Pressure-propagation-based method for determining discharge and recovery speed at initial stage of coalbed methane exploitation

A technology for the development and determination of coalbed methane, which is applied in the fields of production fluids, earthwork drilling, special data processing applications, etc., and can solve the problems of blockage of seepage channels, small pressure drop funnels, and lack of theoretical foundations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

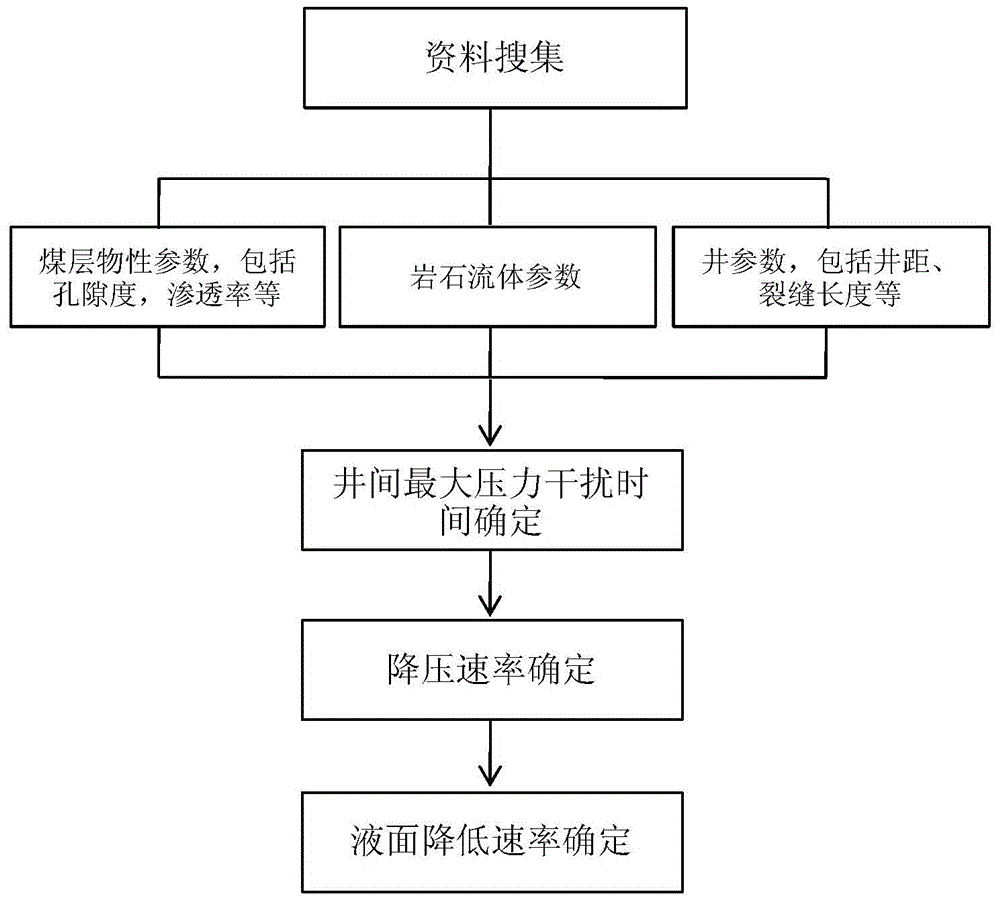

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] Before describing the technical solution of the present invention, first briefly explain the principle on which the present invention is based, mainly including the following two points:

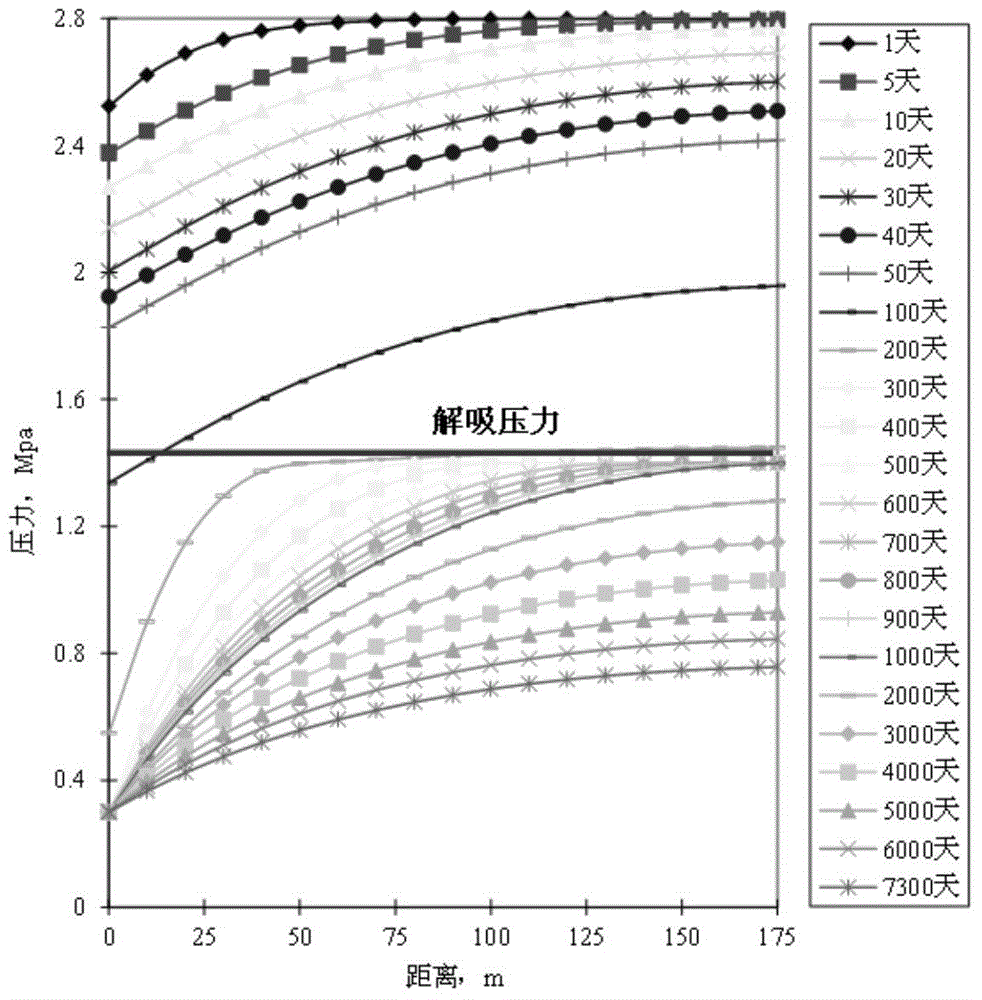

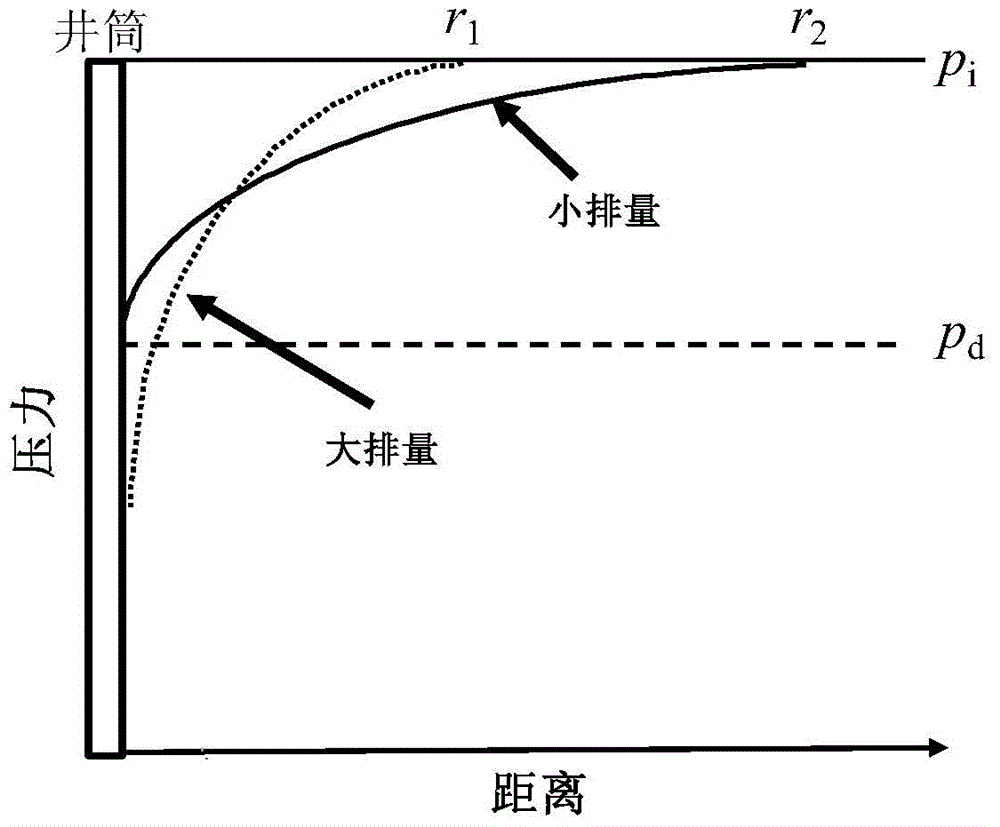

[0023] First, the gas-water two-phase pressure propagation velocity during CBM development is significantly smaller than that in the initial single-phase water stage: by figure 1 It can be seen that the pressure drop speed is fast when the drainage is fixed at the initial stage; as the pressure drops to the desorption pressure, a gas-liquid two-phase flow is formed, and the pressure drop is mainly consumed in the gas-water two-phase region, and the two-phase region expands slowly.

[0024] Second, too fast drainage speed will lead to premature gas breakthrough in the gas well. Once the gas breakthrough occurs, the pressure drop will be mainly consumed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com