Wear Particle Constraint Device for Particle Force Chain Observation

A technology of restraint device and abrasive grain, which is applied in the direction of applying stable tension/pressure to test the strength of materials, analyze materials, instruments, etc., and can solve the problems that the abrasive grain processing cannot be observed and the air pressure grinding wheel cannot be simulated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

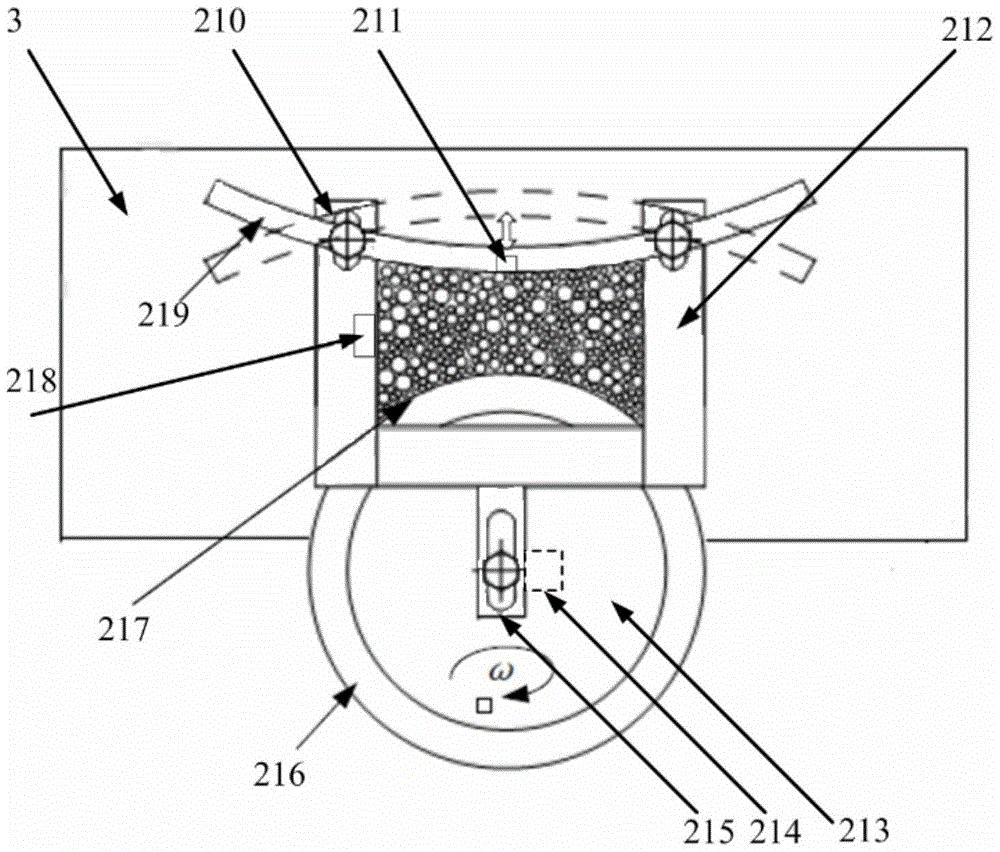

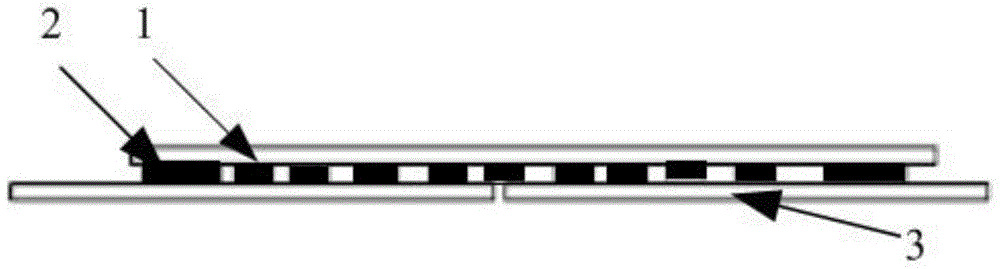

[0019] Embodiment 1 The abrasive particle restraint device for particle force chain observation according to the present invention includes an upper transparent layer 1, a lower transparent layer 3, a middle layer abrasive particle restraint module 2 sandwiched between the upper and lower transparent layers, a plurality of abrasive particle restraint modules for Stress sensors and controllers for measuring the stress state of abrasive grains. The middle layer abrasive grain restraint module 2 includes a cavity 212 for accommodating photoelastic particles, a baffle plate 219, and a force applying mechanism. The cavity 212 has a side belt There is a gap; the baffle is installed at the gap of the cavity; the bottom of the cavity is equipped with a force applying mechanism for extruding photoelastic particles, and the extrusion part of the force applying mechanism runs through the The bottom plate of the cavity 212 is in contact with the photoelastic particles 217; the upper transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com