coal-rock reservoir drainage production water source and pressure drop path simulation device, comprising the following steps:

[0041] 1) Sample preparation and sealed clamping

[0042] Select the underground coal seam and roof samples of the coal mine, cut and grind them into cube samples of 50 × 50 × 50 mm (or 100 × 100 × 100 mm) (samples with corresponding specifications can be prepared according to the experimental requirements) ((different permeable samples can be selected according to the experimental requirements) rate or the degree of crack development), wrap the sample tightly with a heat shrinkable rubber sleeve, cut 25×25 mm holes on the two top surfaces and two opposite sides, and then place the four diversion pads 165 Paste on the four sides of the sample to form a cylindrical sample and then wrap it with a rubber sleeve. Place the sample in the holder 16, clamp the sealing sleeve 15 on the two bottom surfaces of the sample,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com