Subsurface gate processing technology

A latent gate and processing technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult placement, difficult to archive, large pressure loss, etc., to avoid manual clamping and The effect of disassembly and assembly, improving the degree of automatic production and reducing the difficulty of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

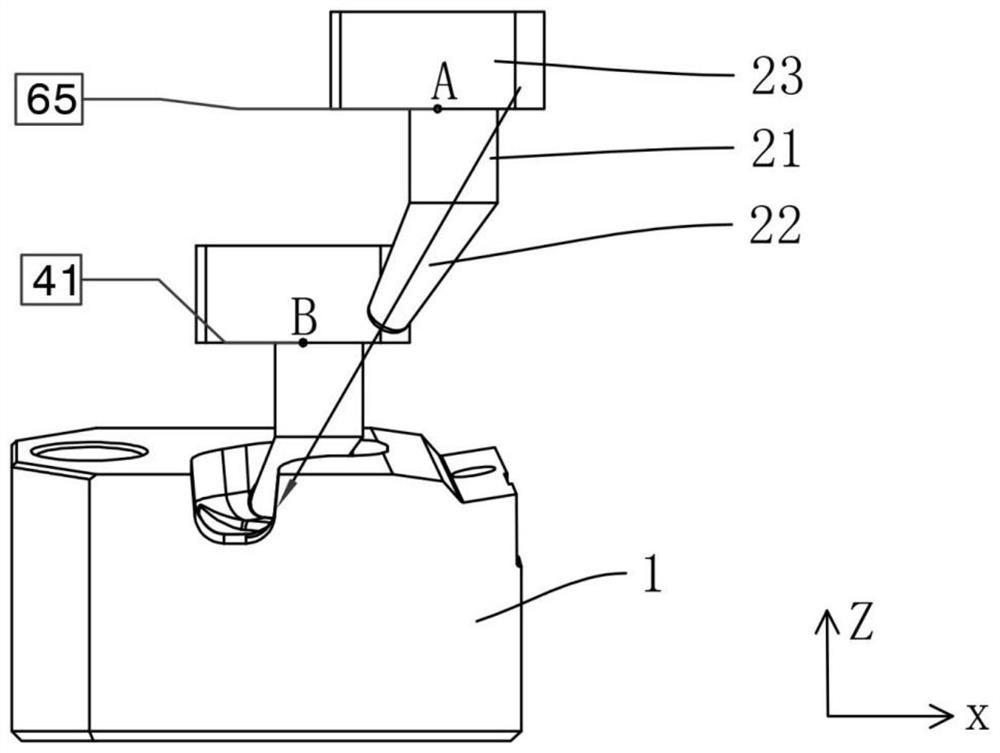

[0032] The present invention is further explained in conjunction with the accompanying drawings.

[0033] see figure 1 A kind of latent gate processing technology shown, comprises the following steps:

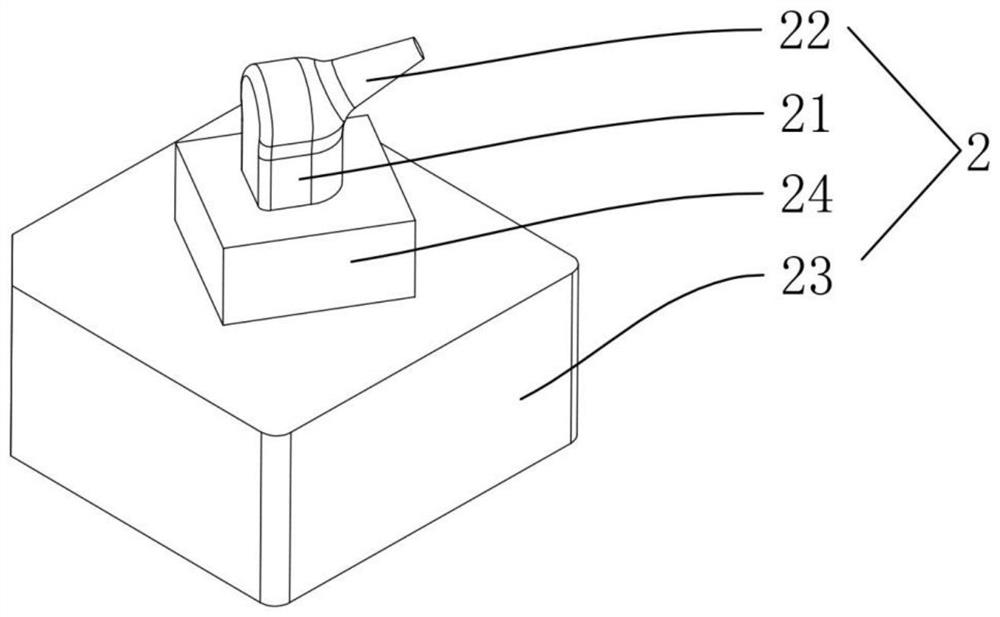

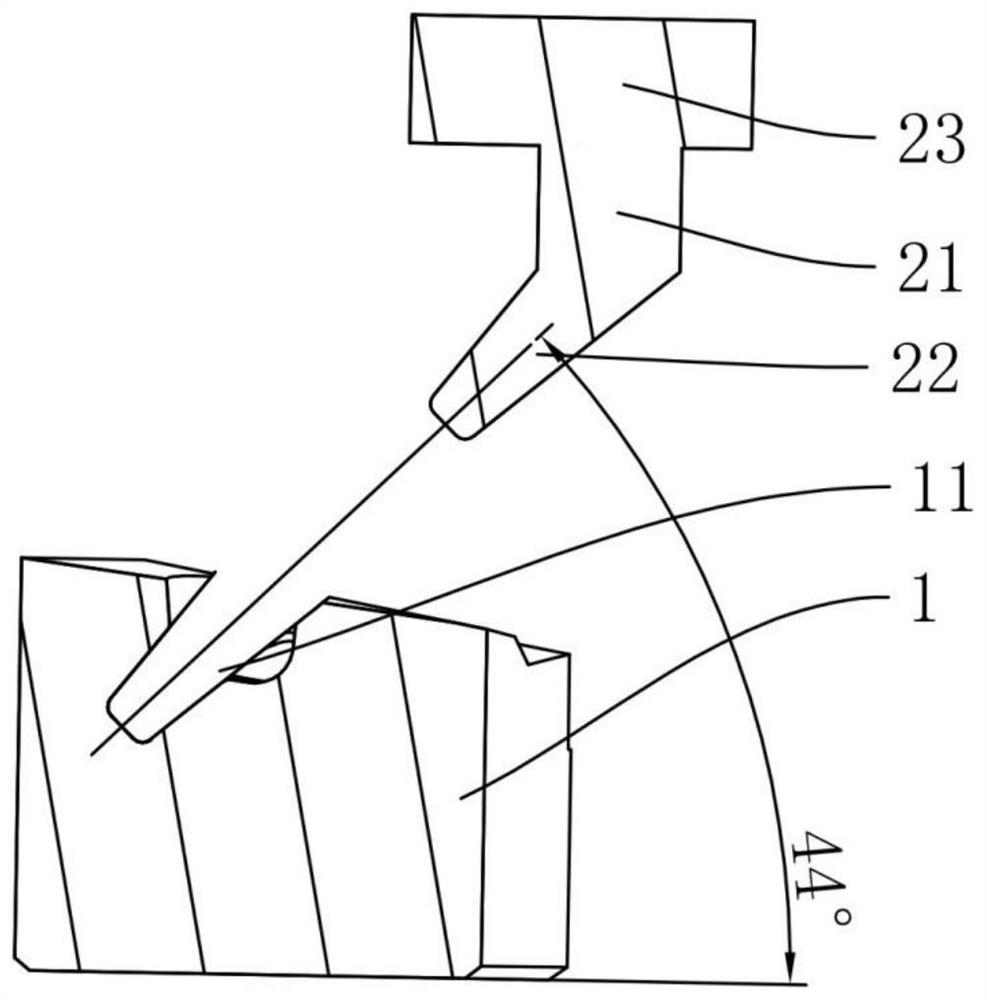

[0034] a. Manufacture an integrated electrode according to the shape of the gate, wherein the integrated electrode includes a reference platform, a connecting part formed on the reference platform, and an electrode head formed by extending the end of the connecting part obliquely outwards, the integrated electrode It also includes a reinforcement seat formed between the reference platform and the connection part to strengthen the strength of the connection part. Since the electrode tip and the workpiece will be subjected to contact discharge machining during processing, the connection part and the connection part will be strengthened by setting the reinforcement part. The strength of the electrode tip is to avoid damage during processing. The bottom surface of the reference pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com