Suspension type headstock chair bracket welding fixture

A welding fixture and suspension technology, which is applied to welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient operation of workers, difficulty of clamping operation and increase of labor intensity, etc., which is beneficial to welding operation. , Improve binding effect, avoid sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

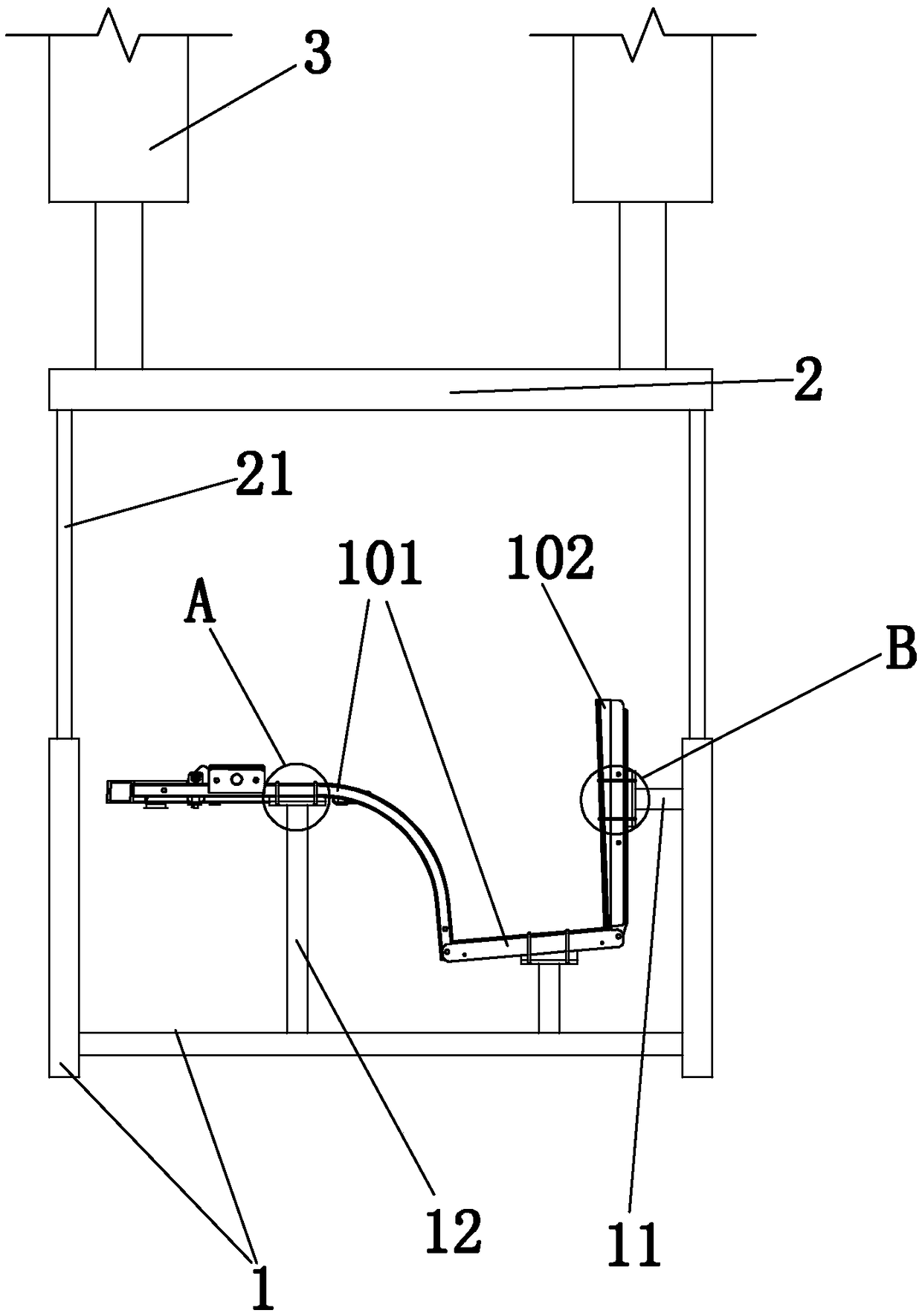

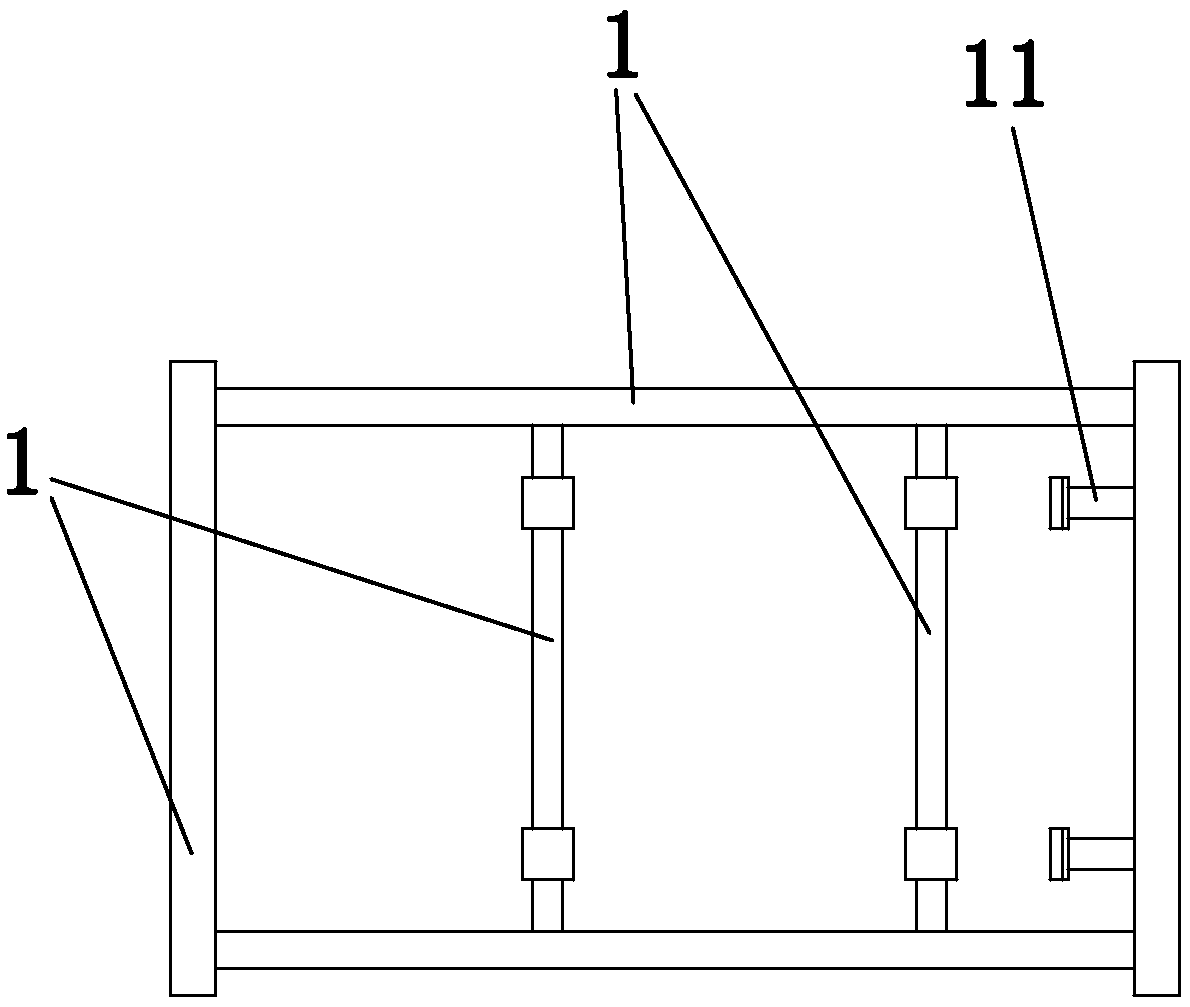

[0028] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 as shown in

[0029] A welding jig for a suspension type head seat bracket, comprising

[0030] Positioning frame 1, lifting frame 2 and several driving cylinders 3 for driving the lifting frame up and down;

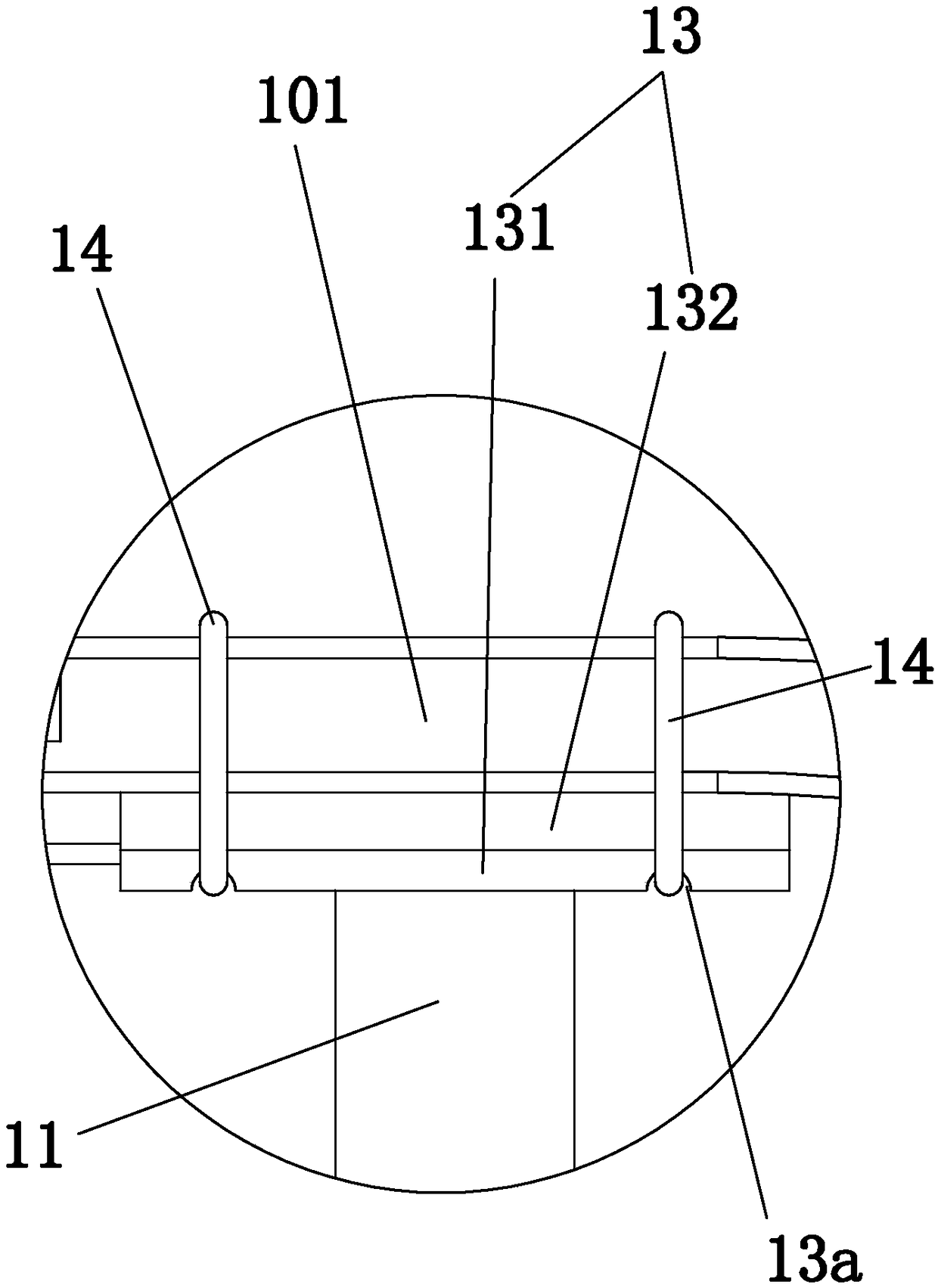

[0031] The positioning frame is provided with some first fixing devices for fixing the front seat bracket and some second fixing devices for fixing the front pillar of the pedal. The first fixing device includes the first base rod 11, the parts support plate 13 and A plurality of straps 14, the second fixing device includes a second base rod 12, a component support plate 13 and a plurality of straps 14;

[0032] In a first fixing device: one end of the first base rod is connected to the positioning frame, the other end of the first base rod is connected to the part support plate, and the part support plate and the front seat bracket are bound by straps;

[0033] In a second fixing device: one end o...

Embodiment 2

[0040] Embodiment 2: based on embodiment 1, such as Figure 5 , Figure 6 as shown,

[0041] It also includes a number of welding dust cleaning devices arranged on the positioning frame and corresponding to the welding positions one by one. The welding dust cleaning device includes an air pump 4 and an air blowing pipe 5. In one welding dust cleaning device: the outlet of the air pump is connected to the inlet end of the air blowing pipe. The gas outlet end of the blowing tube faces the corresponding welding position. When welding for a certain welding position, the welding dust cleaning device corresponding to the welding position will blow air to quickly remove the welding dust (hereinafter referred to as impurities) at the welding position.

[0042] The welding dust cleaning device also includes a suction pipe 6 and a blanking pipe 7, the inlet of the air pump is connected to the outlet of the suction pipe, the inlet of the suction pipe is provided with a suction horn tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com