Patents

Literature

61results about How to "Maximize visibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

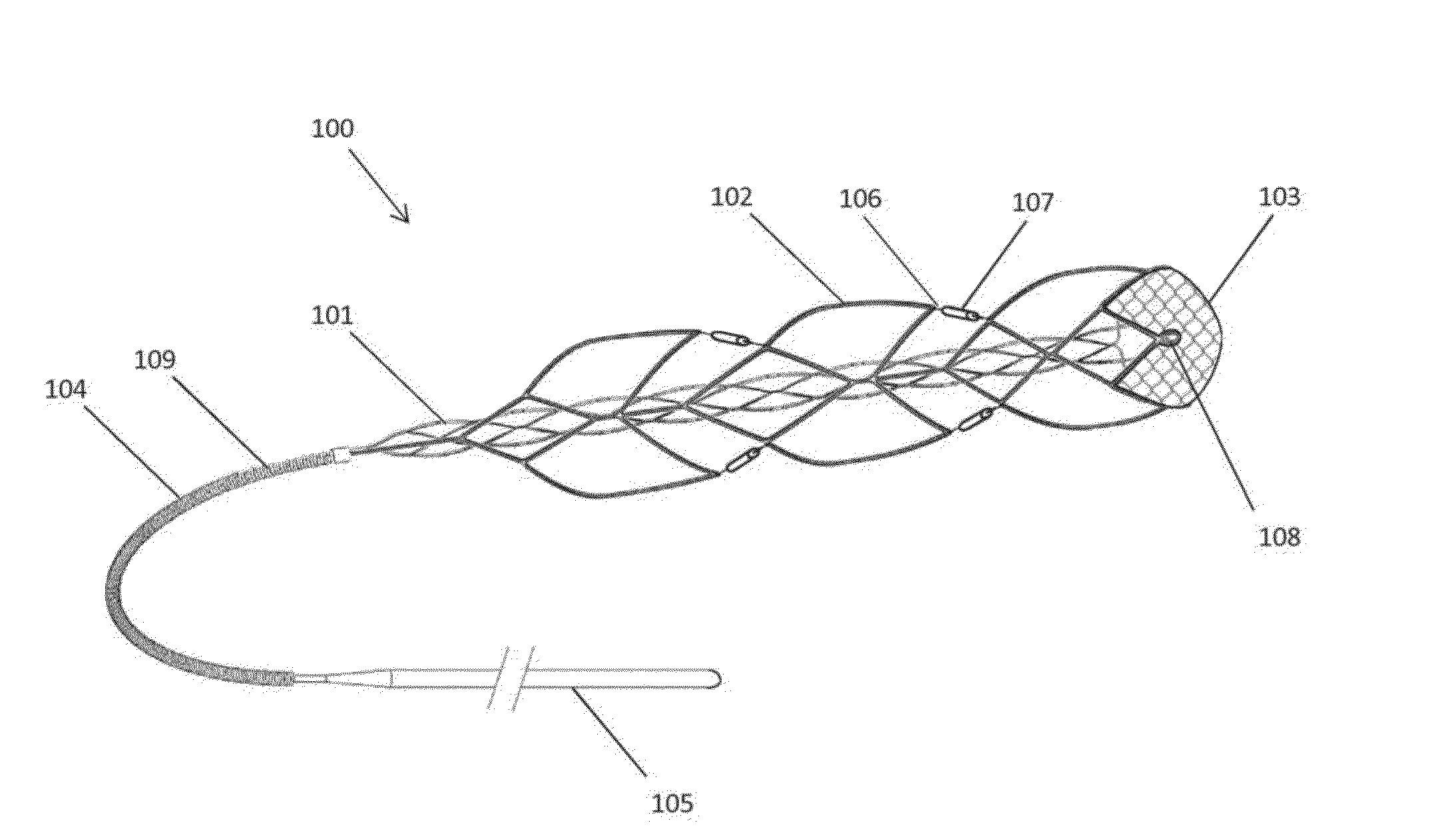

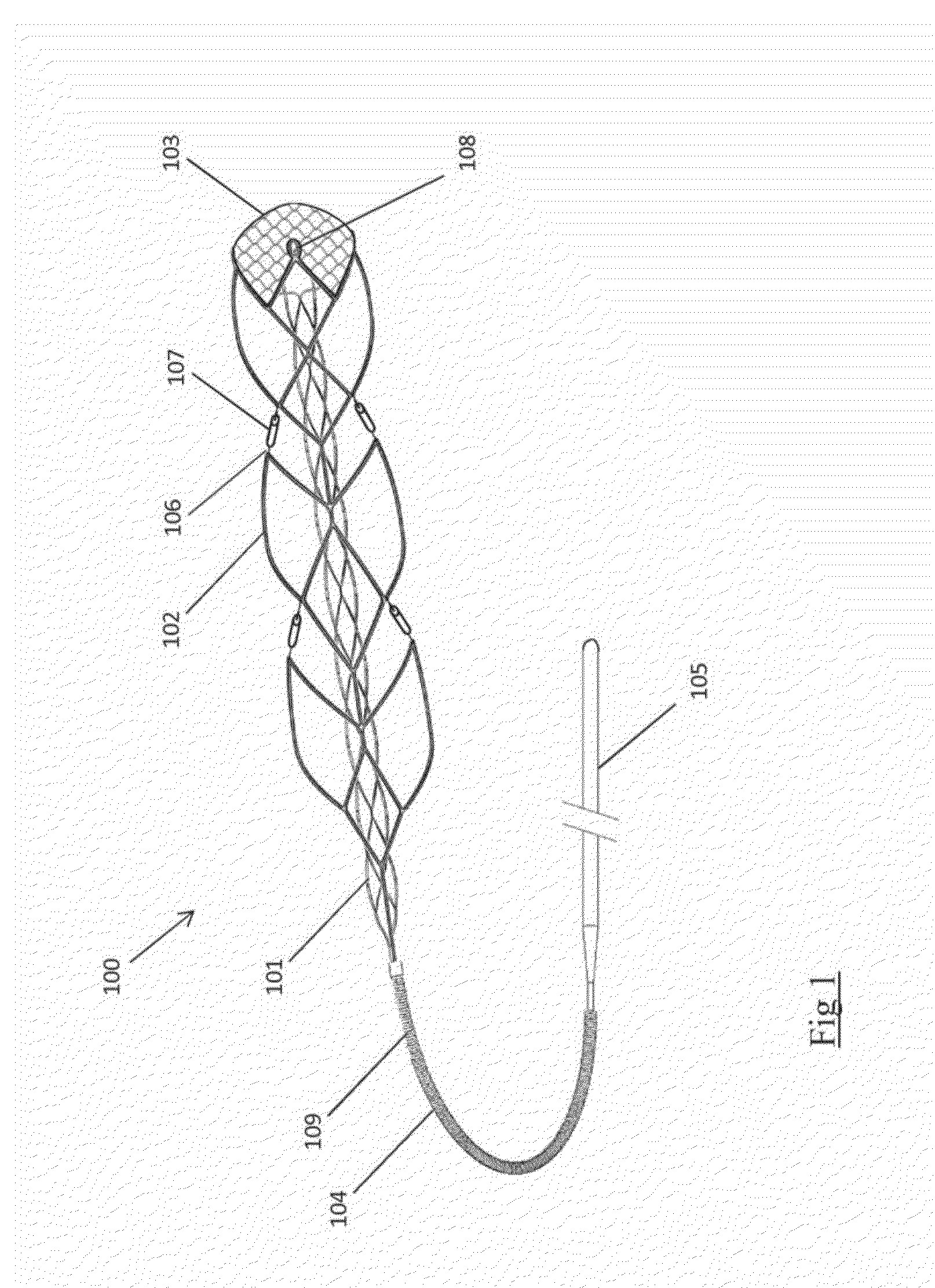

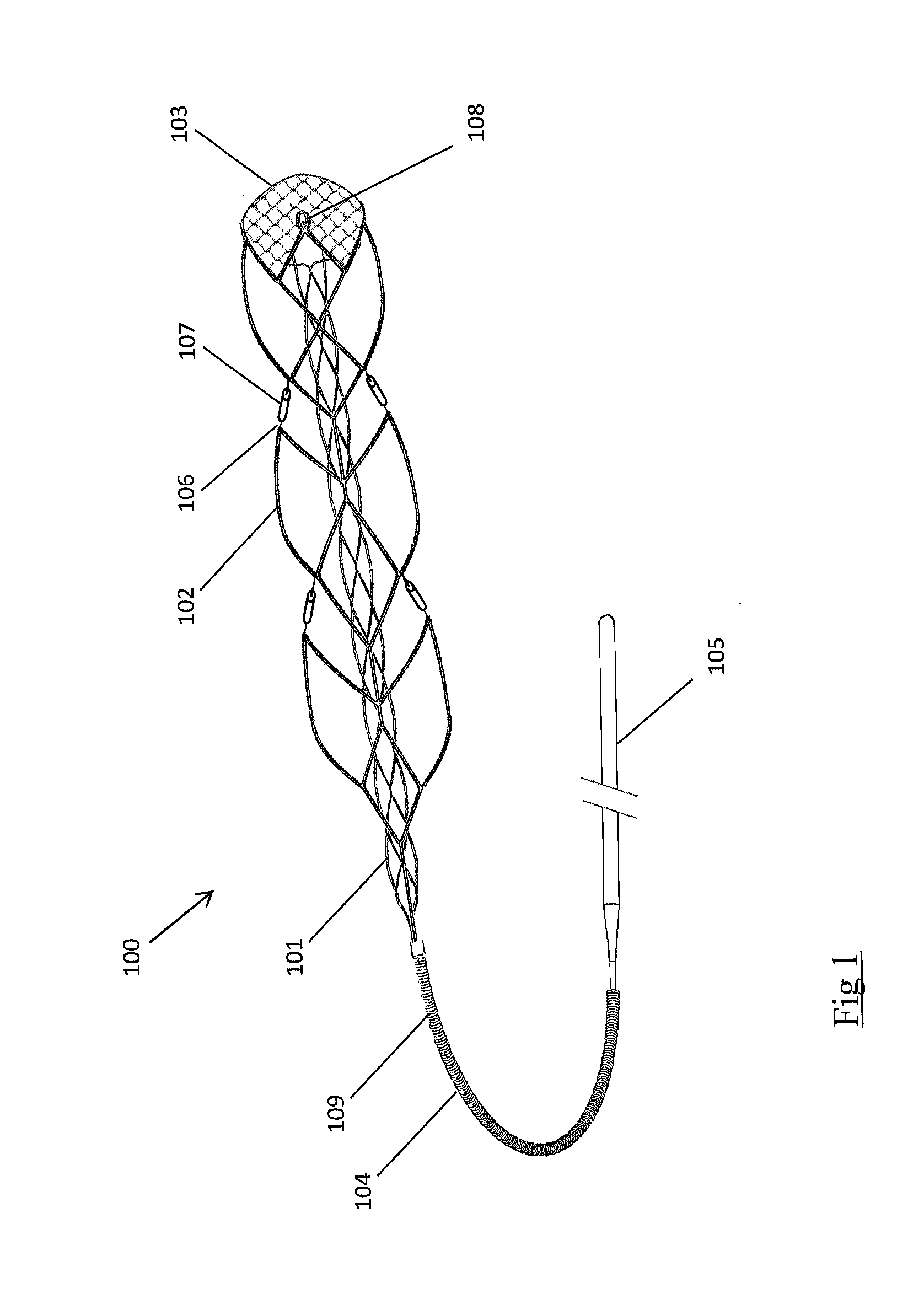

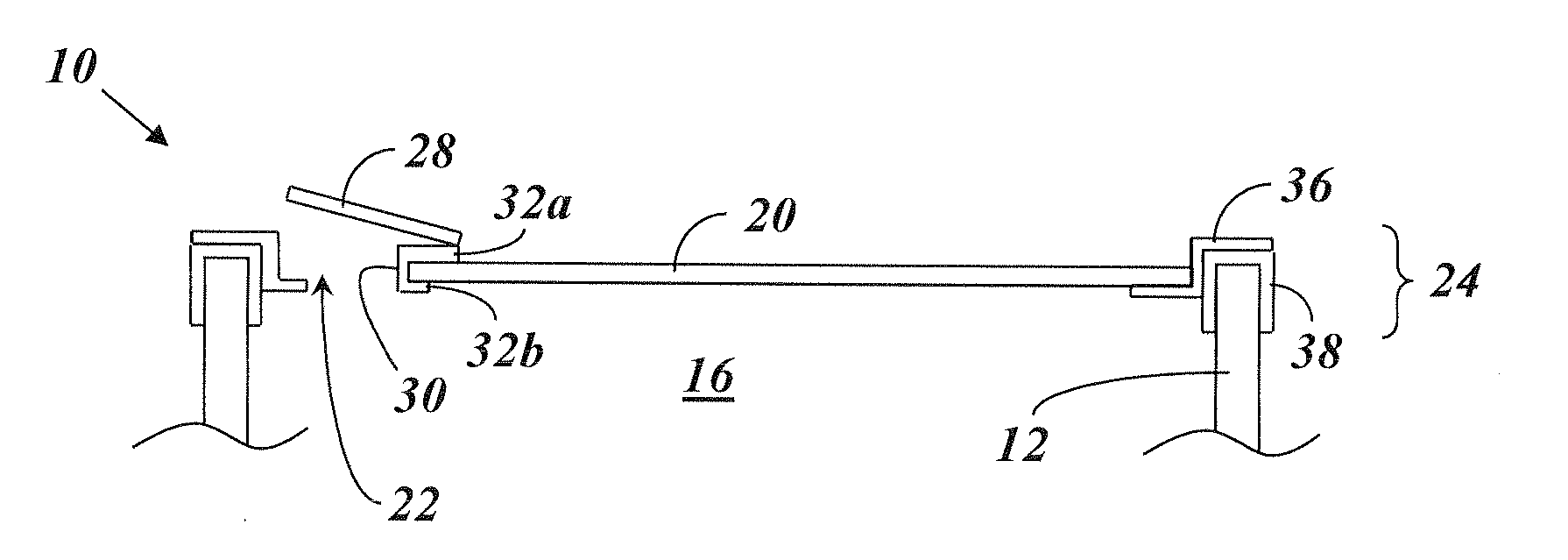

Devices and methods for removal of acute blockages from blood vessels

ActiveUS20160015402A1Maximize visibilityArea maximizationCannulasDiagnosticsBiomedical engineeringBlood vessel

Owner:NEURAVI

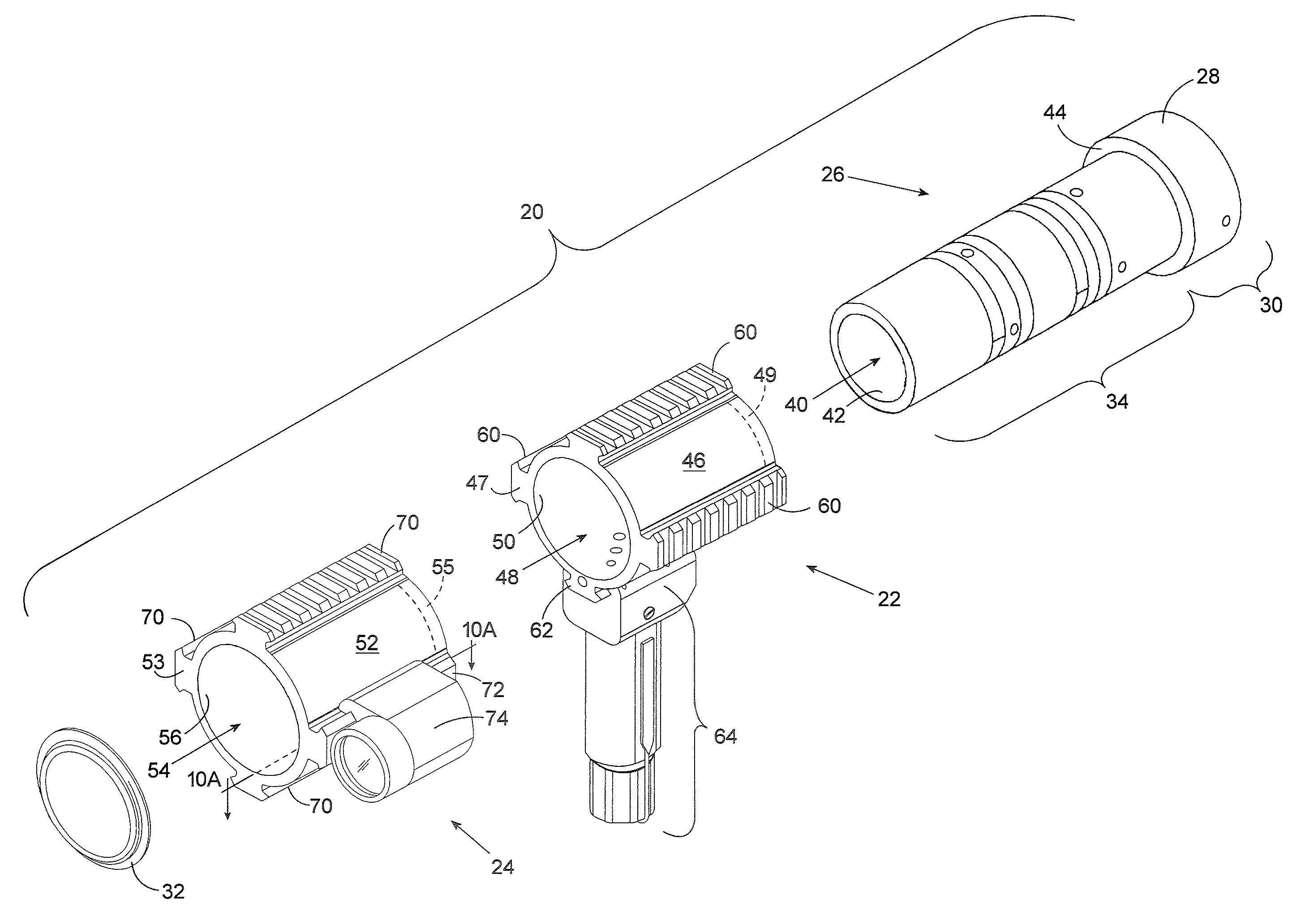

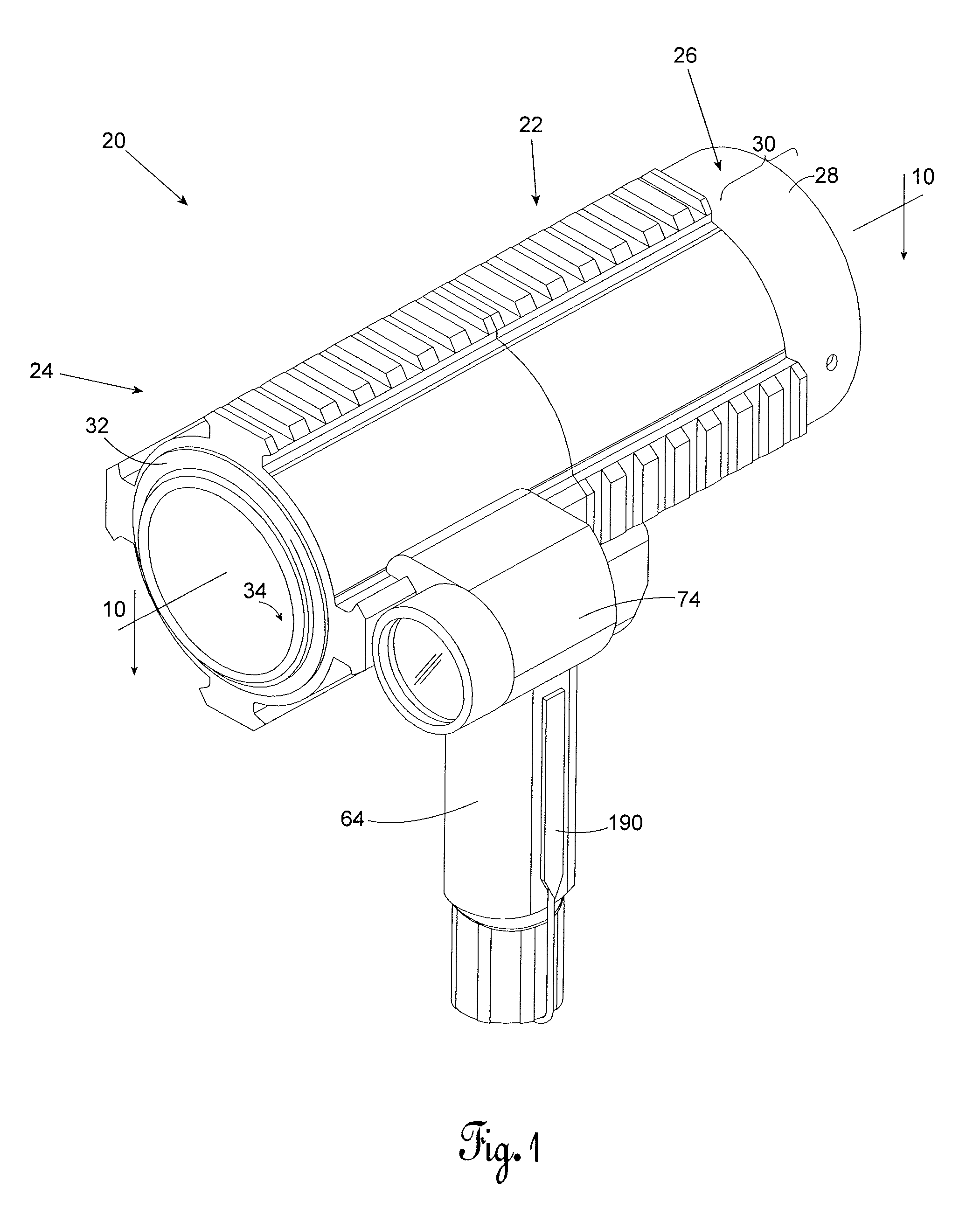

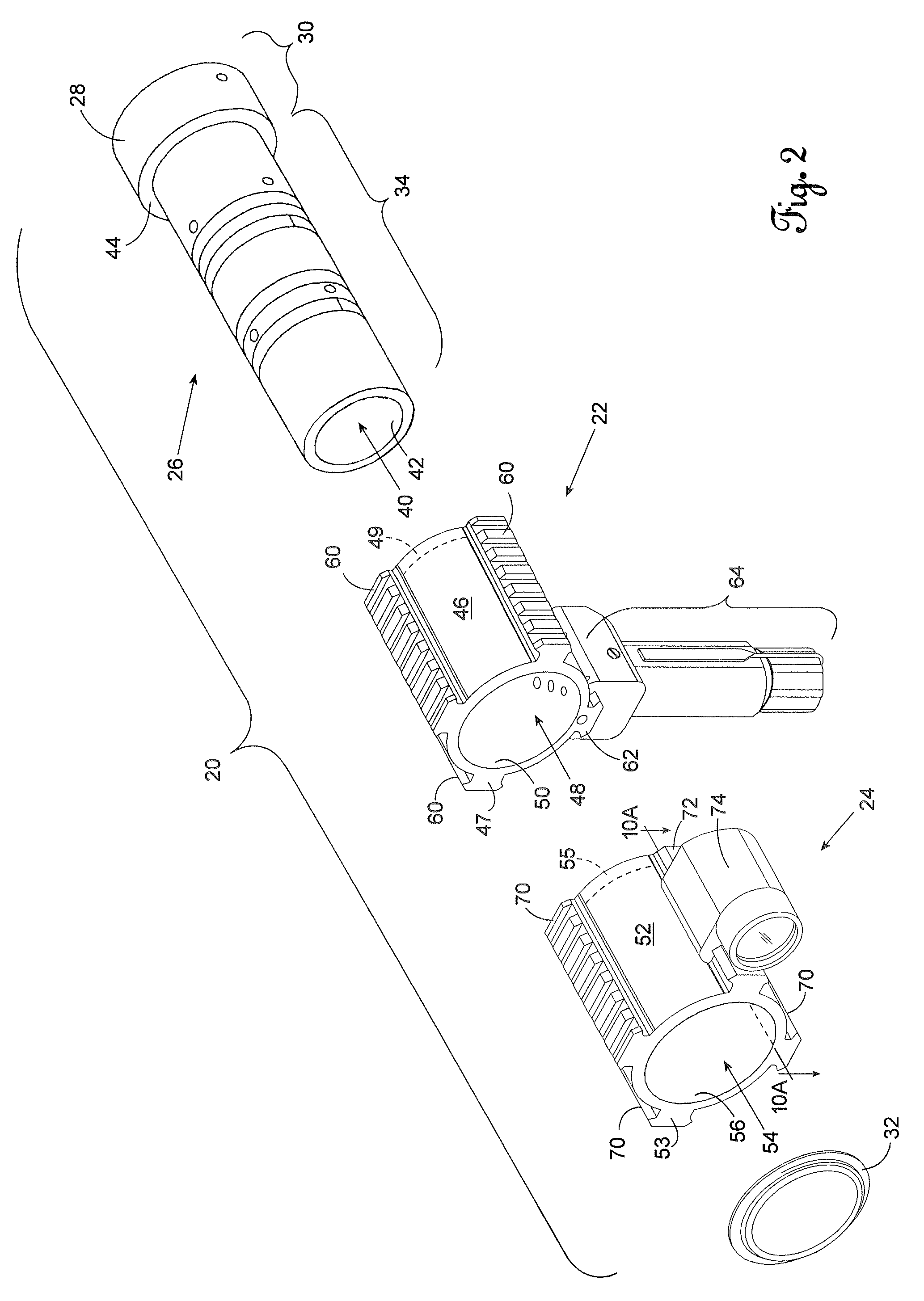

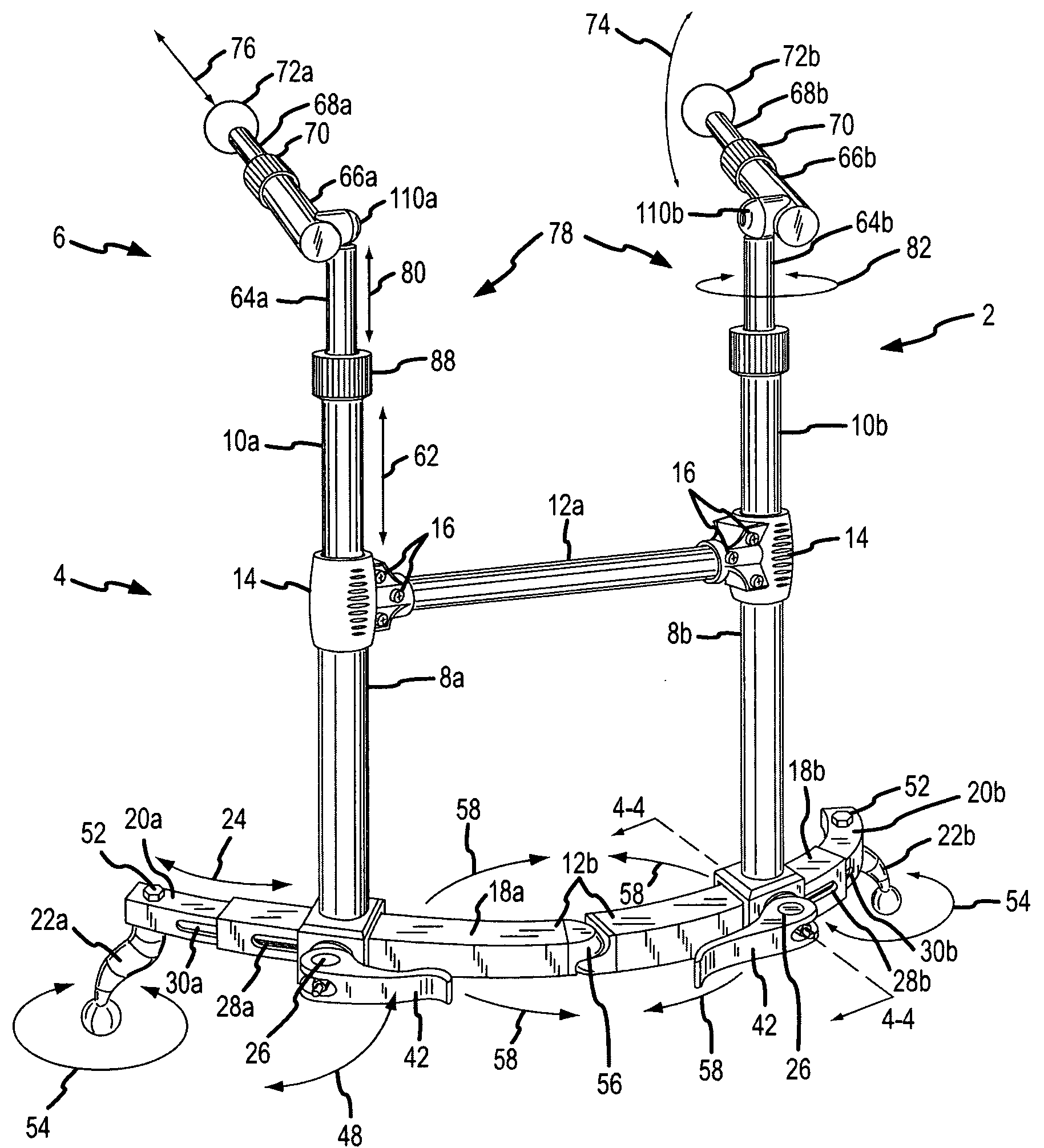

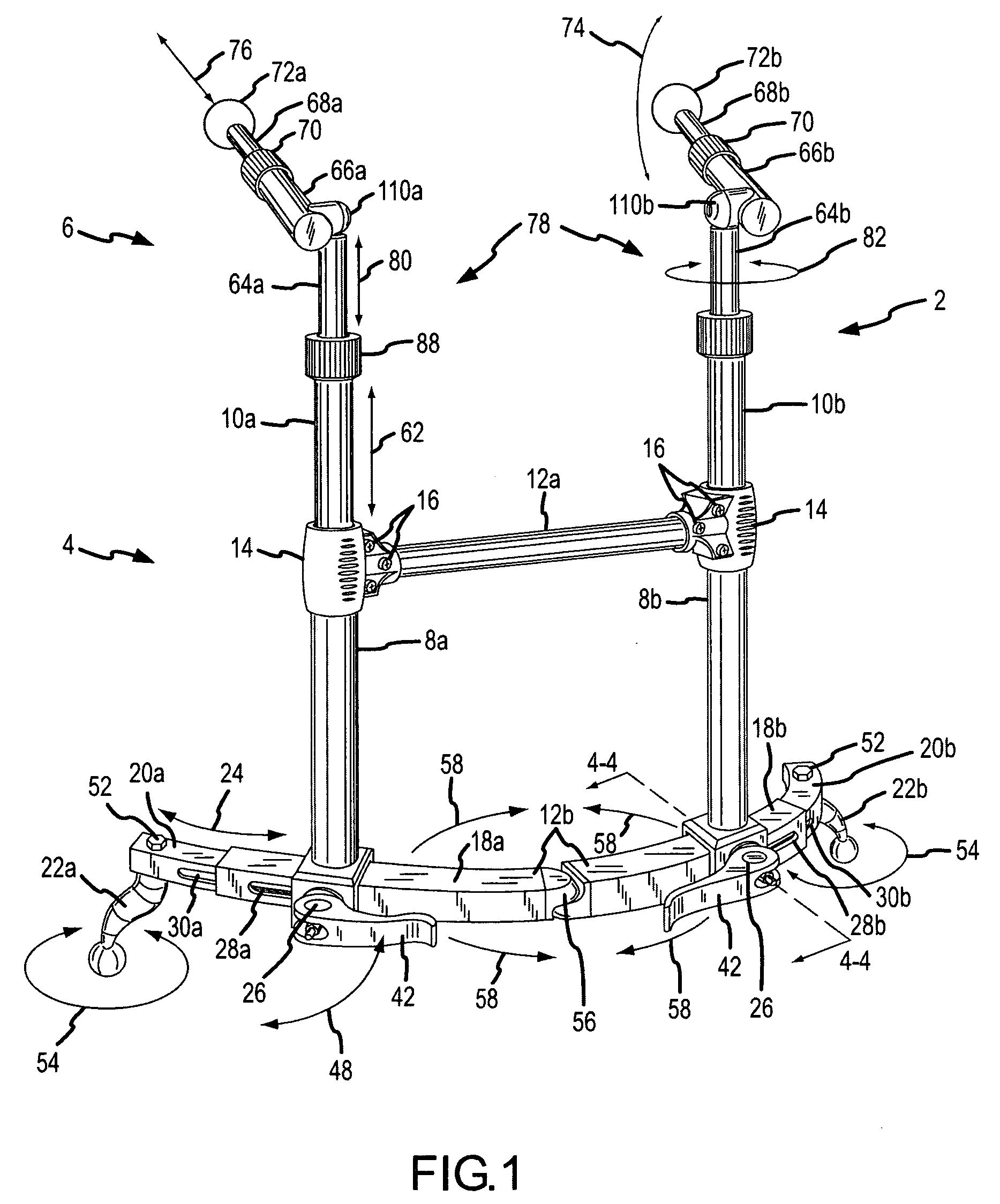

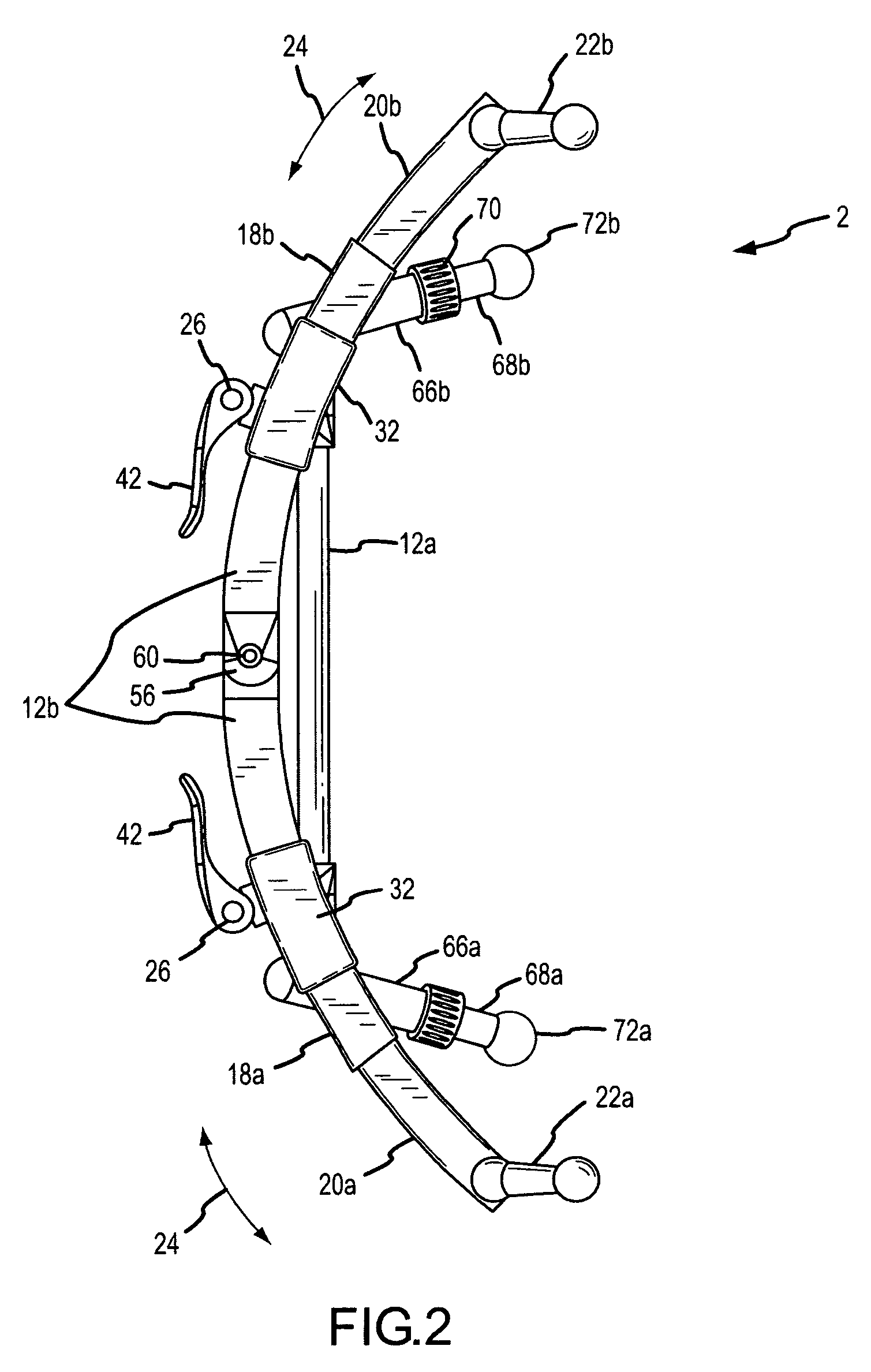

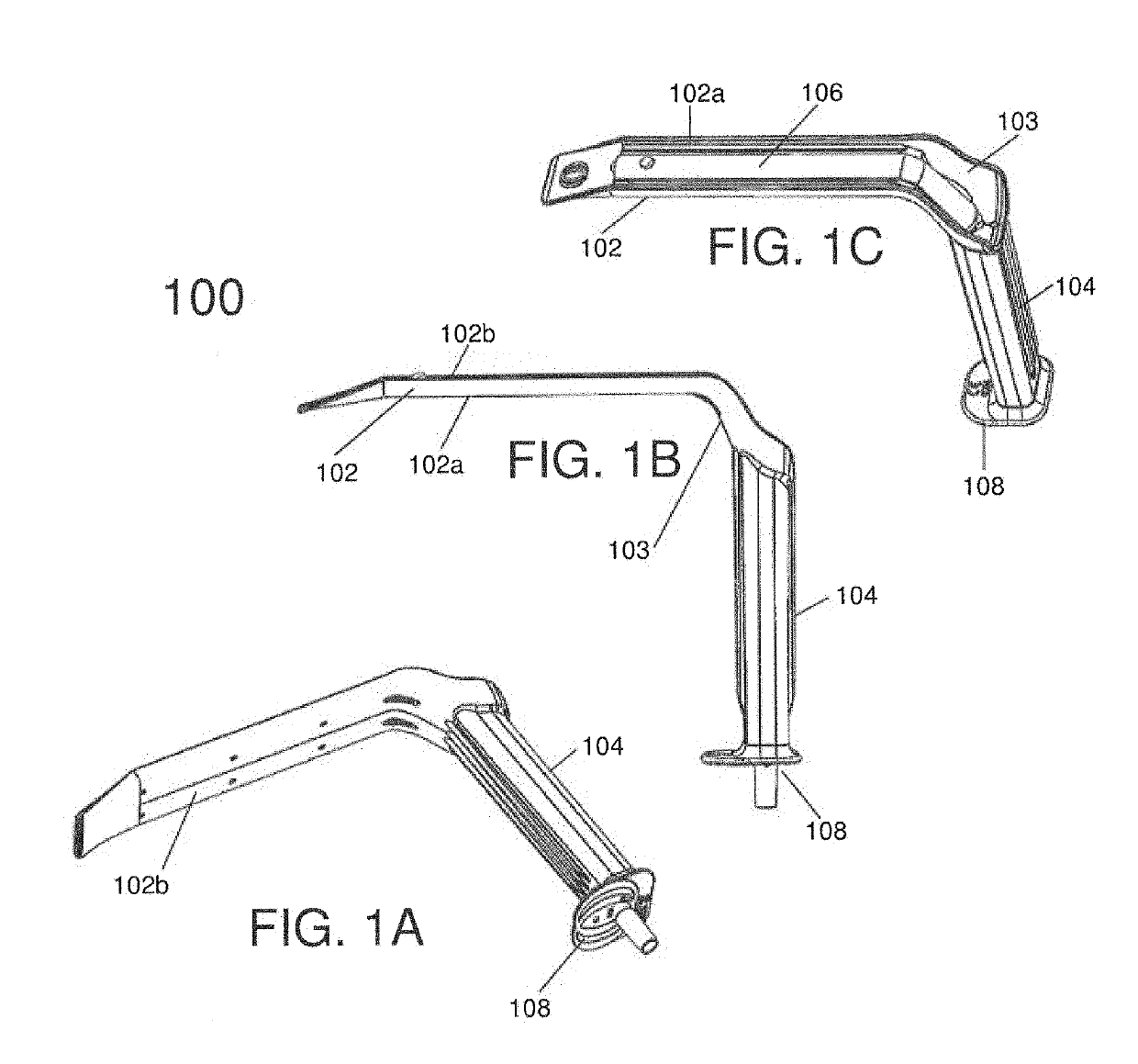

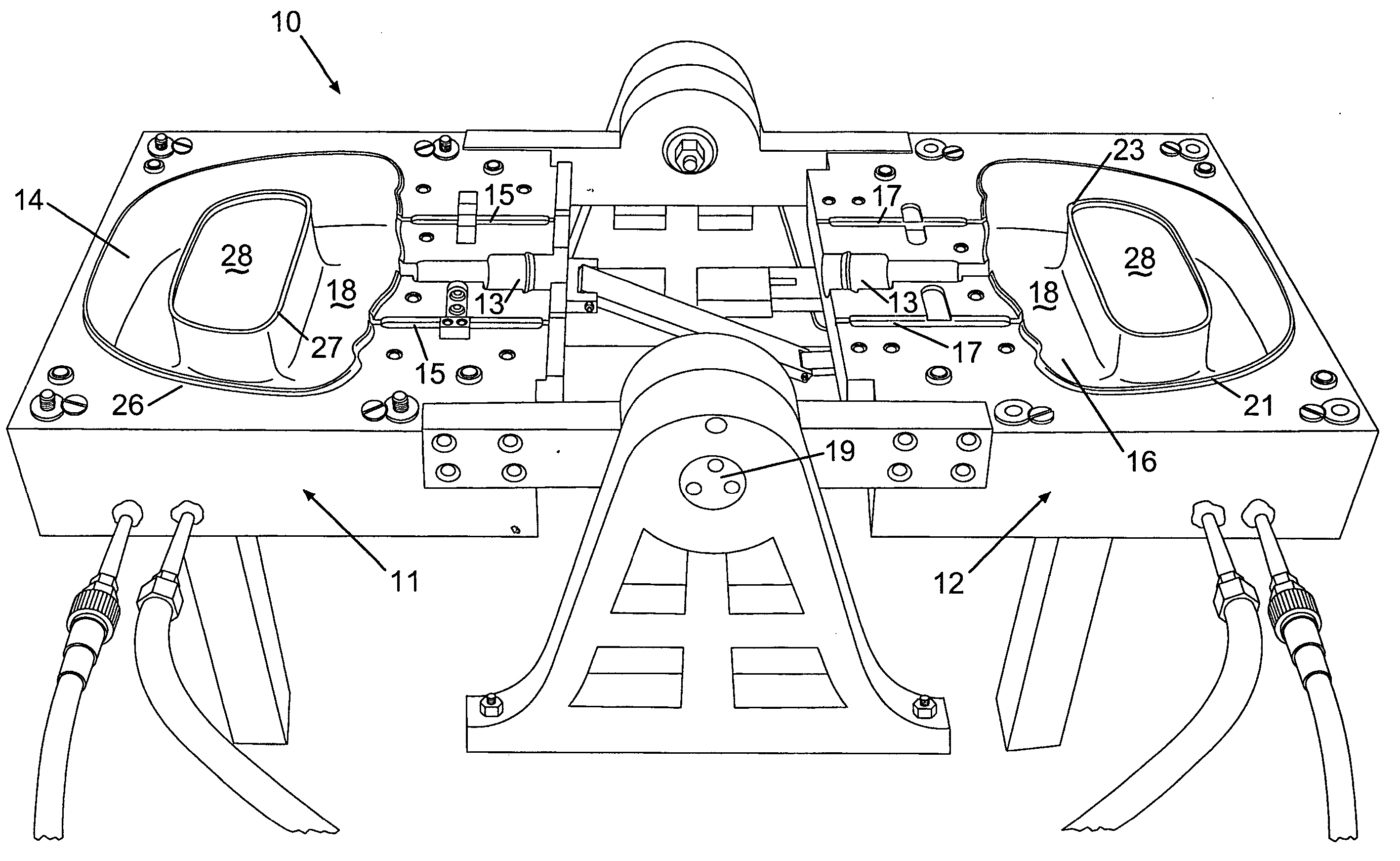

Tactical foregrip assembly

ActiveUS7676975B2Improve positionExtension of timeFiring/trigger mechanismsSighting devicesEngineeringMechanical engineering

A tactical foregrip assembly for use with a firearm, the assembly having an independently rotatable grip mount assembly and an independently rotatable light mount assembly. The invention comprises a stationary mount assembly attachable to the receiver of a firearm, a grip mount assembly radially rotatable about and electrically coupled to the stationary mount assembly, and a light mount assembly radially rotatable about and electrically coupled to the stationary mount and engagable with said grip assembly. The present invention allows the operator to provide light to illuminate an area while simultaneously positioning himself in a manner so as to maximally use available cover.

Owner:BREACHING TECH

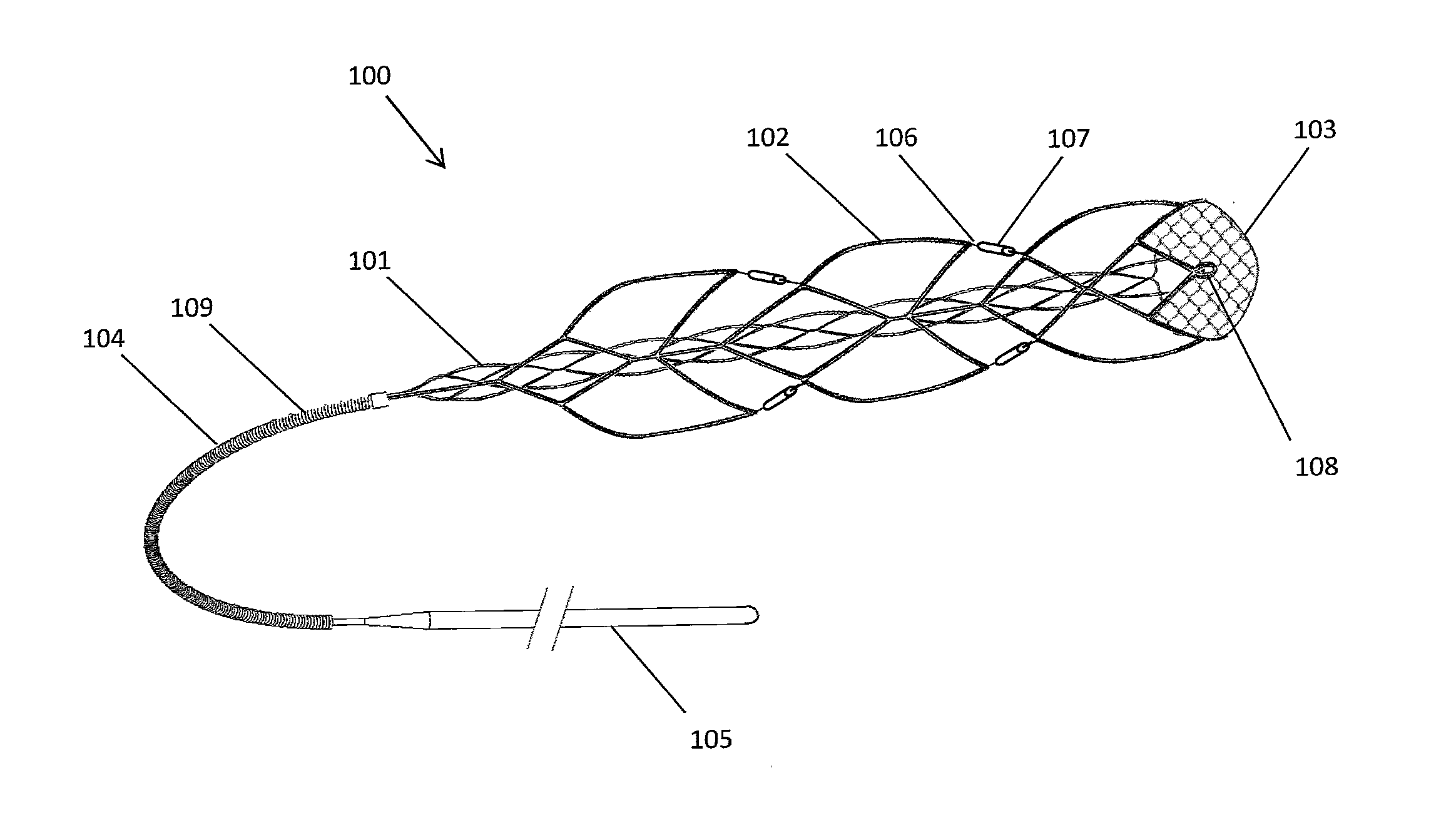

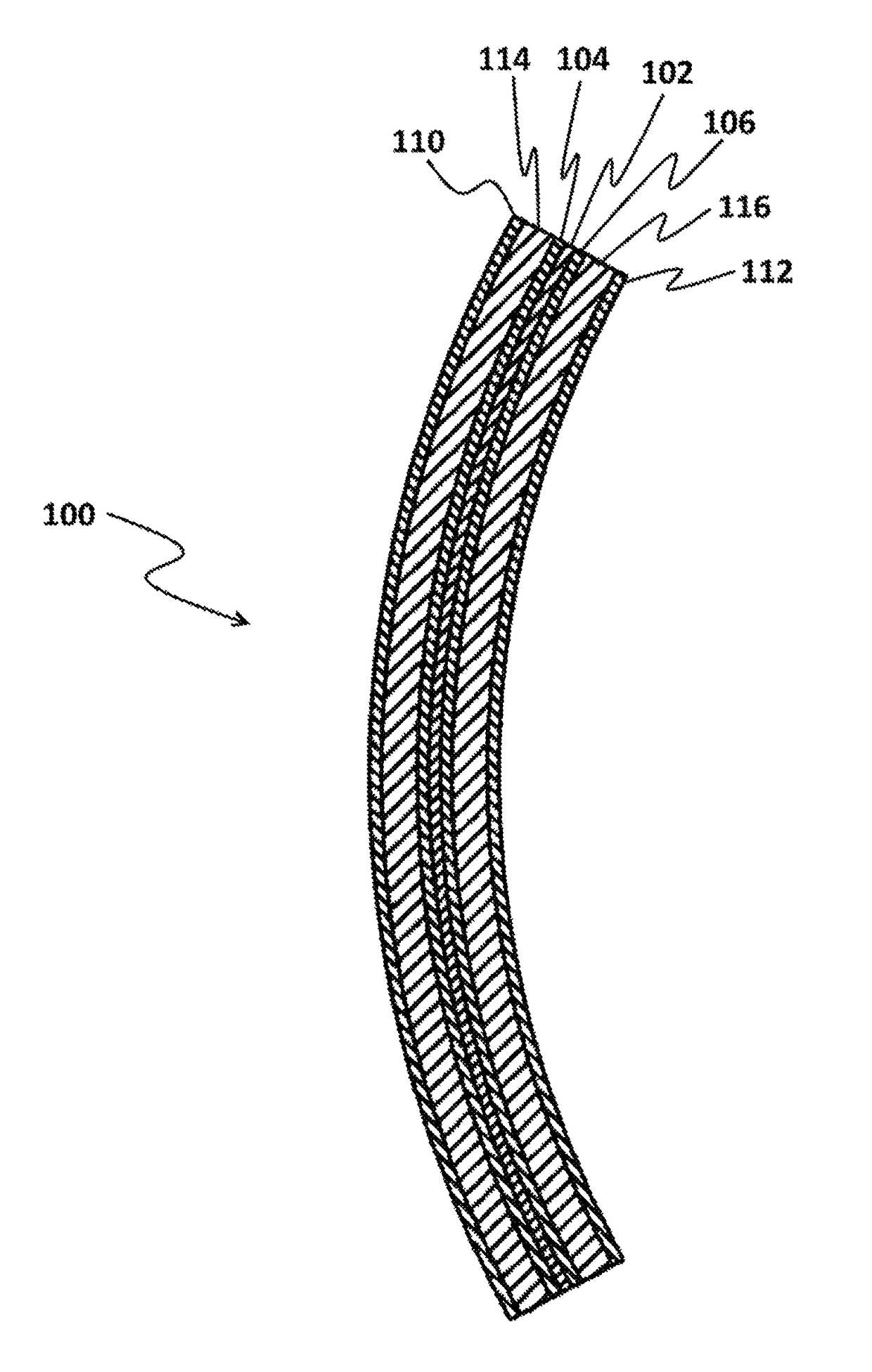

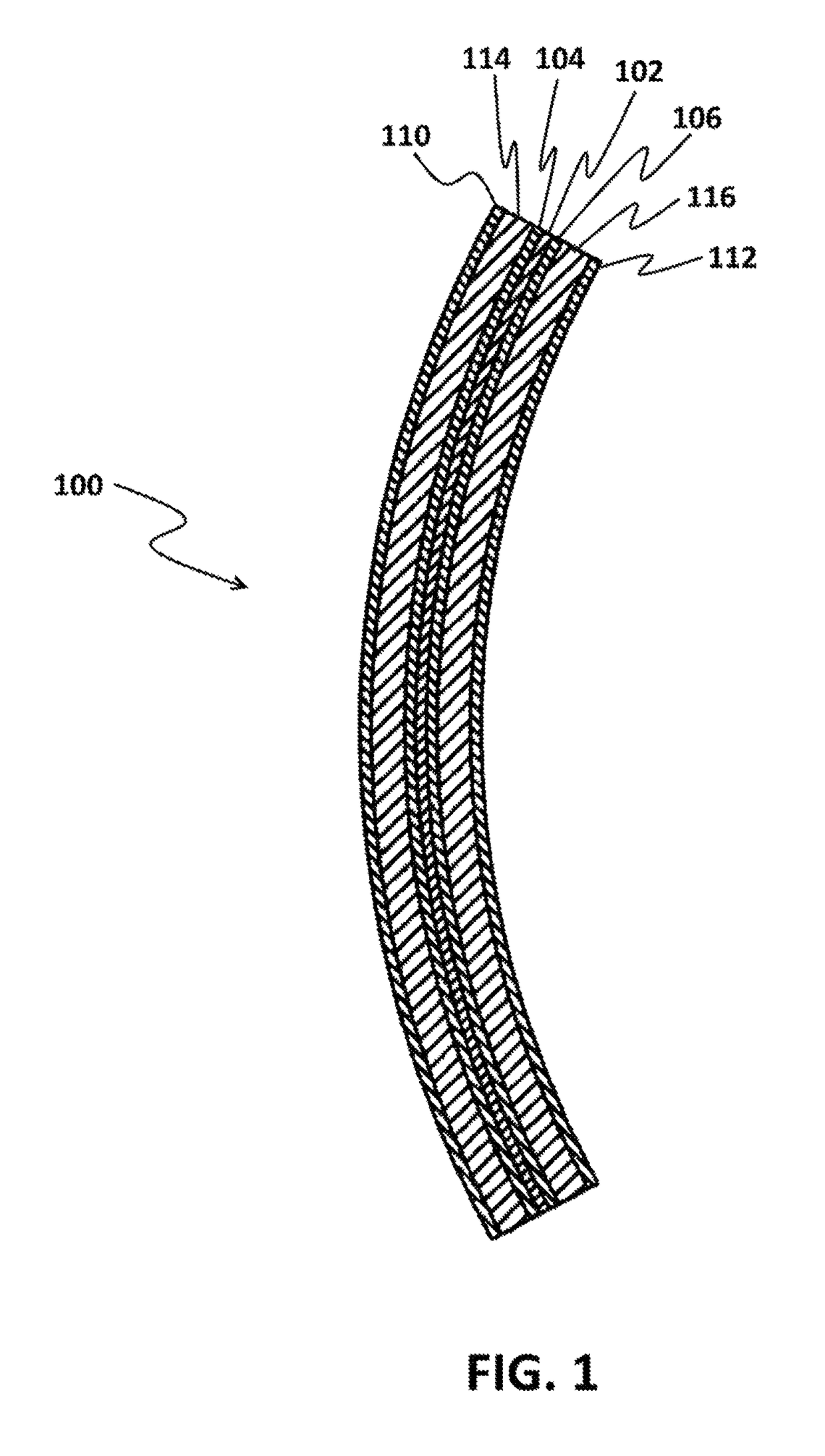

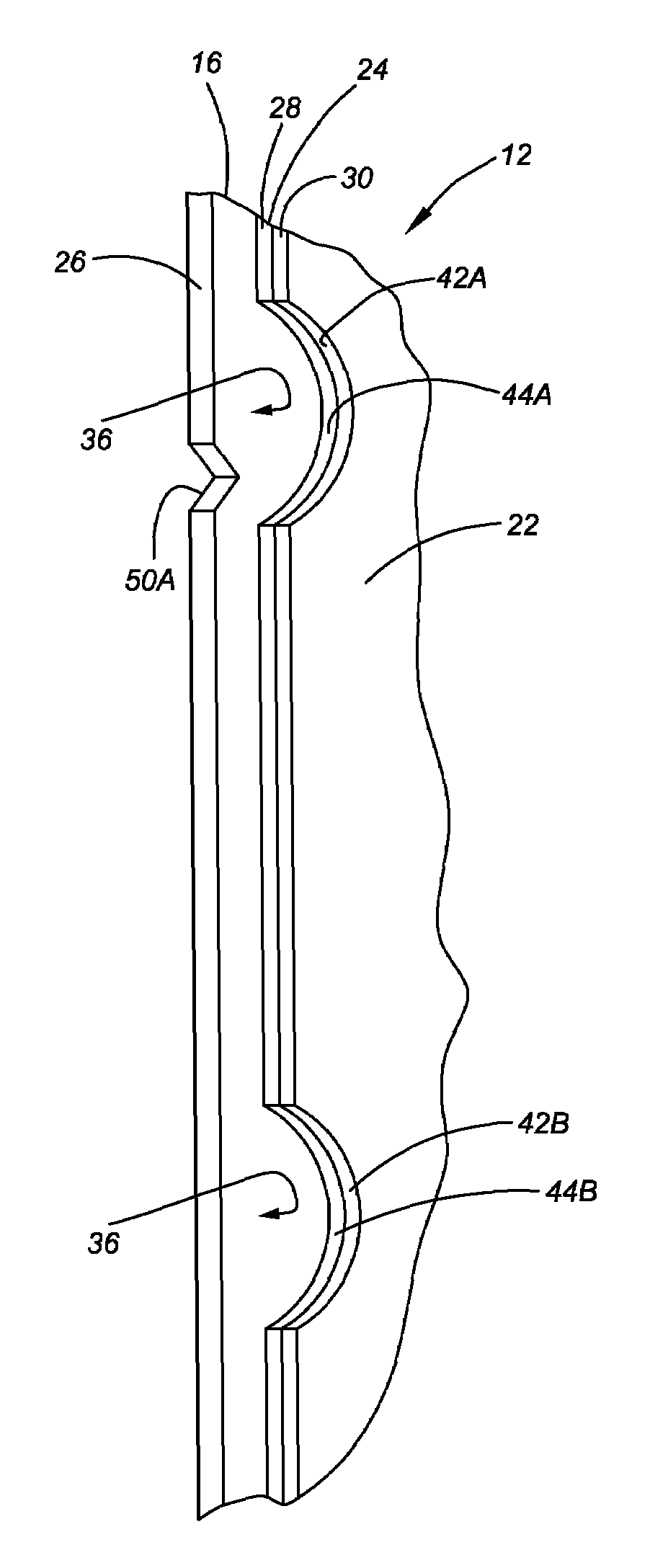

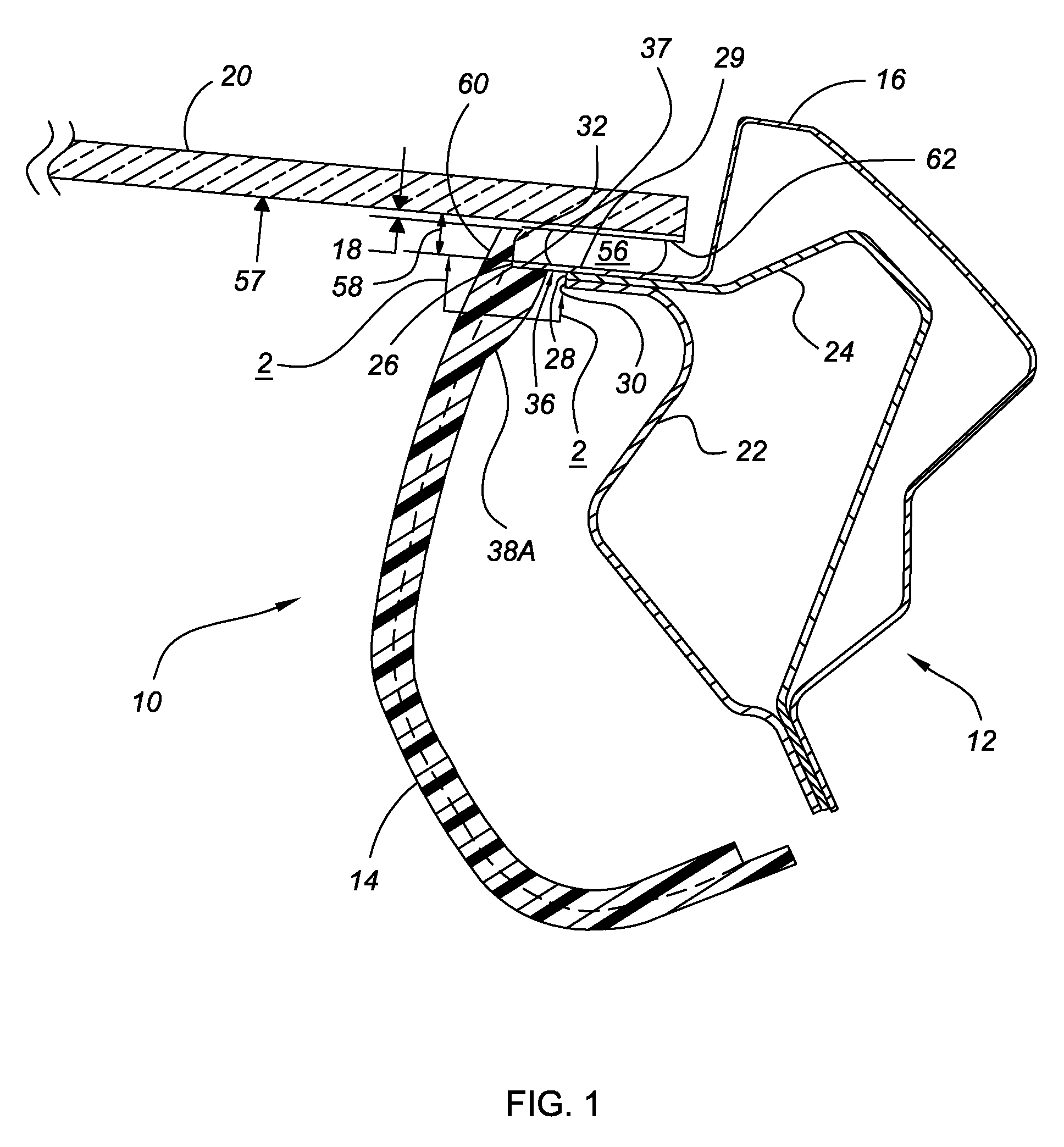

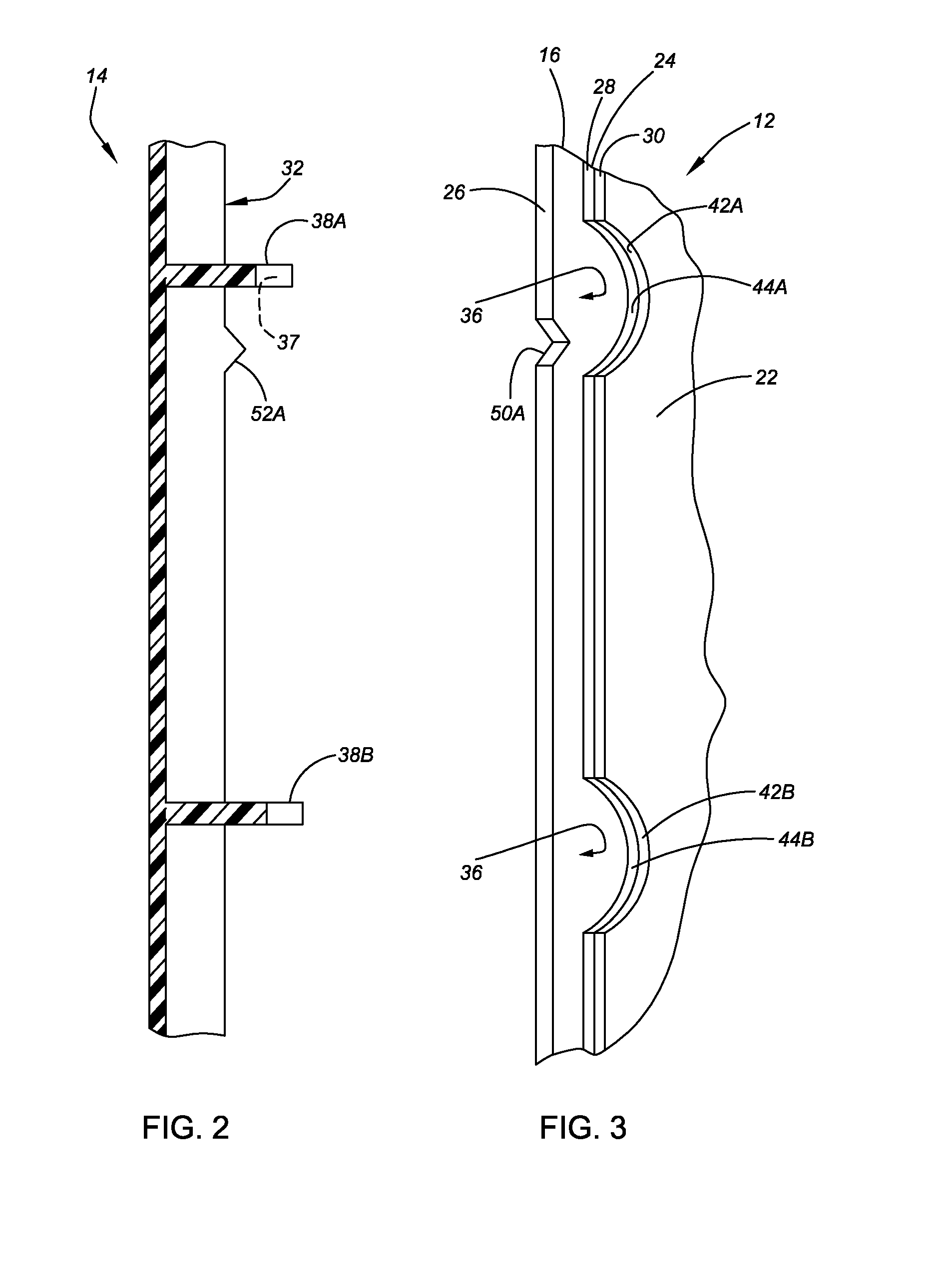

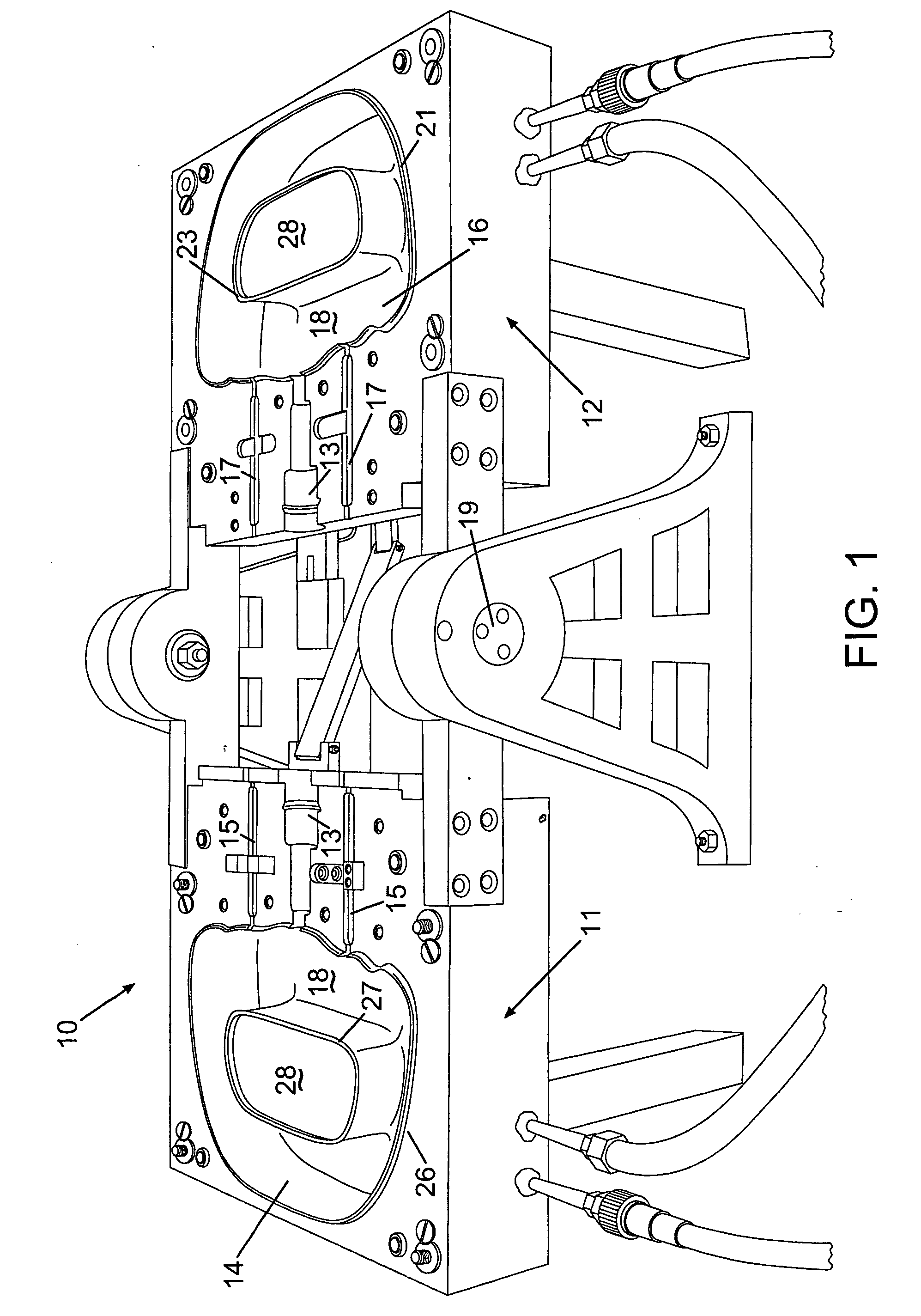

Devices and methods for removal of acute blockages from blood vessels

ActiveUS20140371780A1Overcome limitationsMaximize visibilityDiagnosticsSurgeryEngineeringMechanical engineering

A clot retrieval device may include an elongate shaft and an expandable section. The expandable section may include a framework of interconnected strut elements. The connection region between adjacent strut elements may include crown elements. Additionally, the framework may be formed from a substrate material and at least a portion of a plurality of said strut elements may be coated with a coating material. Further, at least a portion of a plurality of said crown elements may not be coated with said coating material.

Owner:NEURAVI

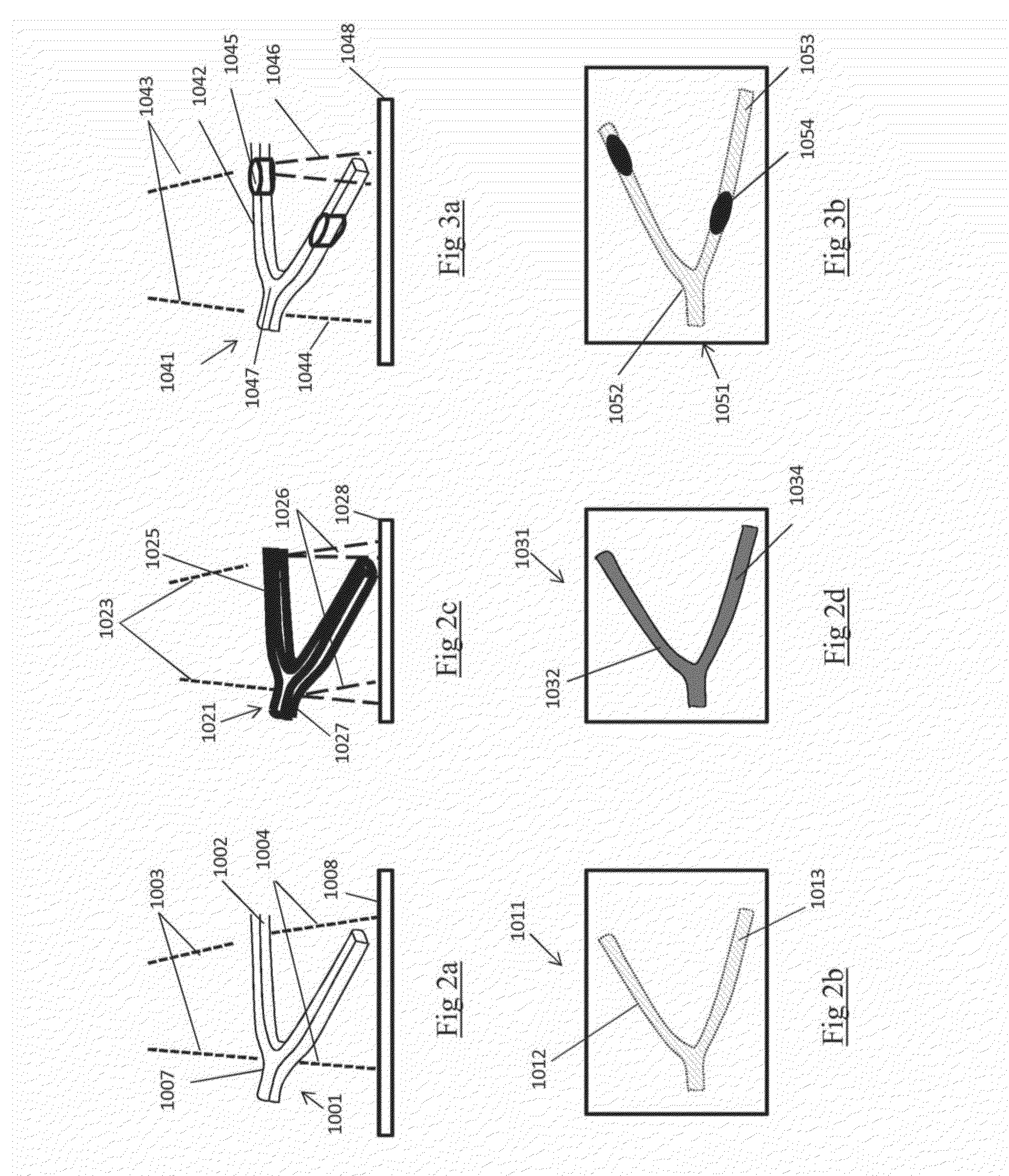

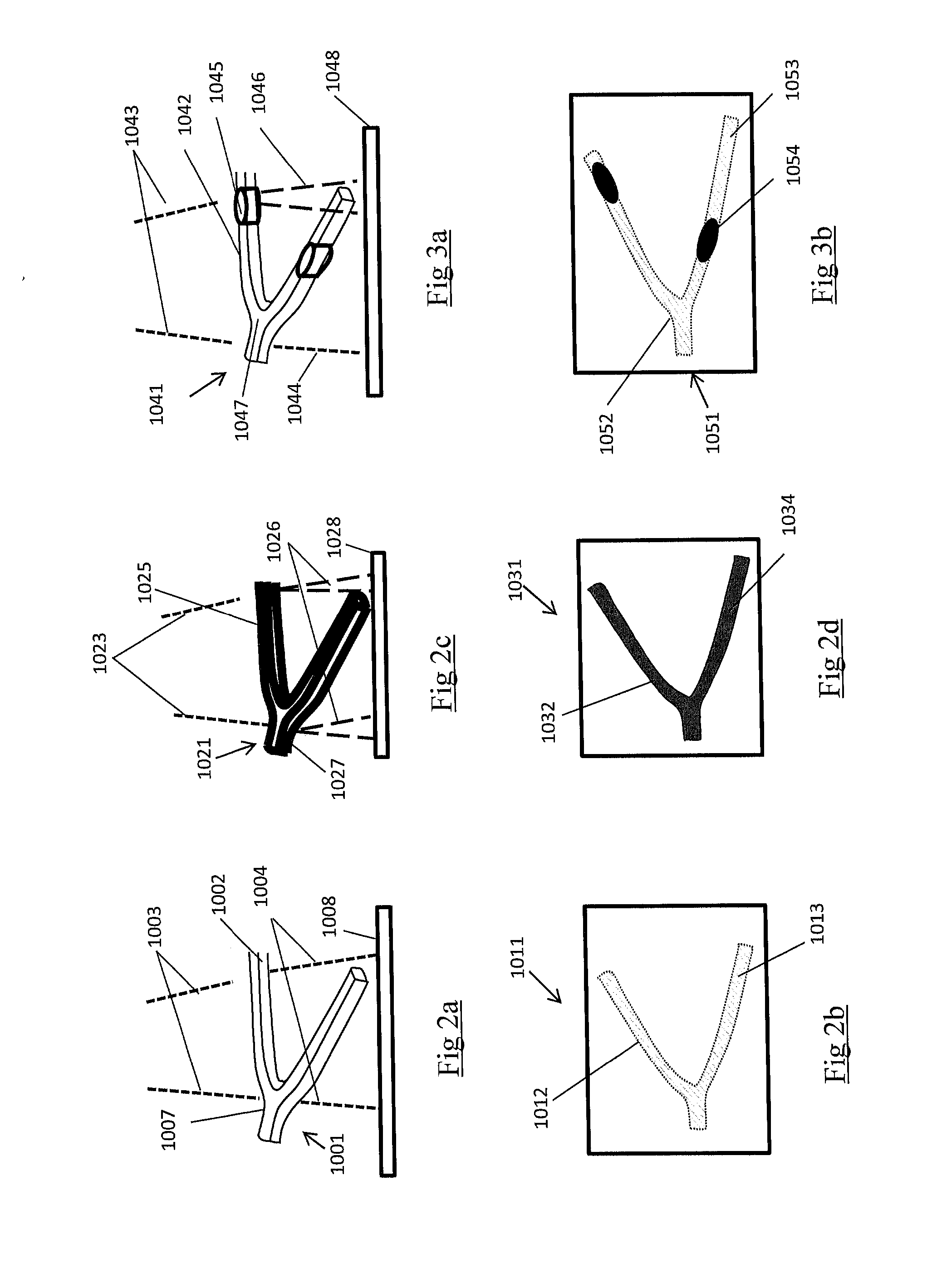

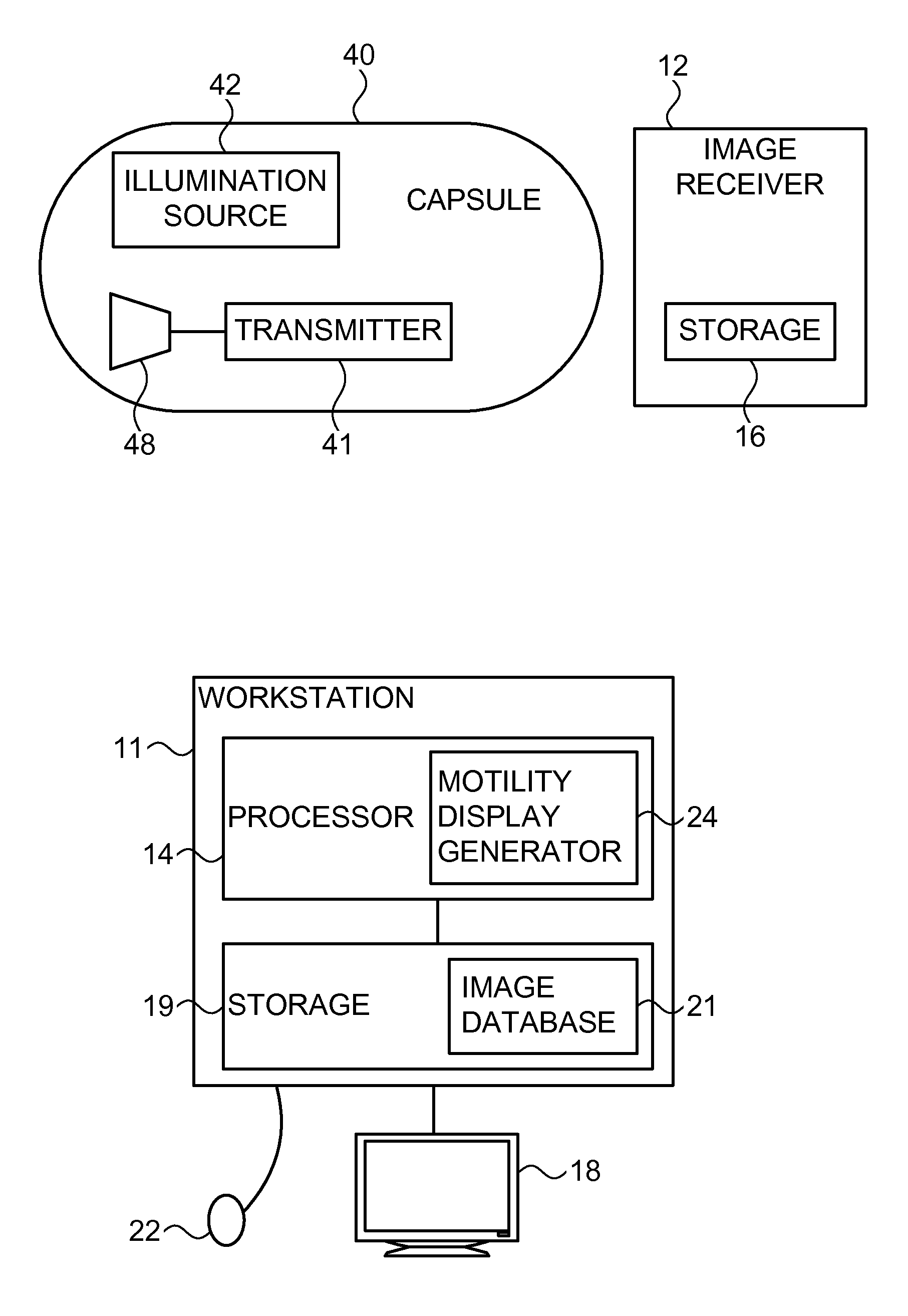

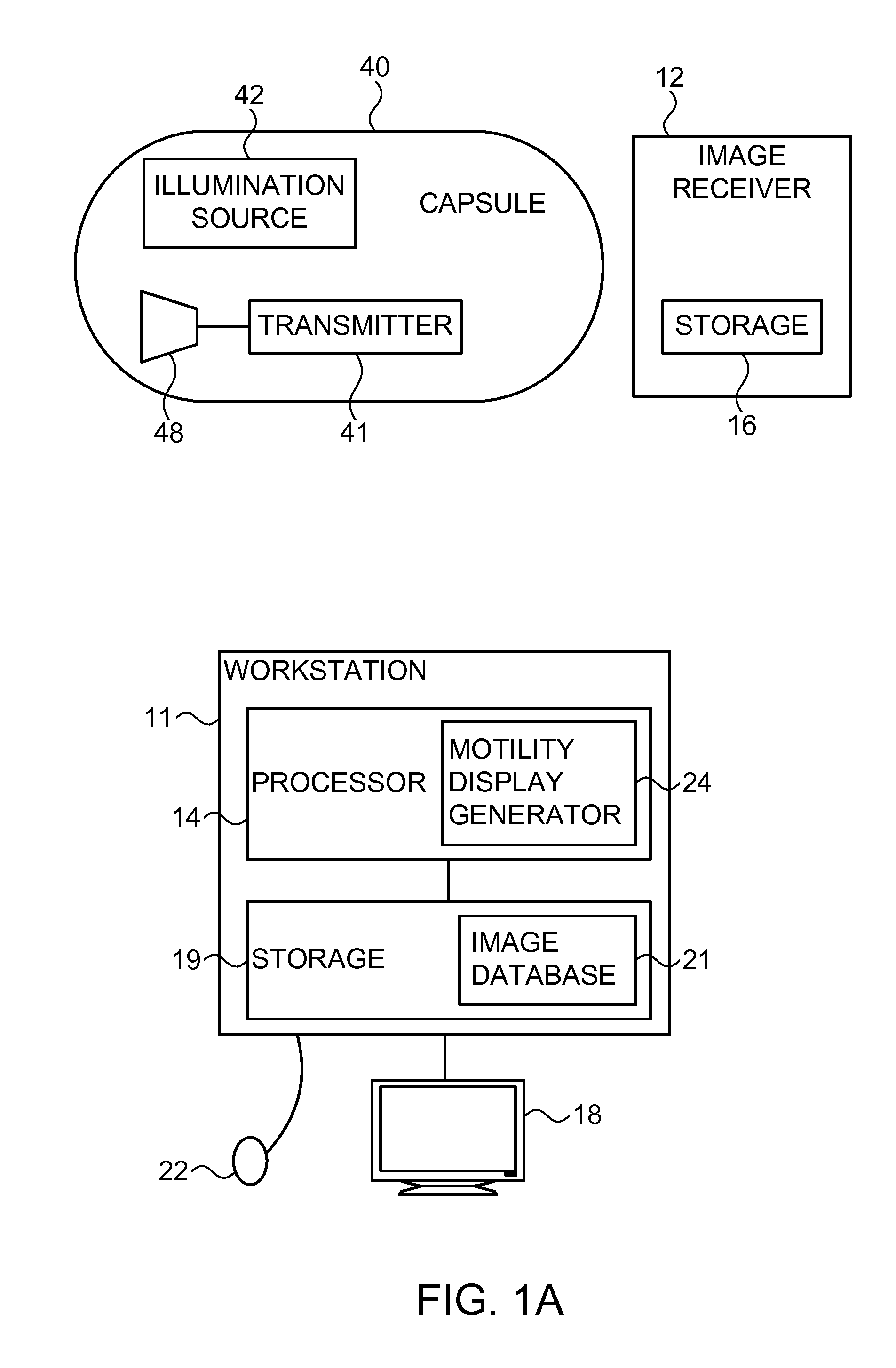

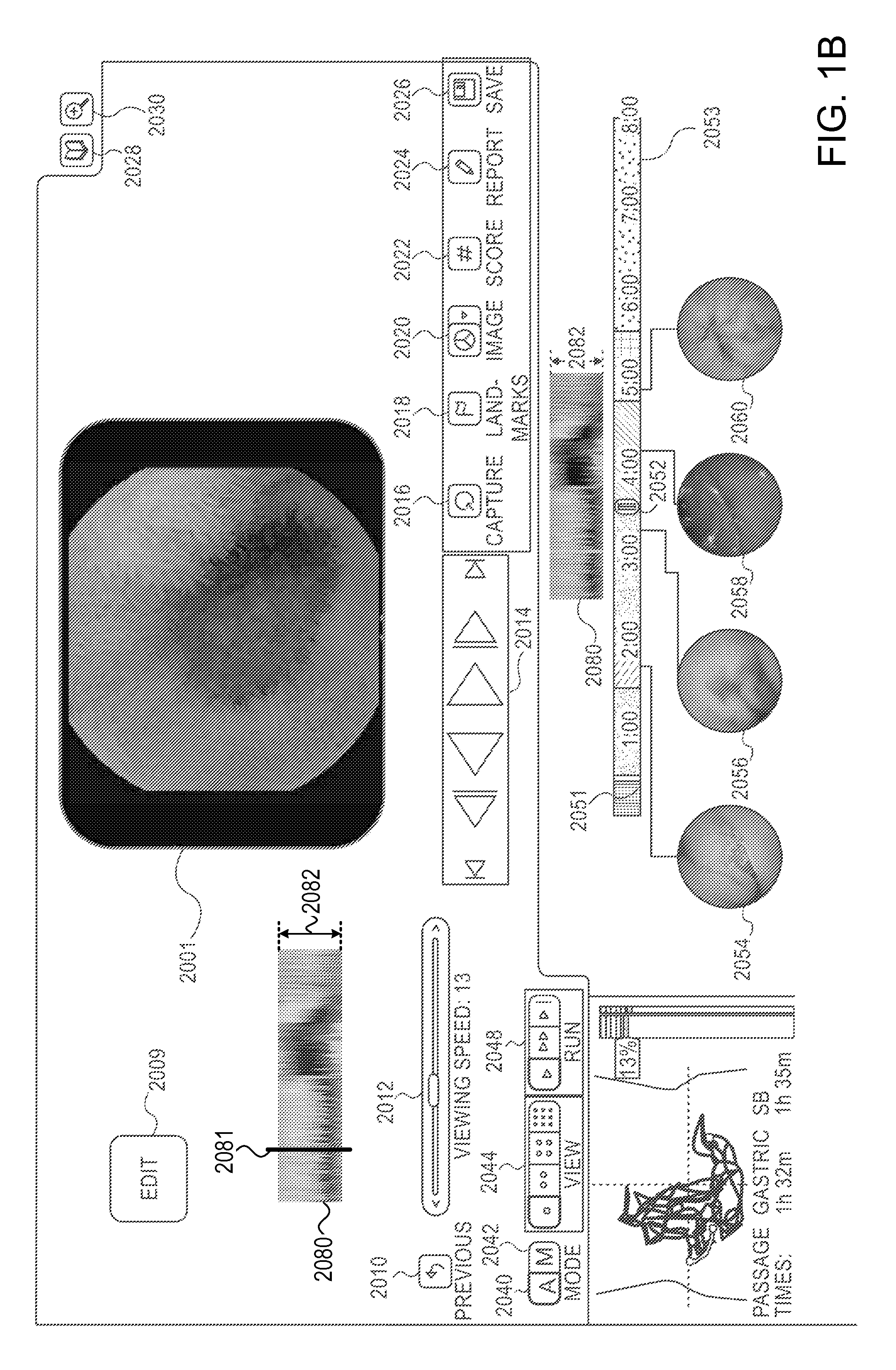

System and method for displaying motility events in an in vivo image stream

ActiveUS20150016700A1Easy to analyzeDiagnosing intestinal motility disordersImage enhancementImage analysisStream captureMotility

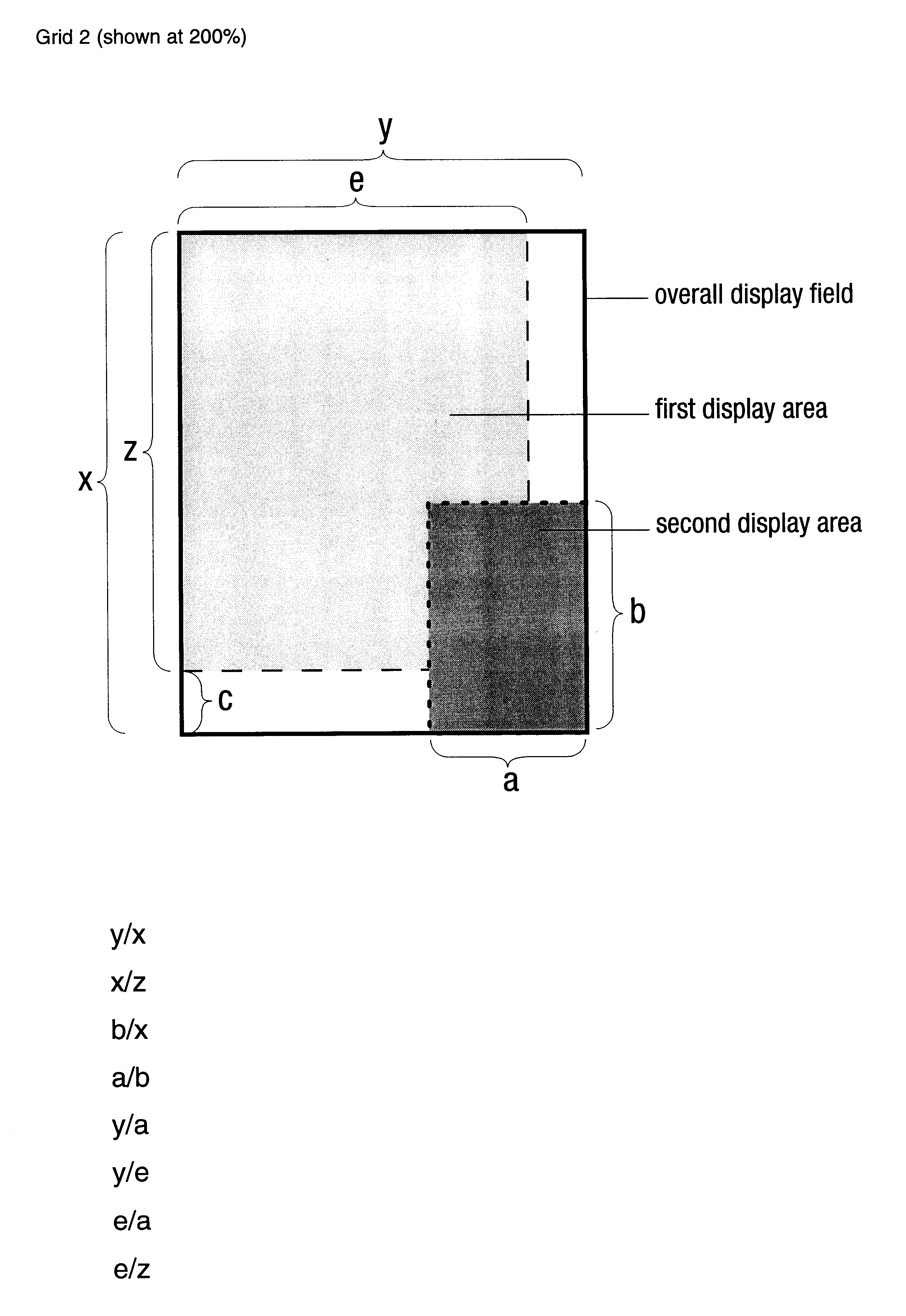

A system and method may analyse and display intestinal motility events, based on an image stream captured by an in vivo imaging device. According to some embodiments, the system includes a storage unit to store image frames from the image stream, a processor to select a strip of pixels from a plurality of image frames of the image stream and to align the selected strips adjacently to form a motility events bar, and a visual display unit for displaying the motility events bar to a user.

Owner:GIVEN IMAGING LTD

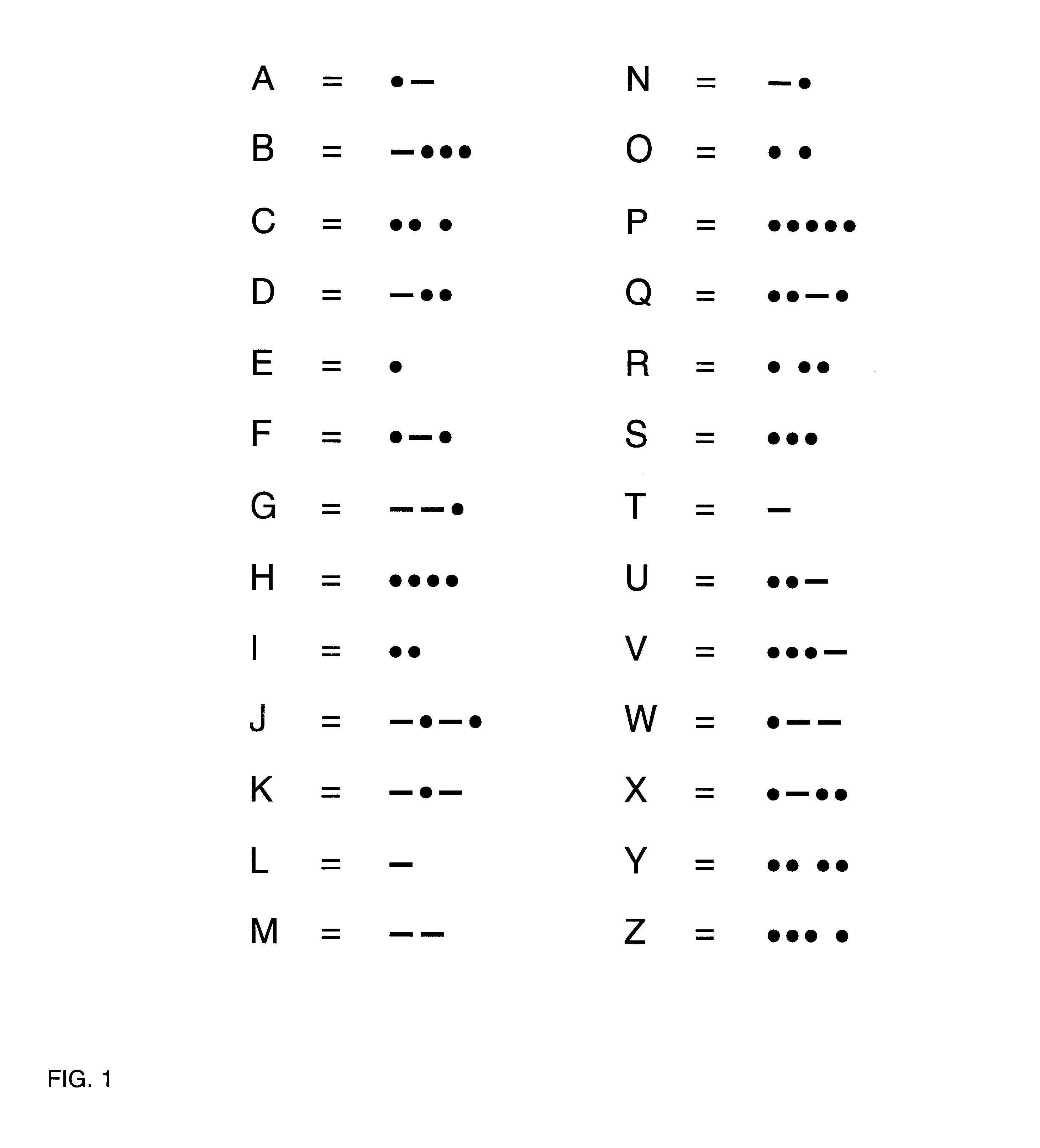

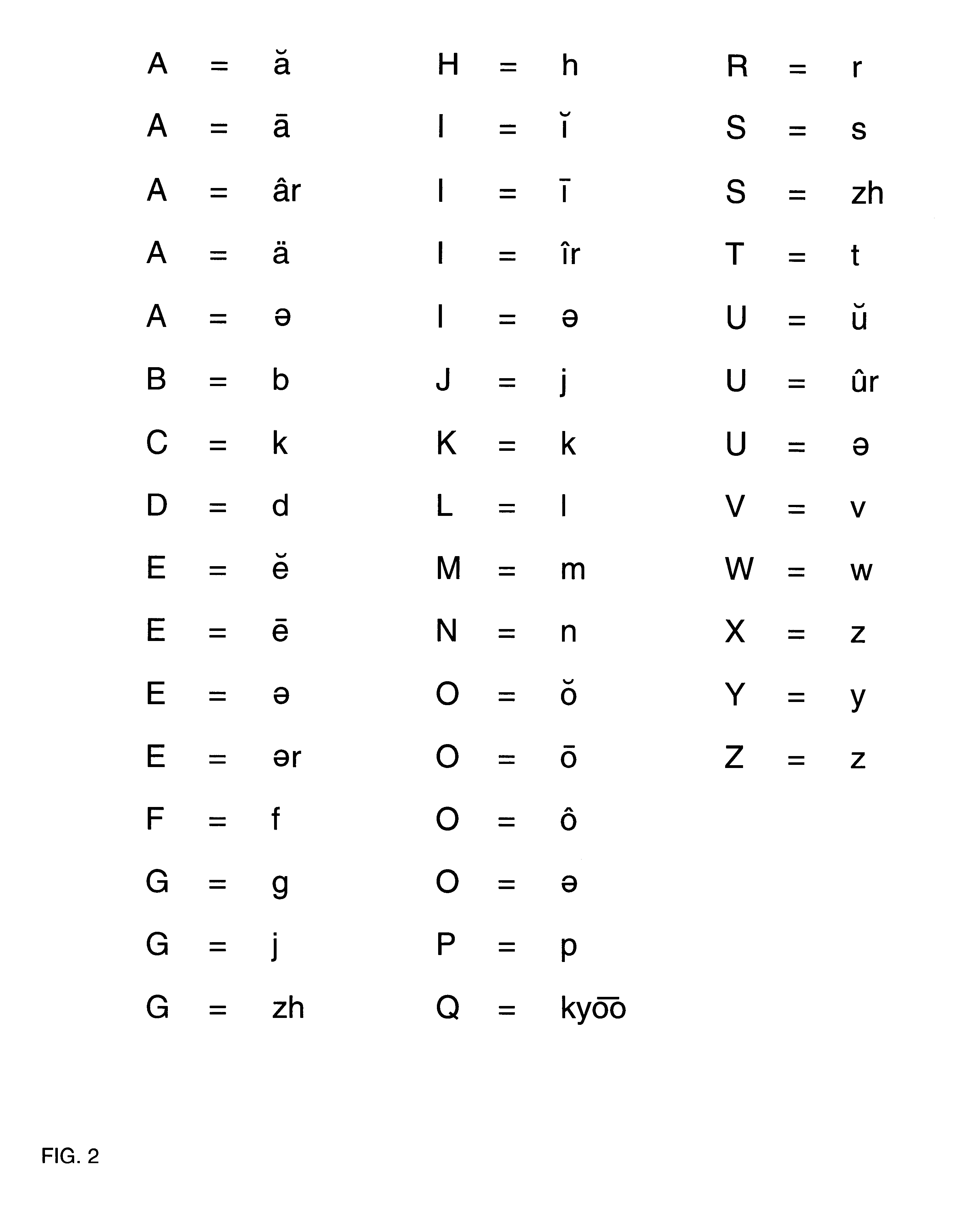

Simultaneous display of a coded message together with its translation

InactiveUS6950986B1Minimizing any tendencyMaximize visibilityOther printing matterDigital computer detailsGraphicsLettering

A system and method for presenting a simultaneous, overlapping display of a coded message and its translation as a single, integrated graphic presentation in any visual medium, that provides quick and full comprehension. It may be used advantageously, for example, to provide an immediate translation of telephone numbers displayed as letters or words in advertising, wherein the letters correspond to numerals found on a telephone keypad or rotary dial.

Owner:NORTH RIVER CONSULTING

System for carrying articles at the front torso of a human being

ActiveUS20070090143A1Minimize movementMaximize user comfortTravelling sacksChildren furniturePhysical medicine and rehabilitationEngineering

A system for carrying articles at the front torso of a human being is disclosed. A substantially rigid article-carrying frame is connected to the front of a harness or backpack worn by the user. The frame transmits the weight of the front-carried articles to the front of the user's hips. The system accommodates bending movements of the user's torso by providing, for example, a variable-length mechanism, or a bending mechanism, or a folding mechanism, or a sliding connector mechanism, or any other equivalent accommodation mechanism that will allow the system to accommodate bending movements of the torso of the user.

Owner:CEDAR MESA DESIGN COMPANY

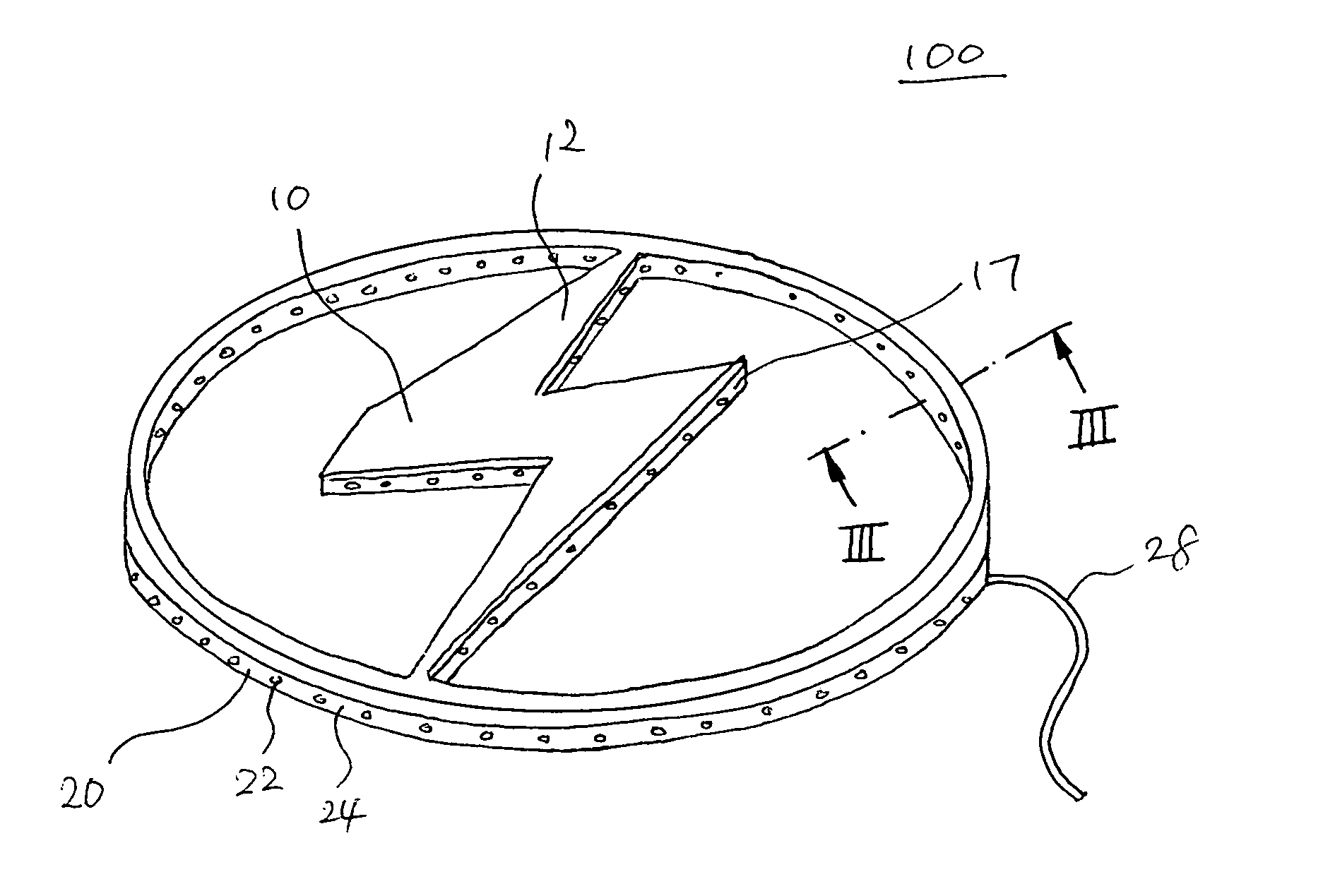

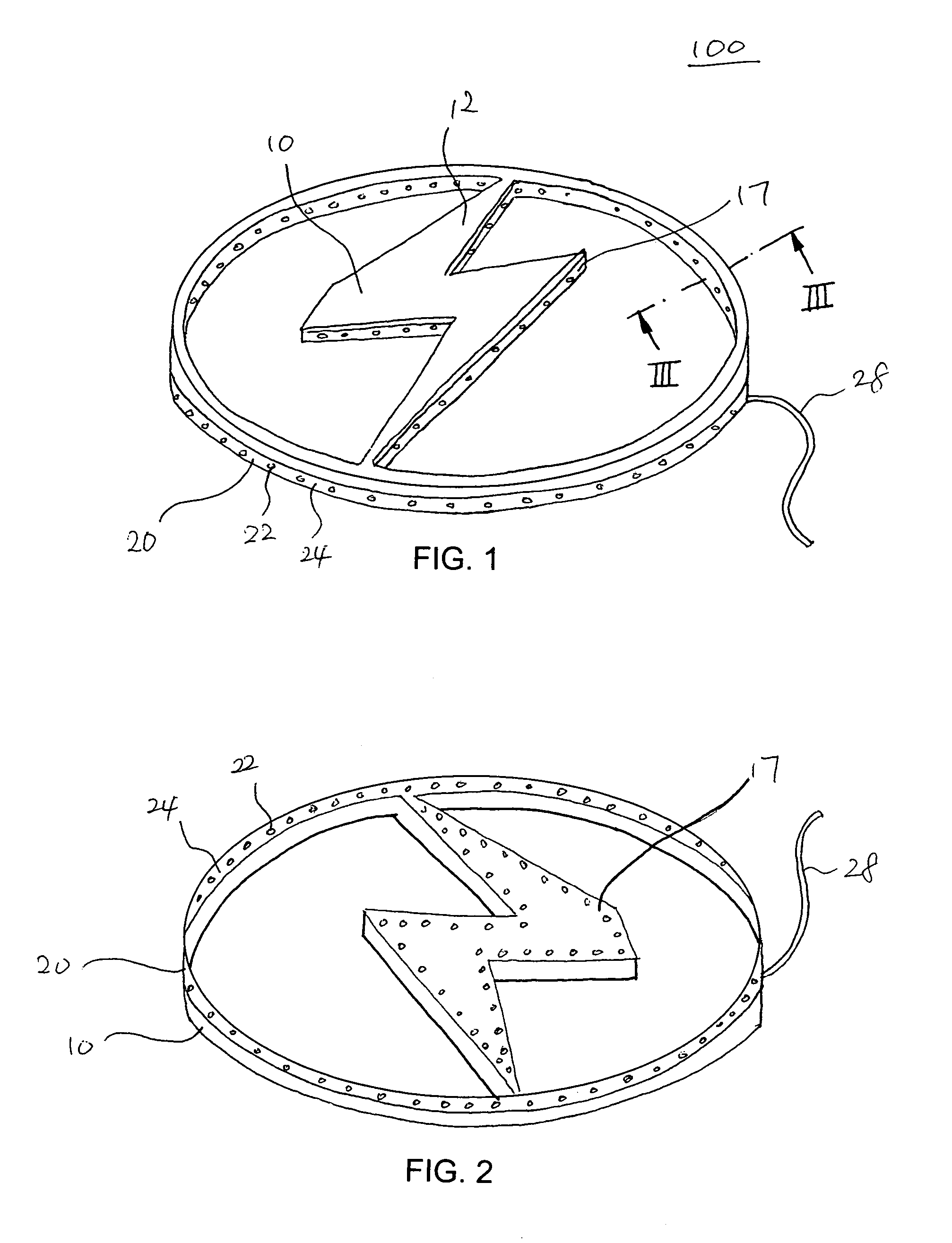

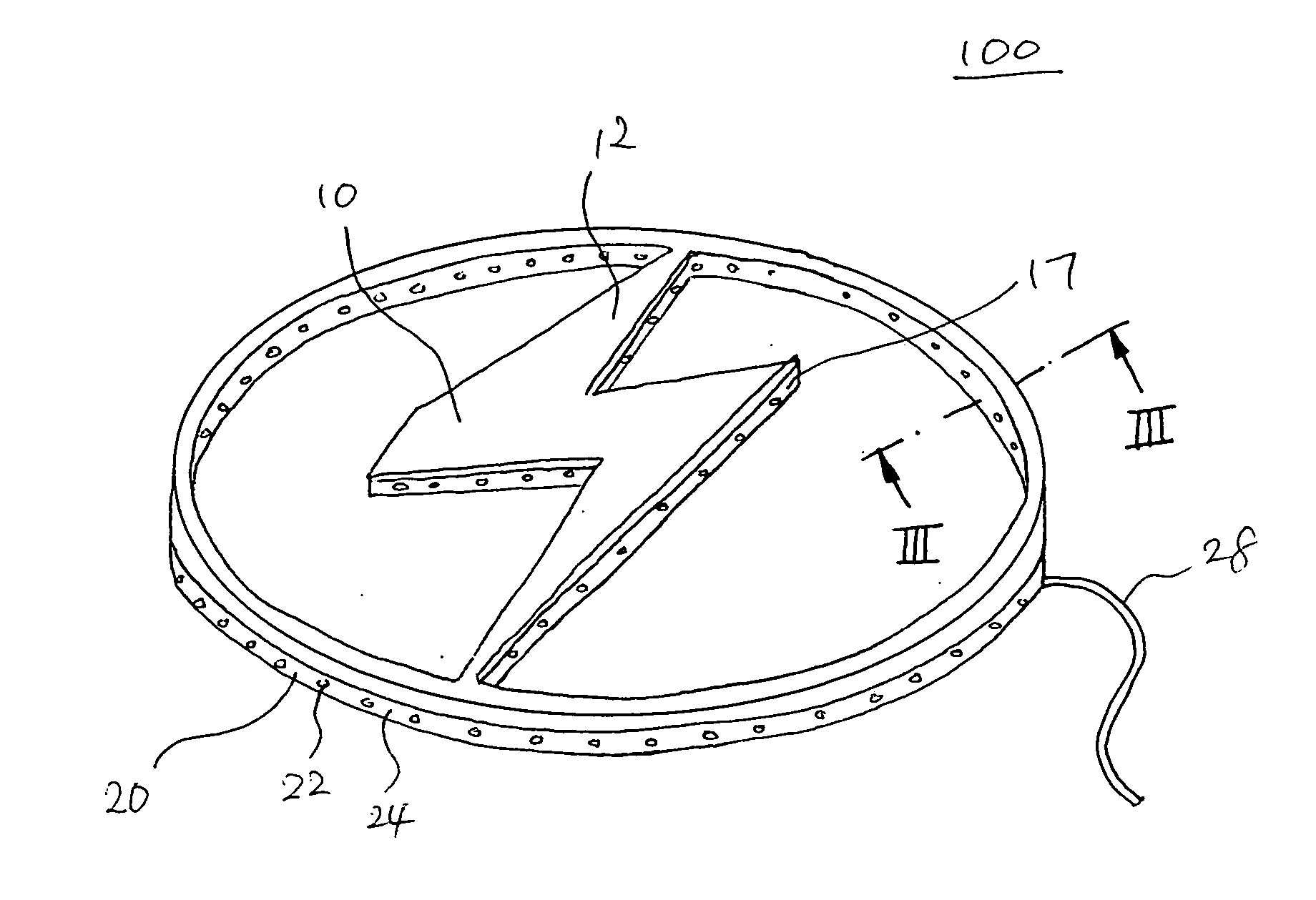

Illuminated exterior decorative device

ActiveUS7175324B2Maximize visibilityHighly effectiveLighting support devicesDwelling equipmentMetal coatingLight emitting device

An illuminated exterior decorative device for vehicles includes a decorative part and an illuminating part. The illuminating part illuminates the decorative part from behind and includes a light source and a light diffusion portion. The light source of the illuminating part is embedded in the light diffusion portion. The light diffusion portion of the illuminating part is optically transmissive, preferably transparent. The light source is disposed along the edge of the decorative part. The light source includes a plurality of light emitting device (LED). The illuminating part has substantially the same pattern as the decorative part. The decorative part may be provided as metal coating on the illuminating part.

Owner:KWON YOUNG CHUL

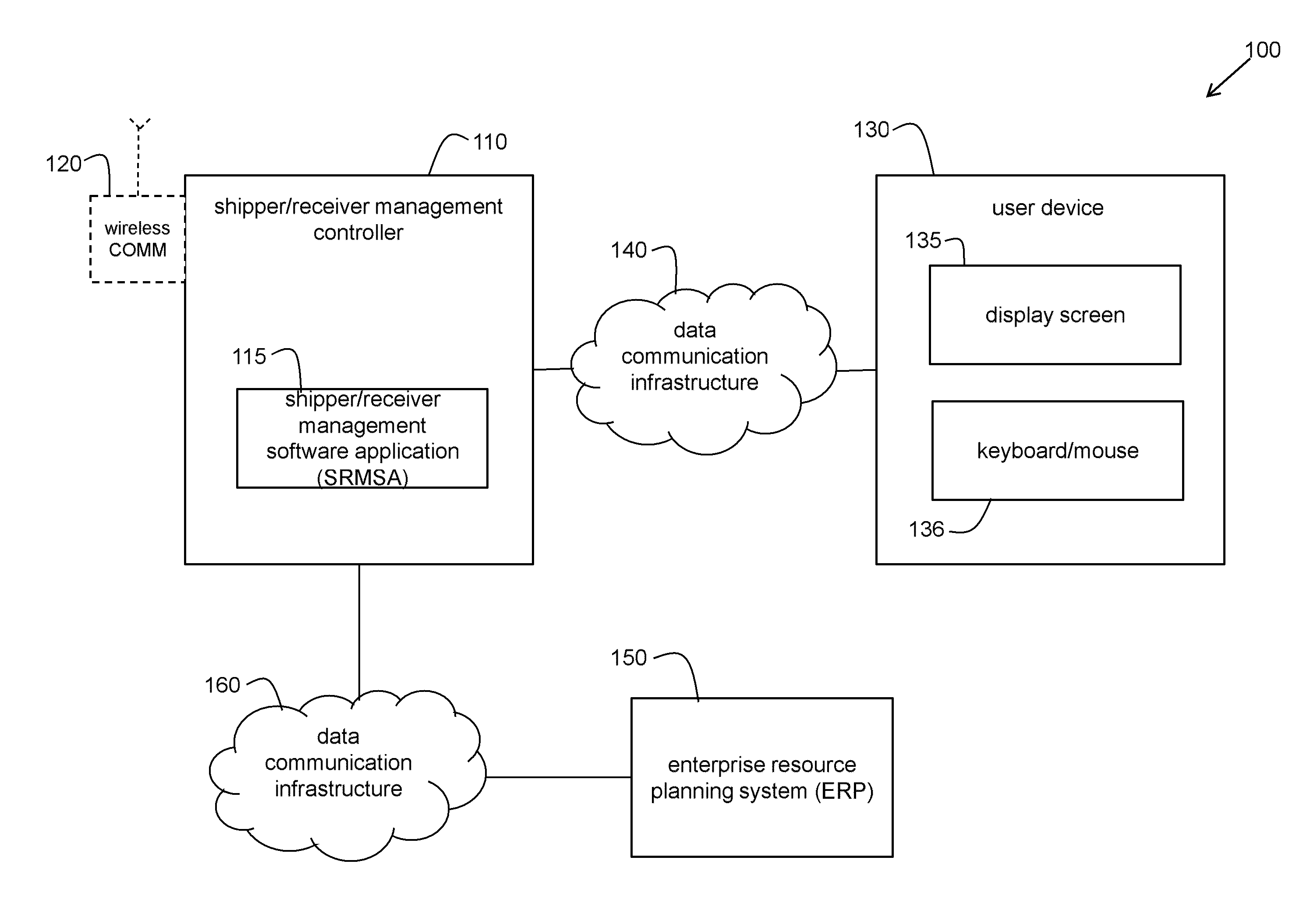

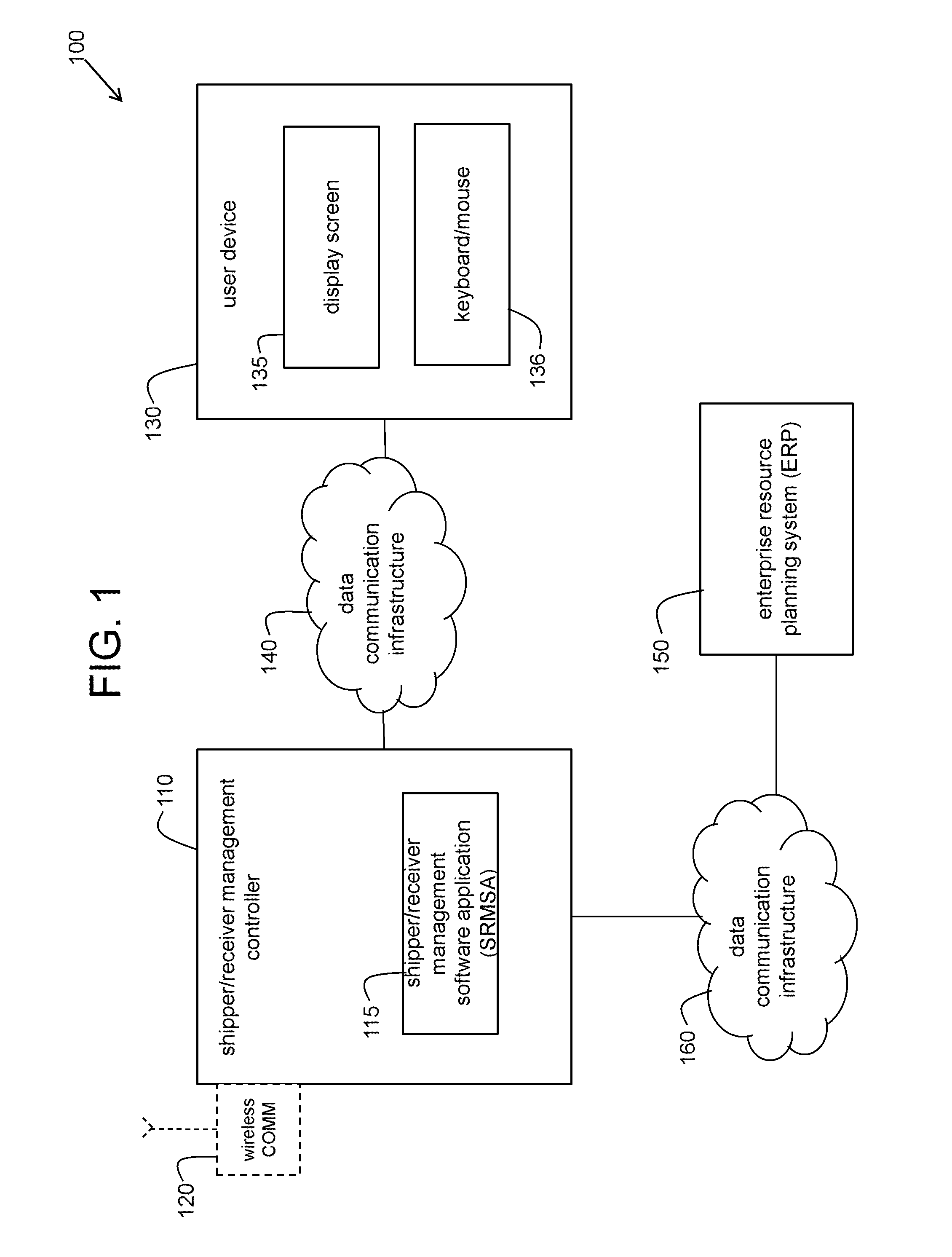

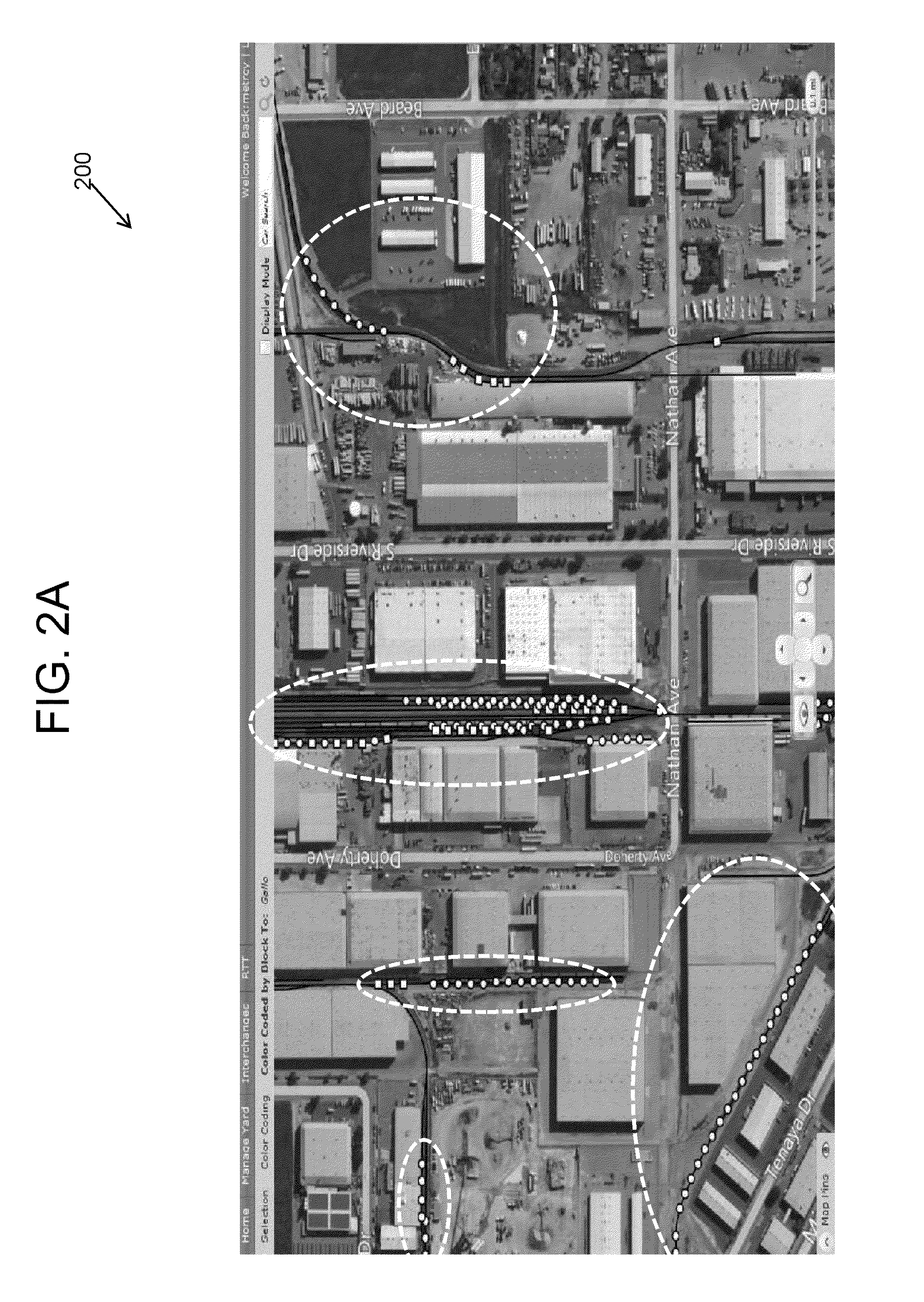

Shipper/receiver fleet optimization system and method

InactiveUS20150051941A1Maximize visibilityEasy to operateTechnology managementResourcesVisibilityReceiving facility

Systems and methods for providing a graphical interface and application for managing assets and products in and between shipper / receiver facilities such as a plant, a port, a warehouse, or a lot. Embodiments of the invention provide a shipper / receiver management software application configured to manage assets and products pro-actively by maximizing visibility of the shipper / receiver facility and by providing selectable options to a user to improve operations across the shipper / receiver facility and between shipper / receiver facilities. Aspects can be directed toward fleet and individual asset optimization according to various constraints and values, including orders, availability, revenues, costs, and others.

Owner:GENERAL ELECTRIC CO

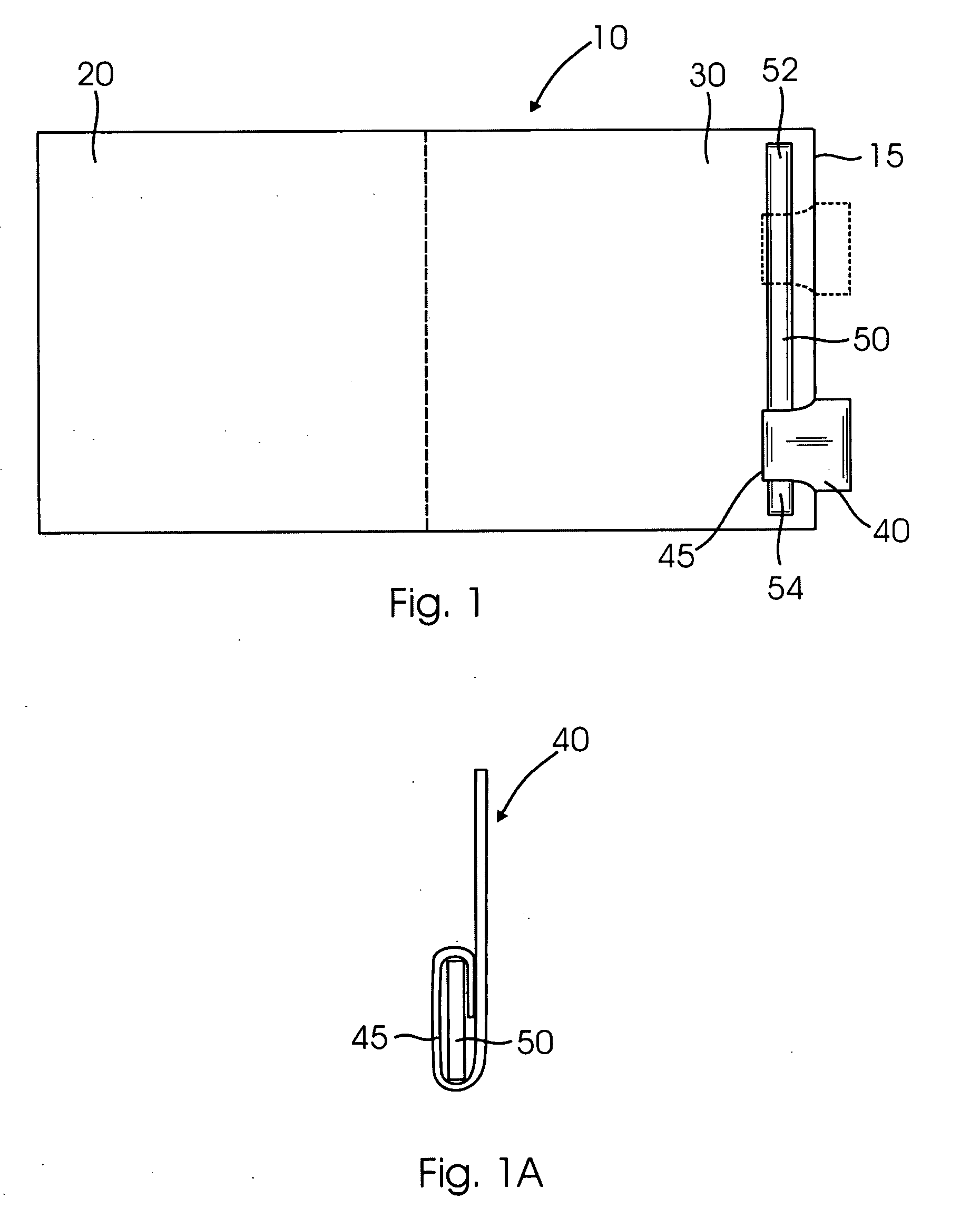

File divider with slidable tab

InactiveUS20070234601A1Maximize visibilityOvercome disadvantagesEnvelopesFiling appliancesComputer scienceWrap around

File dividers having slidable tabs for systematic and efficient management of files are provided. A track is attached to a file divider such that the track runs substantially parallel to a file divider edge. A tab has a terminal end that wraps around a portion of the track to be capable of sliding along the track. In another embodiment, a slit running substantially parallel to a file divider edge is formed on an extended leaf, so that terminal portions of a tab can be inserted into the slit to be able to slide along the slit. In still another embodiment, a guiding track substantially parallel to a file divider edge slideably interlocks with a mating member of a tab. Lastly, a tab can have a pair of retention lips to hold a support bar or a track in order to be capable of sliding along the support bar or the track.

Owner:BM INNOVATIONS

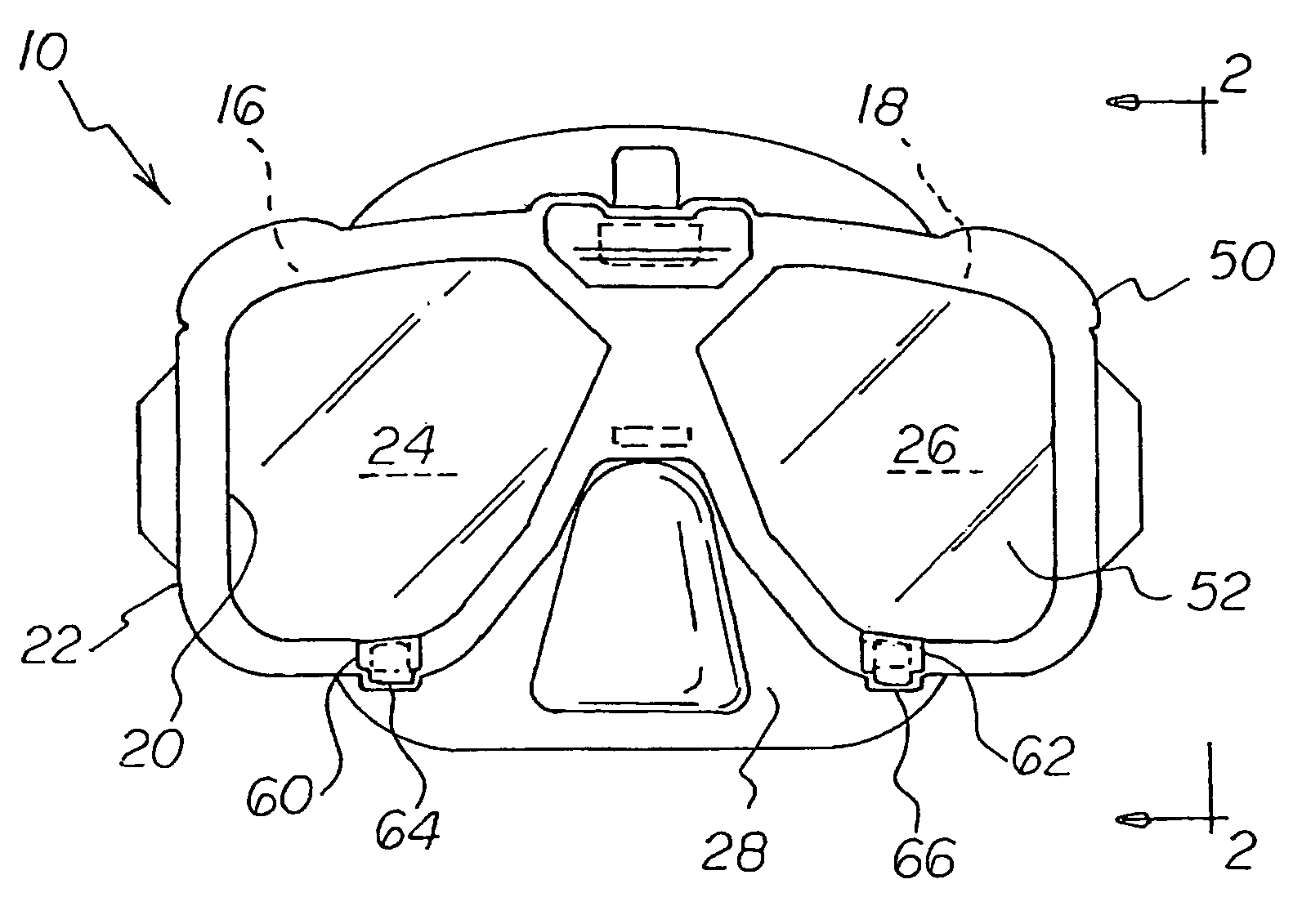

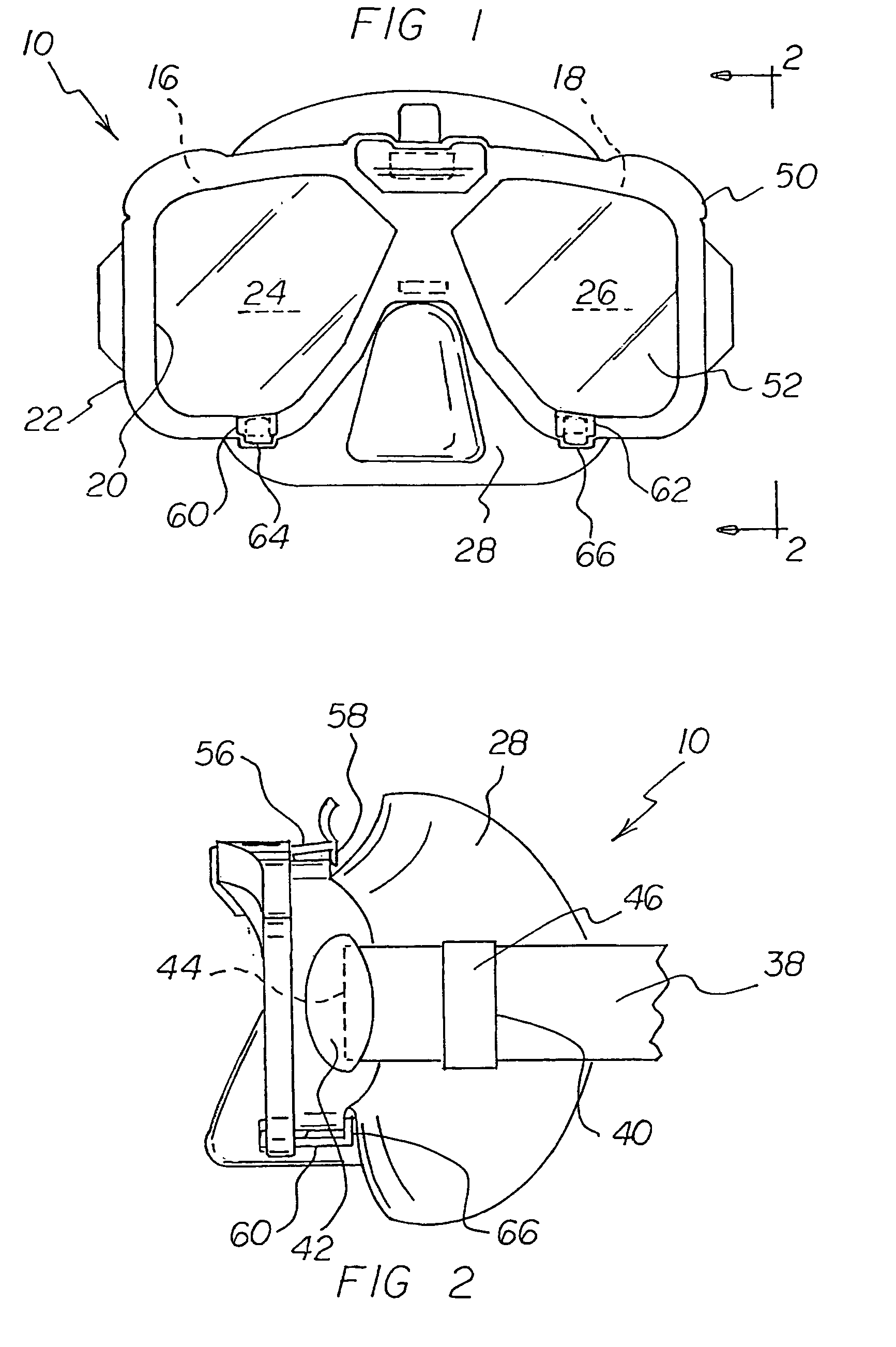

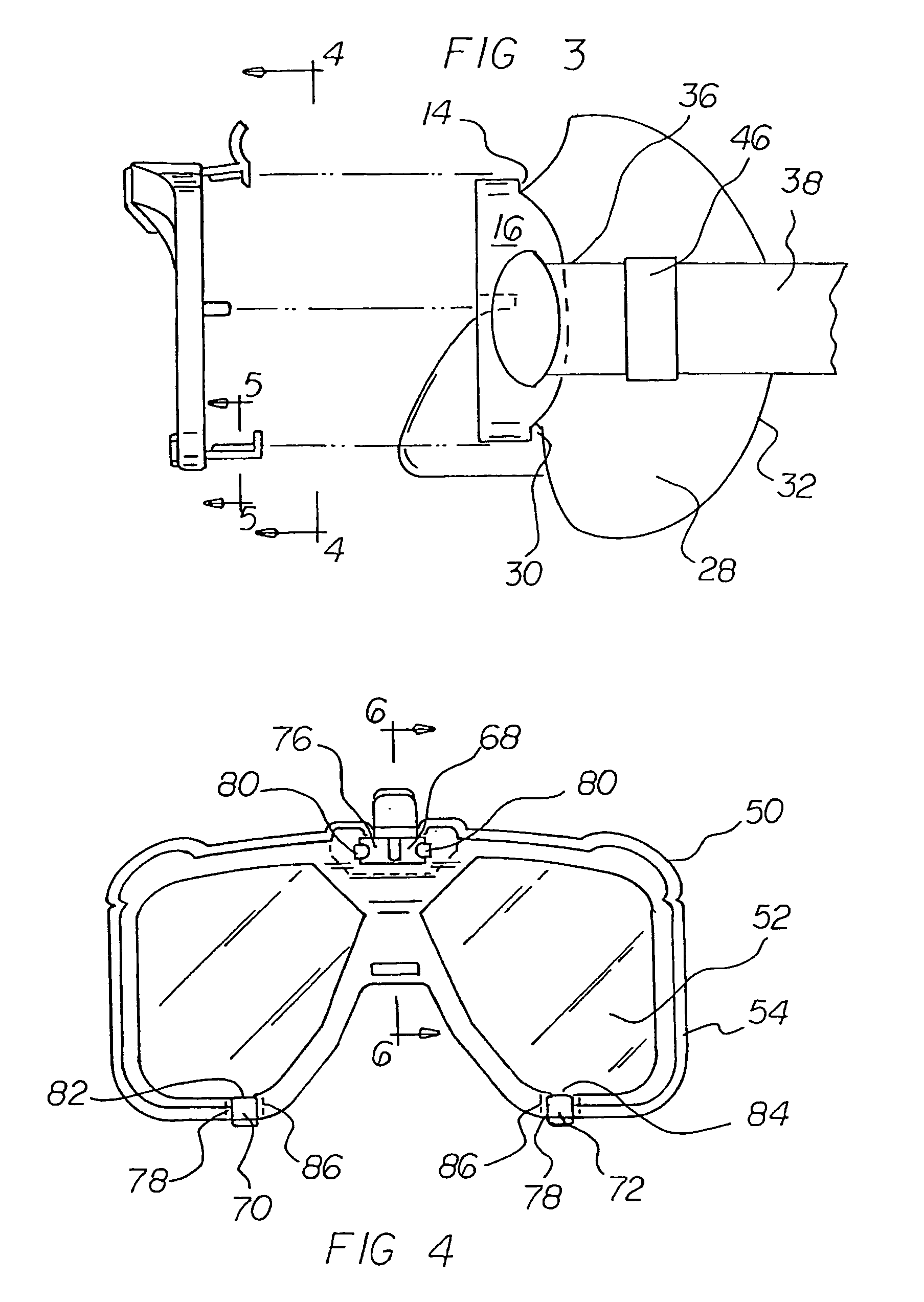

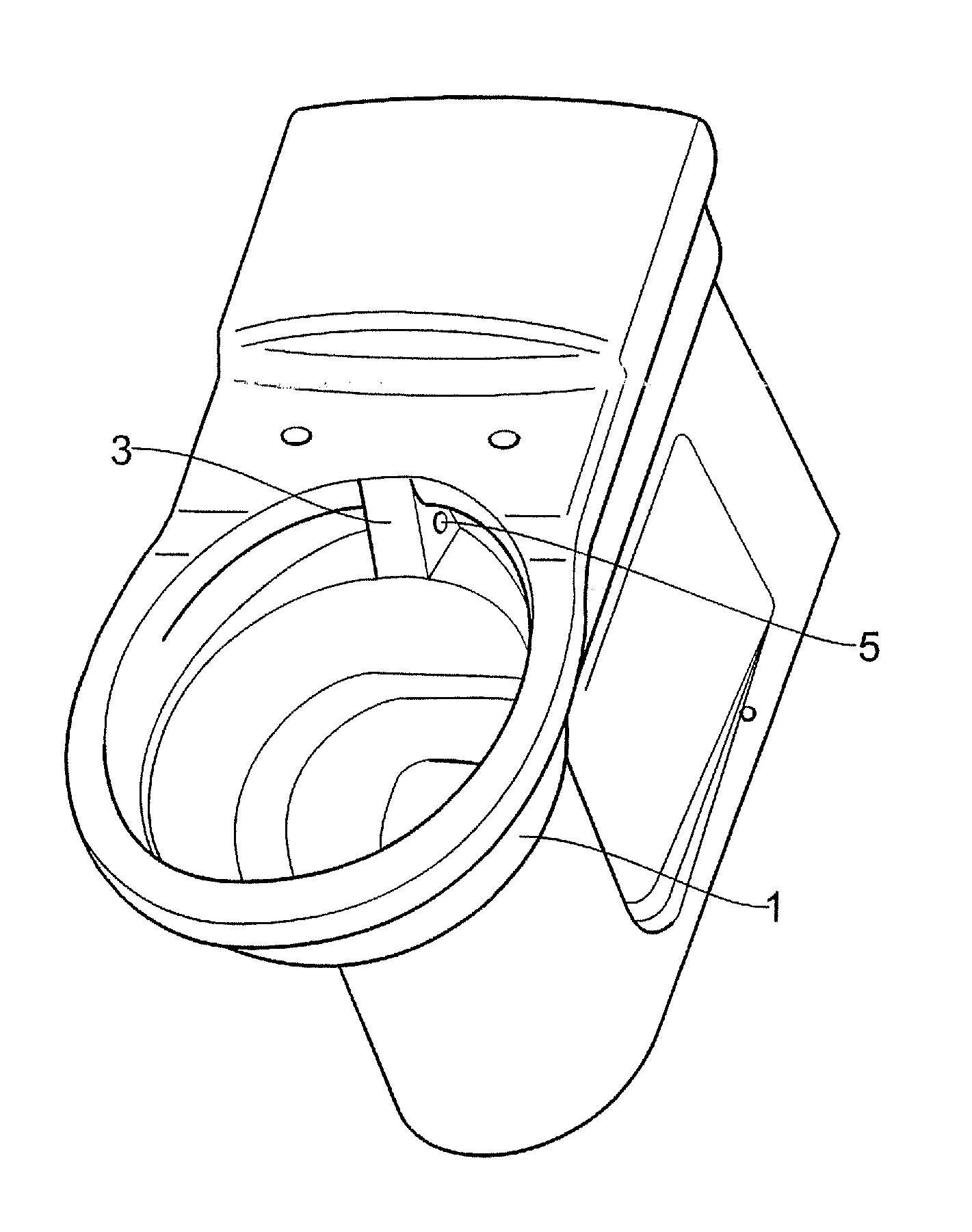

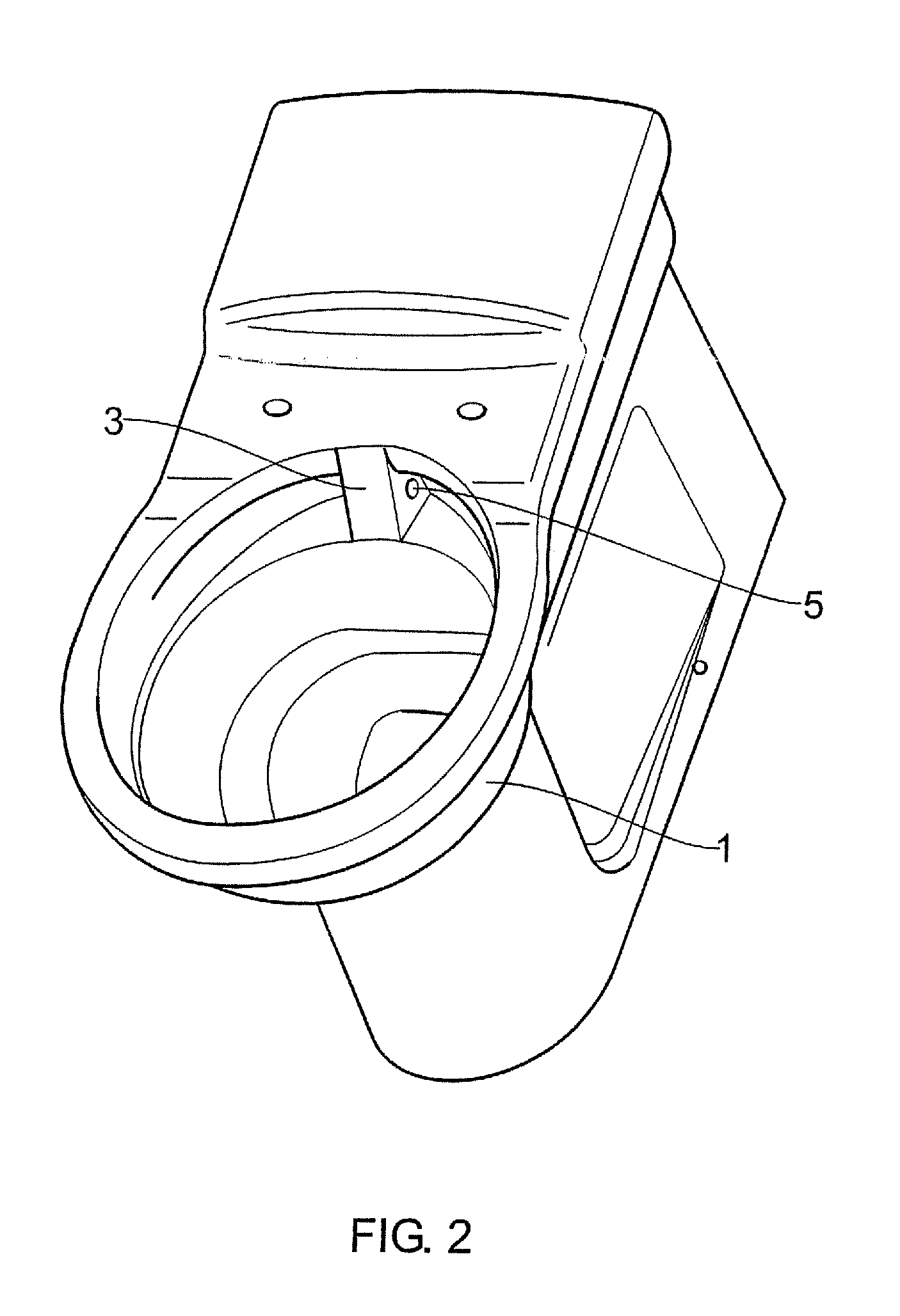

Dive mask system

InactiveUS6953247B1Easy to shapeReduced flexibilityGogglesProtective garmentEngineeringMechanical engineering

A mask assembly has two circumferential frames with an interior edge, an exterior edge and a lens. The assembly includes a skirt with a forward edge coupled to the frames. The forward edge extends rearwardly and terminates at a periphery positionable on the face of a wearer. A strap assembly includes a strap that is positionable around the head of a wearer. Free ends are secured to the vertical areas. The free ends of the strap are for securement and adjustment. A shield assembly has a front area that is positionable in front of the frames and lenses. The assembly has a peripheral ledge. An upper projection that extends from the shield. A finger extends adjacent to the horizontal area of the frame. Projections extend from the shield. Each has a finger extending upwardly. The projections and fingers are adapted to releasably couple the shield assembly to the mask assembly.

Owner:ICARE INDS

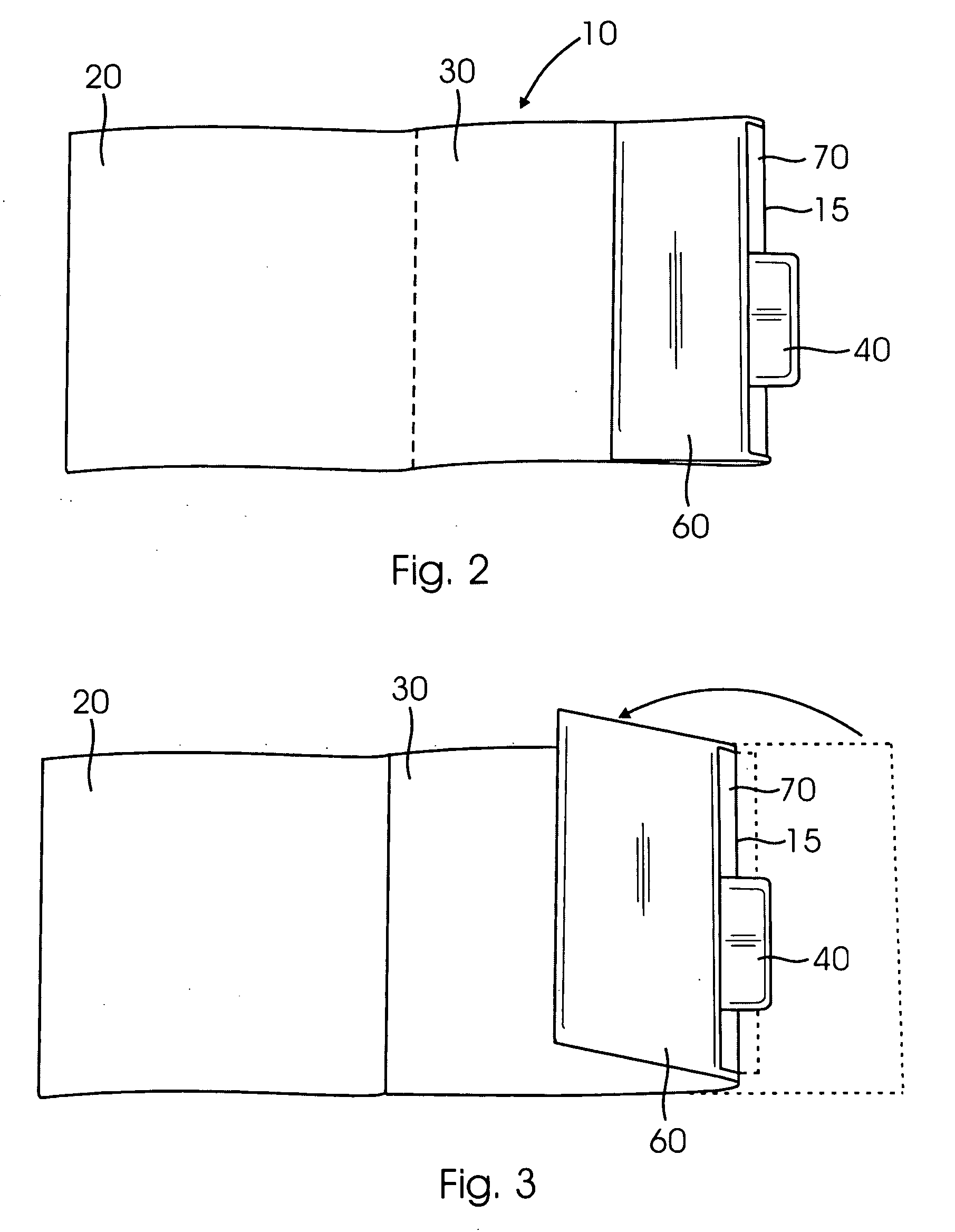

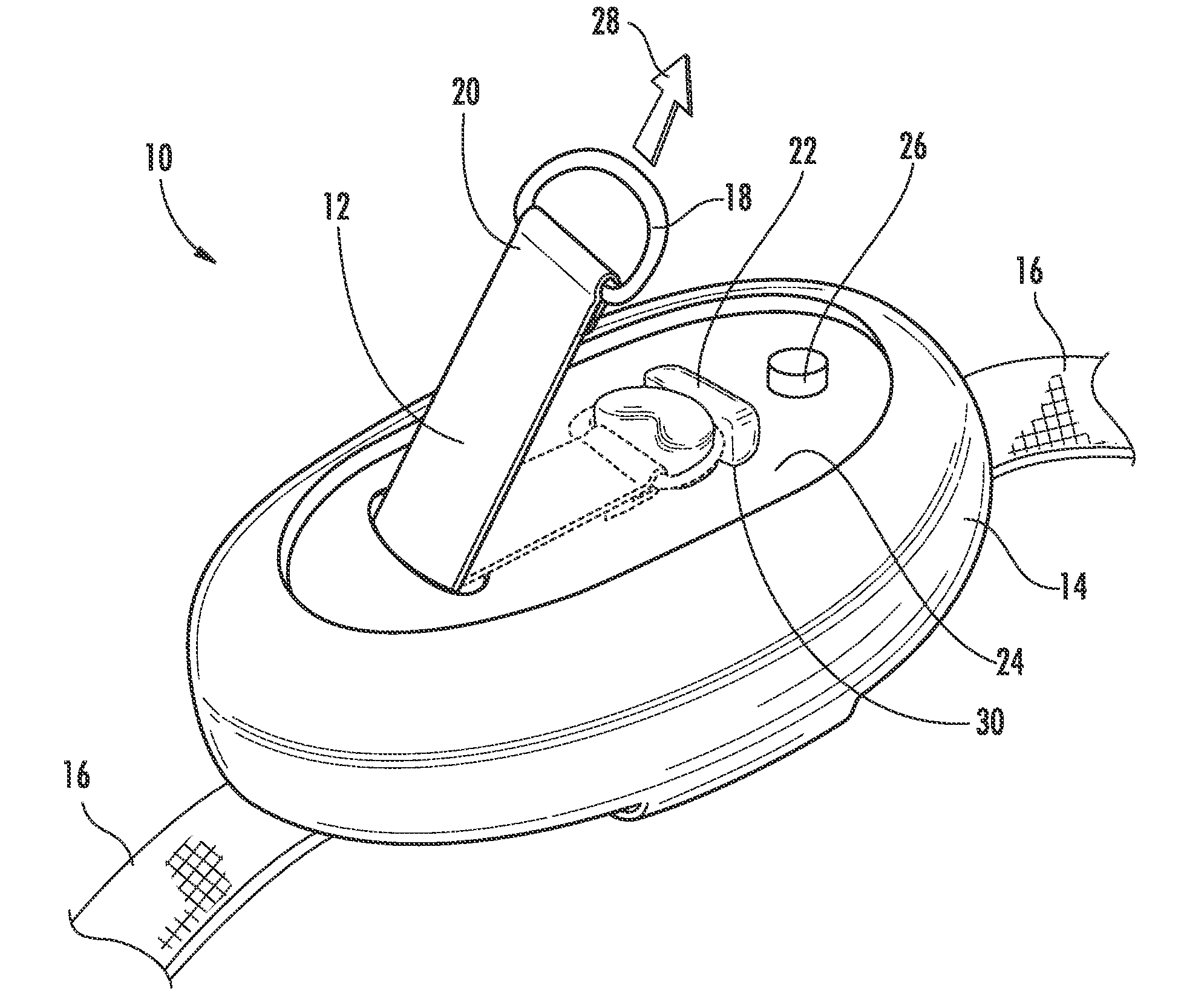

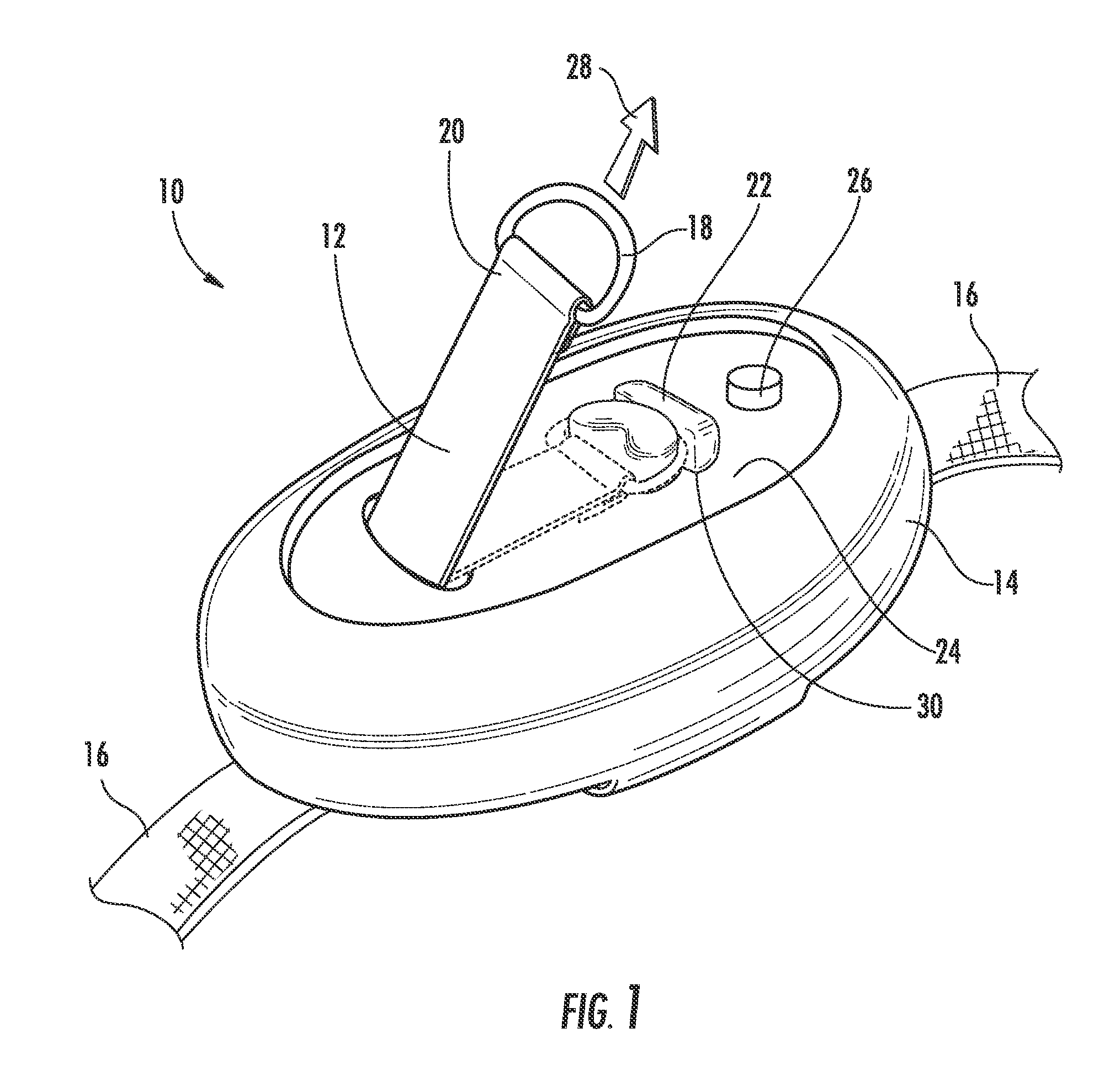

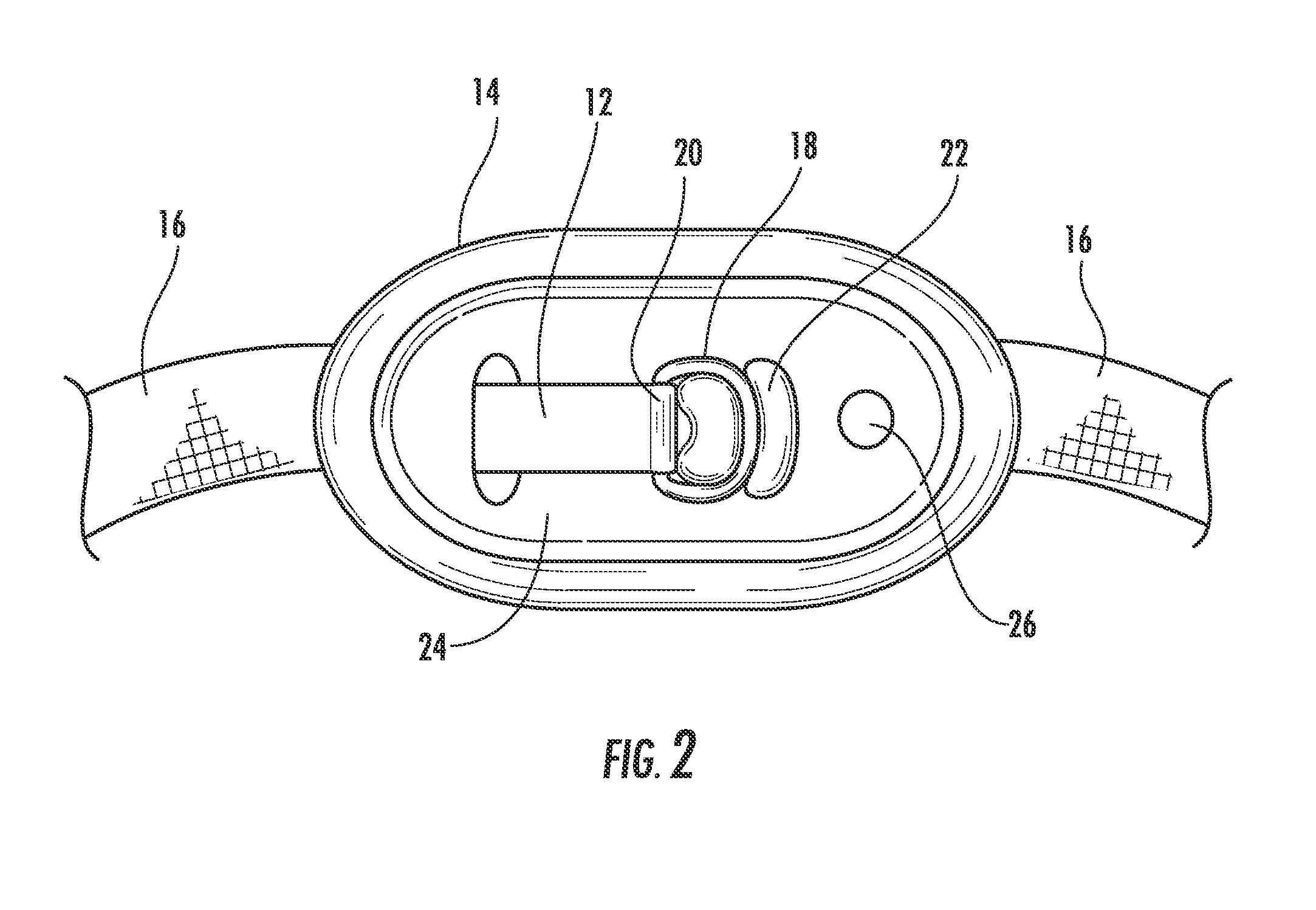

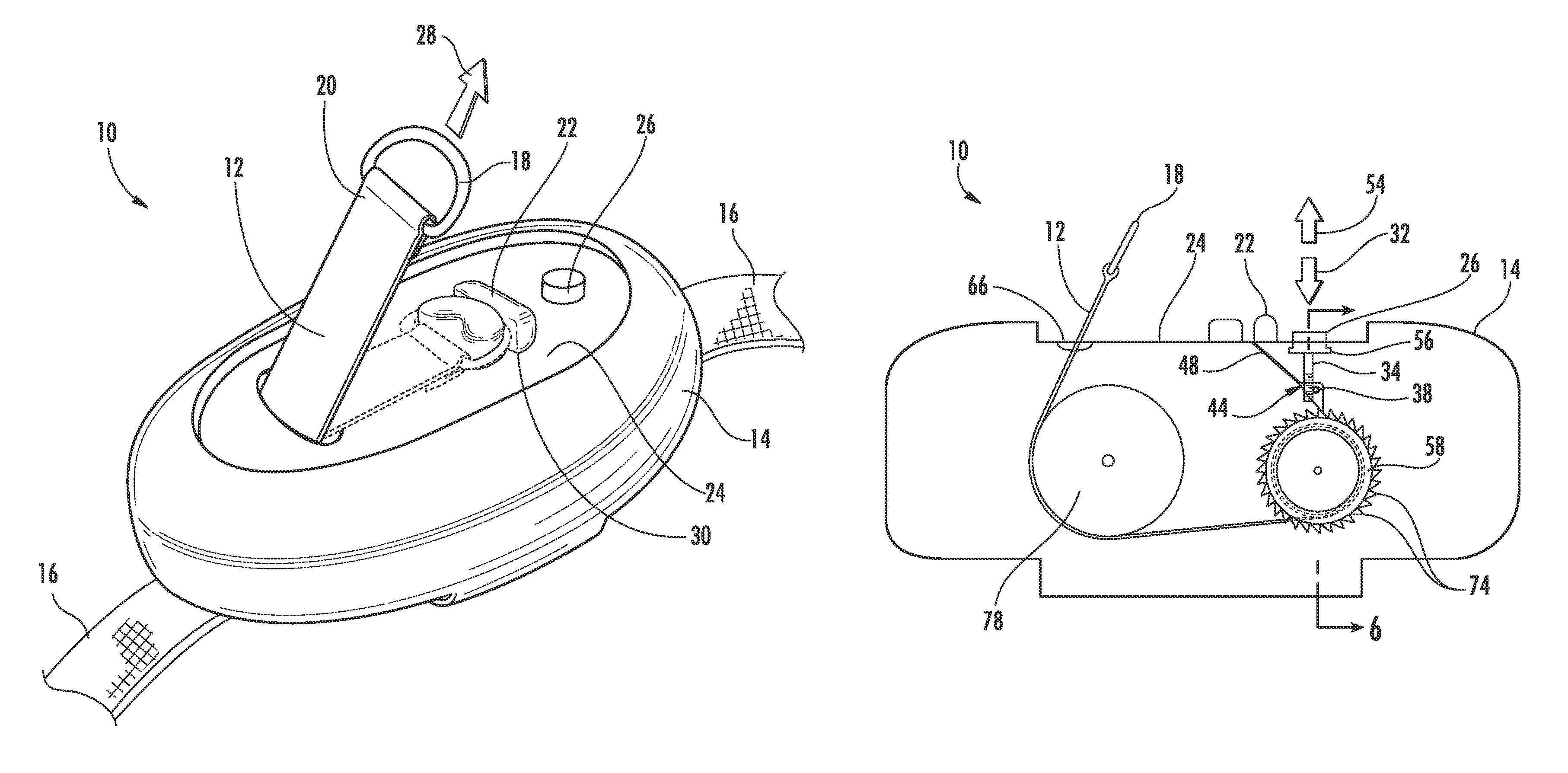

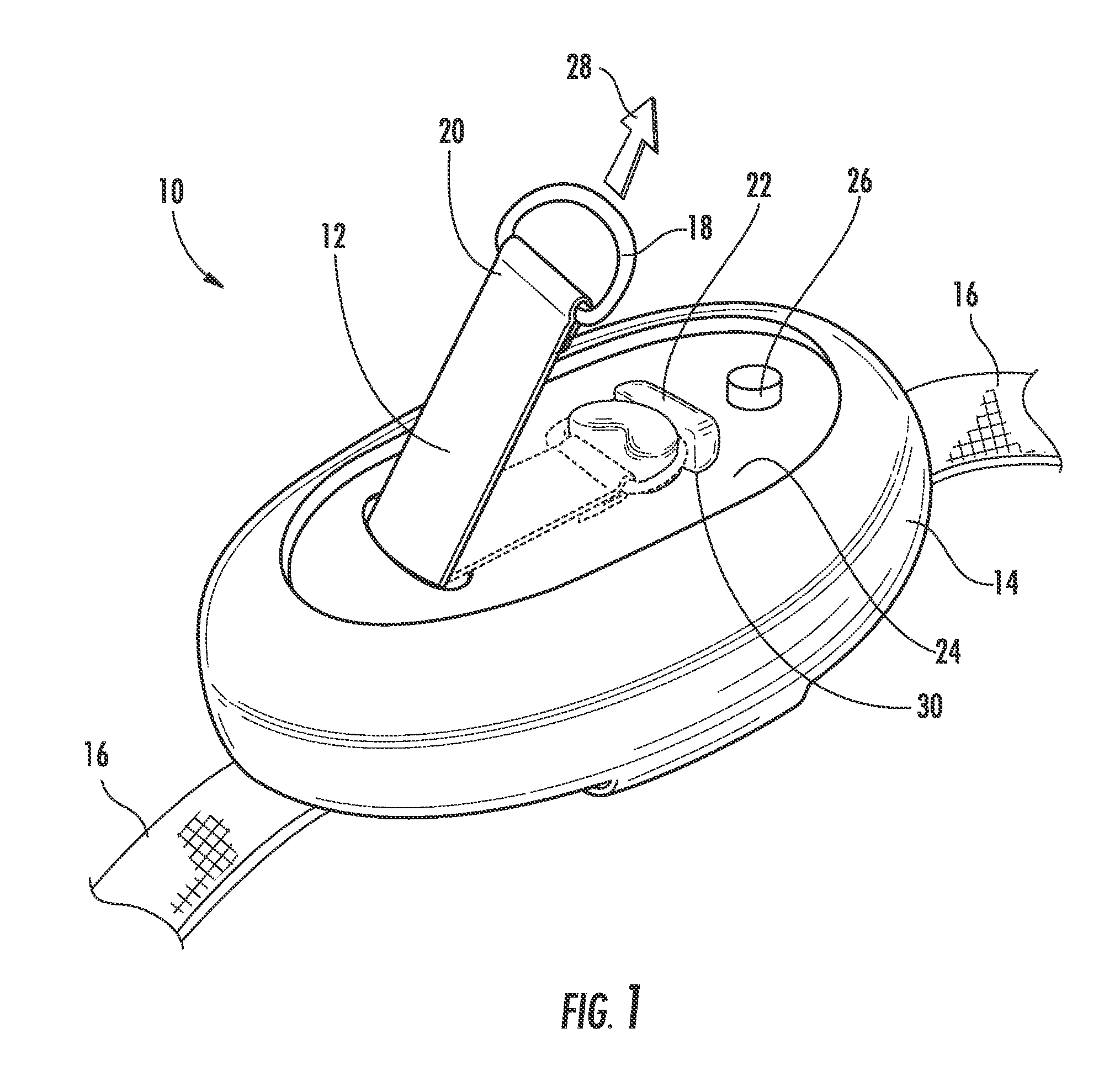

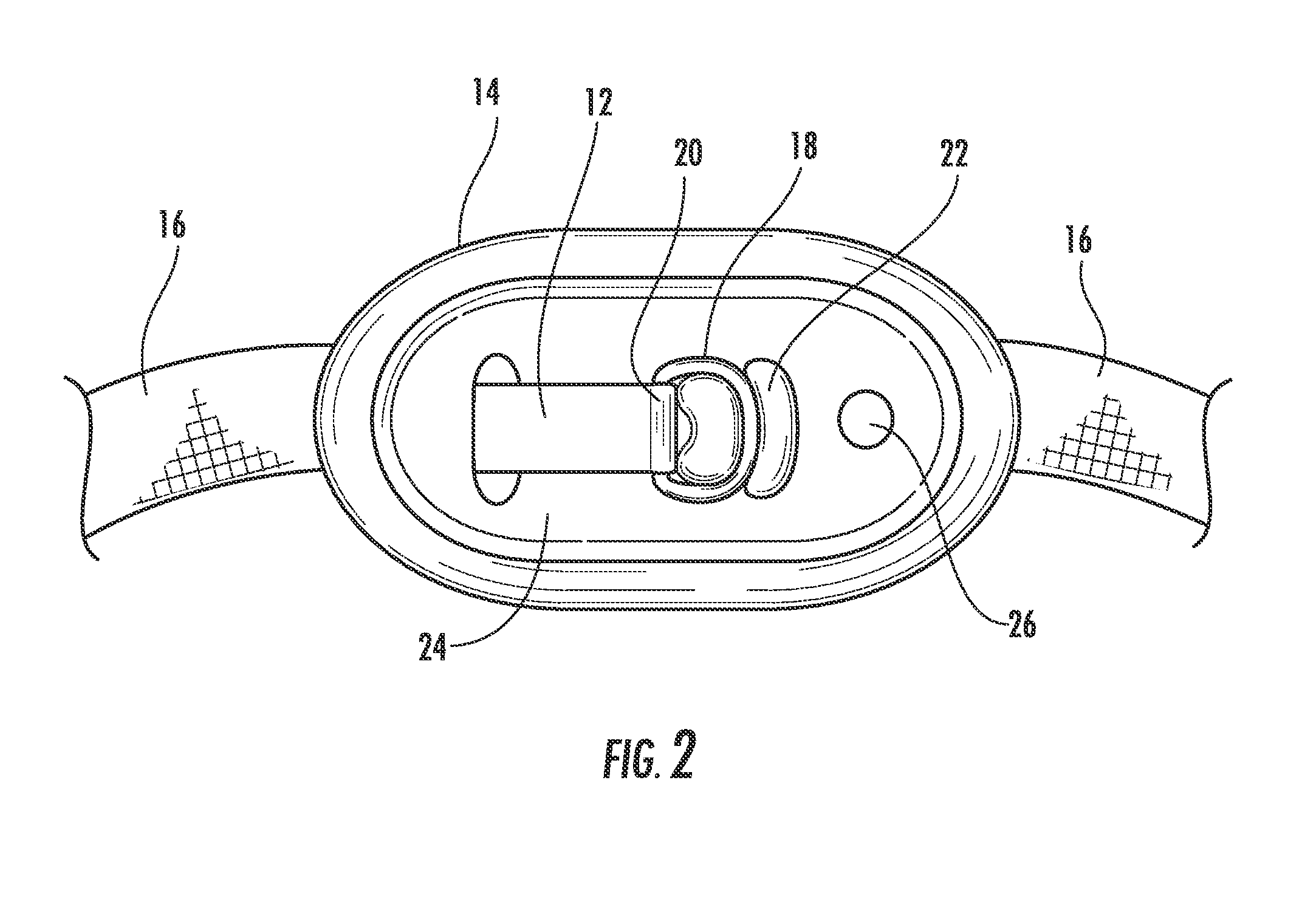

Pet collar having retractable leash

ActiveUS20110036304A1Minimize visibilityMaximize visibilitySafety beltsTaming and training devicesEngineeringActuator

A pet collar assembly is removably attached to a pet collar and carries a leash. The assembly allows for extending and retracting the leash and includes a housing, an actuator assembly for actuating retraction of the leash upon receiving force higher than a threshold retraction force, and a spool communicating with the actuator assembly and biased for coiling the leash. The actuator assembly has a button and a button shaft that mechanically communicates with a hook shaft attached to a hook. The hook engages a plurality of teeth disposed on the circumference of a rim of the spool. An elastic band applies force against the hook so that the actuator assembly remains in a locked configuration unless a force higher than the threshold retraction force is received by the button.

Owner:SMITH SANDRA W

Illuminated exterior decorative device

ActiveUS20060291233A1Maximize visibilityHighly effectiveLighting support devicesOptical signallingLight sourceMetal coating

An illuminated exterior decorative device for vehicles includes a decorative part and an illuminating part. The illuminating part illuminates the decorative part from behind and includes a light source and a light diffusion portion. The light source of the illuminating part is embedded in the light diffusion portion. The light diffusion portion of the illuminating part is optically transmissive, preferably transparent. The light source is disposed along the edge of the decorative part. The light source includes a plurality of light emitting device (LED). The illuminating part has substantially the same pattern as the decorative part. The decorative part may be provided as metal coating on the illuminating part.

Owner:KWON YOUNG CHUL

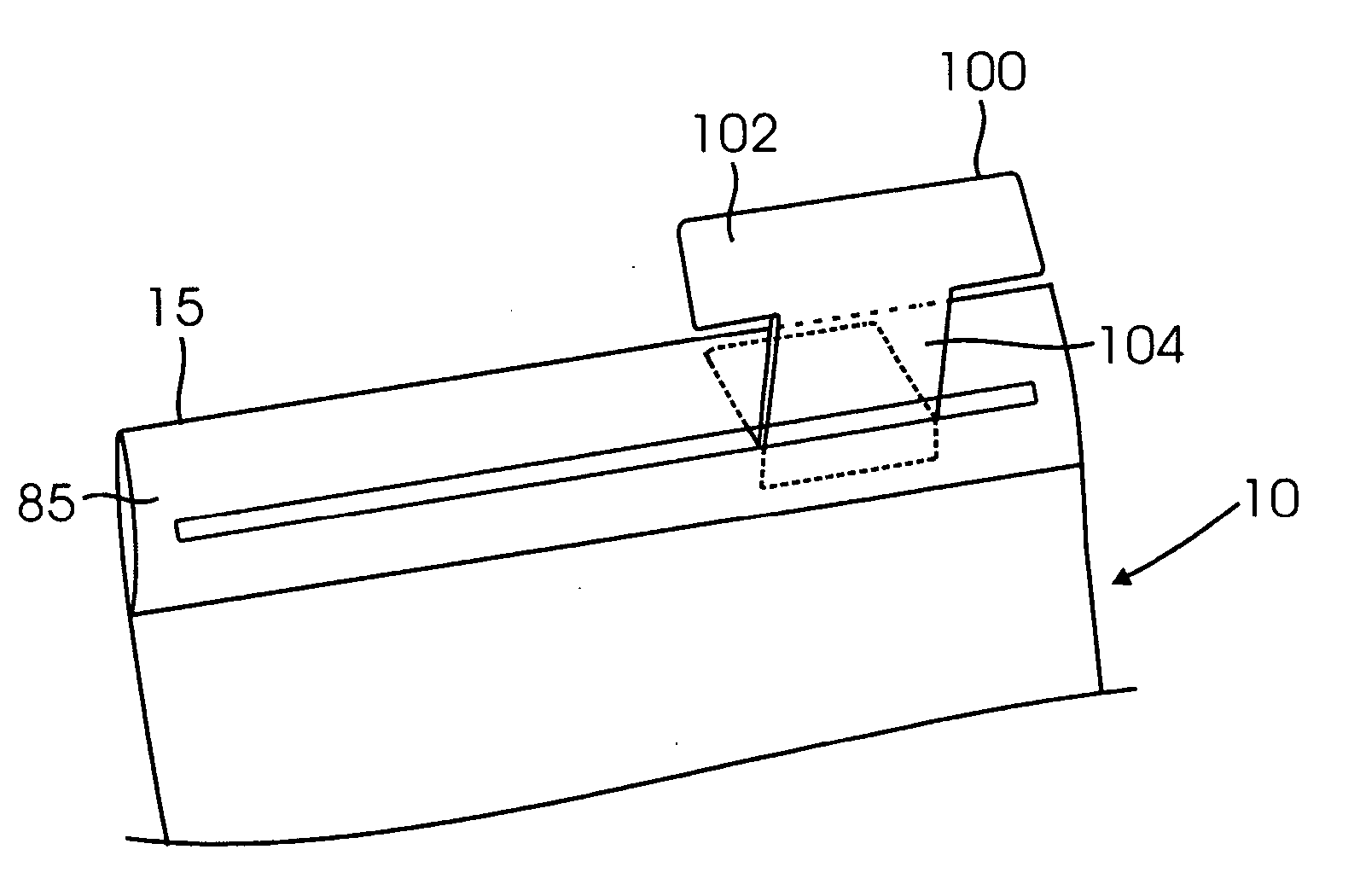

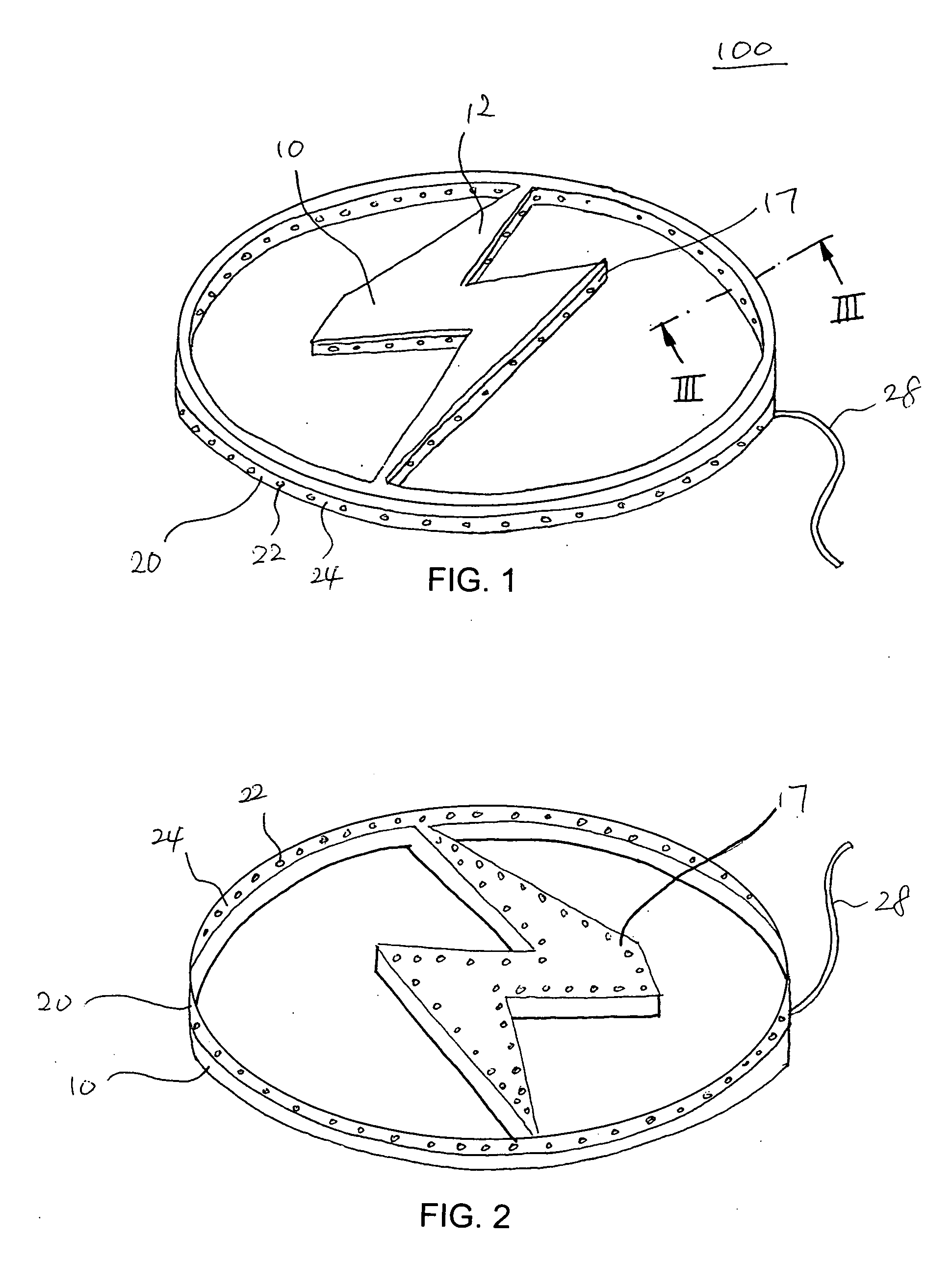

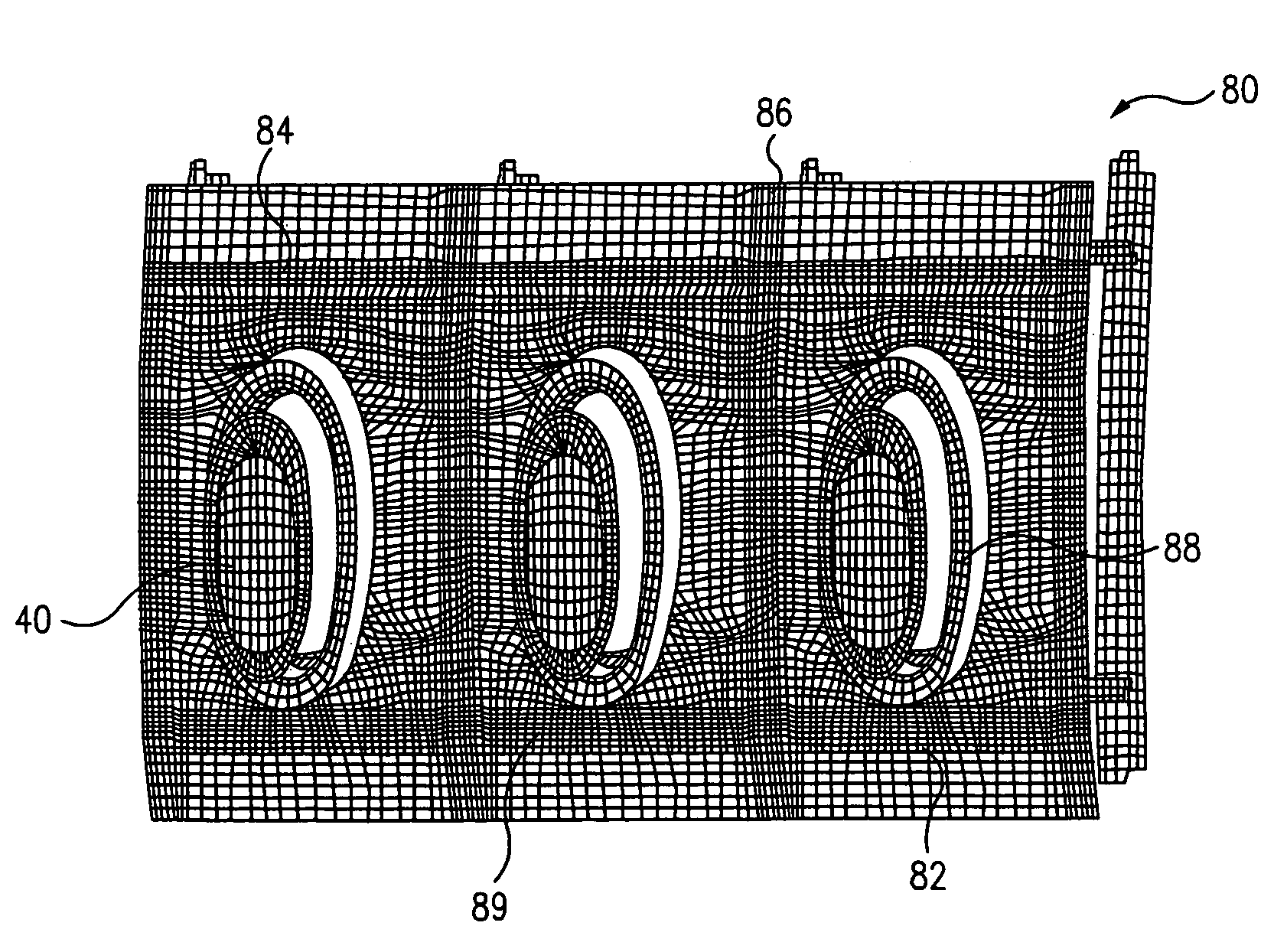

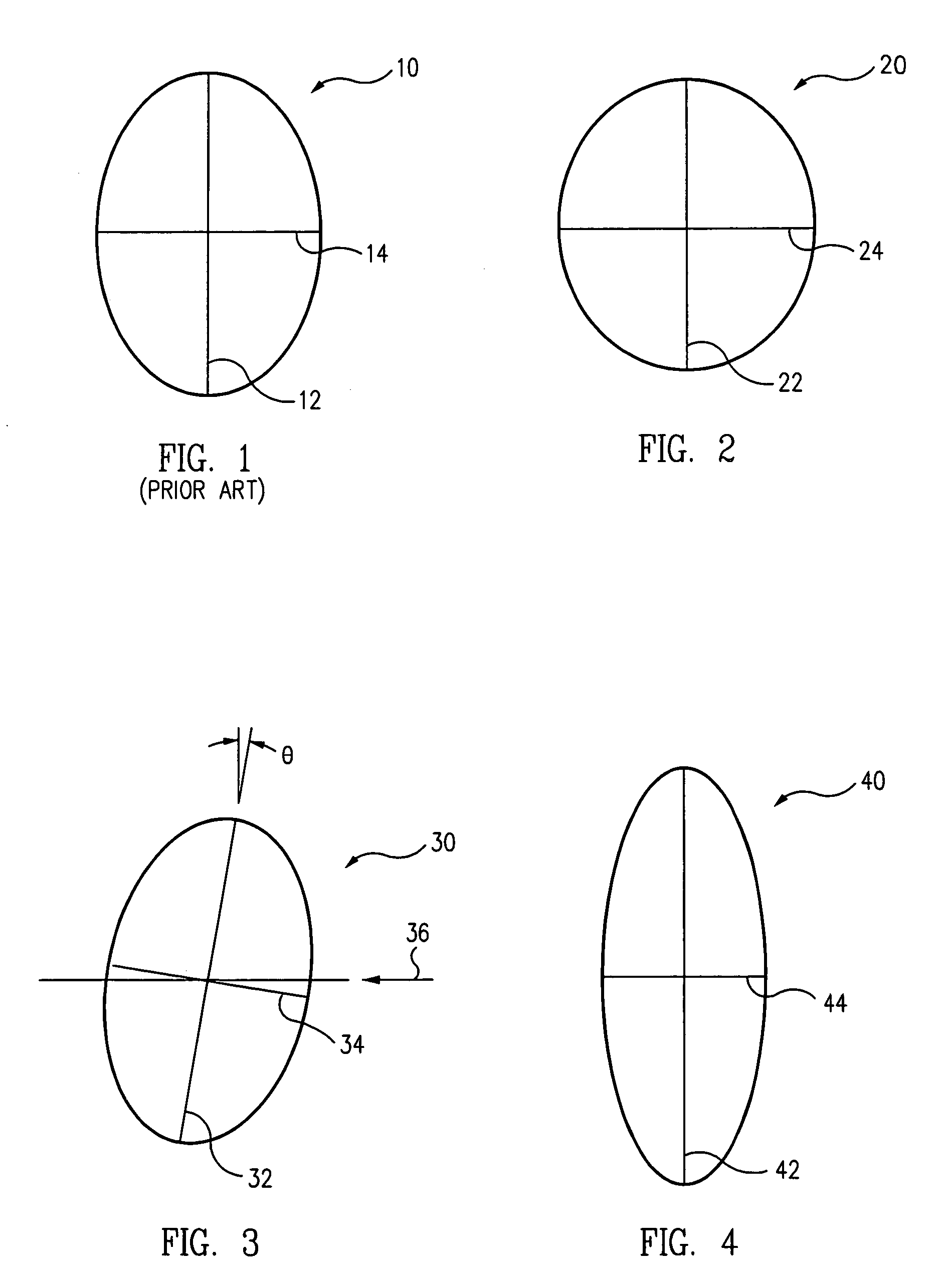

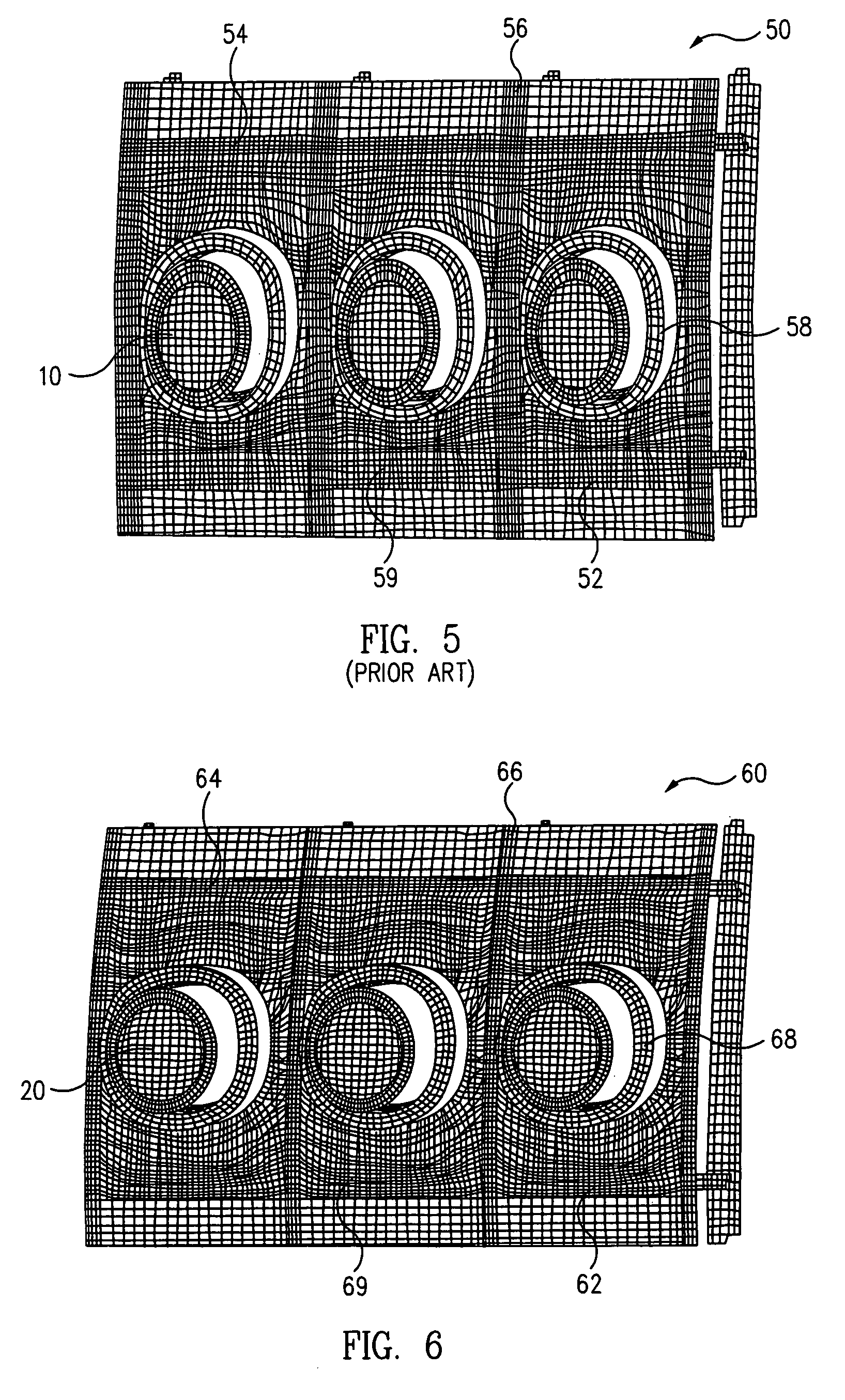

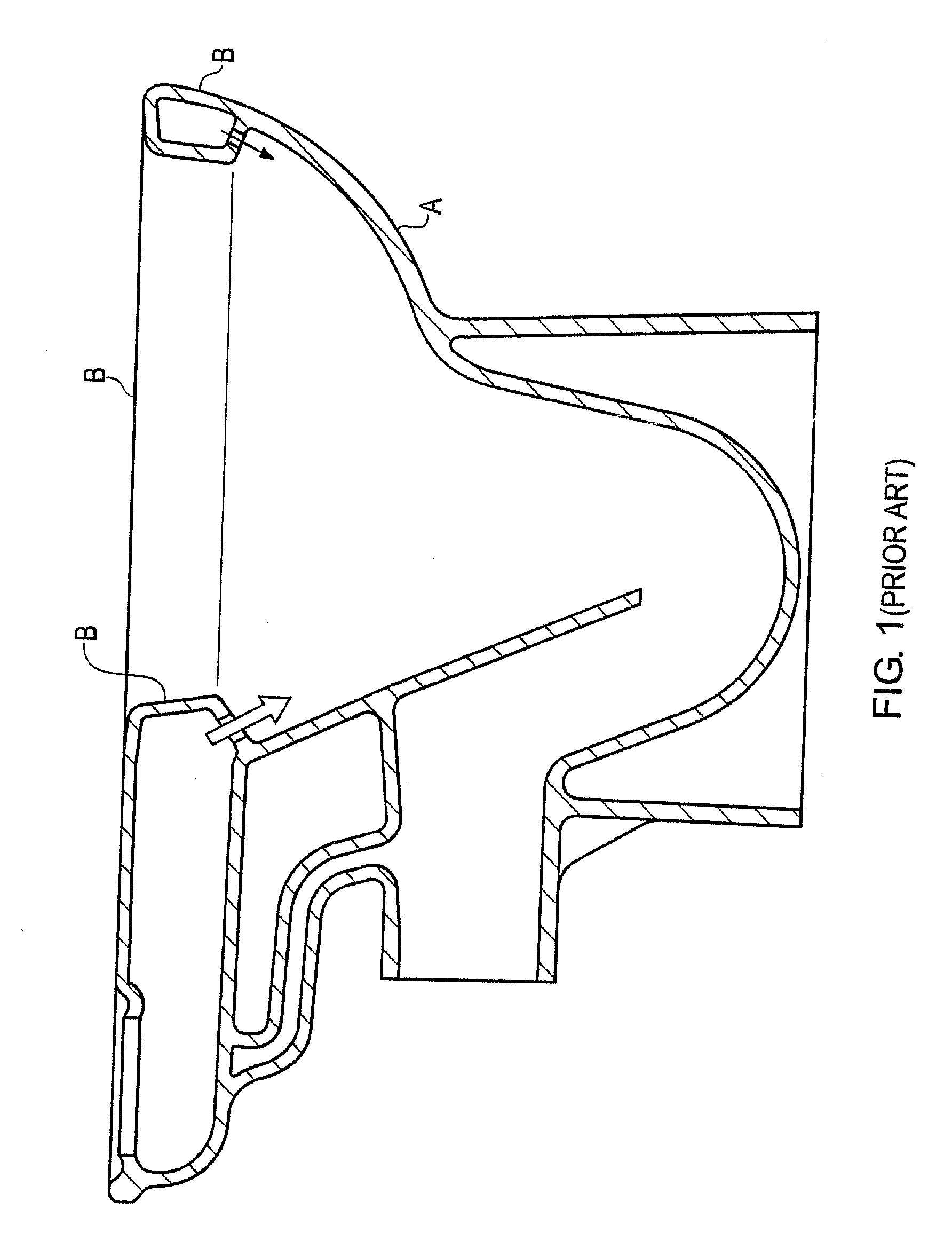

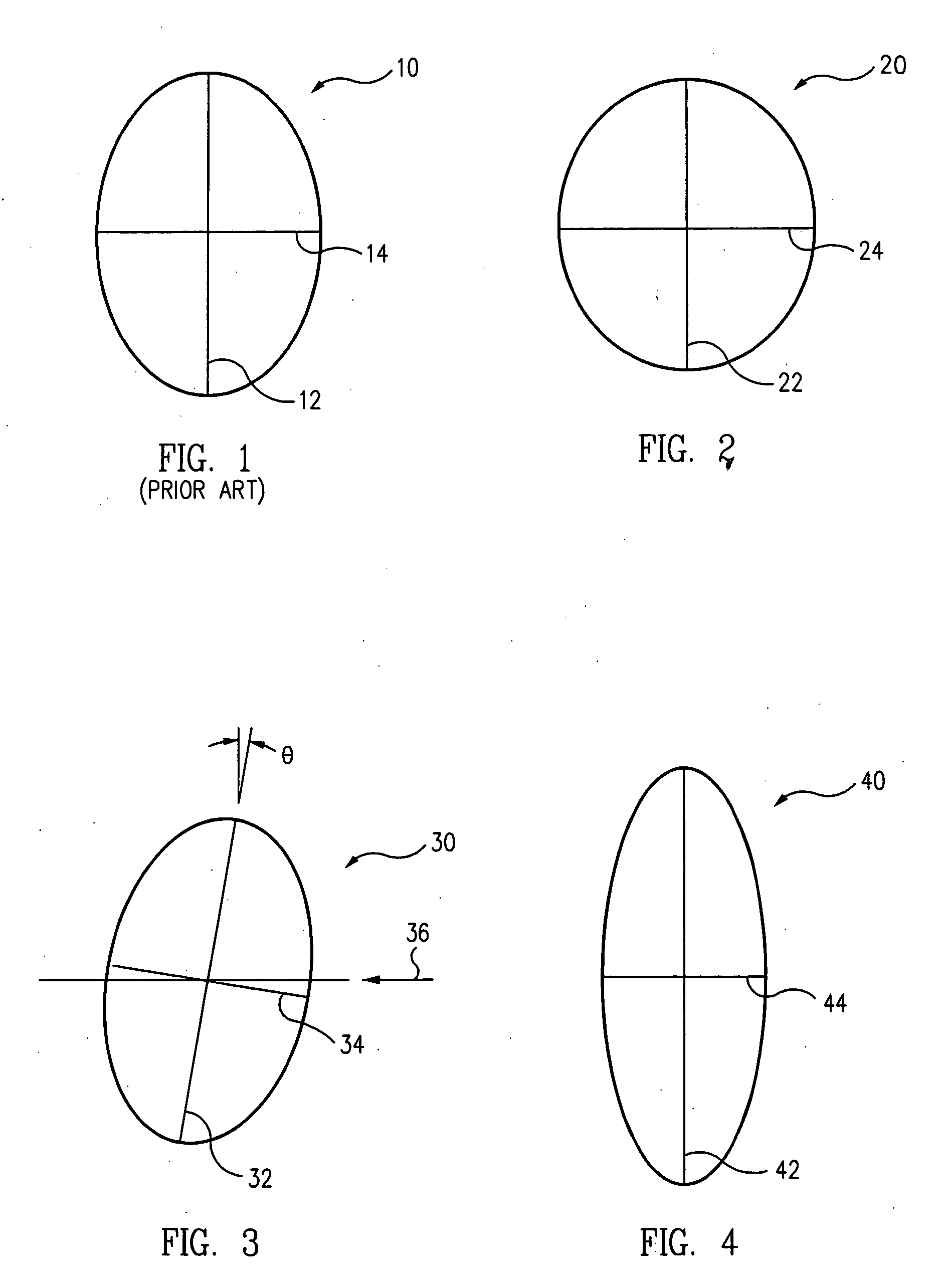

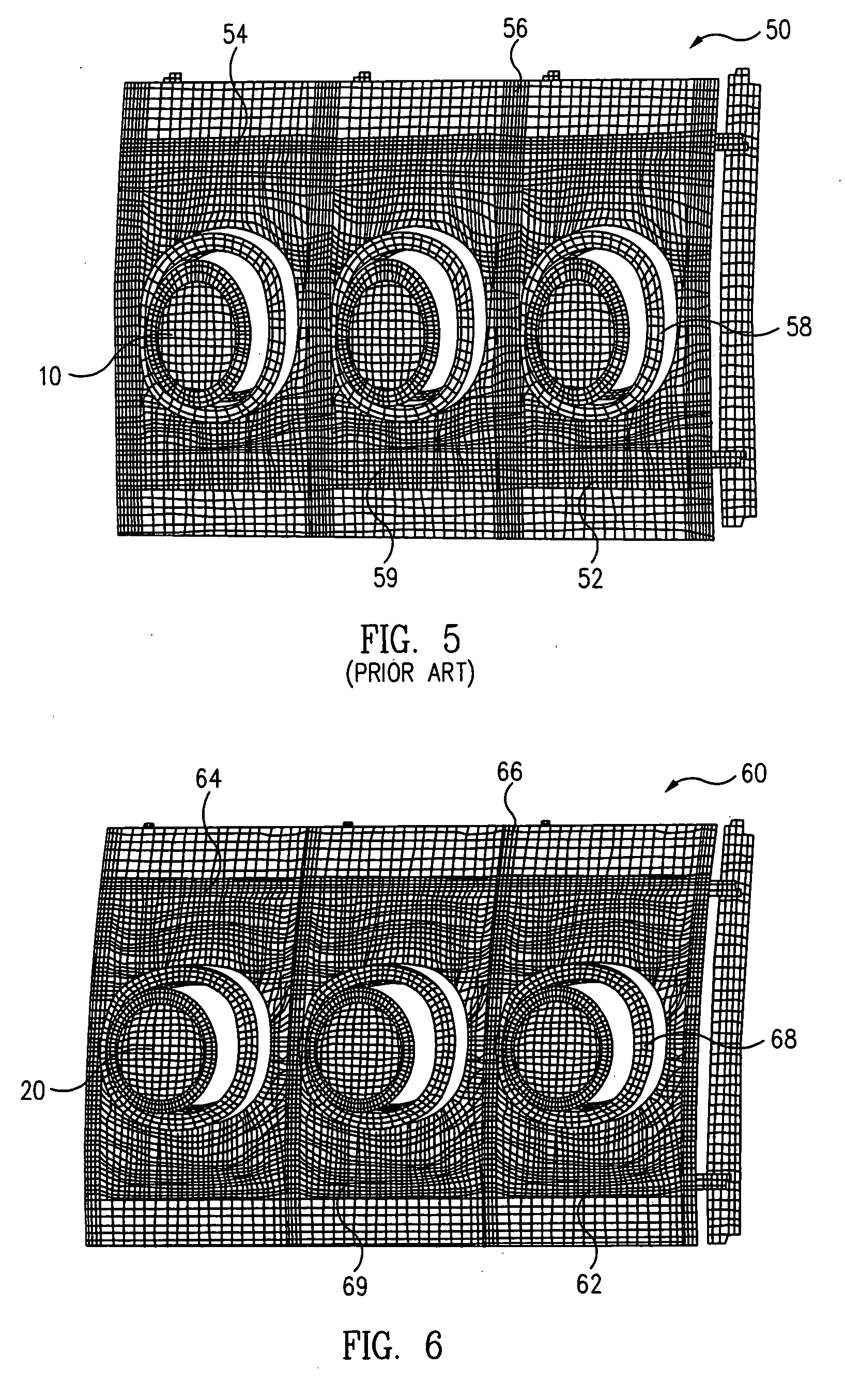

Optimal aircraft window shape for noise control

ActiveUS7438263B2Quantity minimizationMaximize visibilityEar treatmentAir-treatment apparatus arrangementsVisibilityNoise control

A window for a subsonic passenger aircraft that provide maximum optical visibility while minimizing the amount of exterior acoustic noise transmitted through the windows to the passenger cabin during flight of the aircraft includes at least one substantially transparent window pane having the shape of an ellipse. The ellipse has a major axis and a minor axis, and the major axis is about twice as long as the minor axis and is disposed generally perpendicular to the direction of flight of the aircraft. In one exemplary embodiment, the window has a height of about 20 inches and a transparent area of about 141 square inches, and includes a pair of substantially similar window panes disposed in a parallel, spaced-apart relationship circumscribed by a mounting bezel. A plurality of the windows are each mounted with the bezels in spaced-apart rows in each of the opposite sidewalls of the aircraft fuselage.

Owner:THE BOEING CO

Pet collar having retractable leash

ActiveUS8230822B2Minimize visibilityMaximize visibilitySafety beltsTaming and training devicesEngineeringActuator

A pet collar assembly is removably attached to a pet collar and carries a leash. The assembly allows for extending and retracting the leash and includes a housing, an actuator assembly for actuating retraction of the leash upon receiving force higher than a threshold retraction force, and a spool communicating with the actuator assembly and biased for coiling the leash. The actuator assembly has a button and a button shaft that mechanically communicates with a hook shaft attached to a hook. The hook engages a plurality of teeth disposed on the circumference of a rim of the spool. An elastic band applies force against the hook so that the actuator assembly remains in a locked configuration unless a force higher than the threshold retraction force is received by the button.

Owner:SMITH SANDRA W

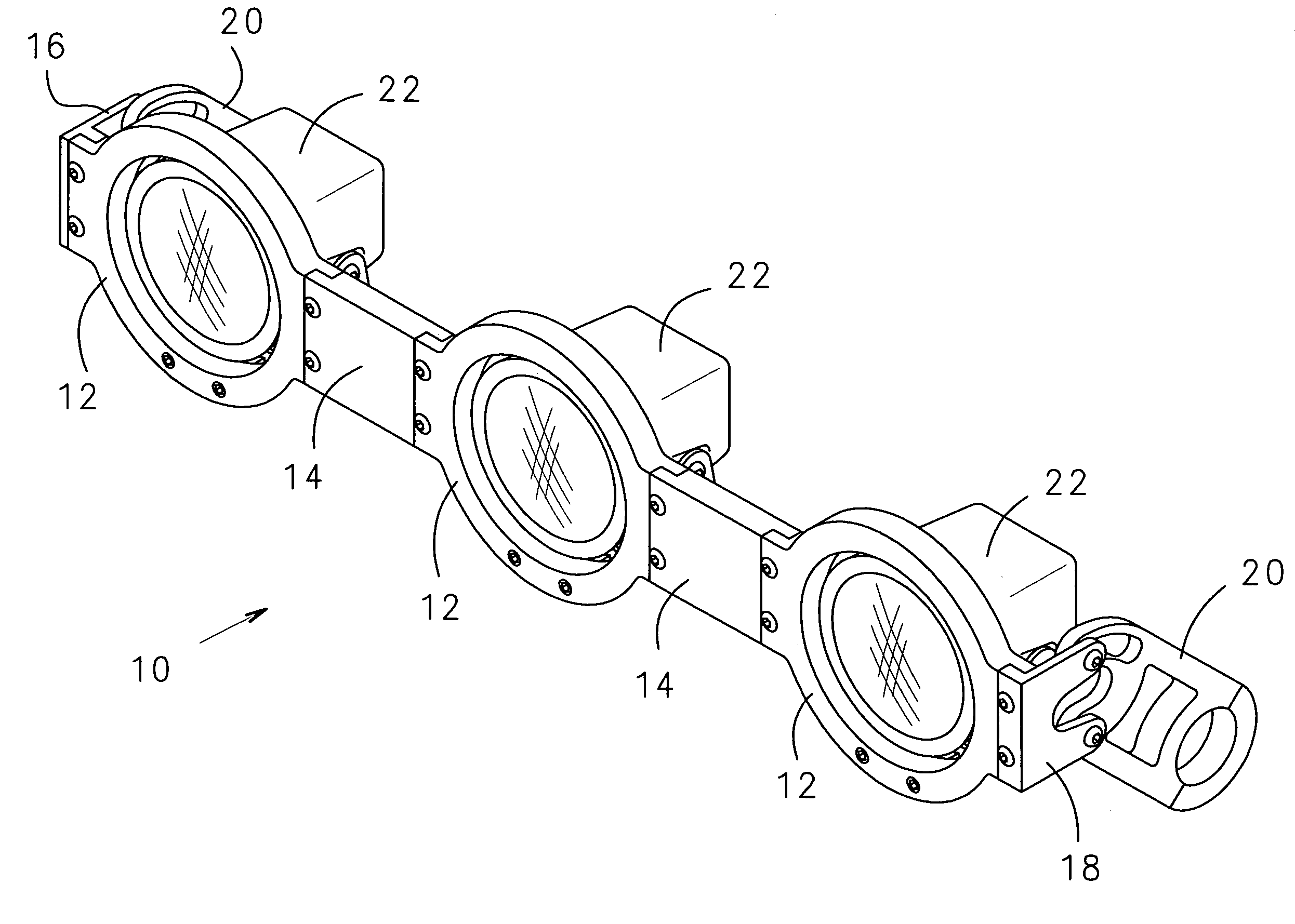

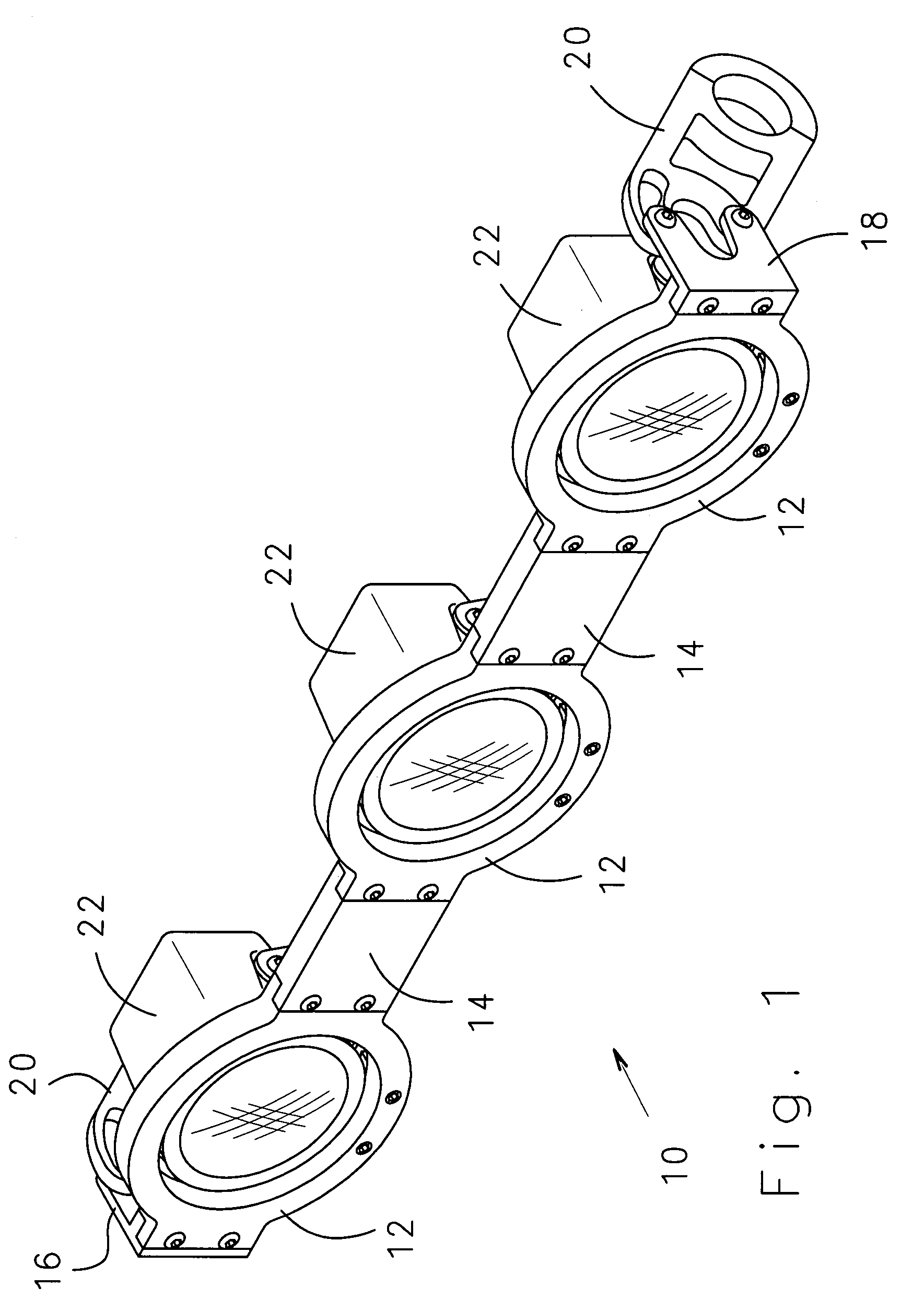

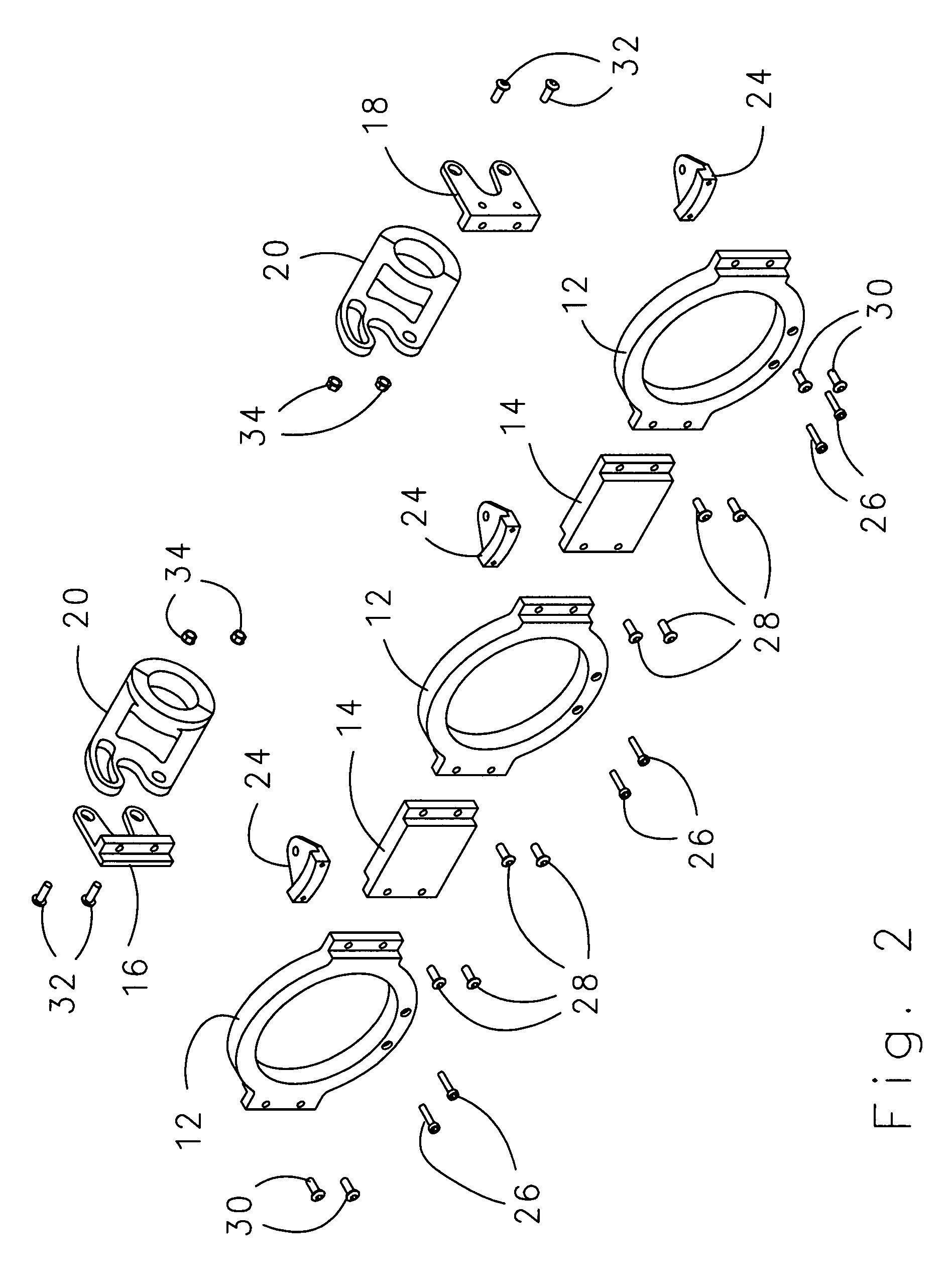

Modular off-road accessory light rack

ActiveUS7789544B1Maximize visibilityImprove visibilityVehicle interior lightingOptical signalModularityEngineering

A modular light rack assembly for off-road vehicles having a plurality of individual pieces that can be selectively connected to form a substantially linear assembly for attaching a variety of headlight subassemblies. In each embodiment, there is a common left hand mounting configuration and common right hand mounting configuration, so that each piece of the modular light rack assembly having one or both of these configurations on its end or ends is selectively connectable to any other piece to form a substantially linear assembly of any desired configuration.

Owner:BESTOP BAJA LLC

Protective bat cover

InactiveUS7171999B2Easy to useQuick and convenient mannerFlexible coversWrappersVisibilityRubber material

A cover for protecting the barrel portion of a baseball bat, or other structure is disclosed. The cover is preferably formed from an elastic rubber material such as neoprene. The flexible cover has the ability to adapt its shape upon insertion of a bat, enabling use with bats of various sizes. The cover is water resistant and is adapted for maximizing the visibility of printed matter thereon.

Owner:CIRONE DOMINICK

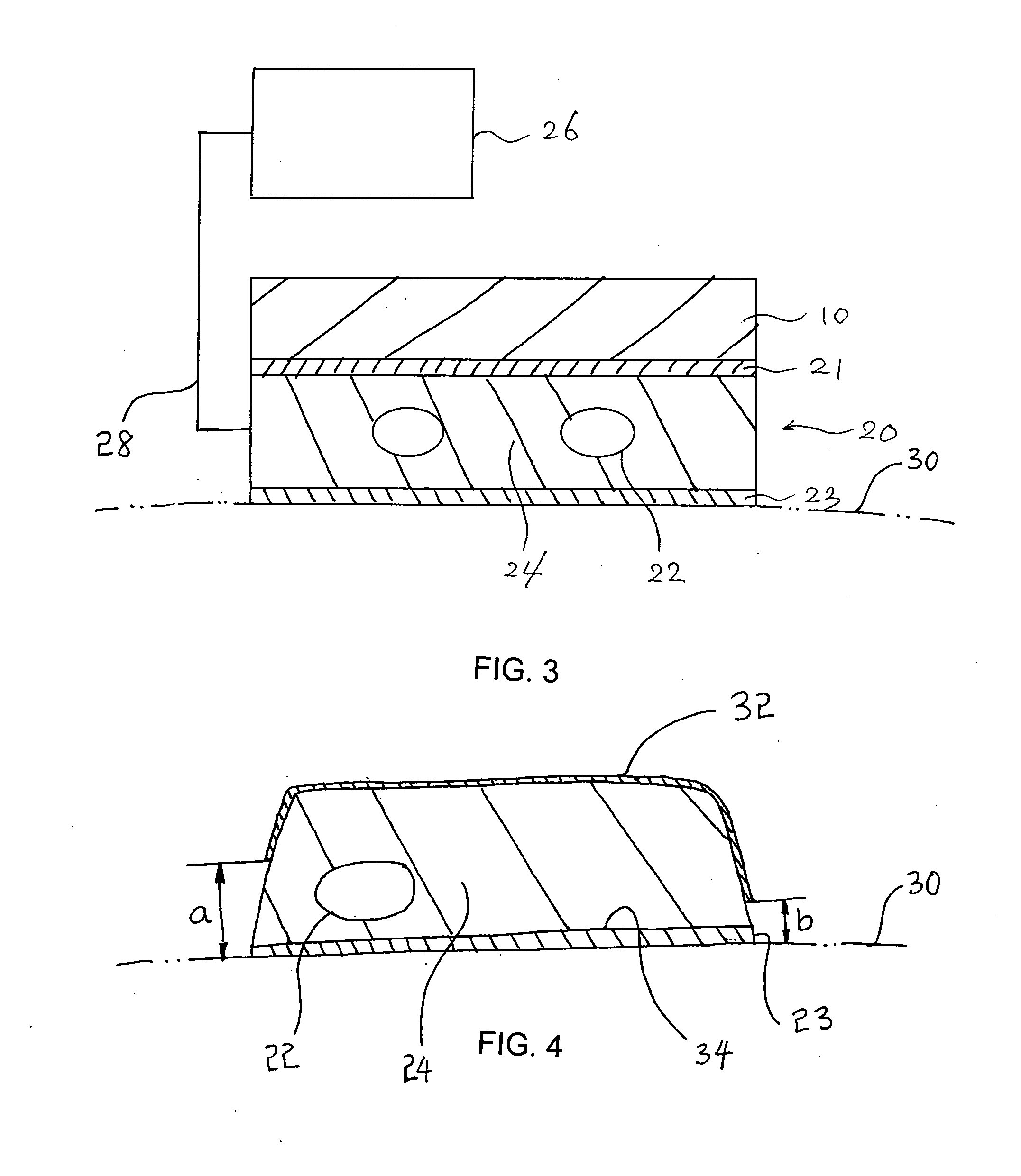

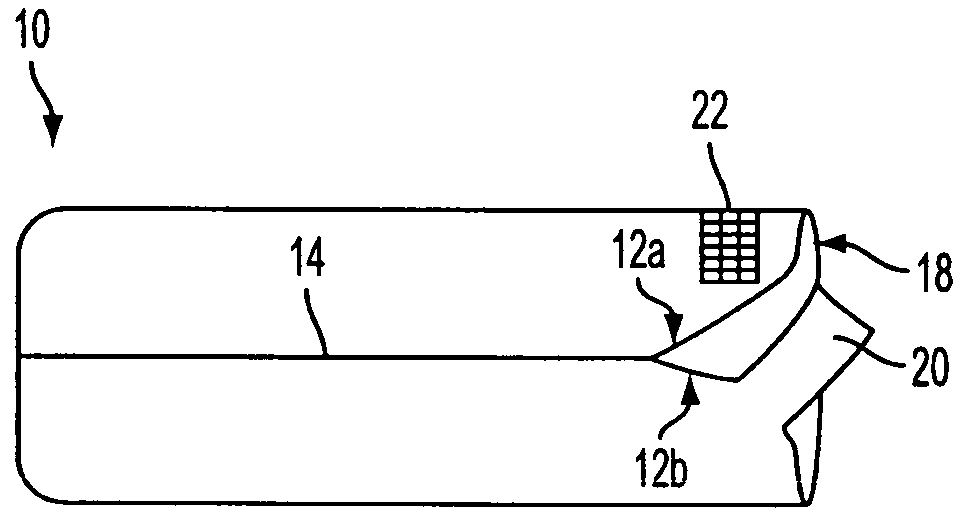

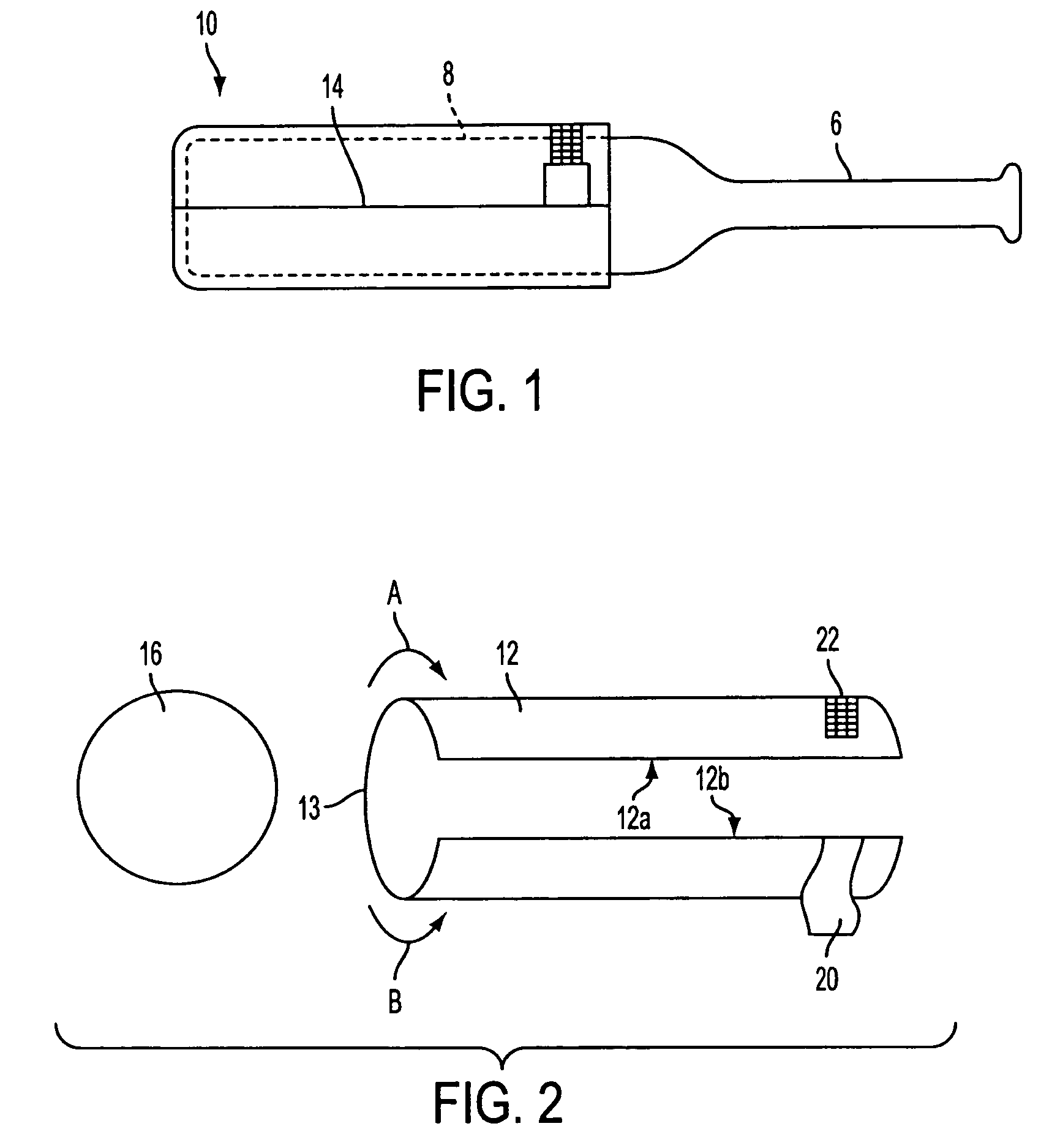

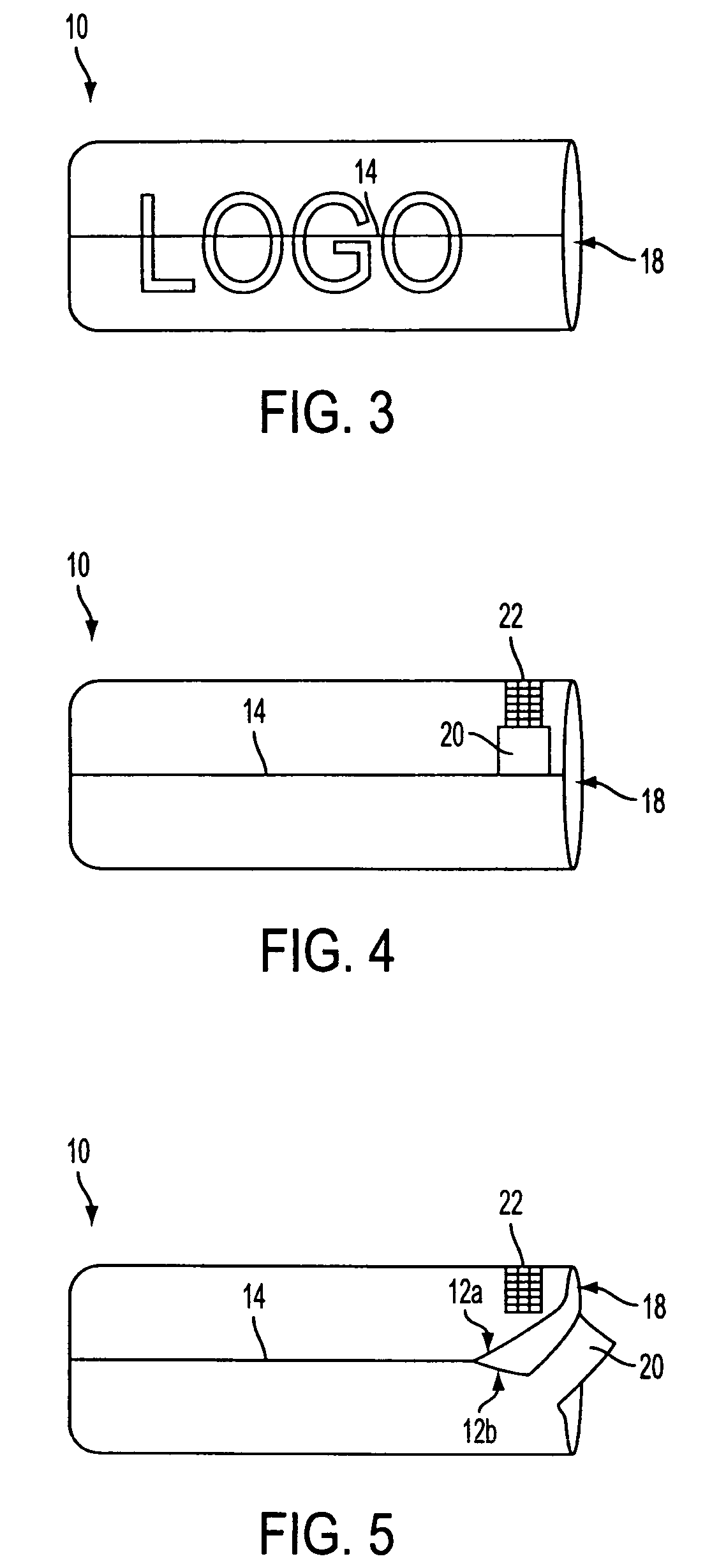

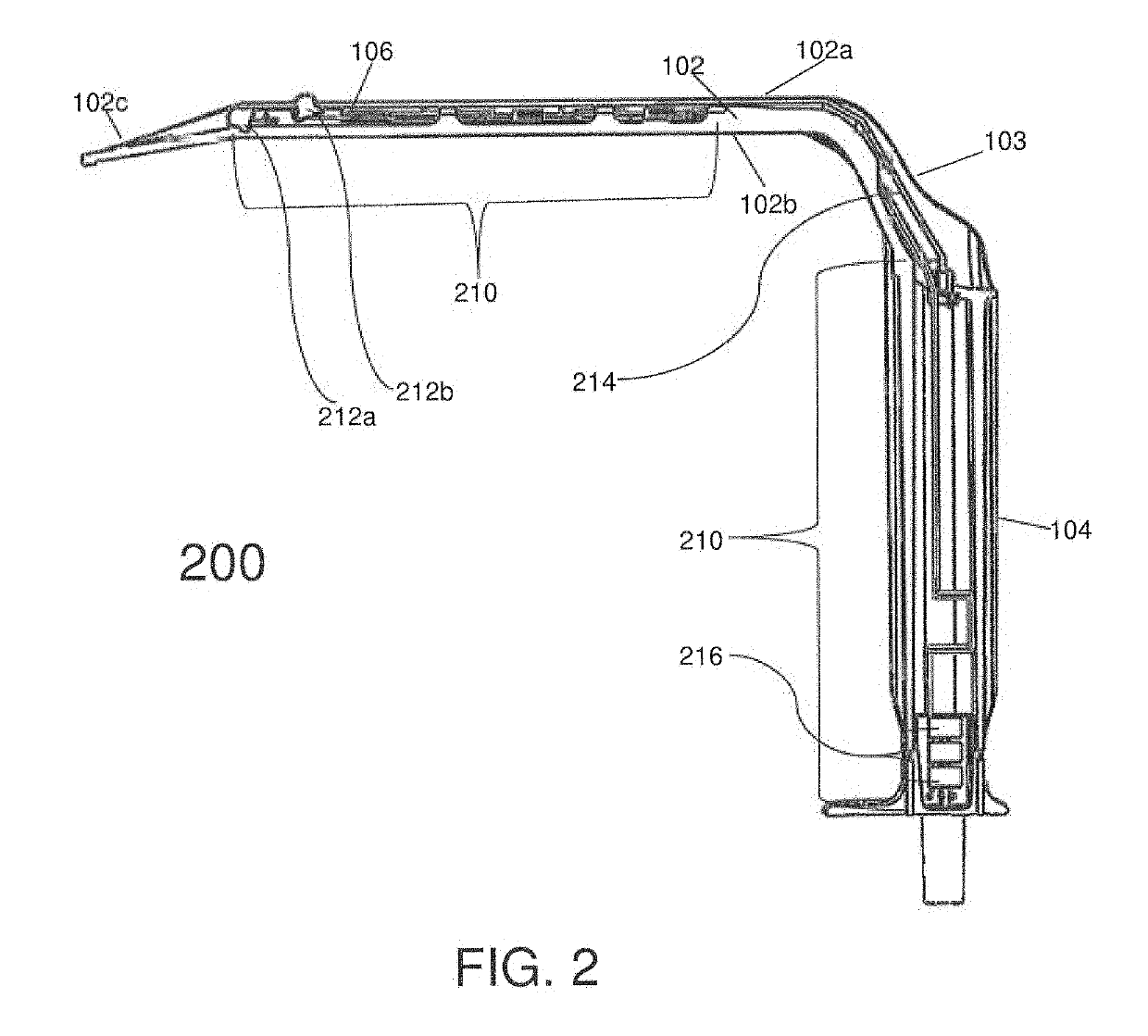

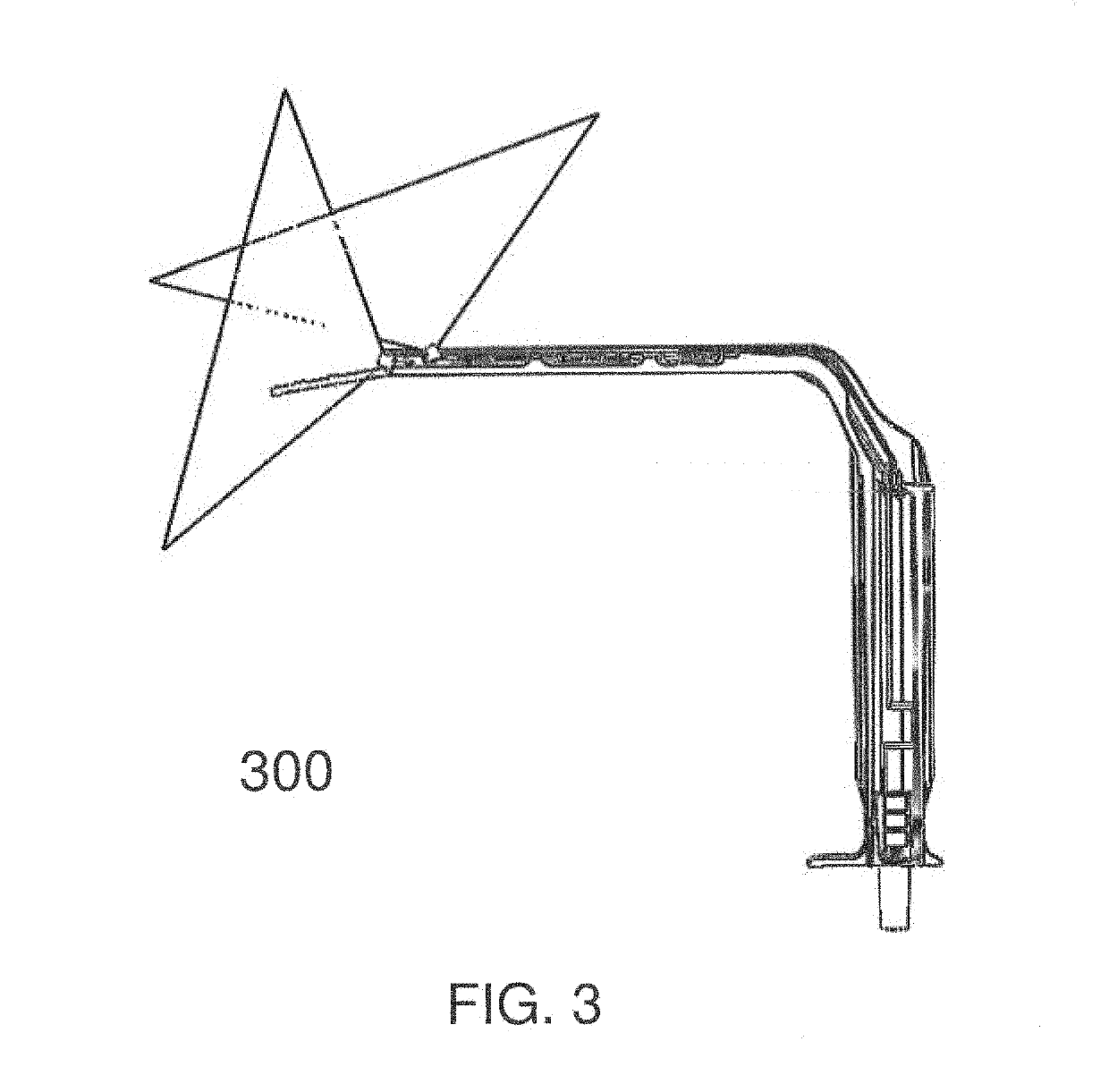

Illuminated medical devices

ActiveUS20190254771A1Maximize illuminationMaximize visibilityBronchoscopesLaryngoscopesMedical deviceBiomedical engineering

A surgical retractor comprising a handle and a blade extending at an angle from the handle; an illumination assembly having a plurality of direct light sources provided on the blade, at least one of the light sources being angled differently relative to the blade than another one of the light sources; and a cover configured to enclose the illumination assembly, wherein the cover comprises a plurality of openings, each opening corresponding in position to a respective light source of the illumination assembly when the cover is attached to the blade.

Owner:OBP SURGICAL CORP

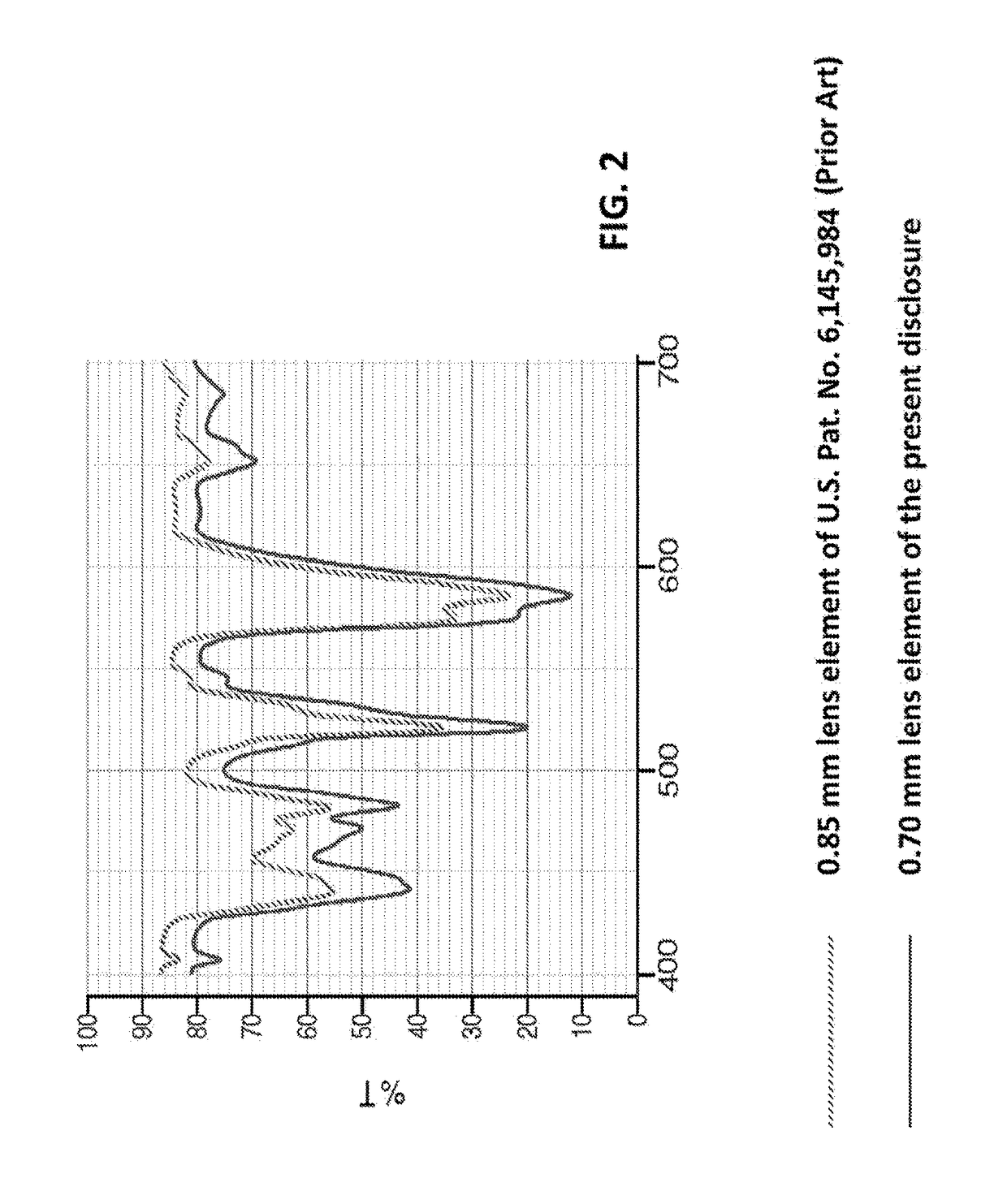

Color-enhancing thin lens for eyewear

ActiveUS9671622B1Facilitate cognitionMaximize visibilitySpectales/gogglesCoatingsSpectral transmissionUltraviolet

The presently presented inventive lens will provide an eyeglasses / sunglasses wearer with improved perceptions of color saturation and optical contrast without requiring any apparent coloration (except gray) in the transmitted tint (although other colors may be used), promoting a sense of heightened accuracy and differentiation in viewed colors while providing full protection from UV. Further, the lenses of the invention provide increased visual acuity, and maximize the visibility of objects partially obscured by fog or atmospheric haze. Lens embodiments having certain spectral-transmission properties as defined herein achieve one or more of these objects, while filtering out (i.e., providing local / relative minima) of certain human-visible light wavelengths in a manner enhancing crisp color perception. In particular, the present disclosure provides a very thin lens with a tetrachromatic transmittance profile that offers wearers crisp, clear, and vibrant color perception, while reducing overall light transmission in a manner that enhances wearer comfort.

Owner:MAUI JIM

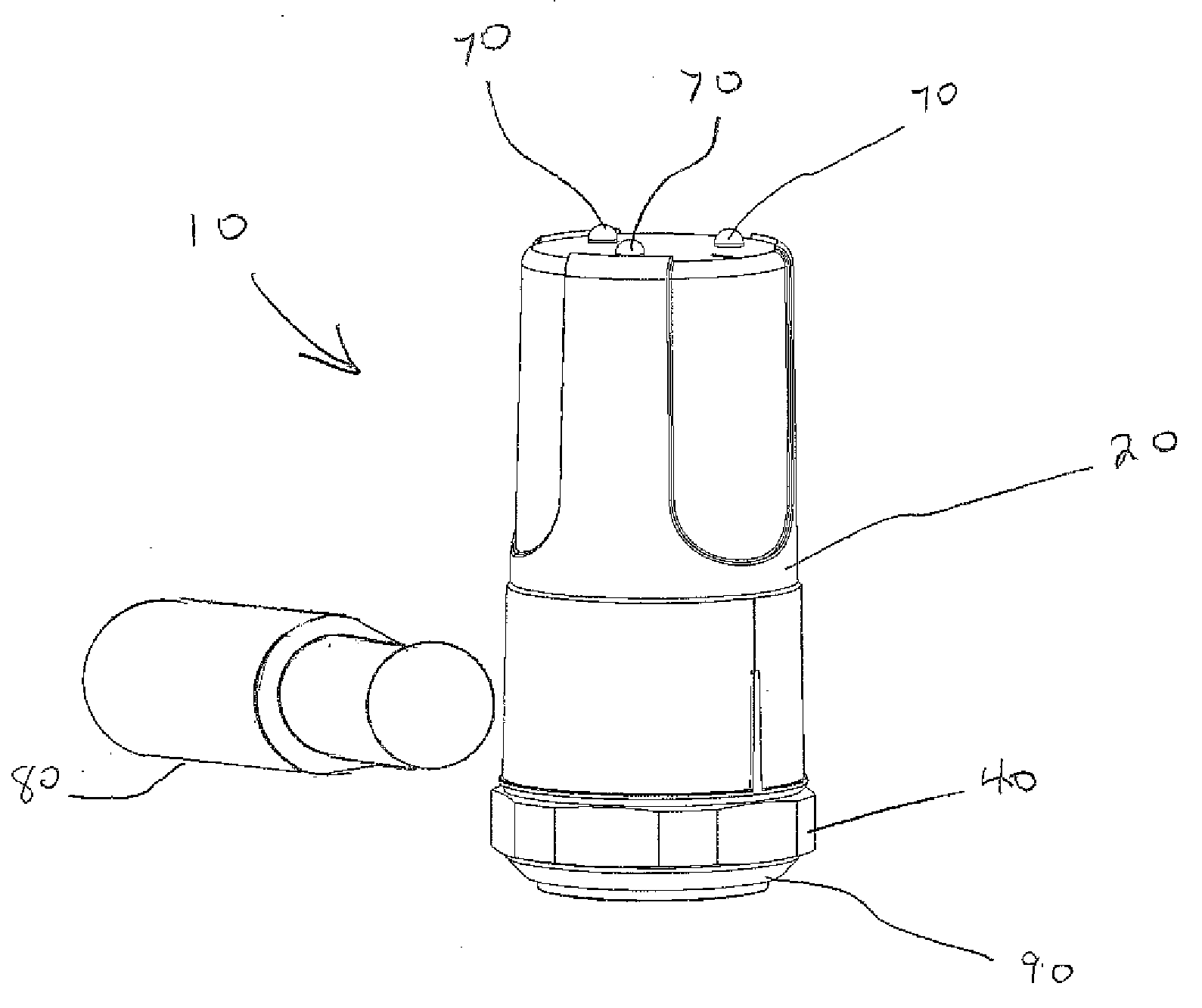

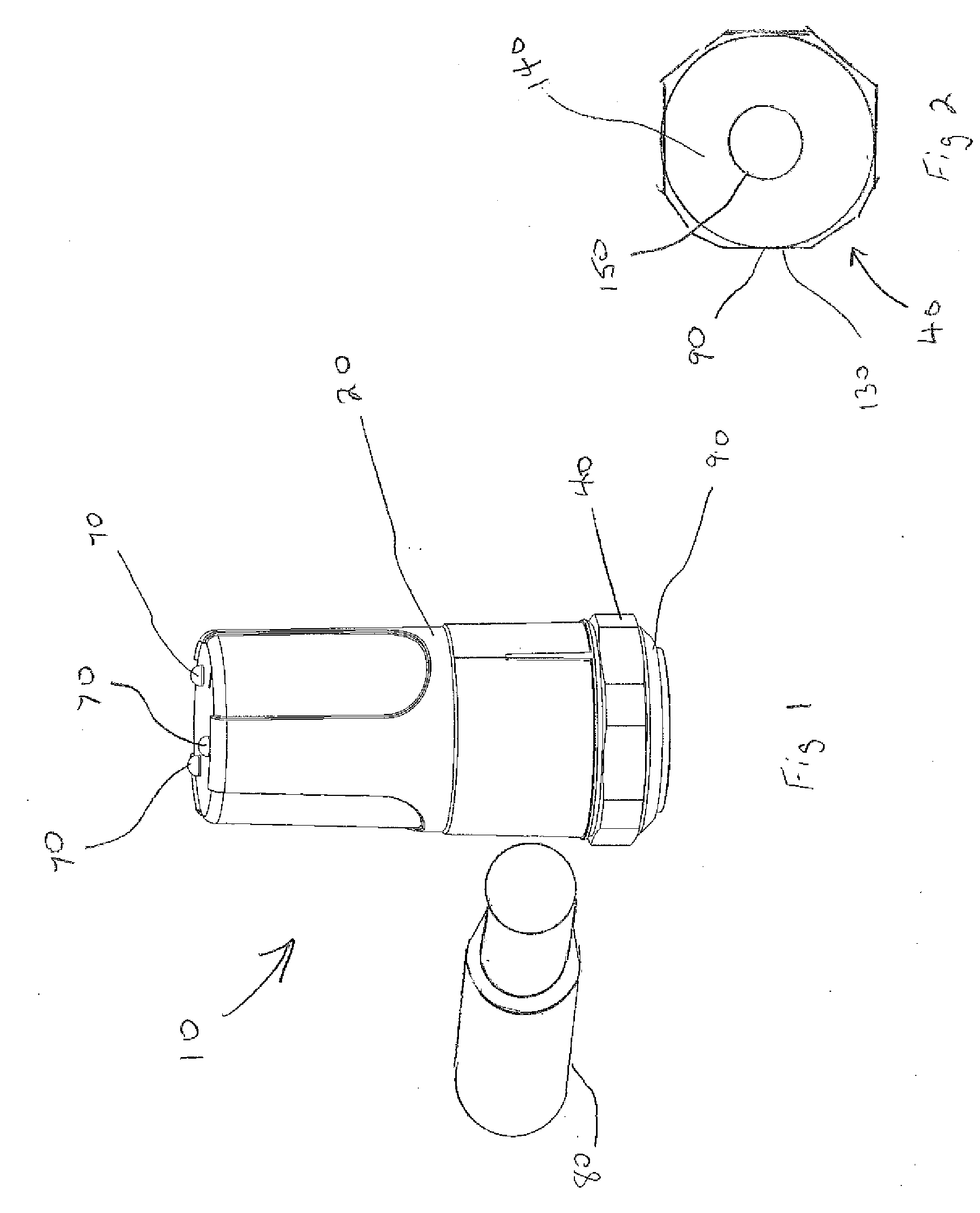

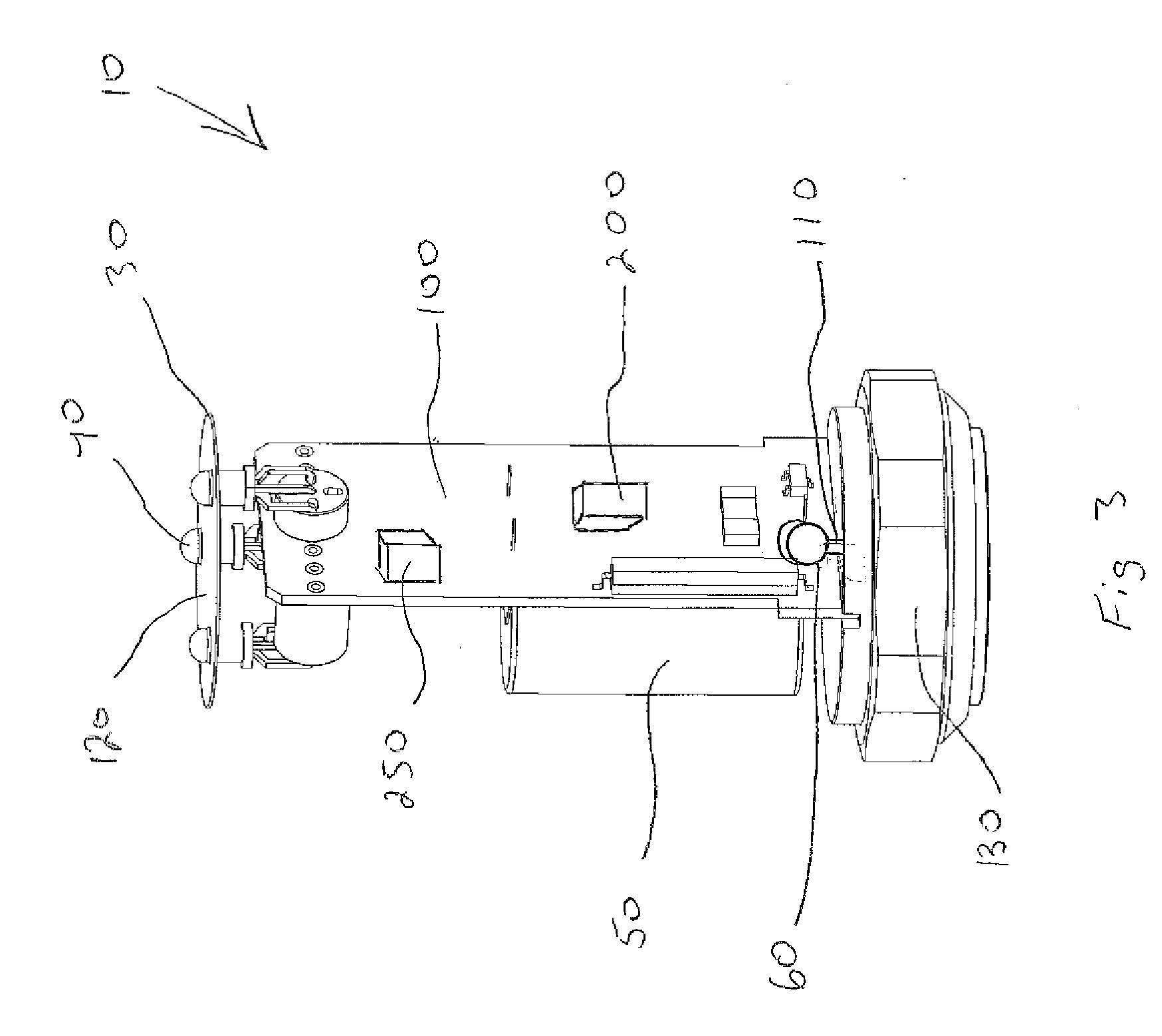

Warning device and method for monitoring alarm status of a vibration level of a piece of rotating machinery having an adaptive alarm indicator

InactiveUS20150211916A1Maximize visibilityConvenient power supplyVibration measurement in solidsMachine part testingVisibilityInitial rate

A warning device apparatus for monitoring an alarm status of a bearing that is mounted to a piece of rotating machinery is provided. The warning device includes a body portion, a top portion, a base portion, a power source for powering the device throughout a life of operation, a controller for controlling the operation of the warning device and at least one LED for displaying the alarm status. An operator inspects the warning device for an initial alarm indication by visually inspecting the at least one LED. The at least one LED is controlled to blink at a relatively quick initial rate and / or intensity that maximizes indicator visibility to the operator at initial indication. The at least one LED is controlled to blink at a slower / decreasing rate as time passes. Battery life of operation is extended by virtue of the slower / increased blink rate and conversely the increased pause time.

Owner:AB SKF

Automotive body and trim assembly with complementary locating and positioning features and method of assembling same

InactiveUS7686386B2Minimizes variabilityGap minimizationVehicle seatsSuperstructure subunitsMetal sheetBody frame

An automotive body and trim assembly is provided that utilizes locating features on only a single sheet metal layer of a multi-layer body frame pillar to position a trim member, thus minimizing variability in the final assembled position of the trim member. The single sheet metal layer has both a fore-aft-locating feature and a cross-car-locating feature. A fore-aft-positioning feature and a cross-car-positioning feature on the pillar trim member are spaced to permit contact with the fore-aft-locating feature and the cross-car-locating feature, respectively when the pillar trim member is assembled with the body frame pillar, so that only the single sheet metal layer determines the fore-aft and cross-car position of the pillar trim member. A method of assembling a pillar trim member and a body frame pillar having multiple sheet metal layers is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

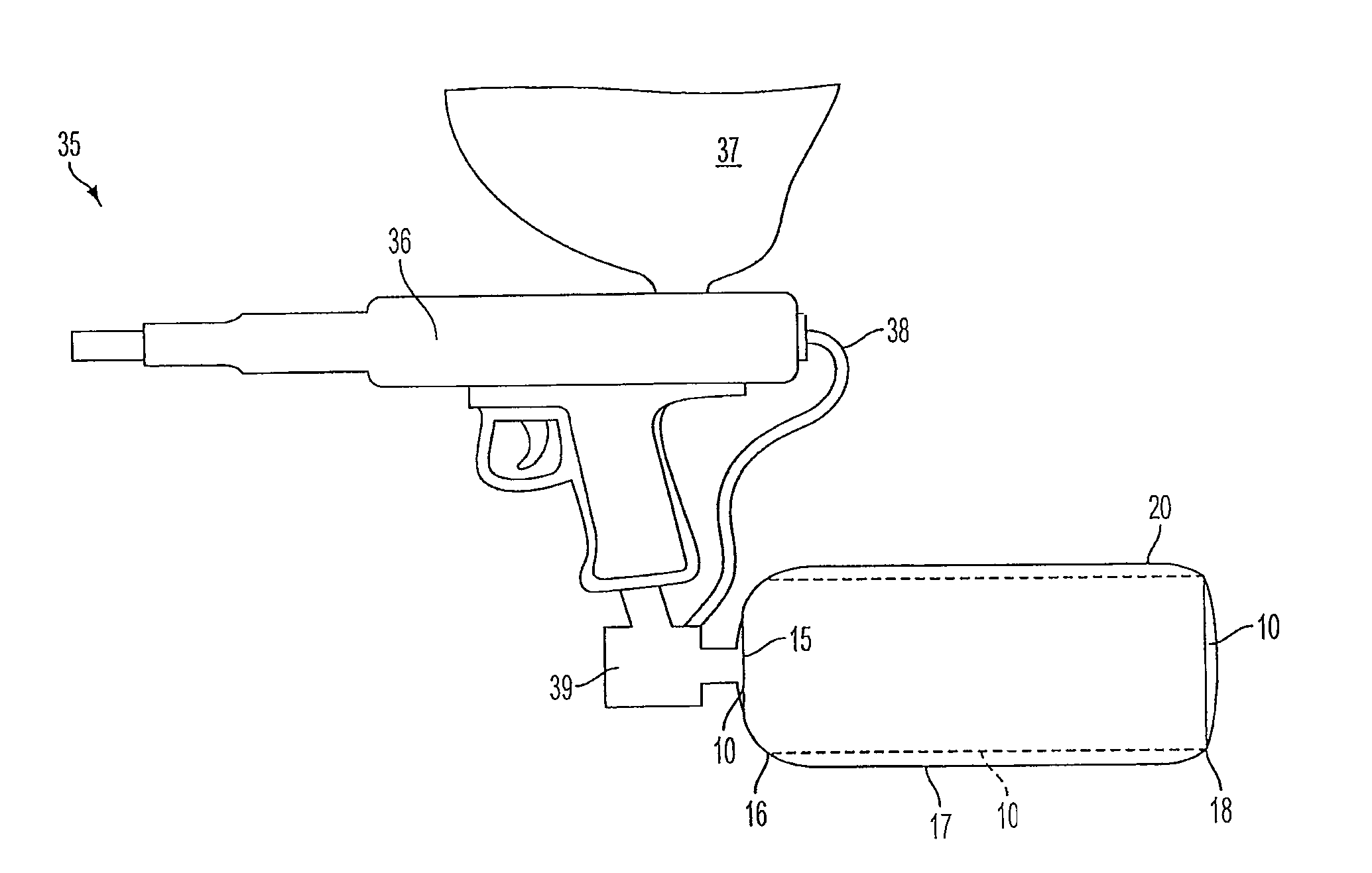

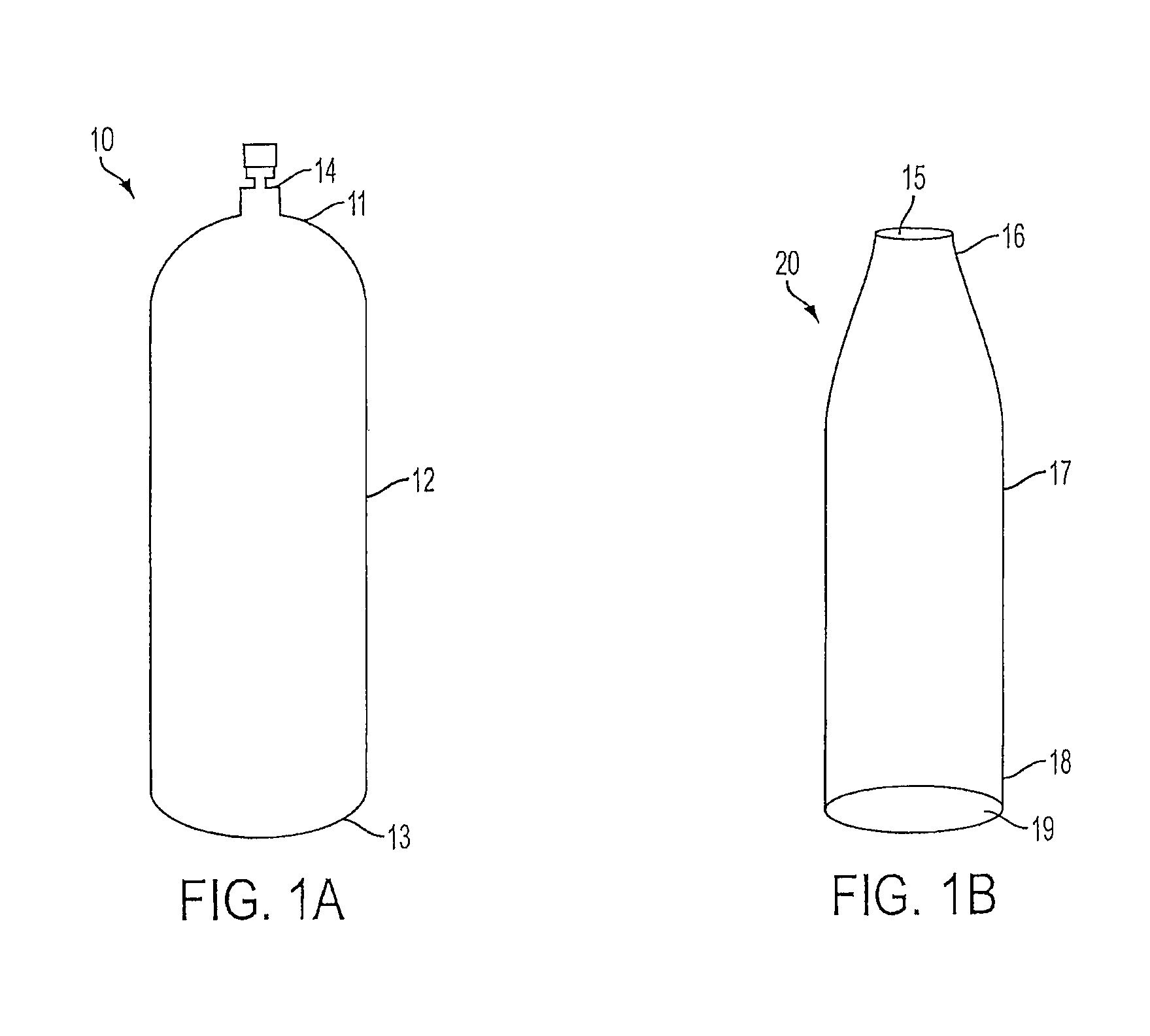

Protective cover for a paintball gun gas canister

InactiveUS7850036B2Easy to useQuick and convenient mannerFlexible coversWrappersRubber materialEngineering

A protective cover for protecting a paintball gun gas canister is disclosed. The protective cover is preferably formed from an elastic rubber material such as neoprene. The protective cover has the ability to adapt its shape when placed over a canister, thus enabling use with canisters of various sizes.

Owner:CIRONE DOMINICK

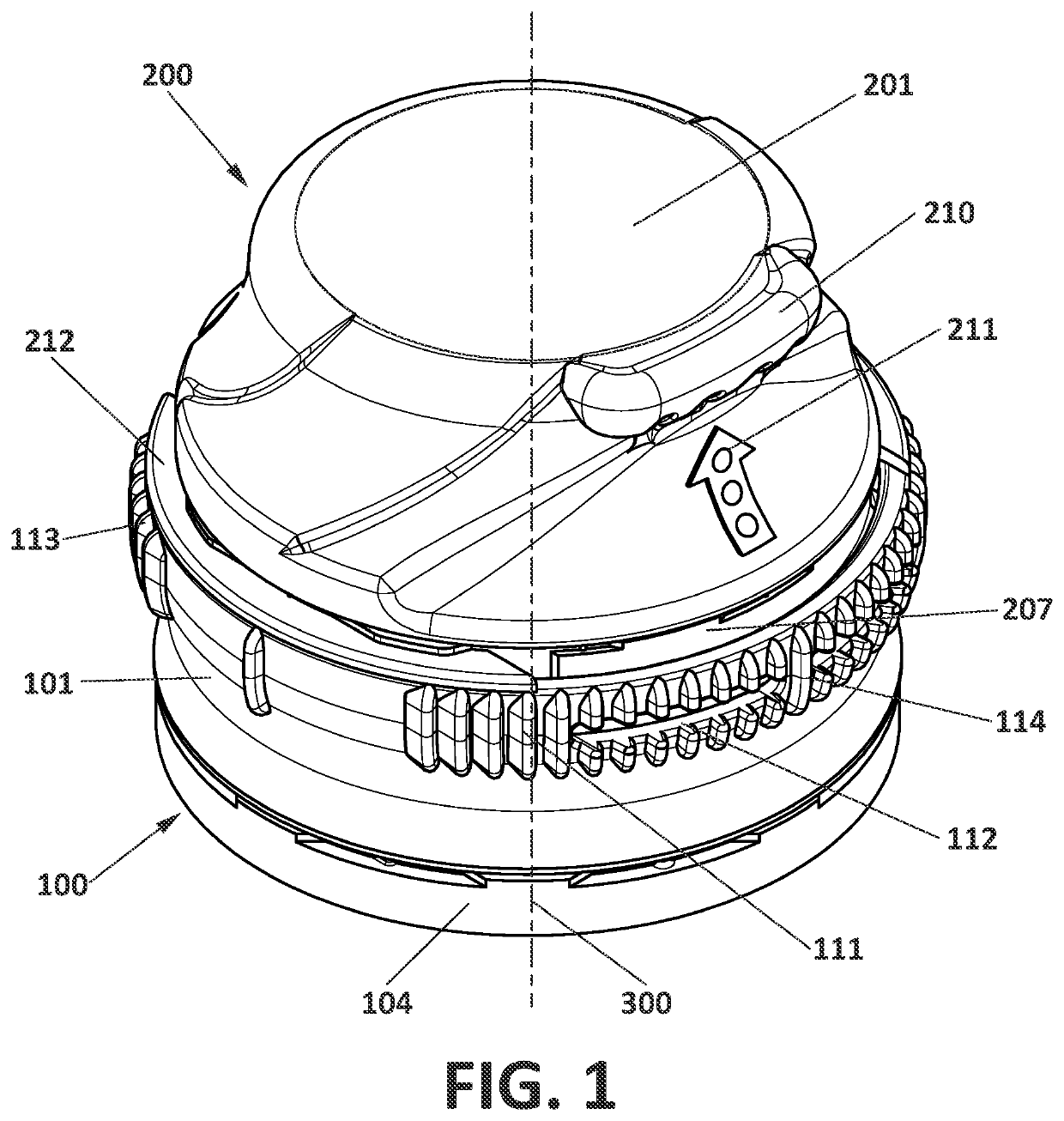

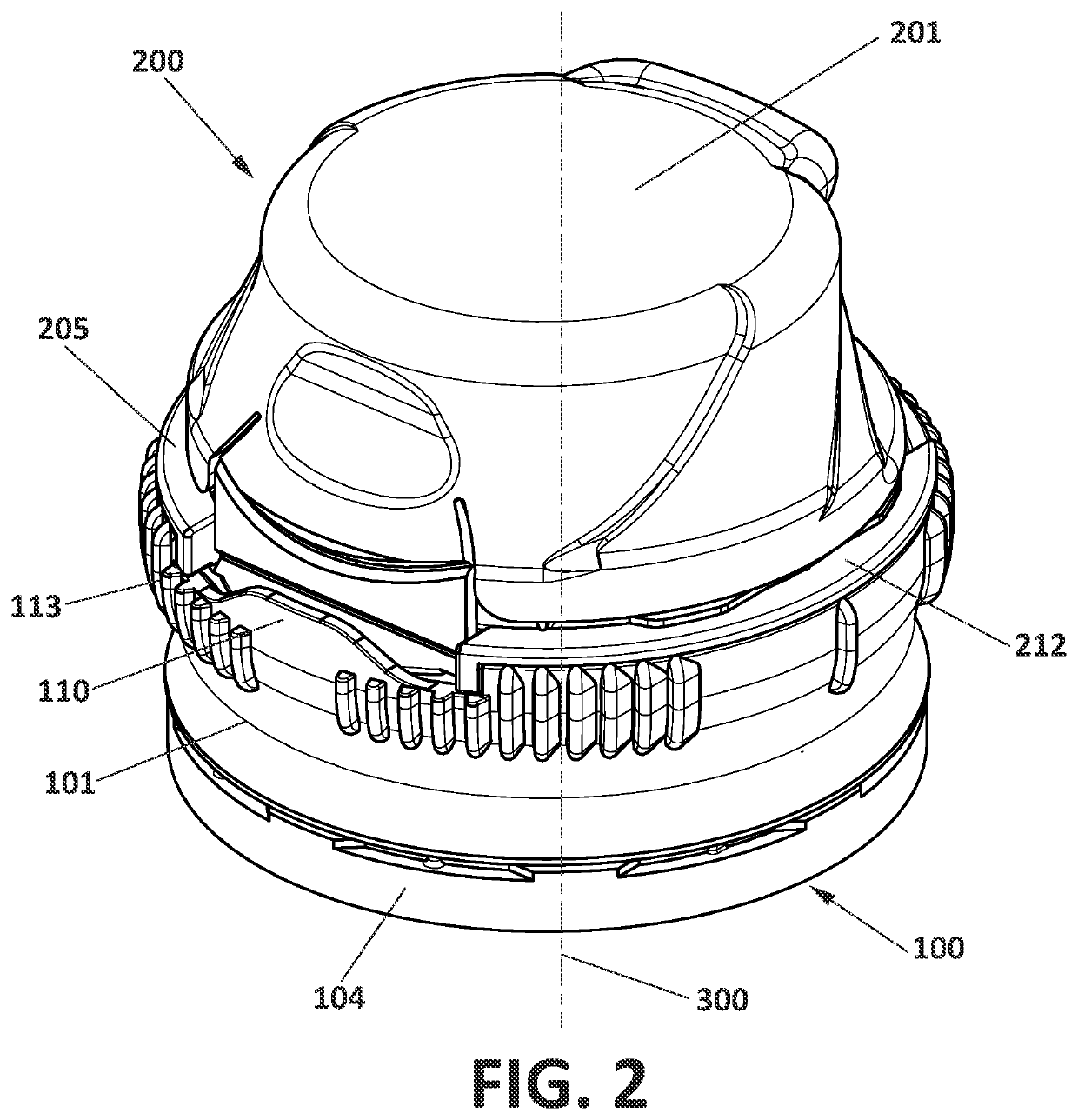

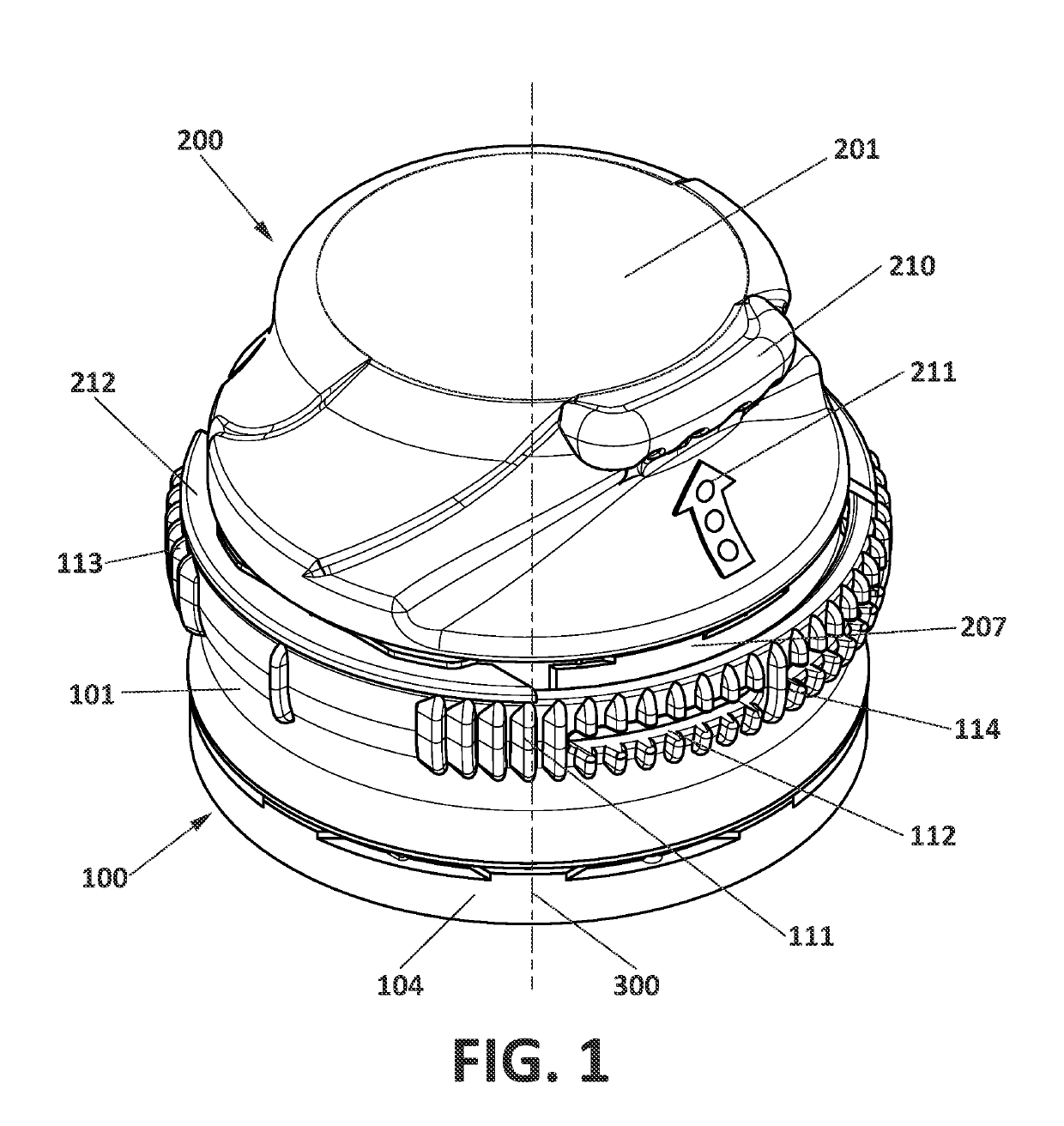

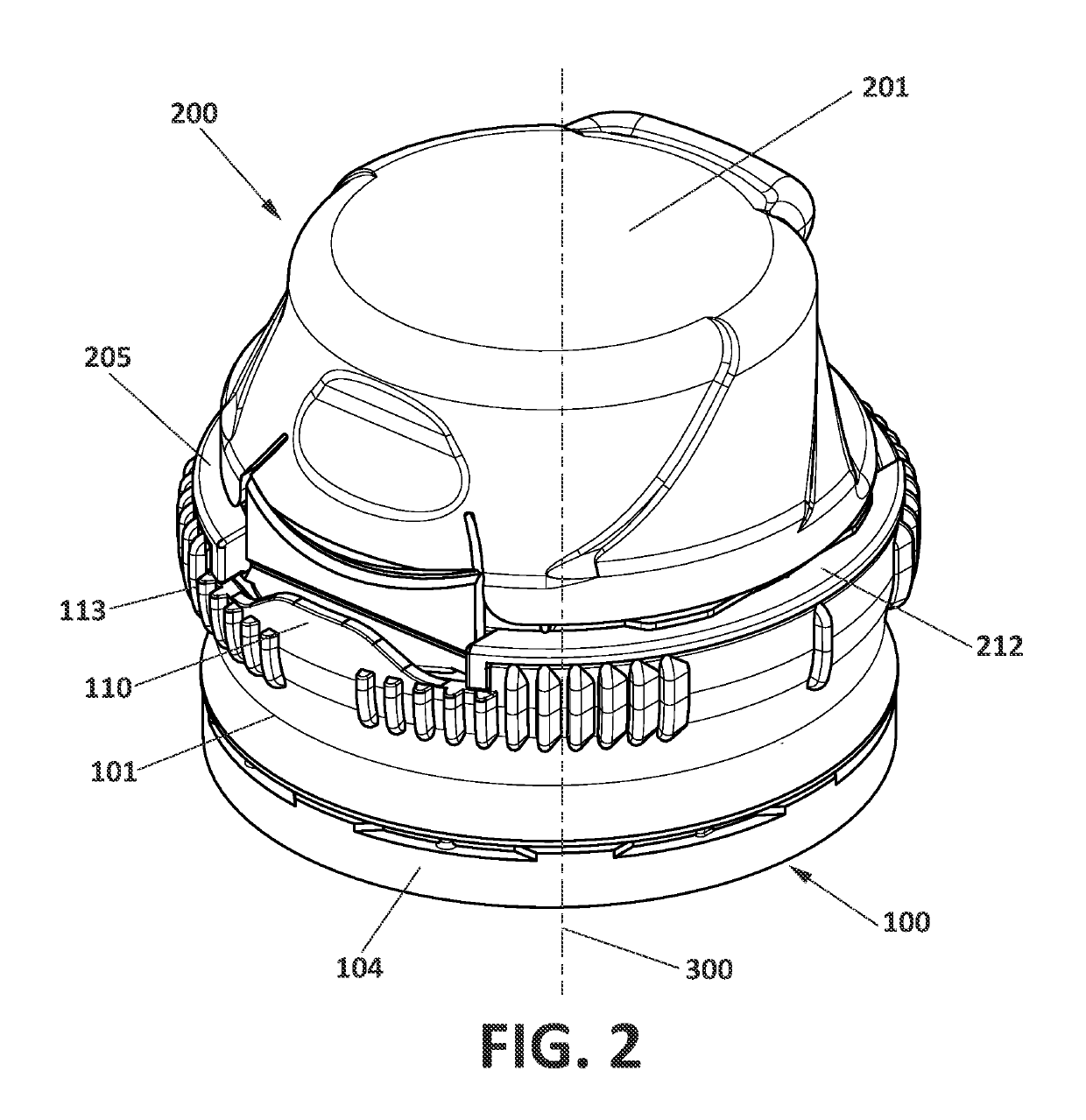

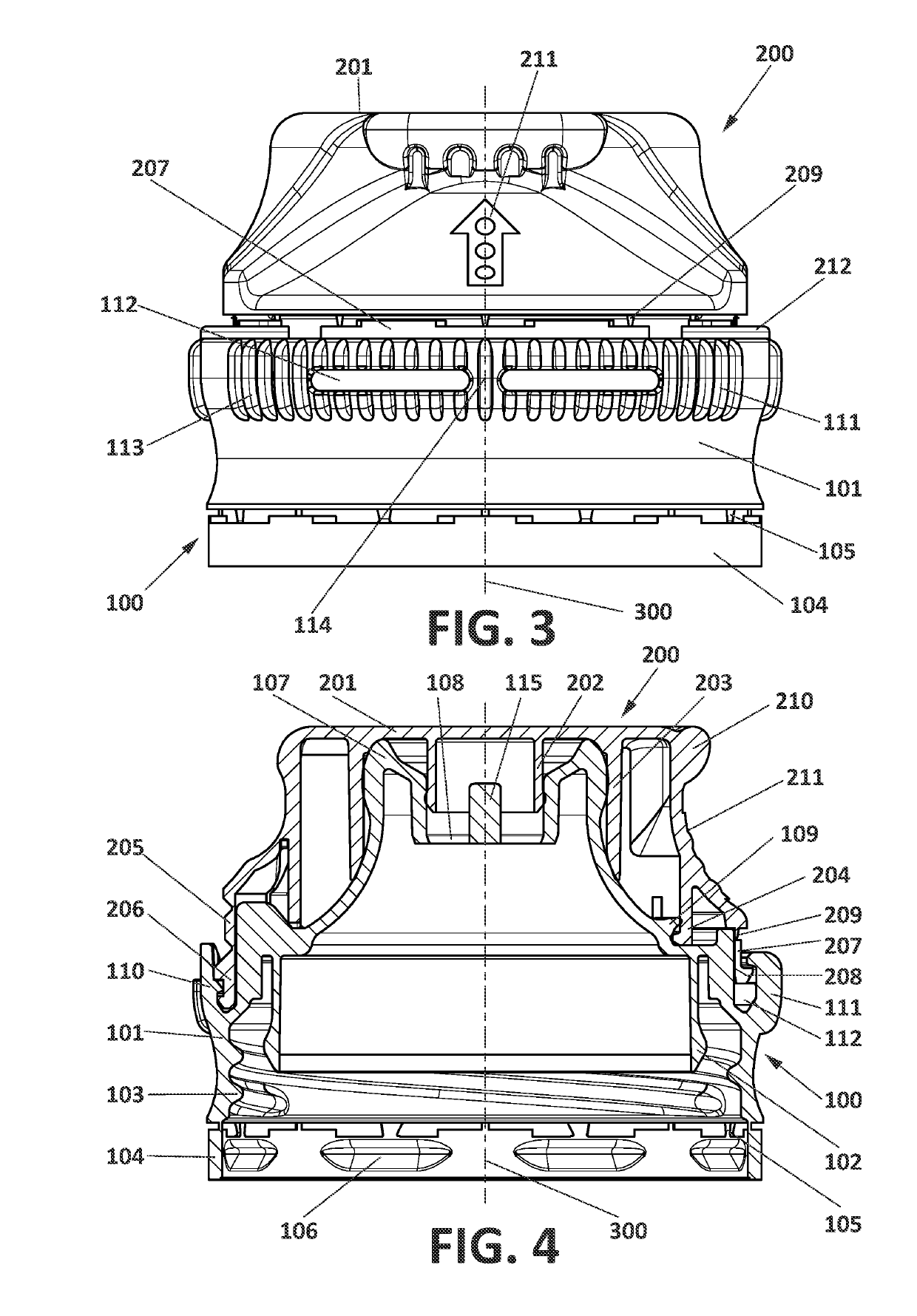

Closure device with opening indicator

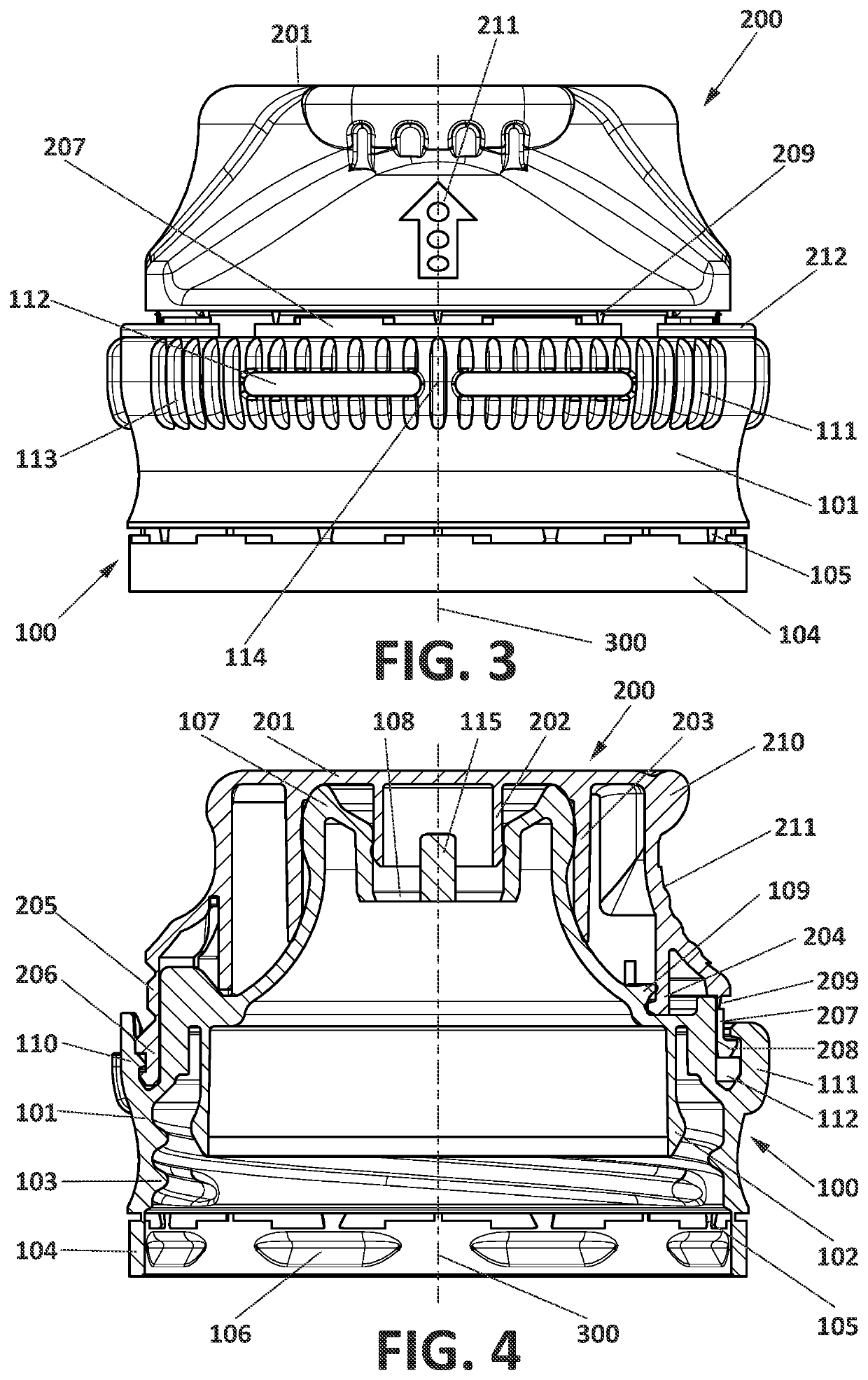

ActiveUS10926923B2Maximize visibilityAvoid accidental removalCapsClosure capsStructural engineeringMechanical engineering

Owner:BETAPACK

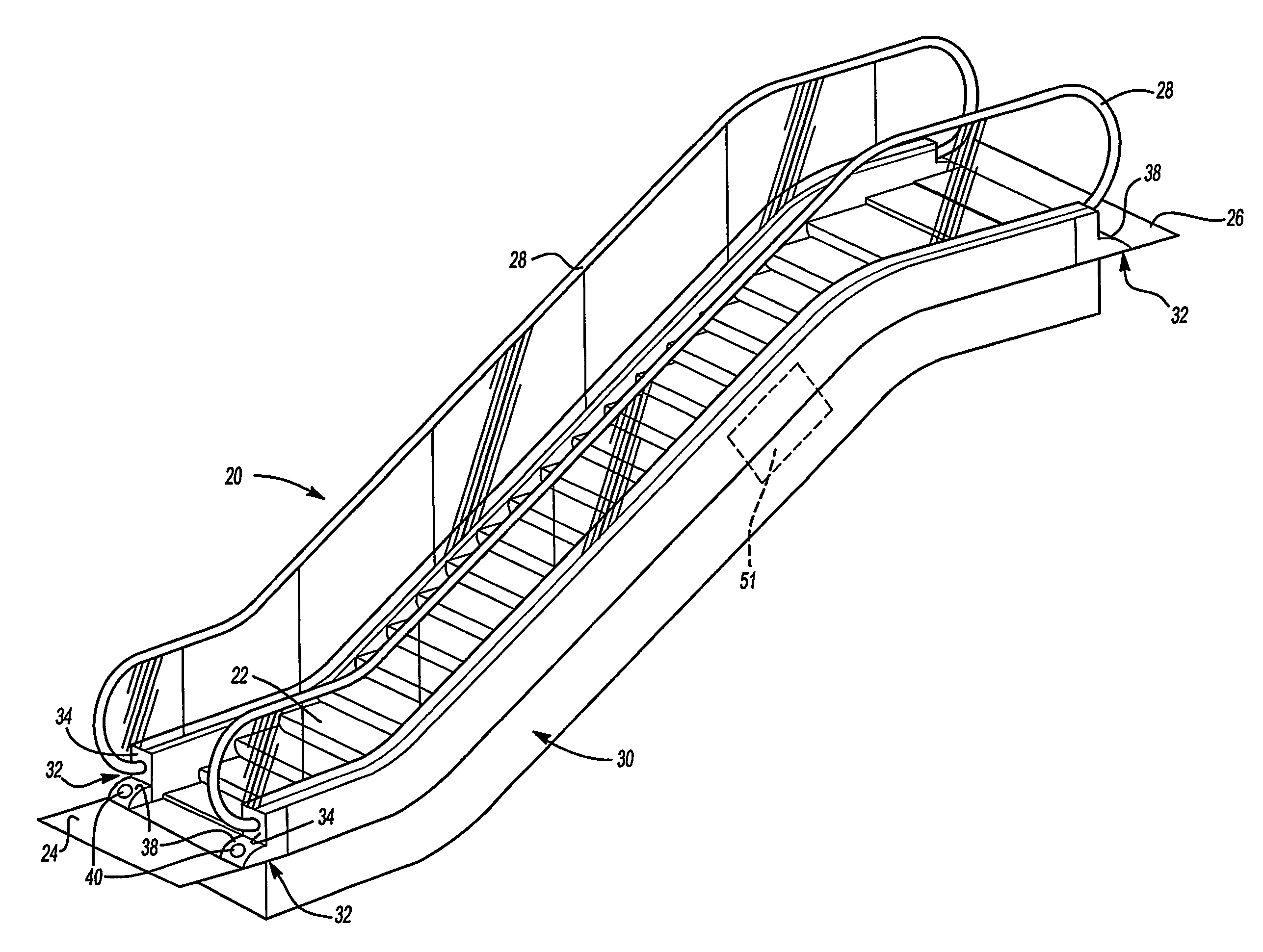

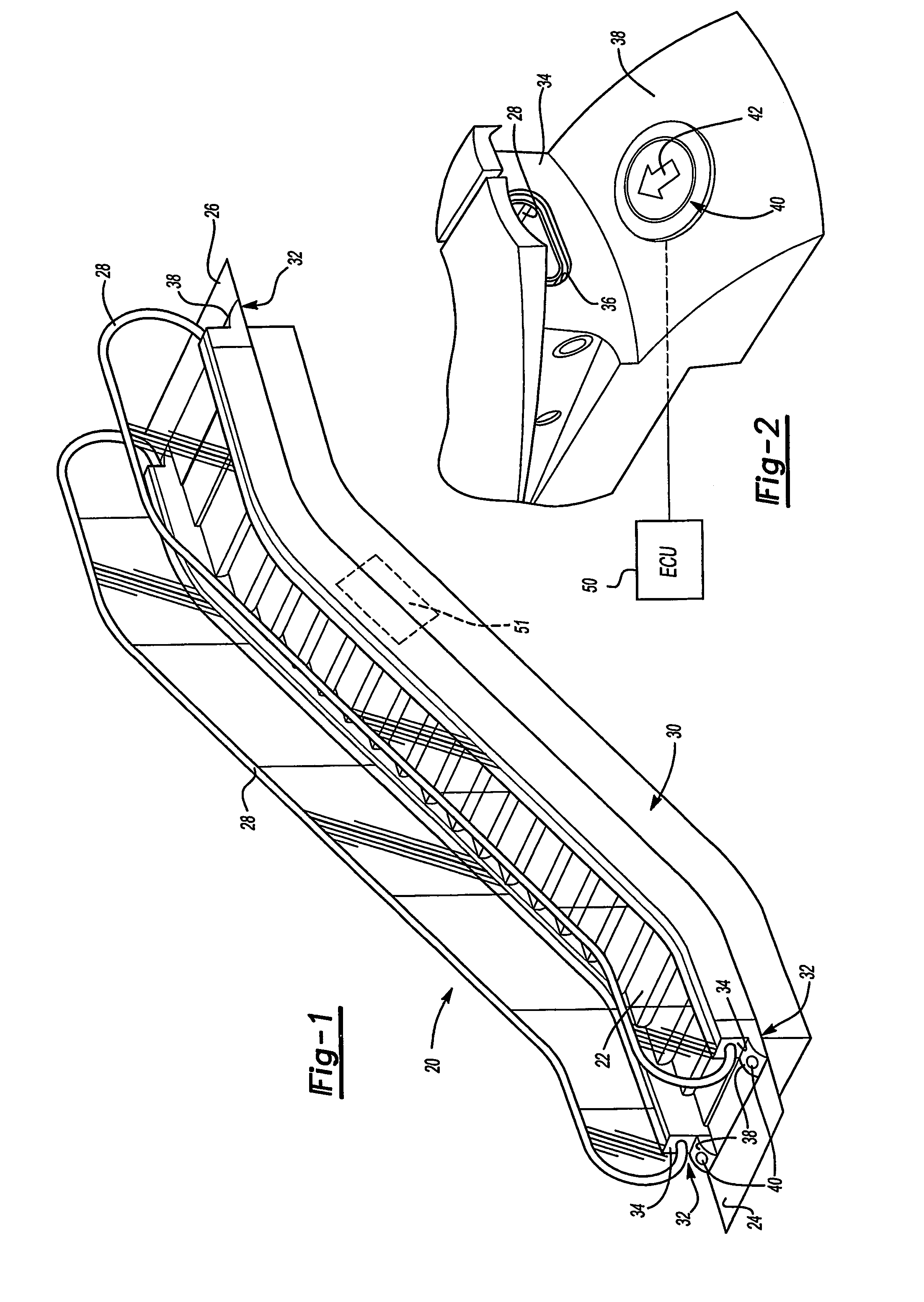

Traffic flow indicator for a passenger conveyor

InactiveUS7249667B2Maximize visibilityConveyorsControl devices for conveyorsVisibilityDisplay device

Owner:OTIS ELEVATOR CO

Optimal aircraft window shape for noise control

ActiveUS20070069079A1Maximize passenger visibilityMinimize amountEar treatmentAir-treatment apparatus arrangementsEllipseFlight vehicle

A window for a subsonic passenger aircraft that provide maximum optical visibility while minimizing the amount of exterior acoustic noise transmitted through the windows to the passenger cabin during flight of the aircraft includes at least one substantially transparent window pane having the shape of an ellipse. The ellipse has a major axis and a minor axis, and the major axis is about twice as long as the minor axis and is disposed generally perpendicular to the direction of flight of the aircraft. In one exemplary embodiment, the window has a height of about 20 inches and a transparent area of about 141 square inches, and includes a pair of substantially similar window panes disposed in a parallel, spaced-apart relationship circumscribed by a mounting bezel. A plurality of the windows are each mounted with the bezels in spaced-apart rows in each of the opposite sidewalls of the aircraft fuselage.

Owner:THE BOEING CO

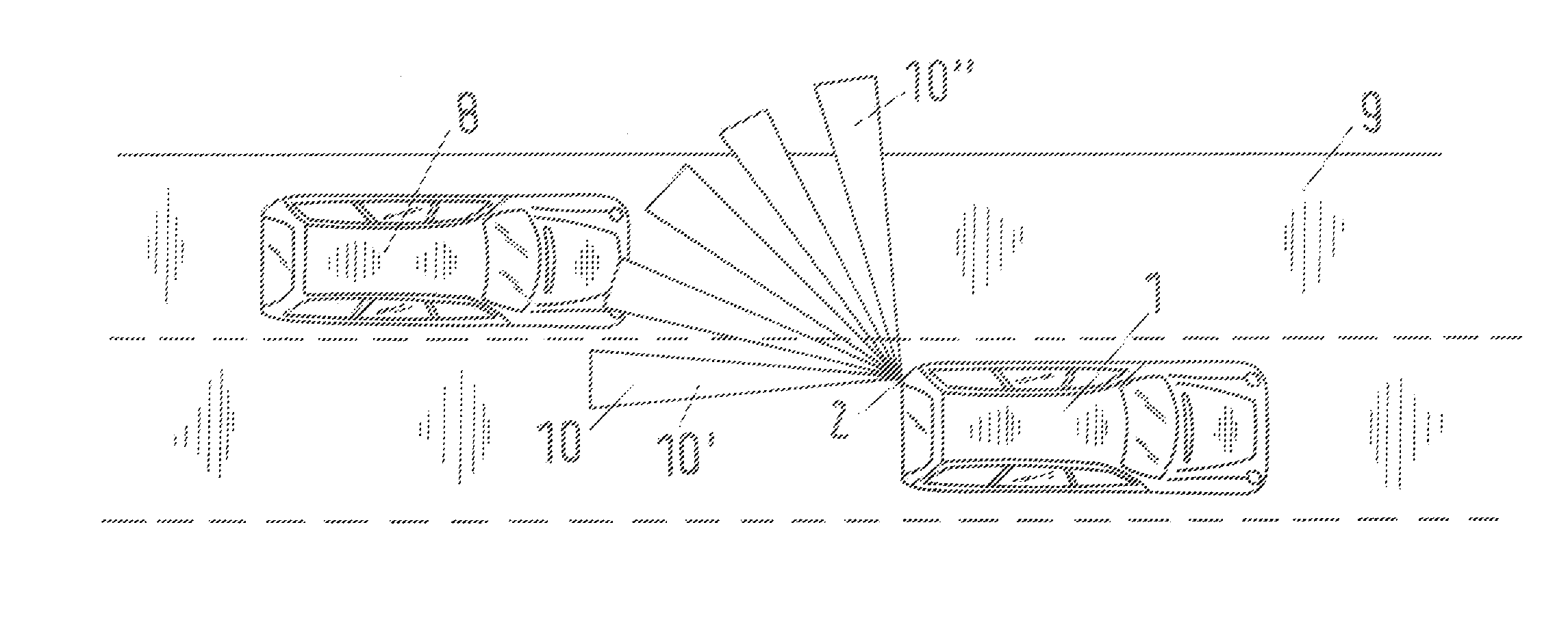

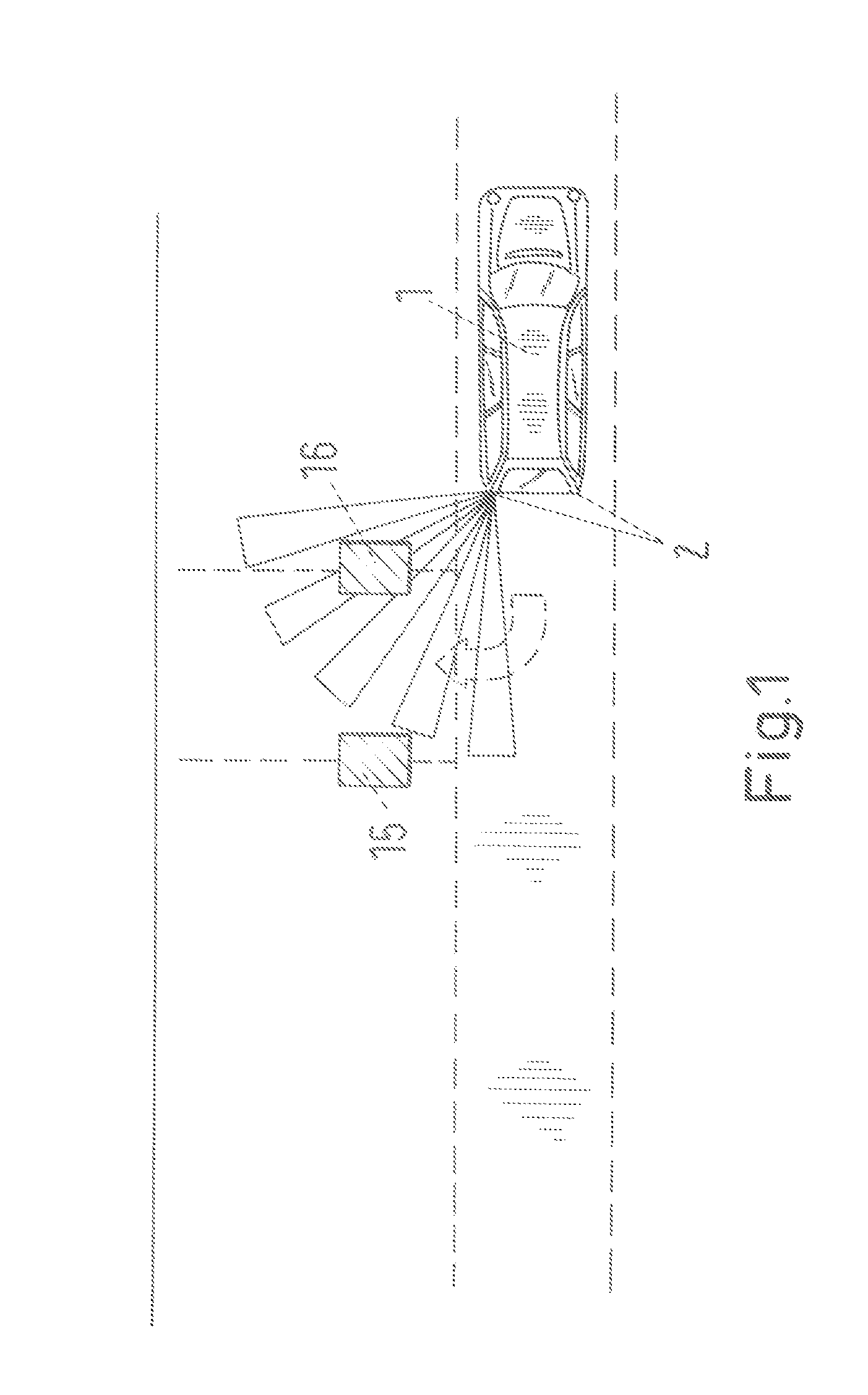

Tail light assembly for a motor vehicle

A tail light assembly for a motor vehicle includes a plurality of signal lights to signal various operations. Each of the plurality of signal lights includes segments of lights that are independently operable. A sensor system is electrically connected to the segments of lights for measuring an event and for creating a control signal in response to the occurrence of an event. The tail light assembly also includes a control module electrically connected between the segments of lights and the sensor system. The control module receives the control signal and operates each of the plurality of segments of lights to ensure each of the plurality of signal lights can operate to maximize visibility through a plurality of positions with respect to the motor vehicle. Brightness of the signal lights is seen in varying degrees of brightness, depending on the angle at which the viewer sees the tail light

Owner:SCHEFENACKER VISION SYST GERMANY

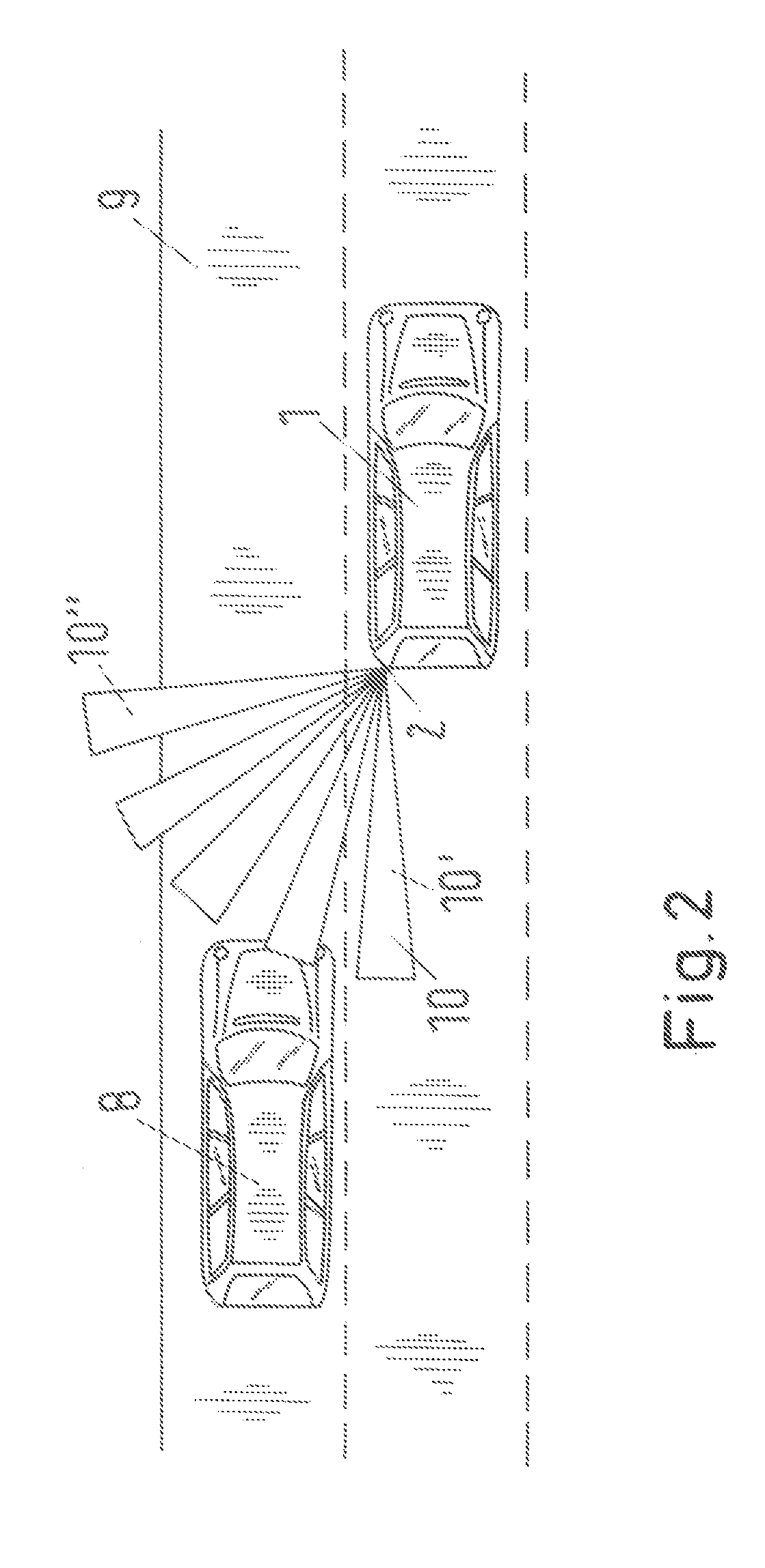

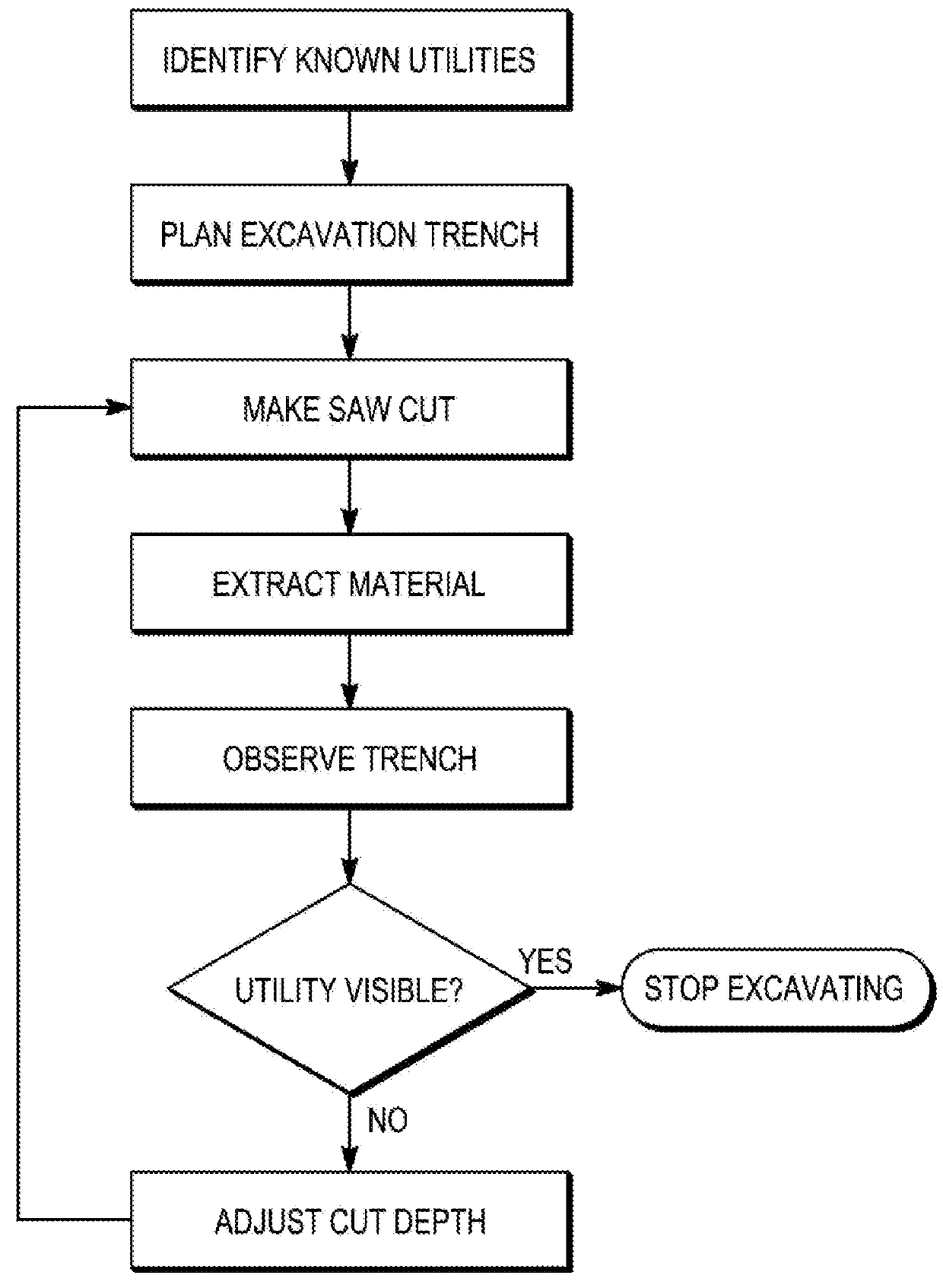

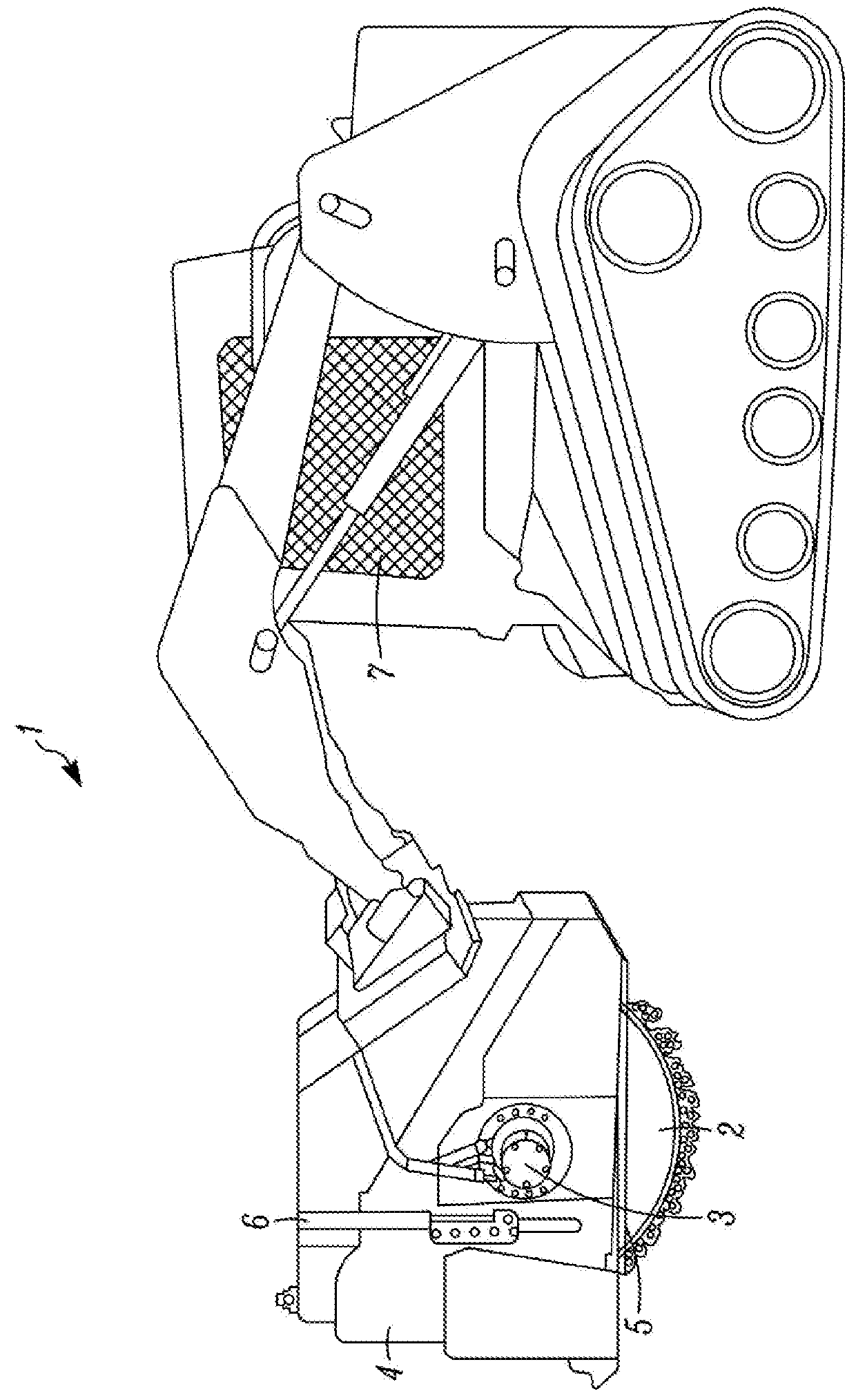

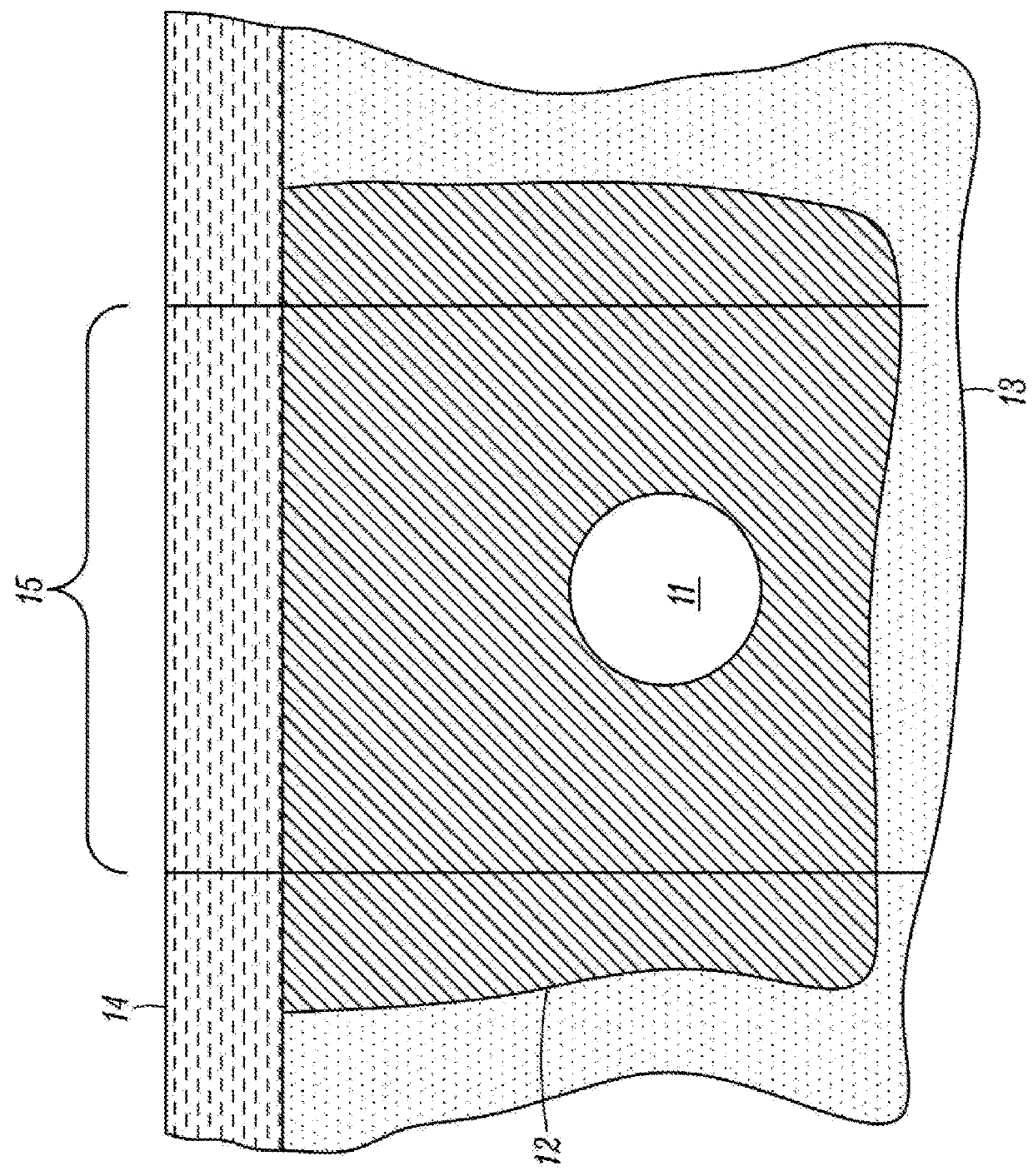

Process For Exposing Underground Utilities

InactiveUS20180274204A1Minimal riskMaximize visibilitySoil-shifting machines/dredgersExcavationsChemistryDepth of cut

A process for safely excavating to reveal underground utilities. The process includes the steps of: identifying known utilities; planning an excavation trench; excavating the trench by: (i) making a cut of the excavation trench at a selected depth; (ii) extracting material from the trench; (iii) observing the trench; (iv) adjusting the depth of cut; and repeating (i) to (iv) until the process is complete.

Owner:VHS IP PTY LTD

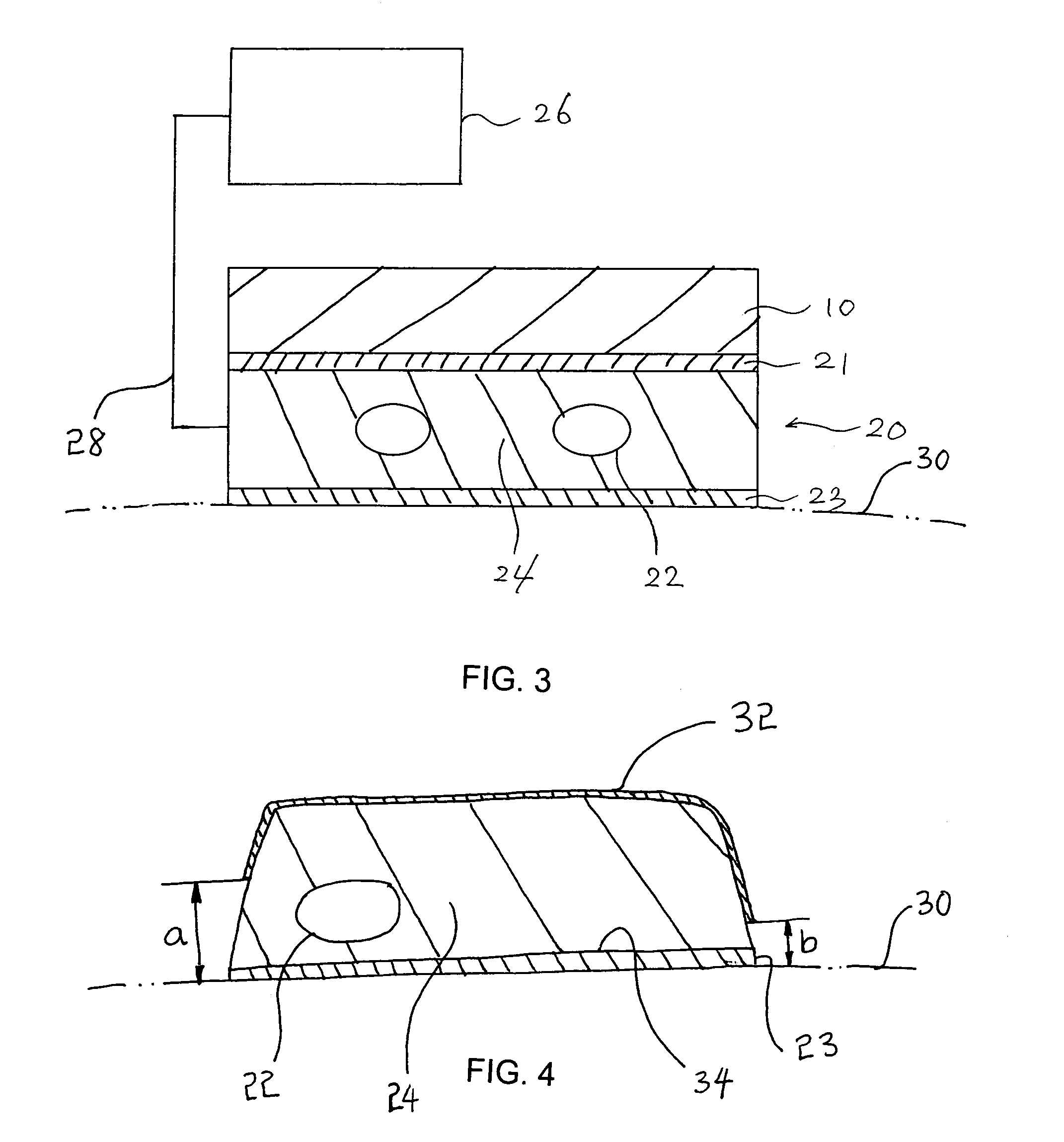

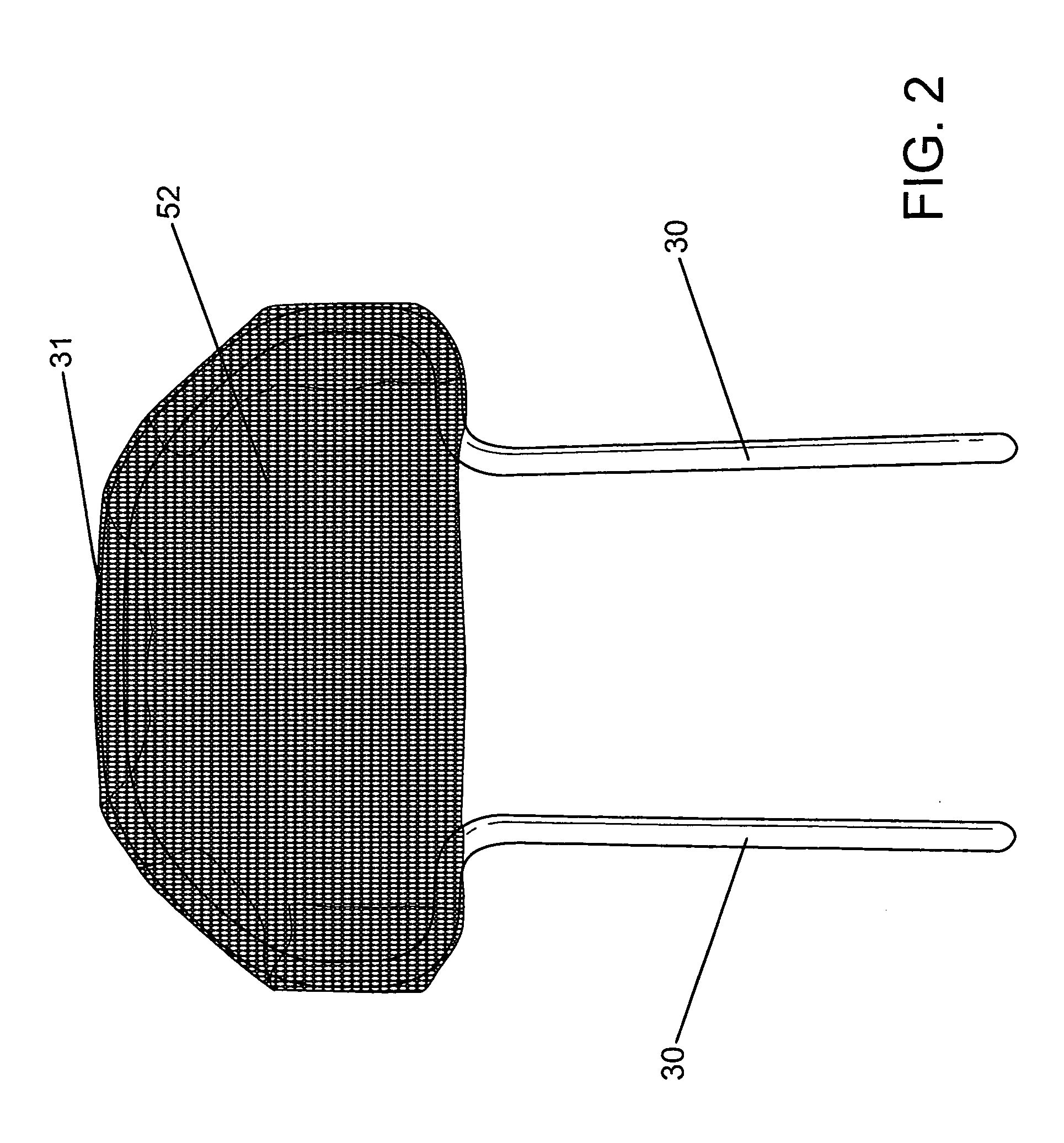

Open style head restraint with closeout and method for making same

InactiveUS20050072433A1Maximize visibilityProvide supportOperating chairsDental chairsVisibilityPlastic materials

An open style head restraint includes a closeout for providing structural integrity and safety. For providing maximum visibility, the closeout is preferably made of see-through material, for example, cellular material, such as mesh or net material, or non-cellular material, such as clear and semi-transparent plastic material, or the like. The open style head restraint is formed by affixing the closeout between the armatures and / or a top or bottom cross member. Next, a sealing material is applied between the closeout and the mold assembly to prevent the foam filler from seeping onto the closeout. Then, a release-mold coat, an in-coat, and a skin coat can be applied to the mold halves. Next, the closeout is properly positioned in the mold assembly and the armatures are secured. The foam filler is then injected while the mold assembly is in the closed position. Then, the foam filler is allowed to cure. After a sufficient period of time, the completed open style head restraint with closeout can be removed from the mold assembly.

Owner:INTIER AUTOMOTIVE INC

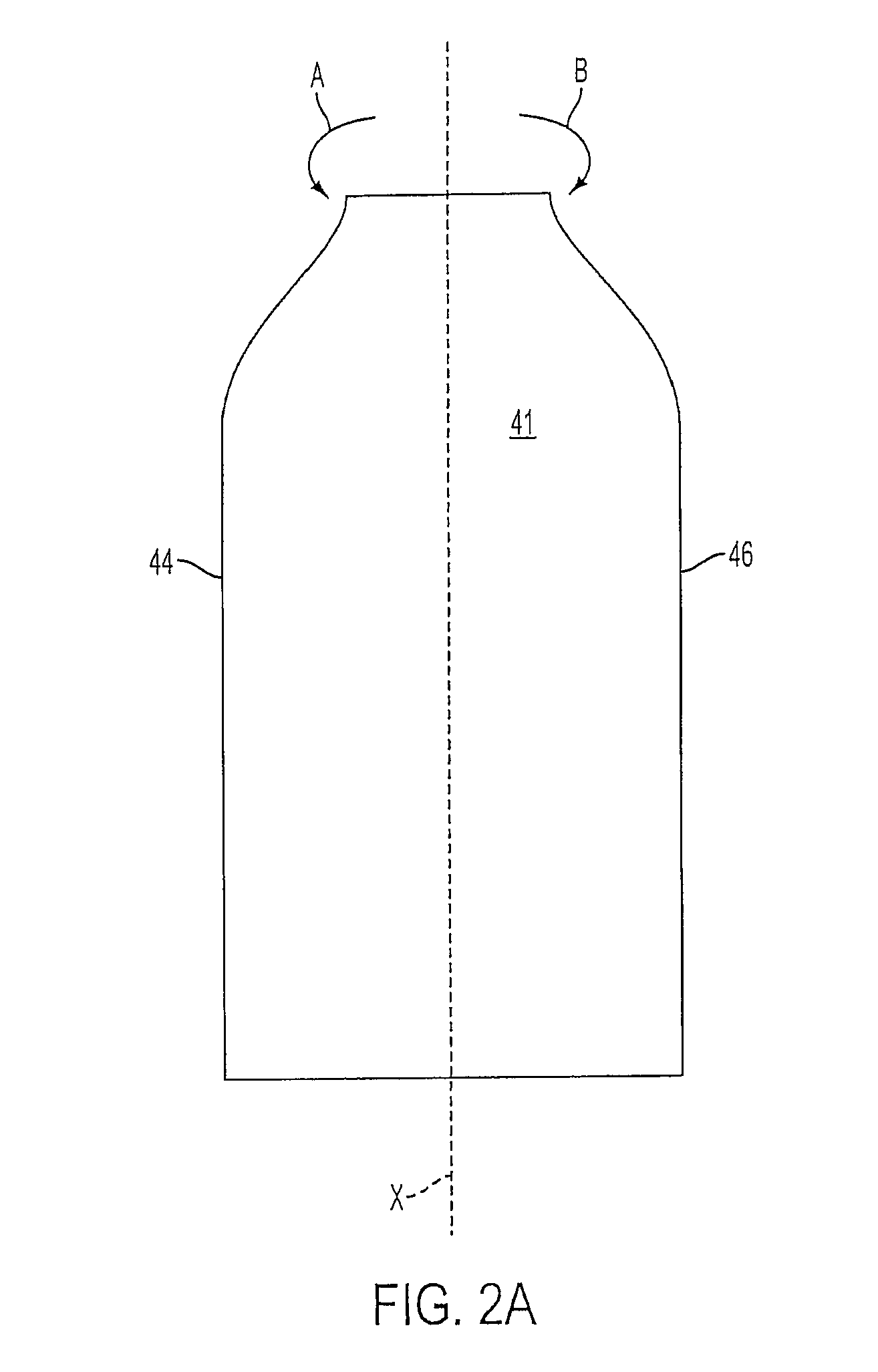

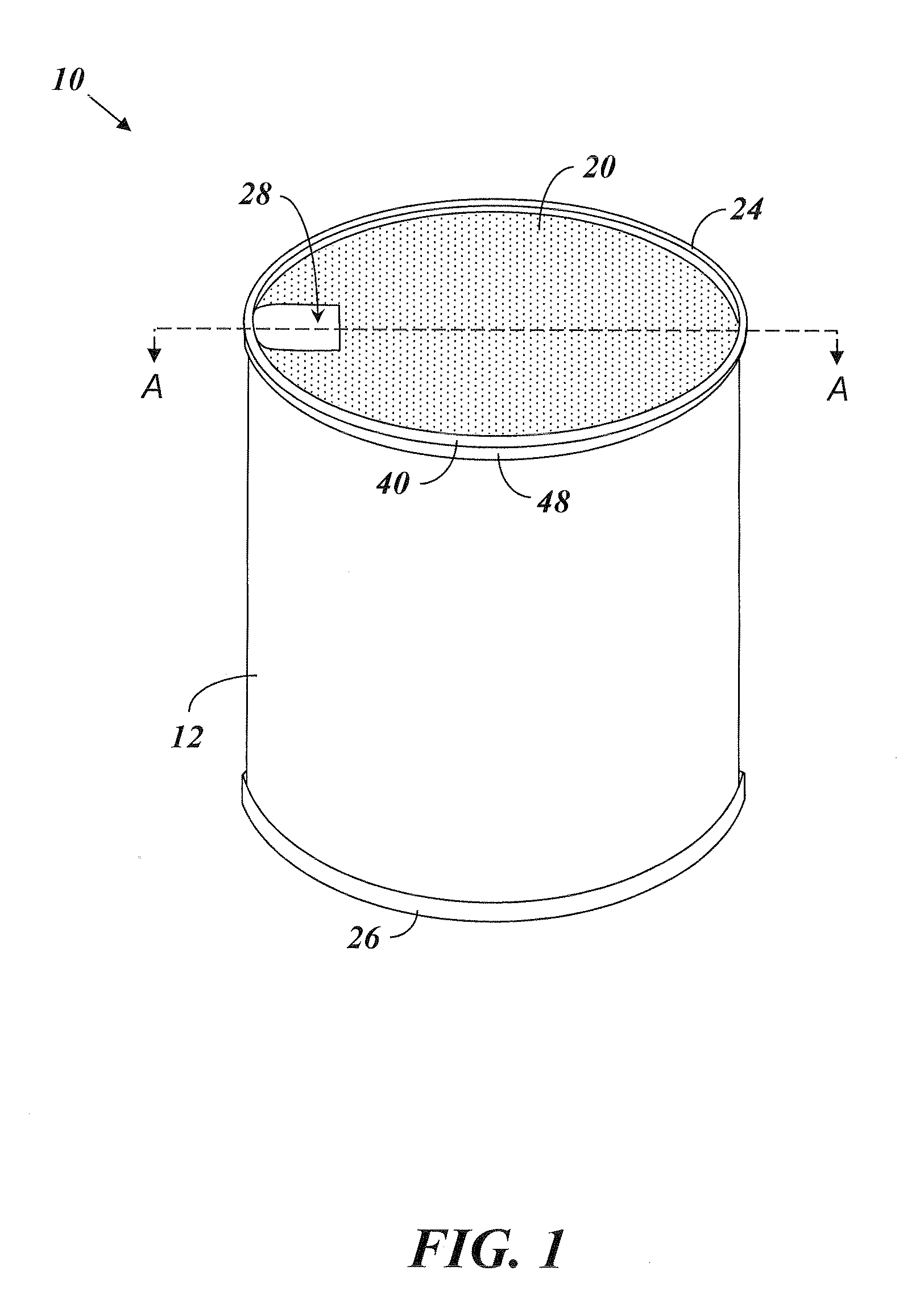

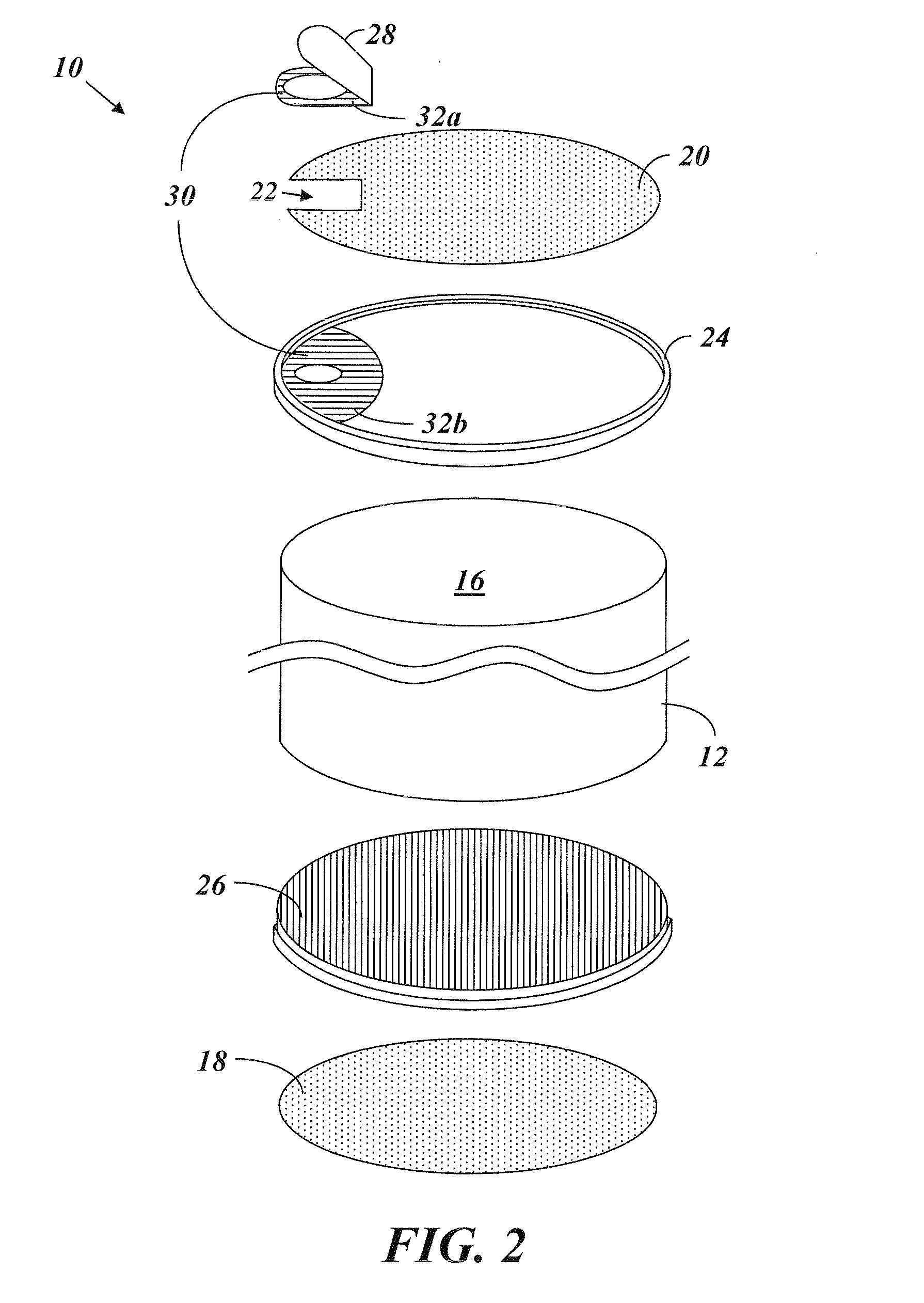

Fluid container

A biodegradable and compostable container for fluids achieves an environmentally friendly look and feel by minimizing the amount of bioplastic component parts that are visible and by maximizing the visibility of component parts made of water-permeable, biodegradable, and compostable material(s). The container includes one or more bioplastic junction pieces that are shaped and positioned to line and seal seams between container wall(s) and a base of the container, container wall(s) and a top of the container, or both. Thus, the one or more bioplastic junction pieces provide water-impermeable barriers at seams in the container where leakage is most likely to occur. The interior of the walls and the cover of the container are coated in one or more biodegradable, water-impermeable materials to ensure that fluid contained in the interior volume is not permitted to pass therethrough, while the resulting container as a whole remains compostable.

Owner:GREATER GOOD

Closure device with opening indicator

ActiveUS20190119008A1Complicate its initial openingSignificant changeCapsClosure capsMechanical engineeringEngineering

Owner:BETAPACK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com