Rimless toilet with flush water distribution apparatus

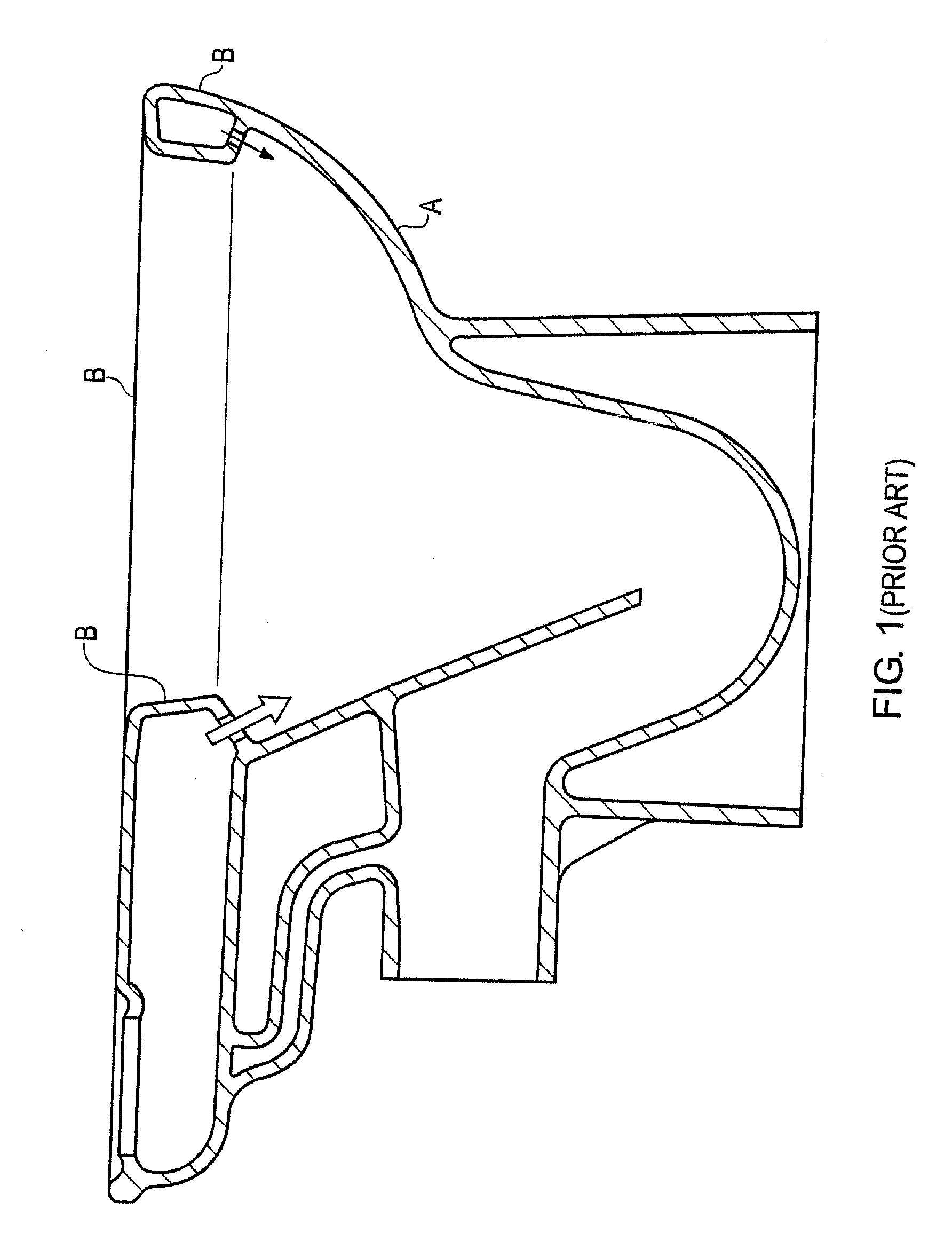

a technology of water distribution apparatus and rimless toilet, which is applied in the field of toilets, can solve the problems of difficult inspection of parts of the underside of the rim, difficult to effectively clean around the rim, and often left uncleaned parts of the toilet for extended periods of time or indefinitely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

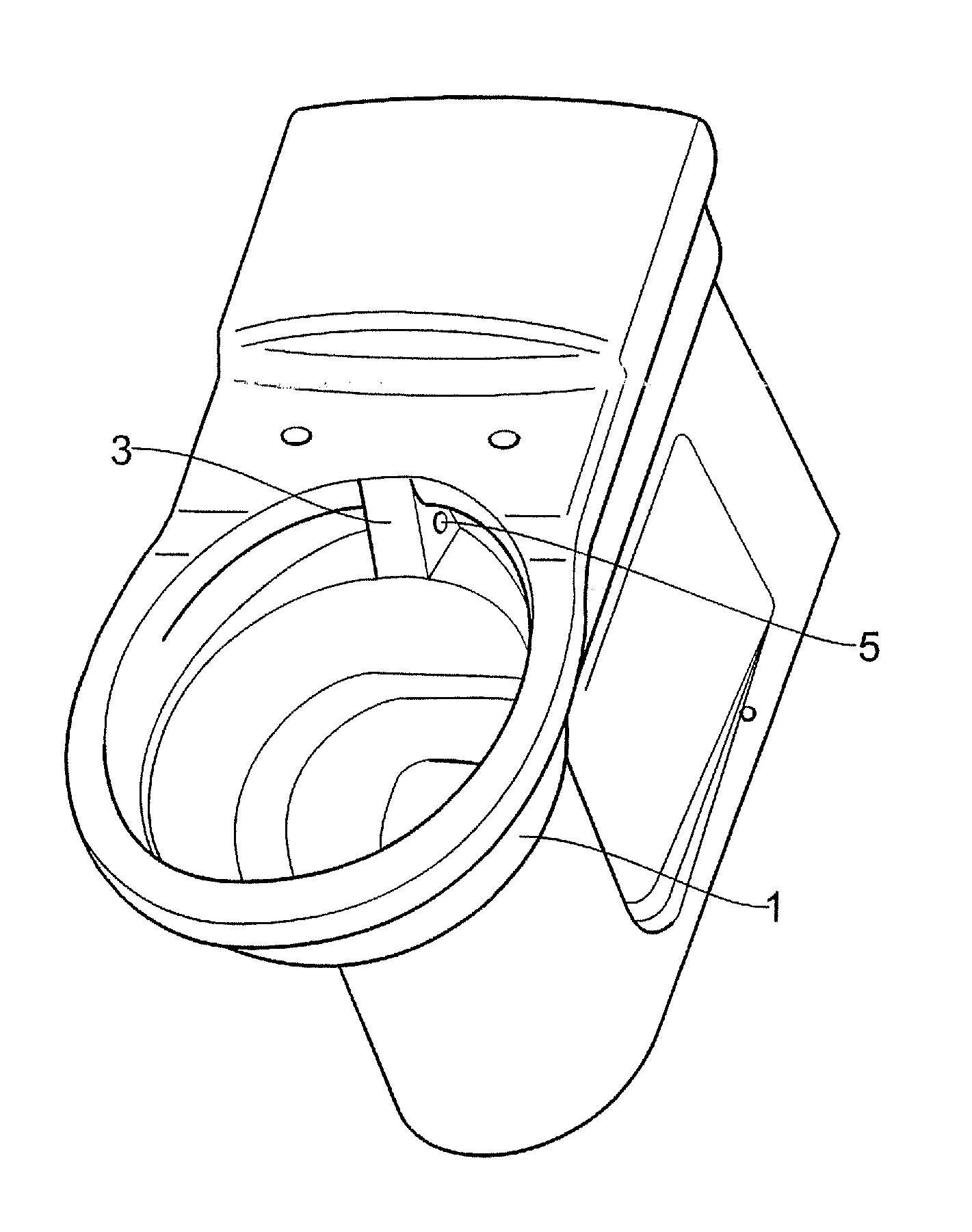

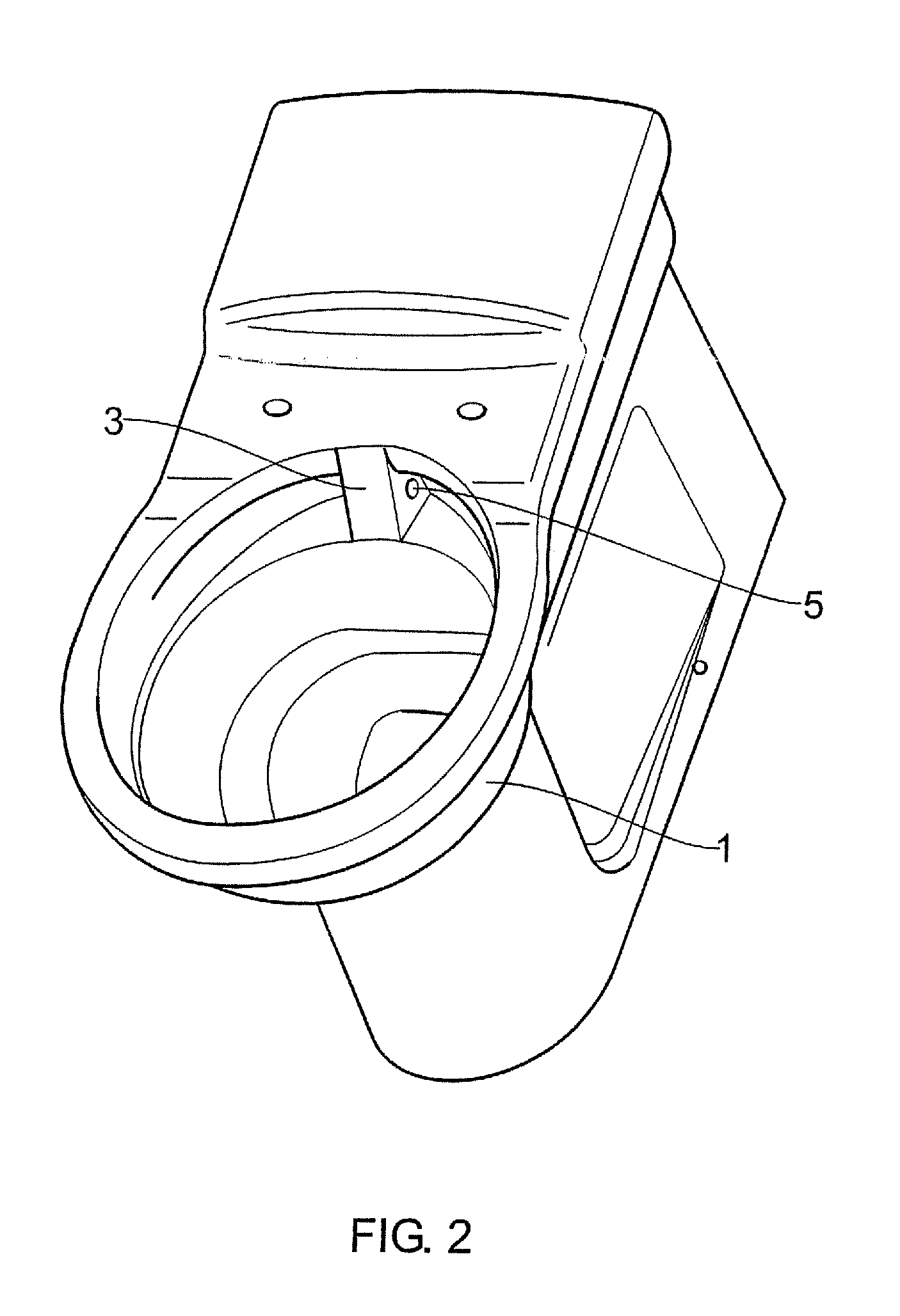

[0042]Referring to the drawings, the toilet according to the invention comprises a rimless toilet bowl 1 and a water reservoir (not shown) for supplying flushing water to said toilet bowl. As shown in FIGS. 2, 4 and 5 a water distribution apparatus or arrangement 3 is integrally formed with the inner wall of the toilet bowl 1. The distribution arrangement is discussed below in more detail with reference to FIGS. 7A and 8.

[0043]As shown in FIG. 4, the water distribution apparatus 3 includes a conduit 4 for receiving water to be supplied to the toilet bowl. This is in fluid communication with the water cistern (not shown). The distribution apparatus also includes two inlets to the toilet bowl 5 and 6 for supplying water to the toilet bowl from the conduit 4. The inlets may be any suitable size depending on the particular water pressures and characteristics of the system into which the toilet is installed. In one example the inlets are provided with a diameter of 20 mm with a tolerance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com