Pull rod lock mode hydraulic tyre vulcanizer

A tire vulcanization and tie-rod locking technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of increasing the maintenance difficulty and maintenance cost of the pressurized oil cylinder, and reducing the accuracy of the quasi-accuracy, achieving a simple structure, avoiding oil leakage and Effects of contamination, ease of maintenance or repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

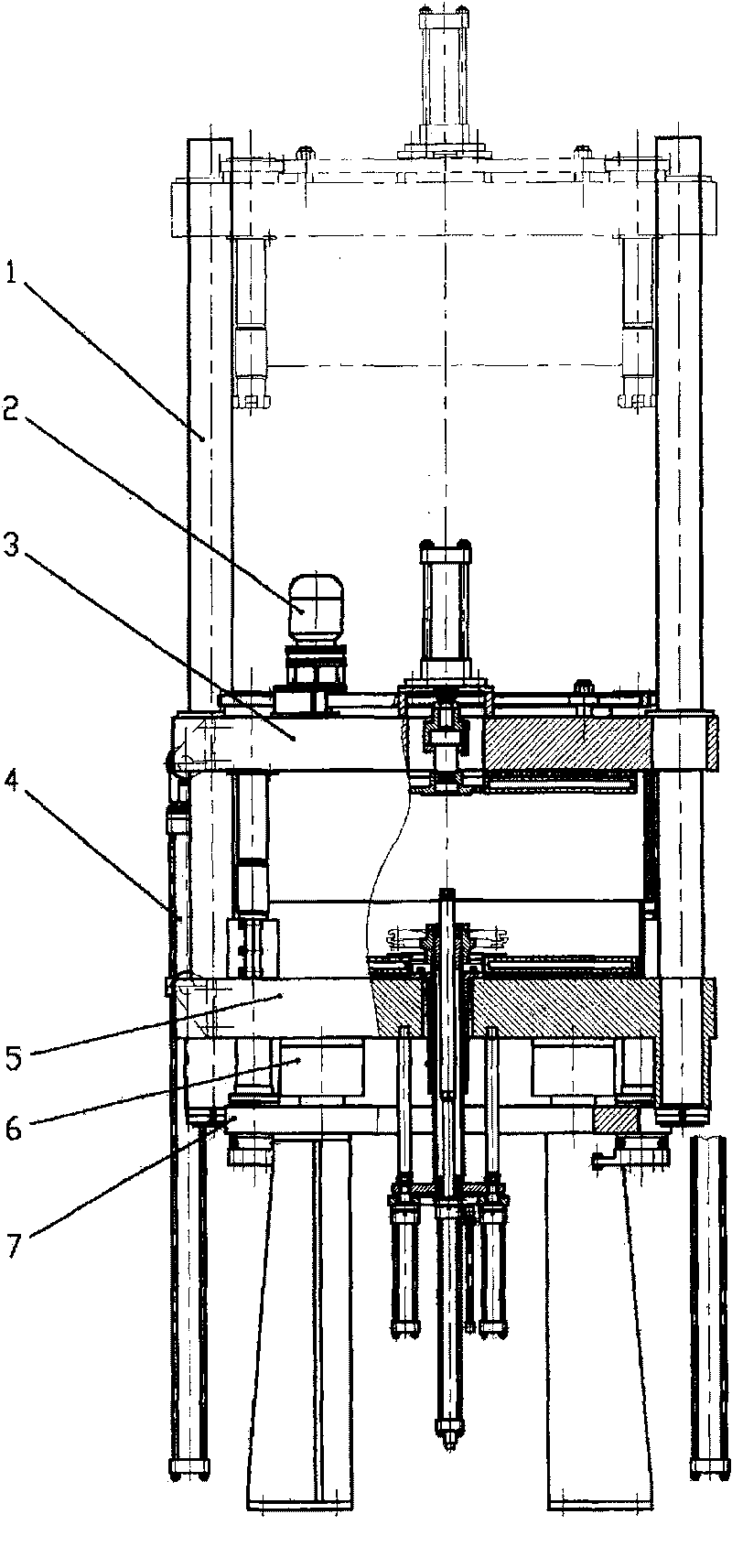

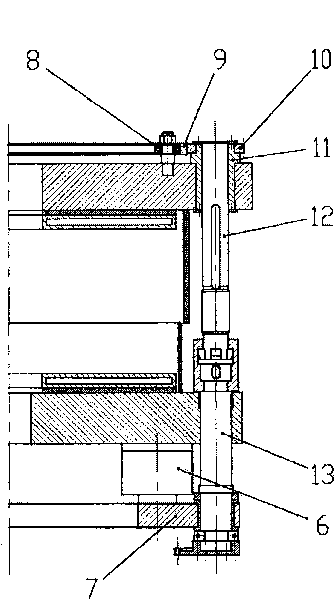

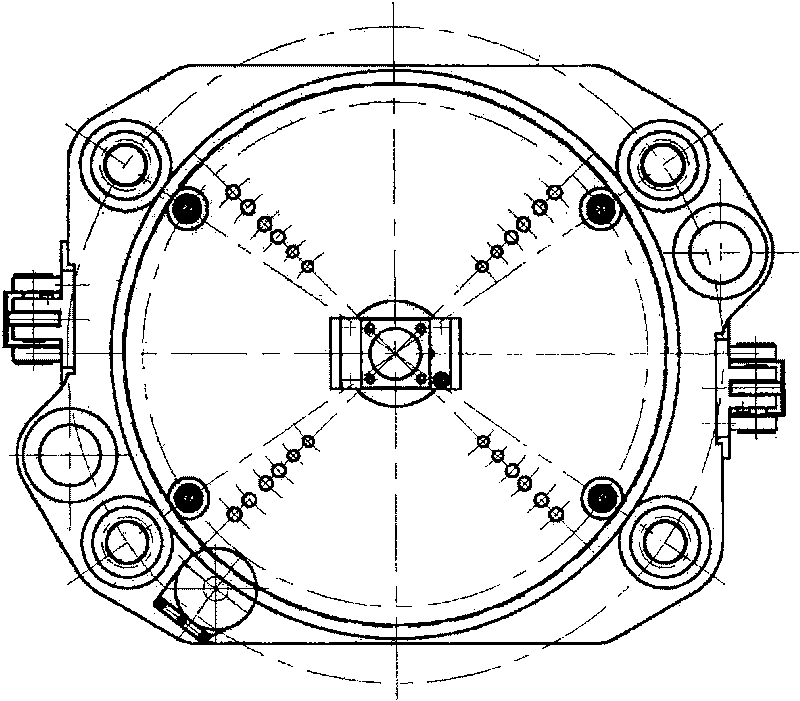

[0043] see Figure 1 to Figure 4 As shown, a hydraulic tire vulcanizing machine with pull rod lock mode is a hydraulic tire vulcanizing machine with double-column single-mode structure. , pressurized oil cylinder 6, pressurized pallet 7, support wheel 8, mold adjusting ring gear 9, mold adjusting pinion 10, mold adjusting nut 11, upper pull rod 12, lower pull rod 13, upper hot plate, lower hot plate, center Mechanism, upper mold, lower mold.

[0044] Among them, there are two uprights 1 for guiding mold opening and closing, which are respectively fixed on the lower crossbeam and are located on the left and right sides of the vulcanizing machine respectively. When molding, an additional bending moment is generated; the left and right sides of the upper beam 3 are respectively equipped with guide sleeves or linear bearings, which slide or roll with the column, so that the upper beam can only move up and down along the column; two mold opening and closing cylinders 4 are located...

Embodiment 2

[0049] see Figure 5 As shown, a pull rod lock mode hydraulic tire vulcanizing machine is a hydraulic tire vulcanizing machine with a double-column single-mode structure. The difference from Embodiment 1 is that it is replaced by three pull rods at the three corners of the vulcanizing machine. One of the four tie rods, which is mainly to change the number of clamping tie rods according to the size of the clamping force, so that it is suitable for tire vulcanization with different requirements.

Embodiment 3

[0051] see Figure 6 As shown, a pull rod lock mode hydraulic tire vulcanizer is a hydraulic tire vulcanizer with a four-column single-mode structure. The difference from Embodiment 1 is that it is replaced by four columns at the four corners of the vulcanizer. The two columns of the vulcanizer are replaced by six tie rods at the six corners of the vulcanizing machine to replace the four tie rods in Embodiment 1. This is mainly to change the number of columns and mold clamping tie rods according to the clamping force and the size of the tire mold, so that it is suitable for different Tire vulcanization required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com