Patents

Literature

42results about How to "Simple and low-cost construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric motor

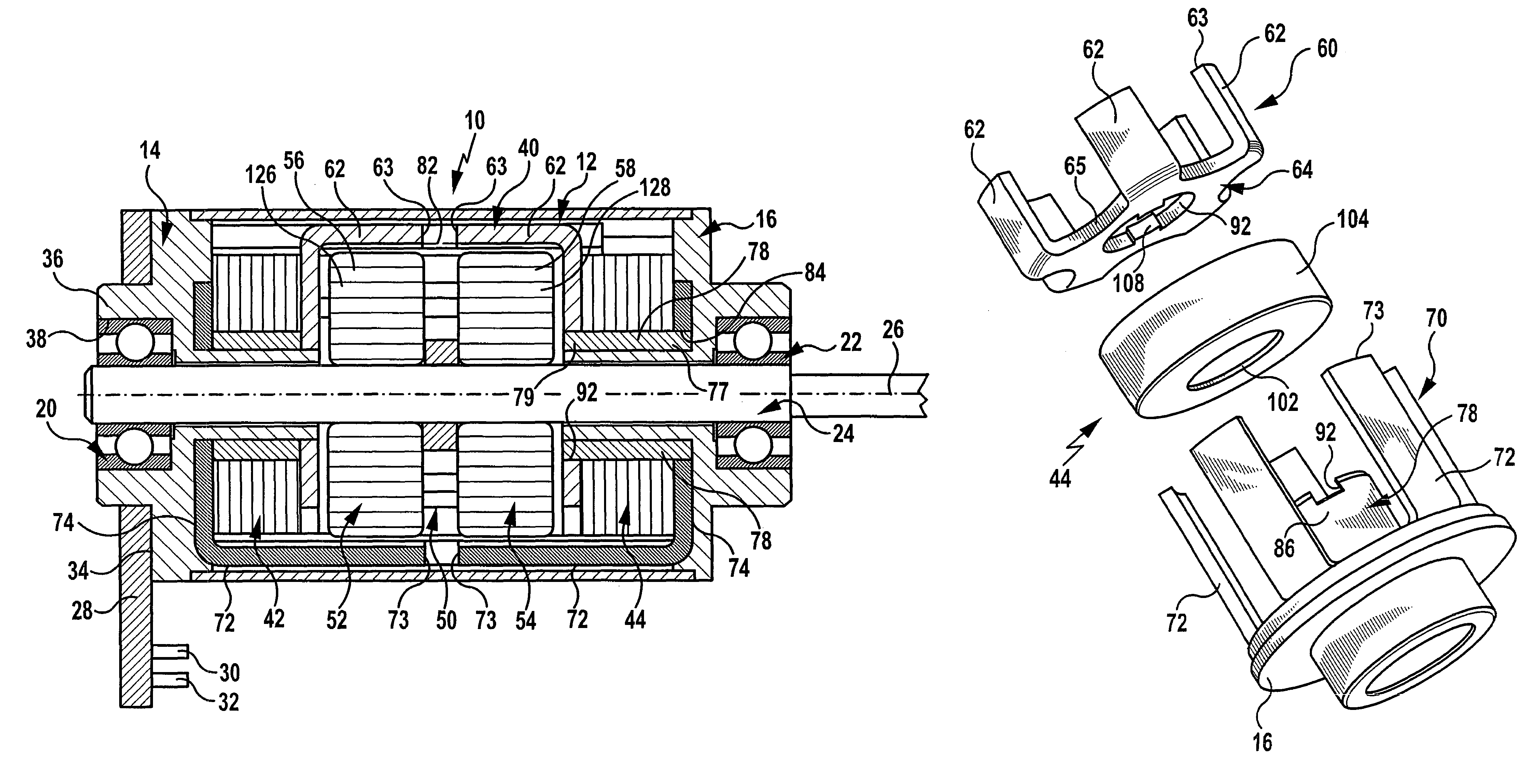

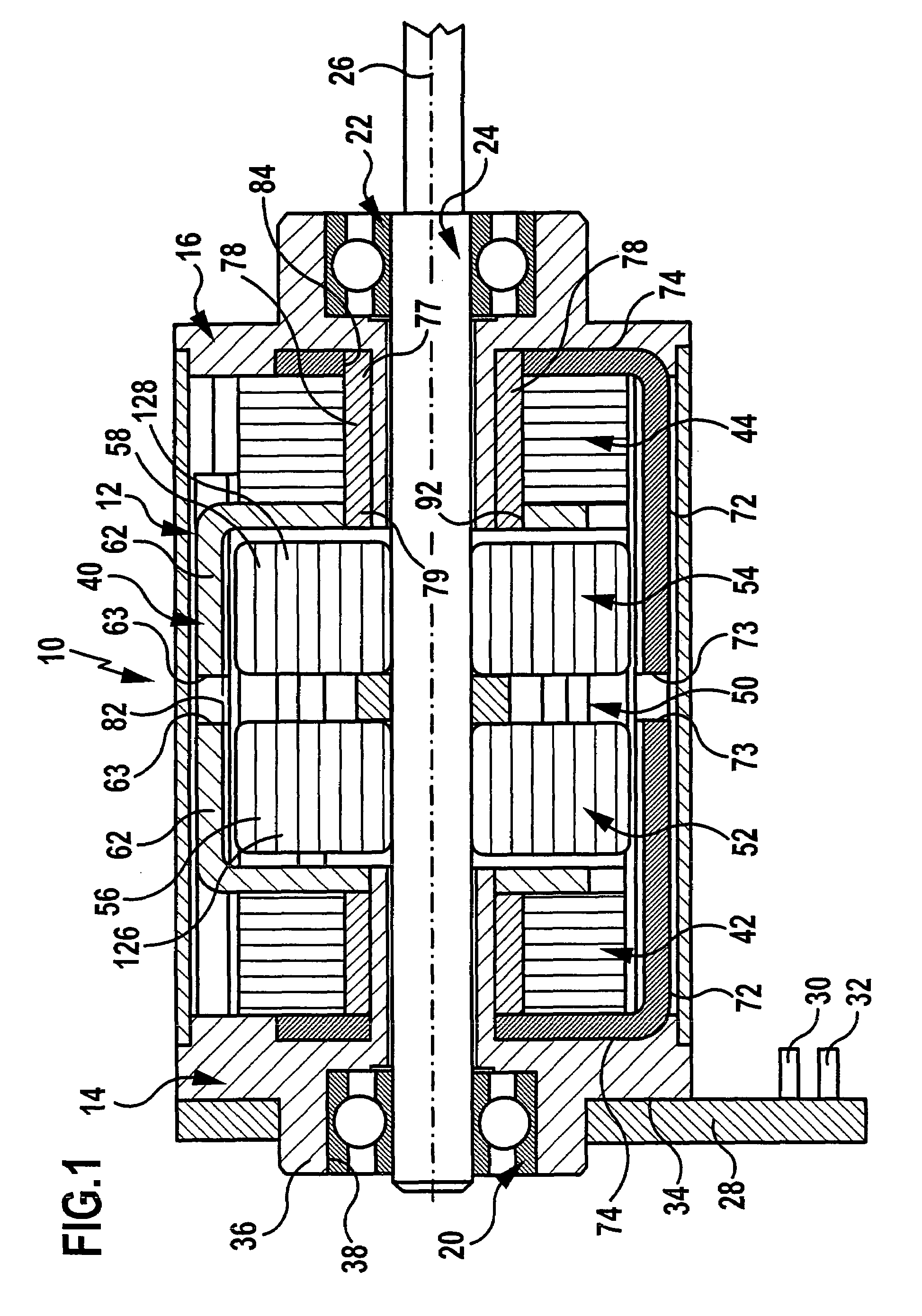

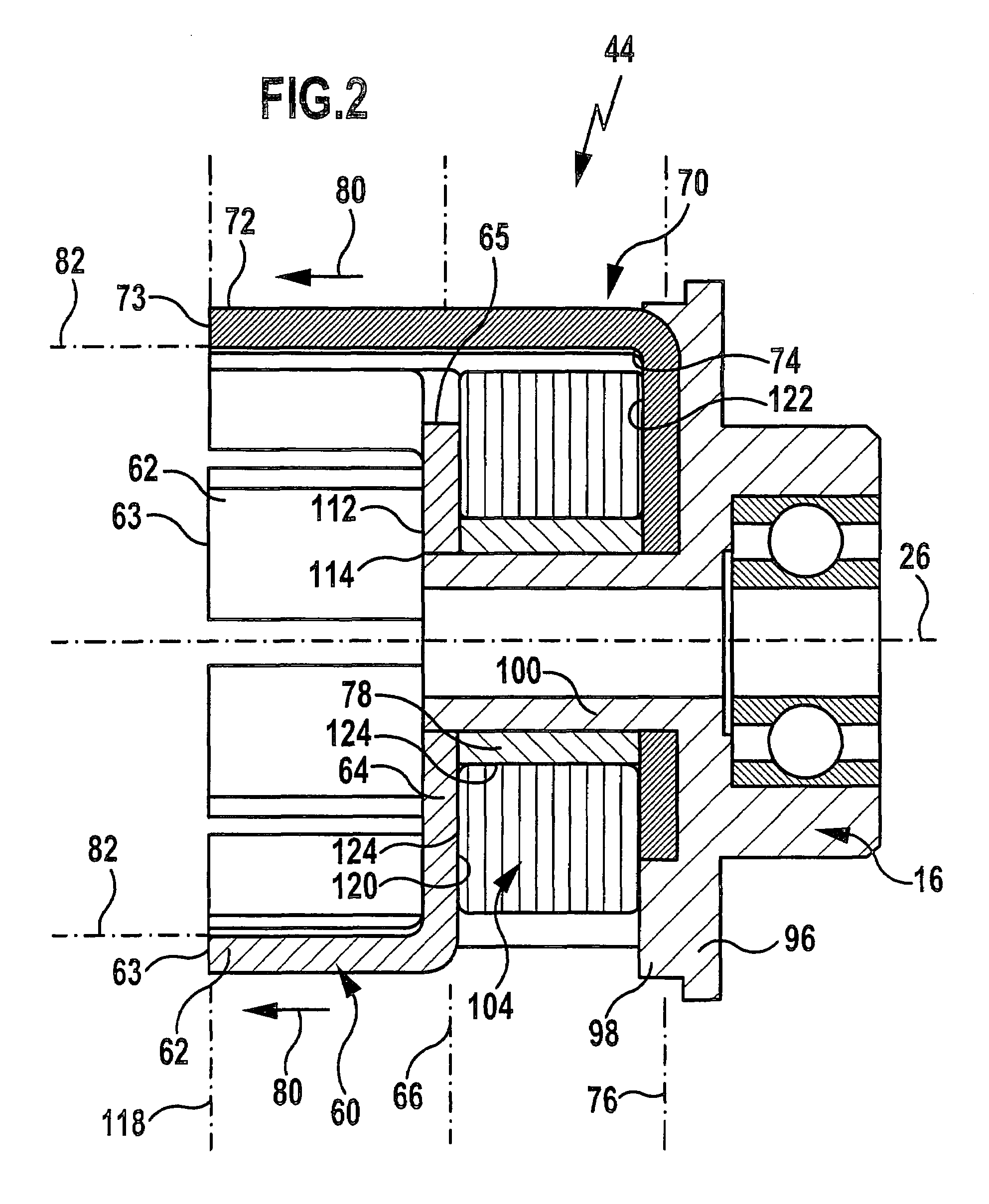

InactiveUS7015603B2Low costLow cost productionMagnetic circuit stationary partsMaster clocksEngineeringPole piece

In order to construct a brushless electric motor comprising a housing, comprising a rotor and comprising a stator, each stator unit including pole shoes, formed as claw poles, as well as a coil positioned following the rotor in the direction of the rotor axis, by means of which the pole shoes can be magnetized, at the lowest possible cost and as simply as possible, it is proposed that the stator unit has two pole shoe elements of which a first pole shoe element has a first pole shoe carrier as well as first pole shoes formed integrally onto this carrier and of which a second pole shoe element has a second pole shoe carrier as well as the second pole shoes formed integrally onto this carrier and that a bearing support made of plastics is molded onto the second pole shoe carrier of the stator unit and is thereby secured to it.

Owner:MINEBEA CO LTD

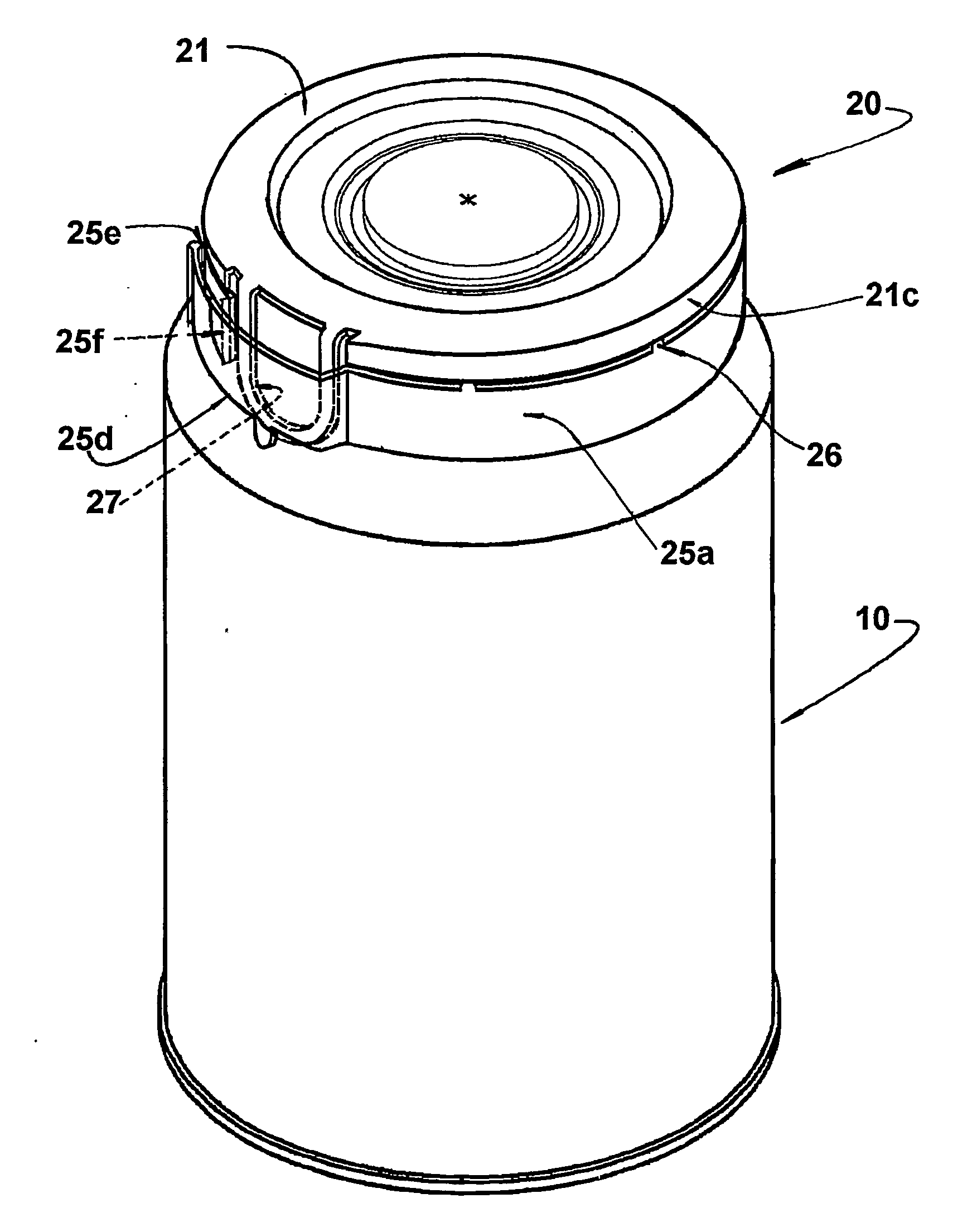

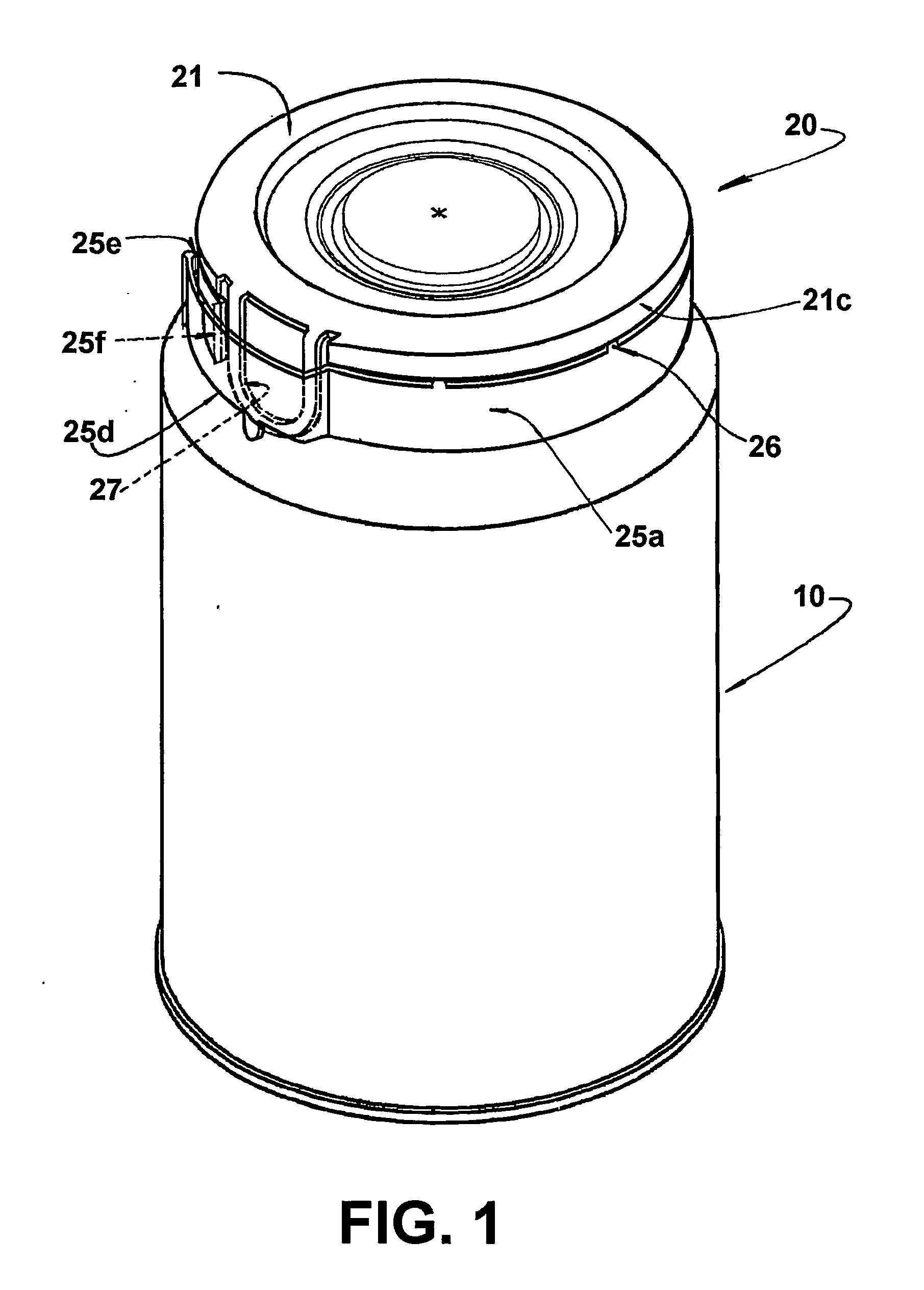

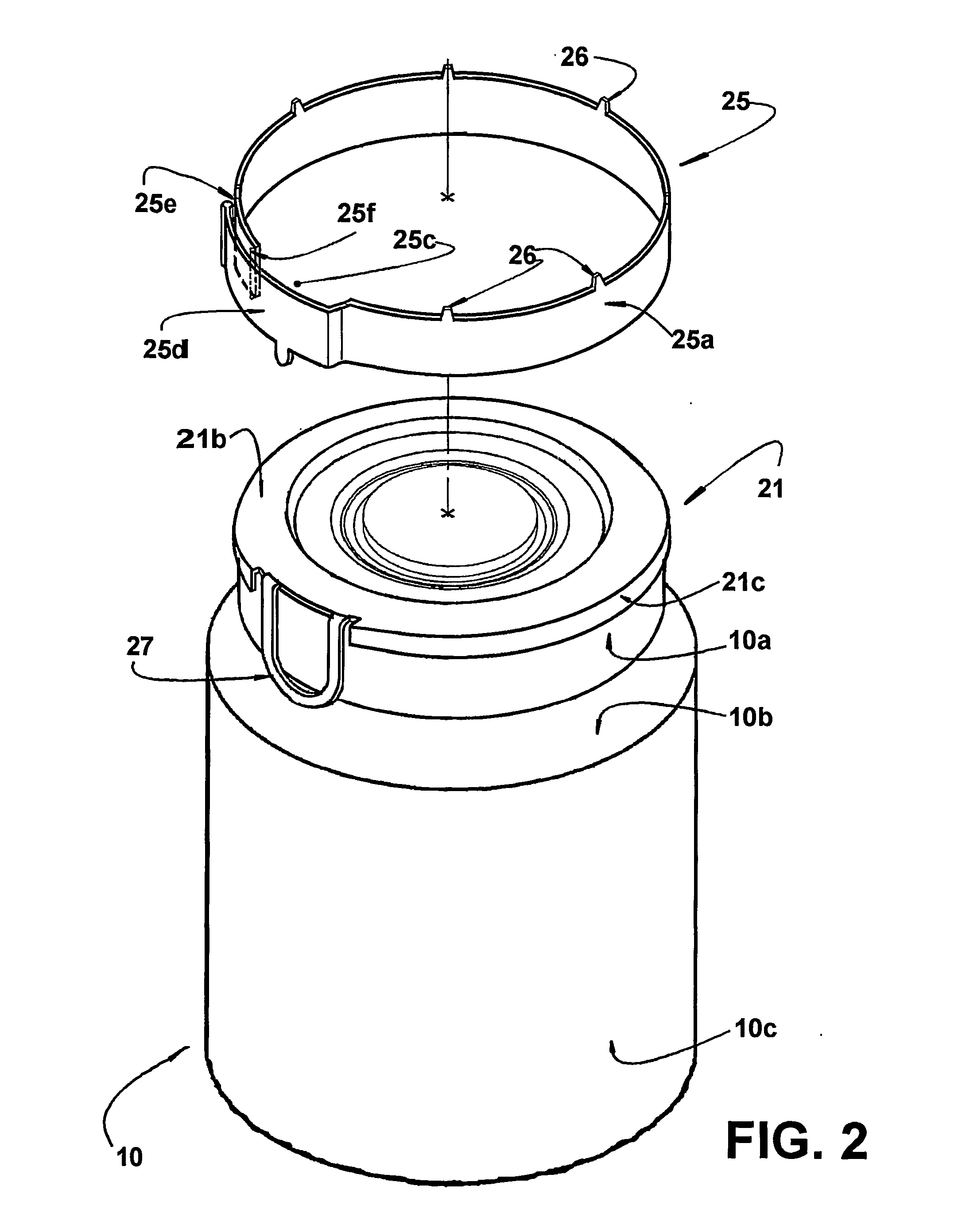

Closure arrangement for cans

InactiveUS20070090111A1Avoid mutual contactBetter load distributionClosure using stoppersRemovable lids/coversEngineeringMechanical engineering

Owner:BRASILATA S A EMBALAGENS METALICAS

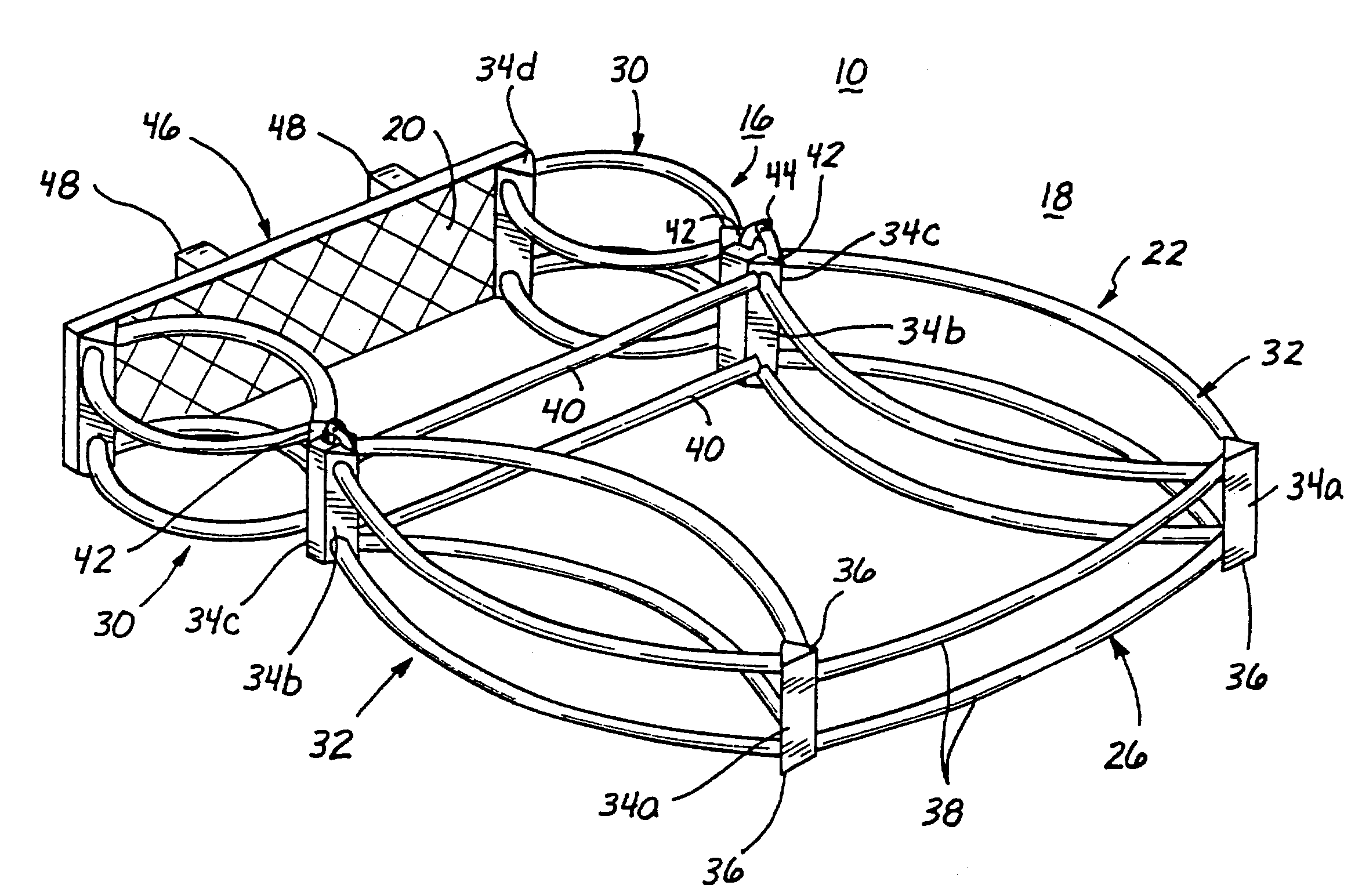

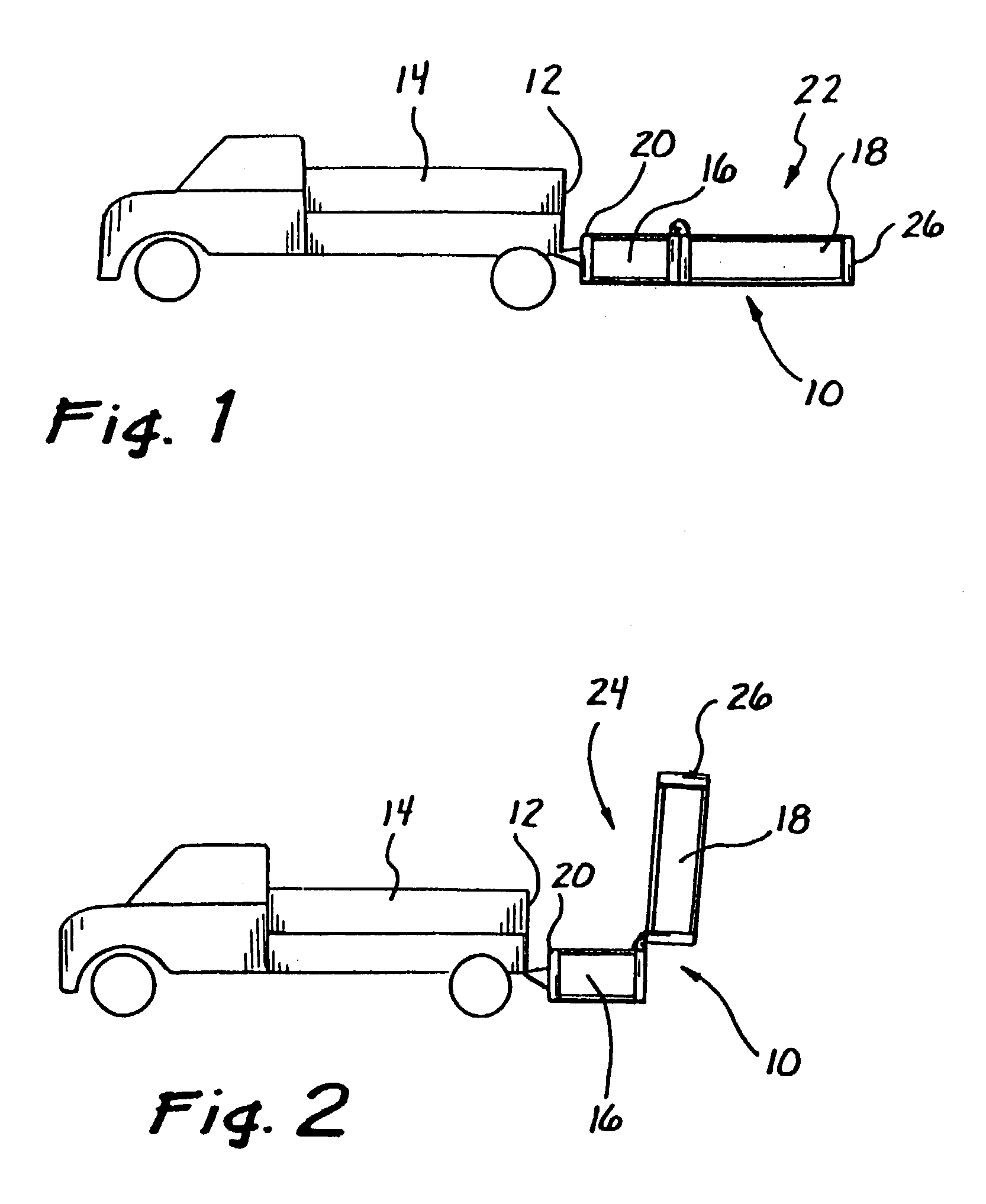

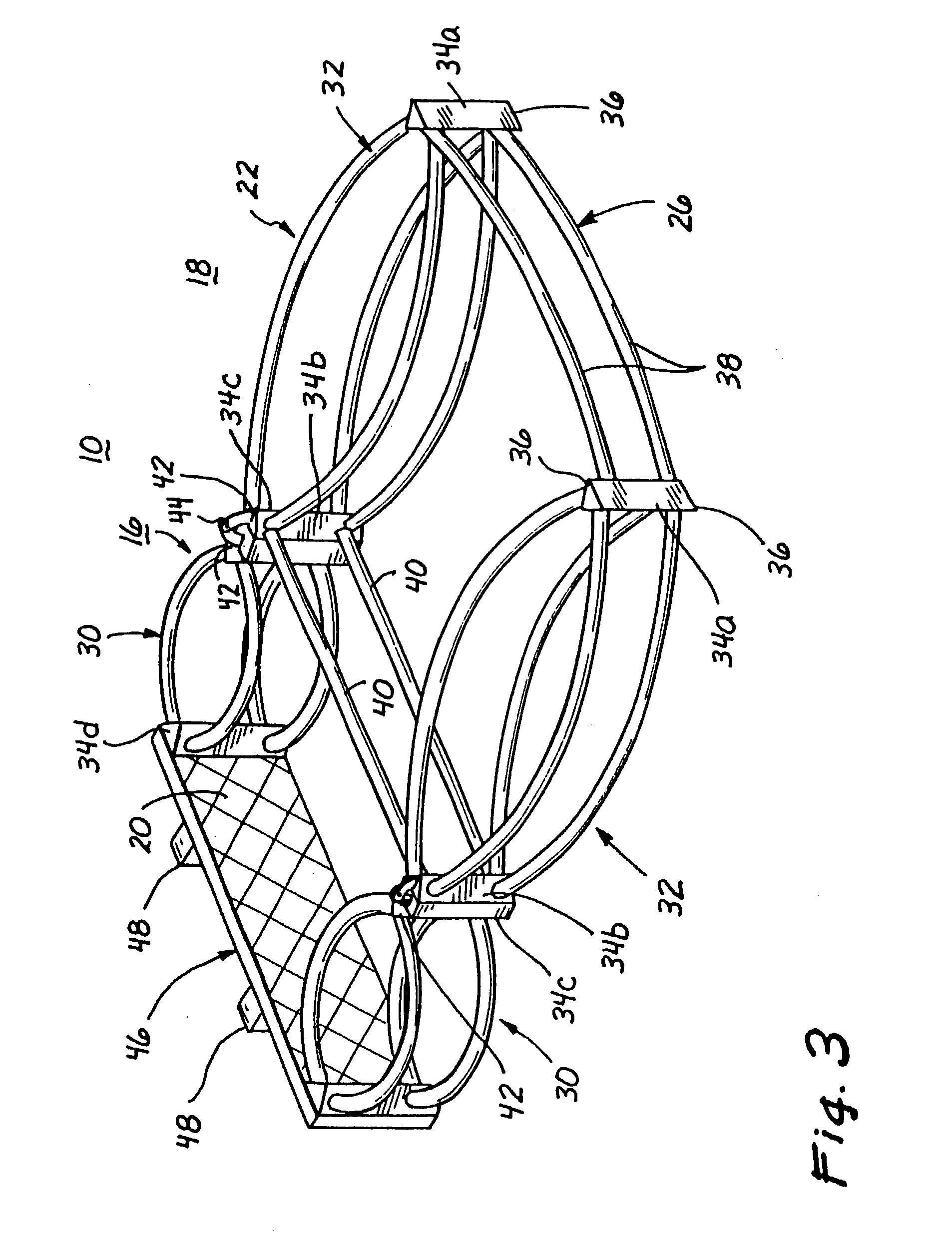

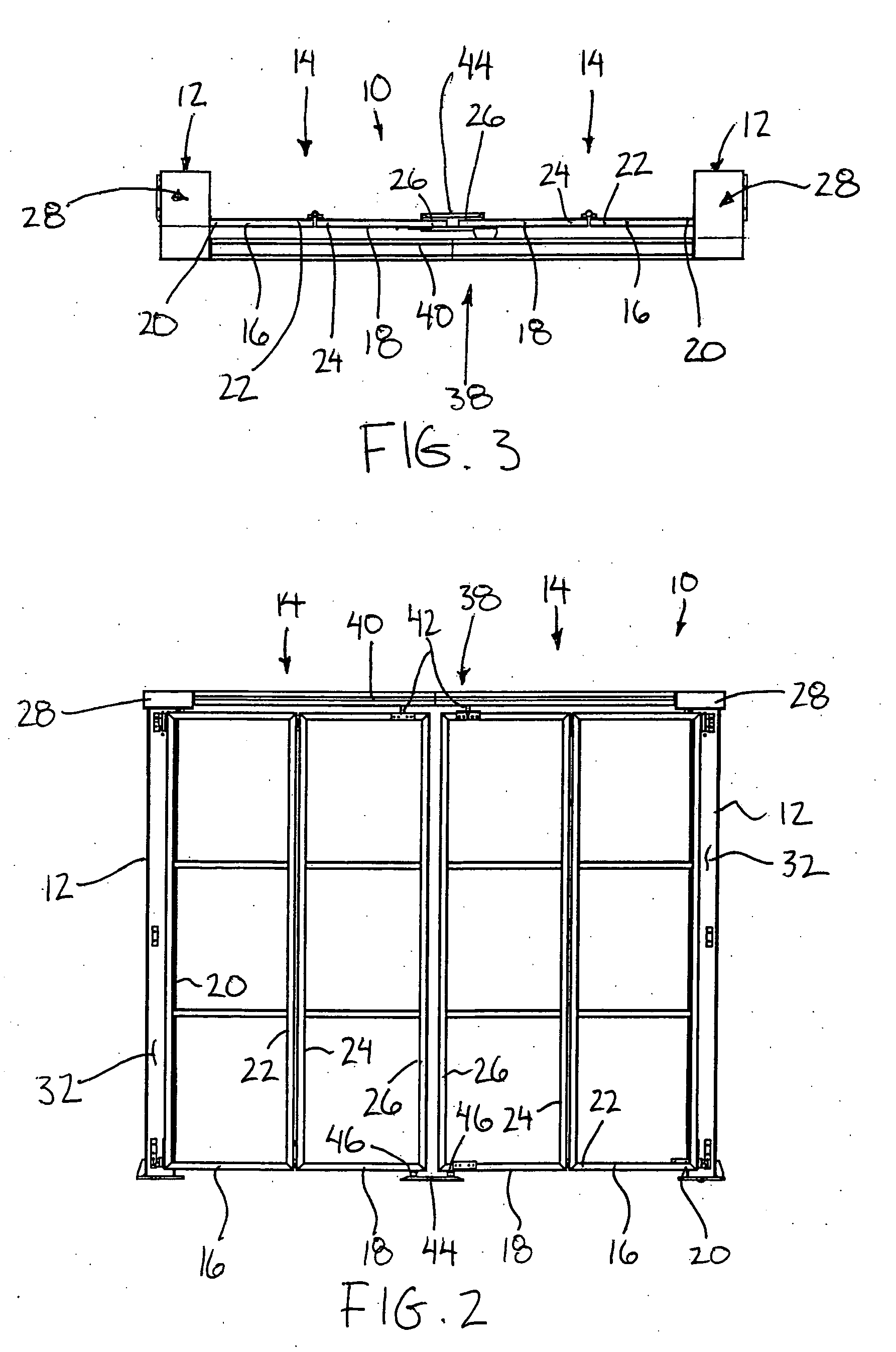

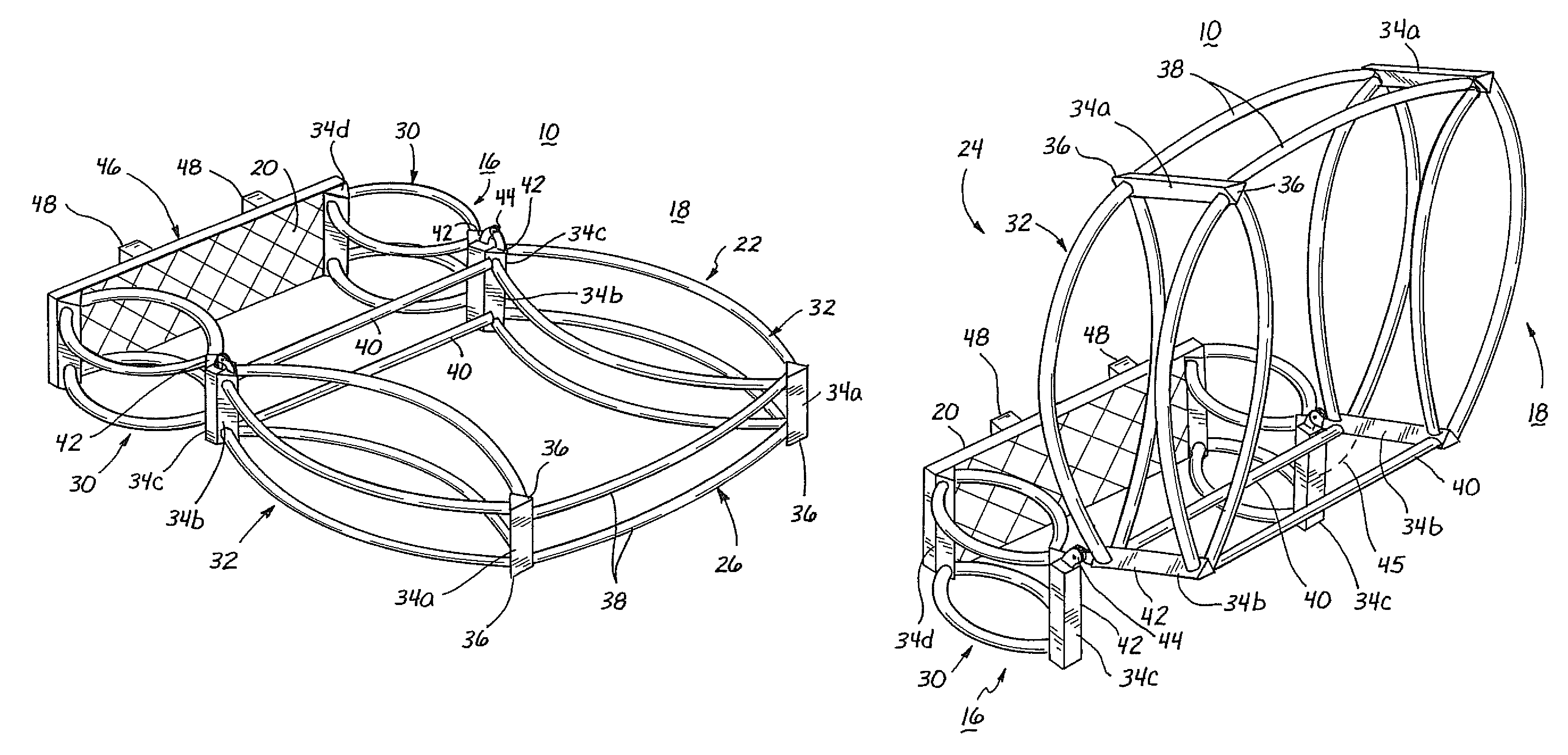

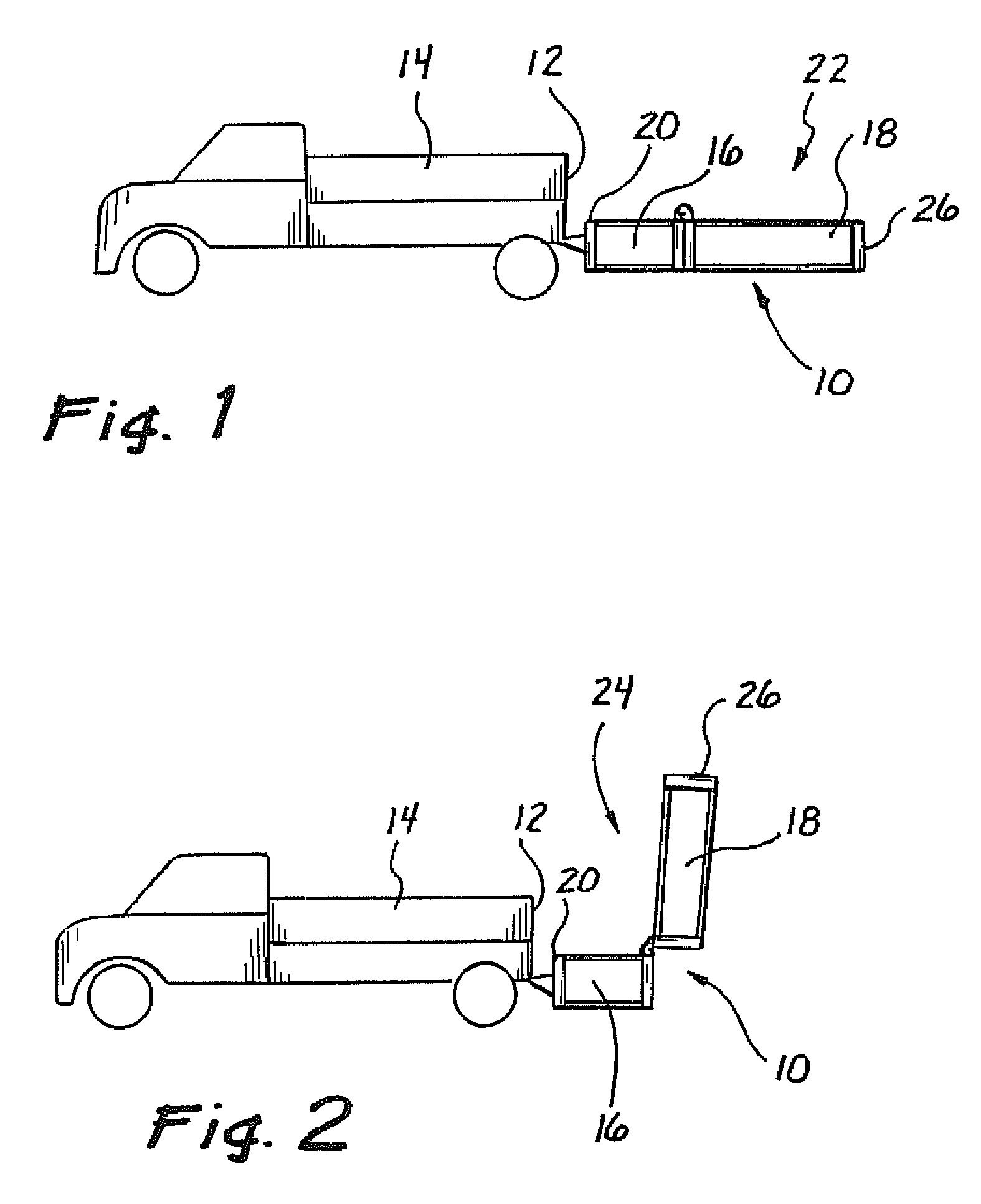

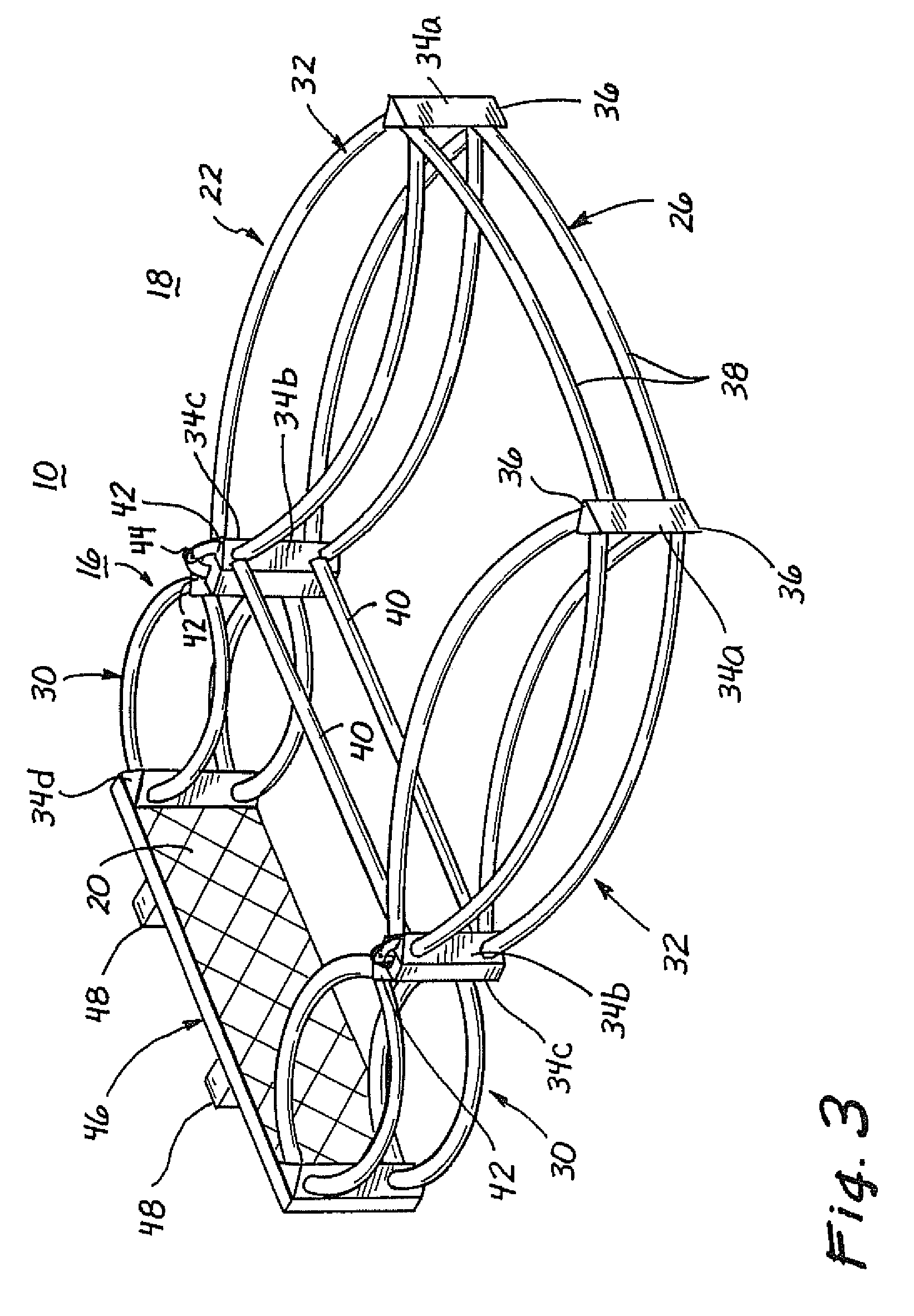

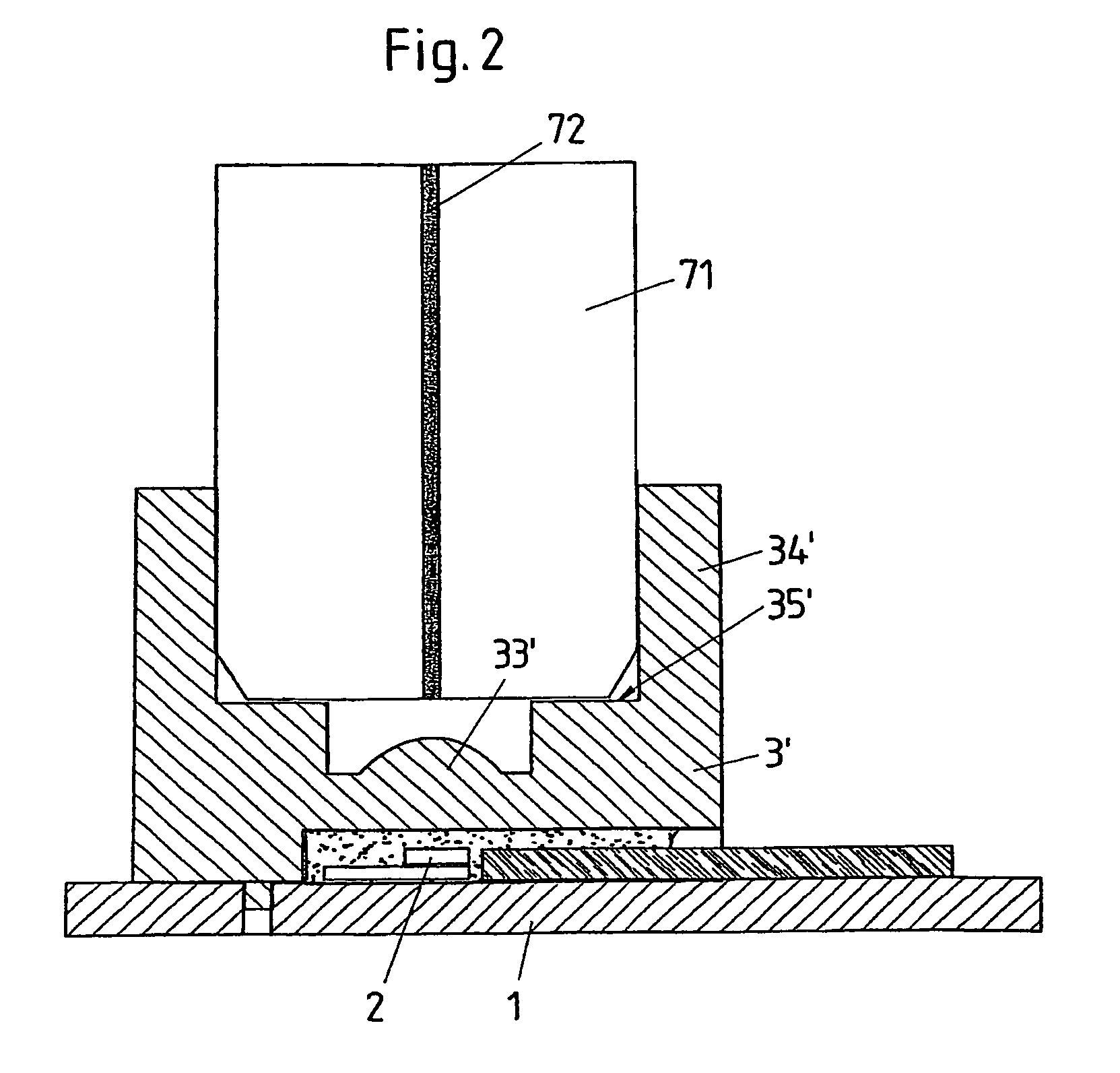

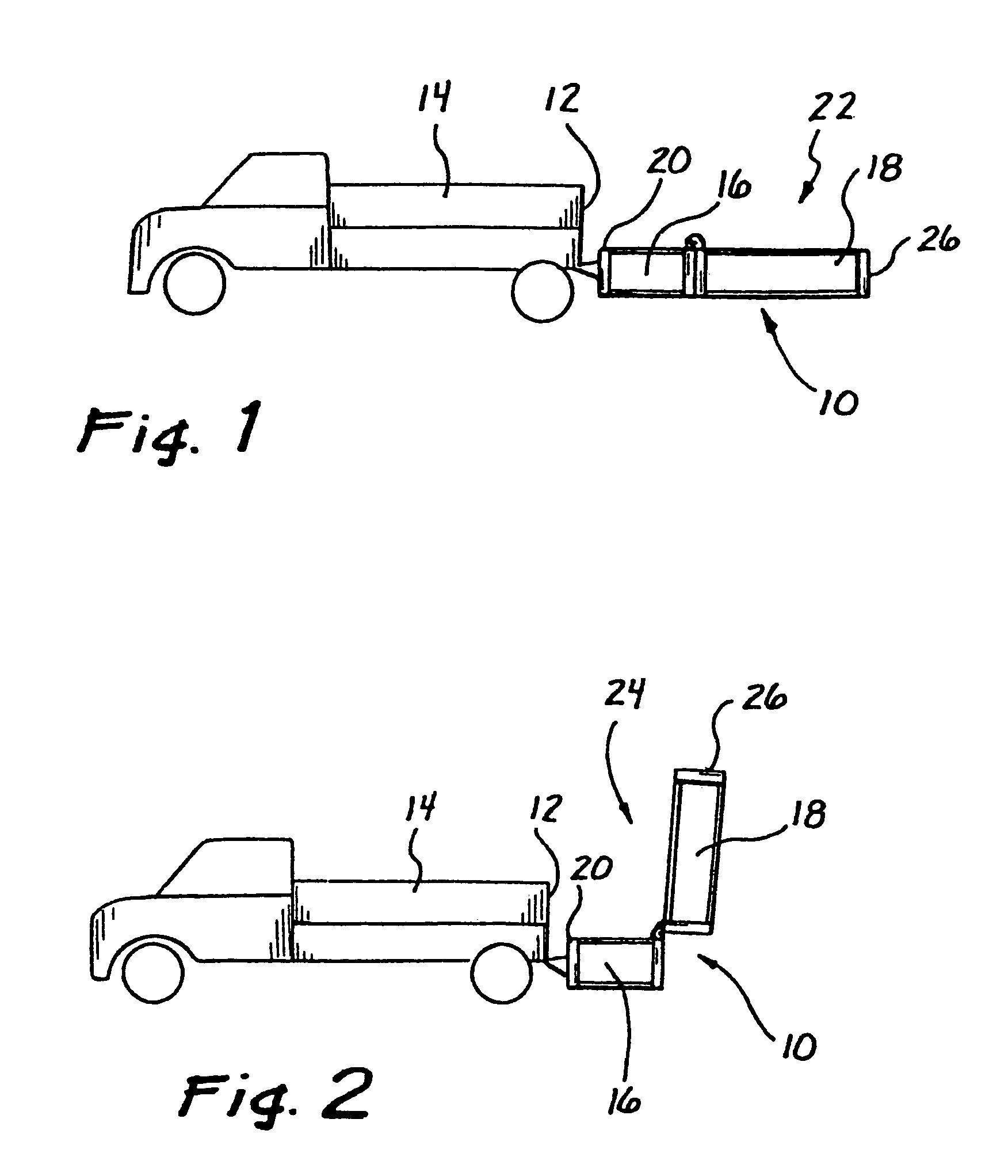

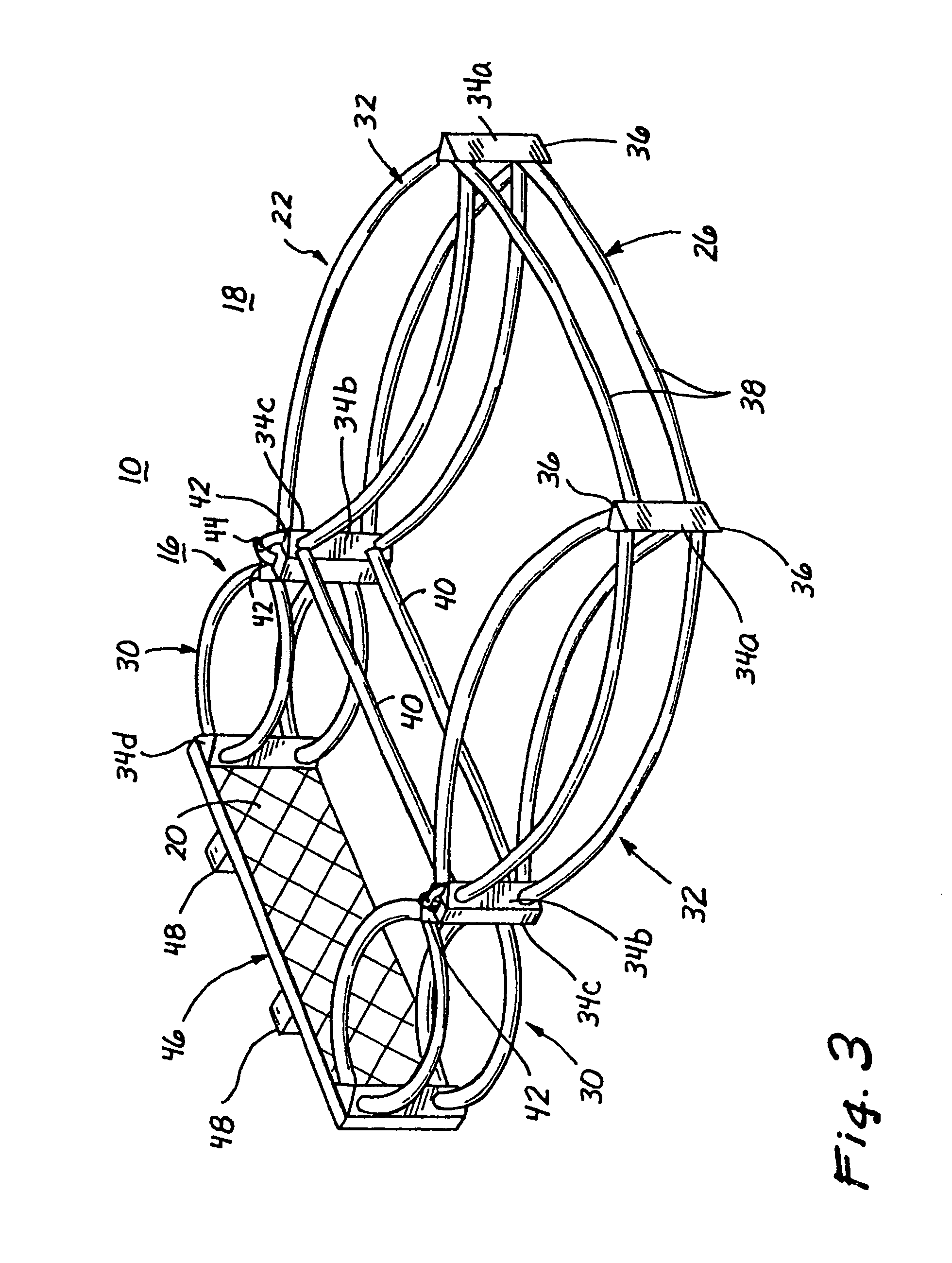

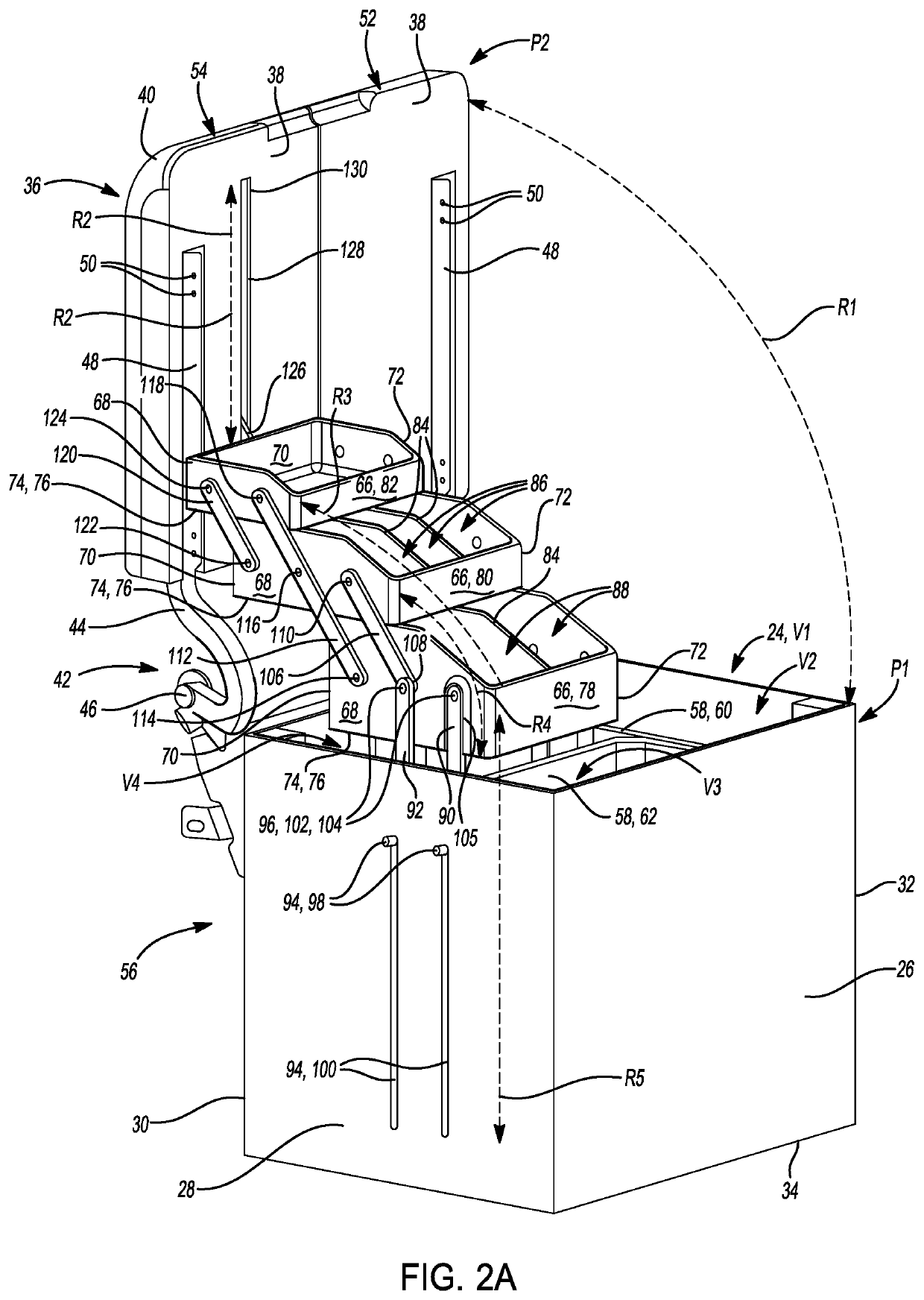

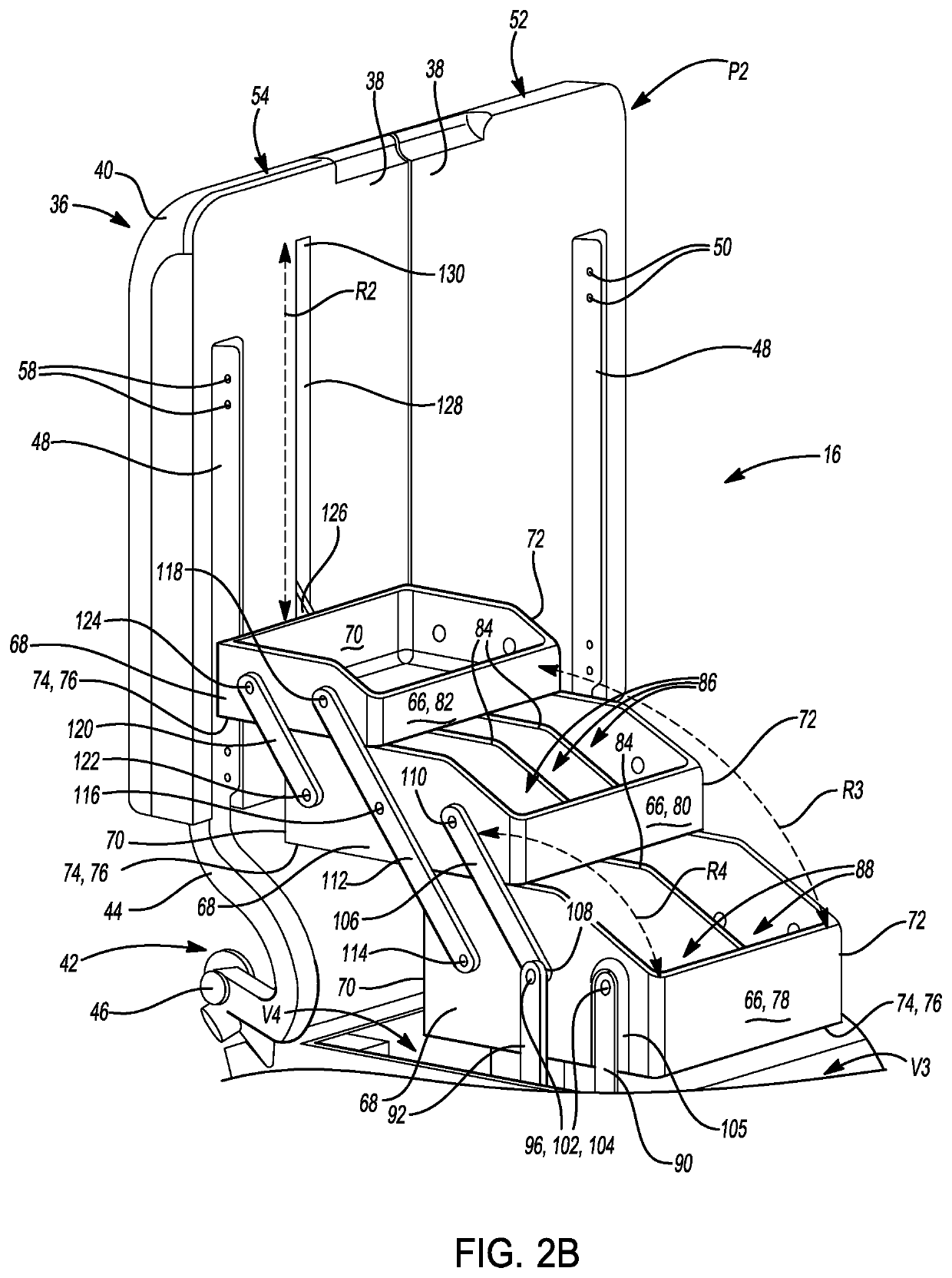

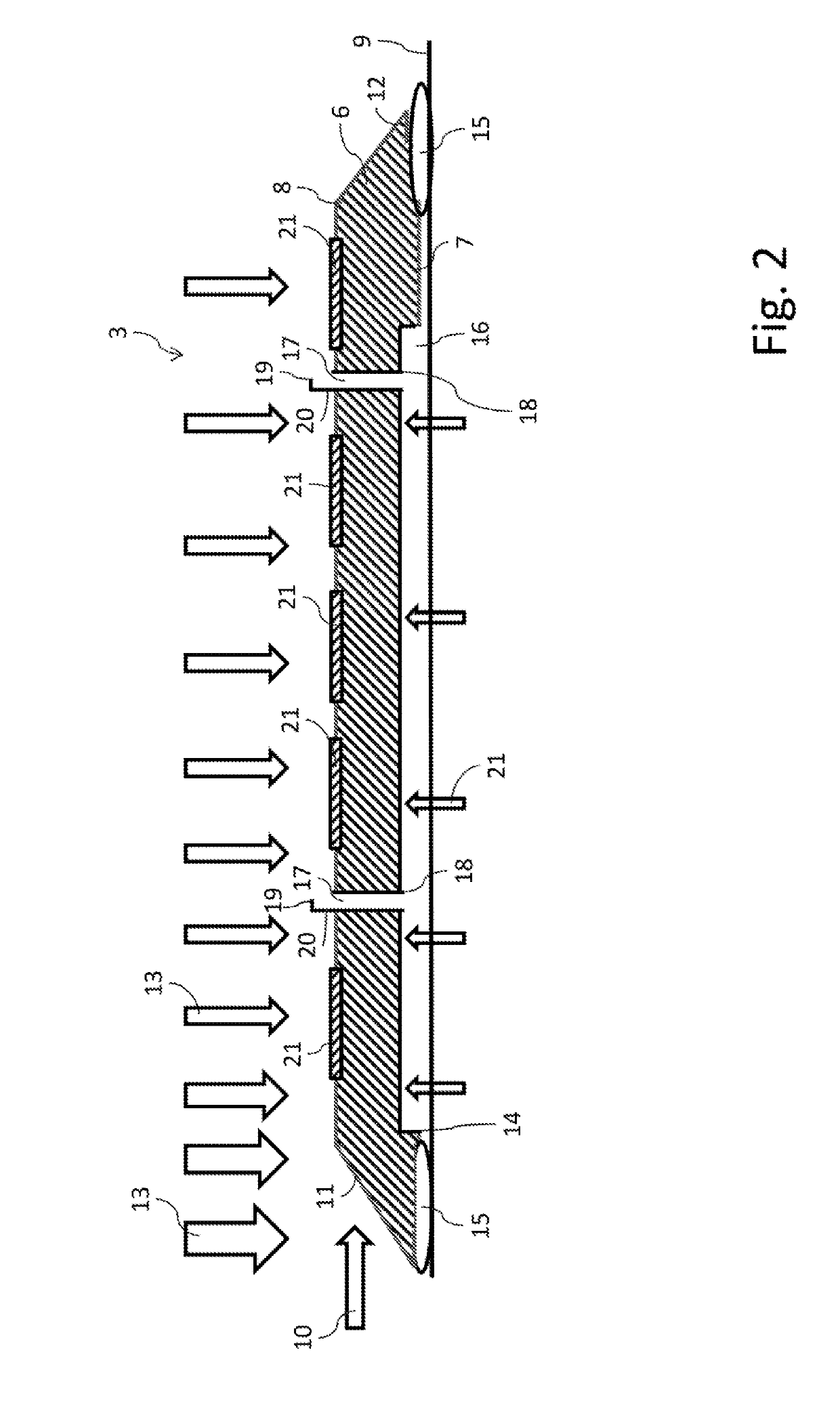

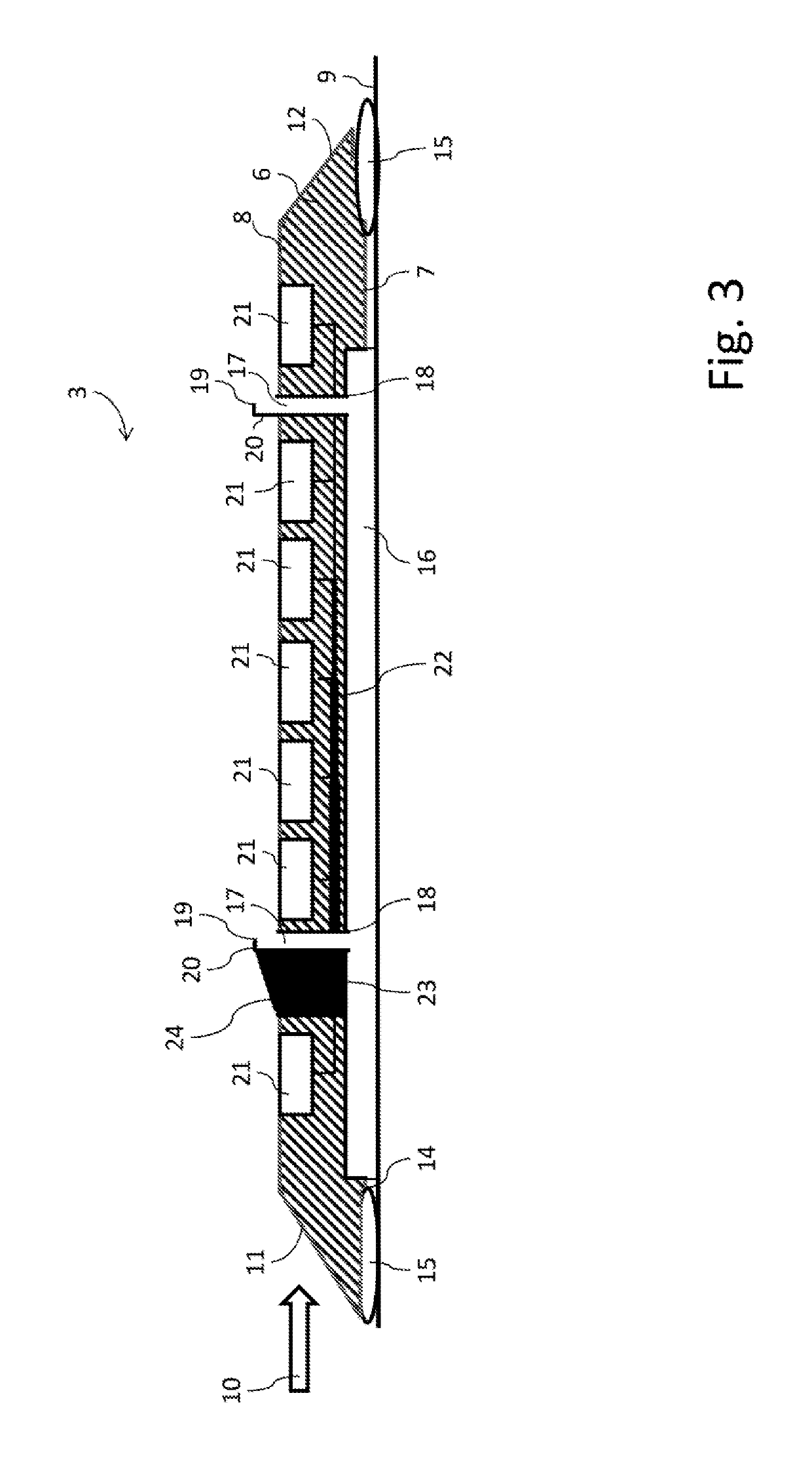

Truck mounted cash attenuator

InactiveUS6926324B1Limited protectionSimple and low cost constructionPasturing equipmentElastic dampersModularityTruck

A truck mounted attenuator (TMA) is constructed to minimize length during use in a horizontal position and height in a vertical transport position, as well as to minimize wind resistance and buffeting at highway speeds. A modular construction is employed, so that only damaged portions of the TMA can be removed and replaced in the field after a vehicle impact. The TMA comprises a plurality of outwardly curved tubular structural members which are designed to buckle upon application to the TMA of forces resulting from vehicular impact. The rigid tubes buckle at a high initial force, then proceed to crush at a lower force once the sides have buckled outwardly sufficiently to protect vehicle occupants during the critical first two feet of travel after impact. This design also provides increased protection for errant vehicles which impact the TMA device from an angle (i.e. “coffin corner” impact).

Owner:TRAFFIX DEVICES INC

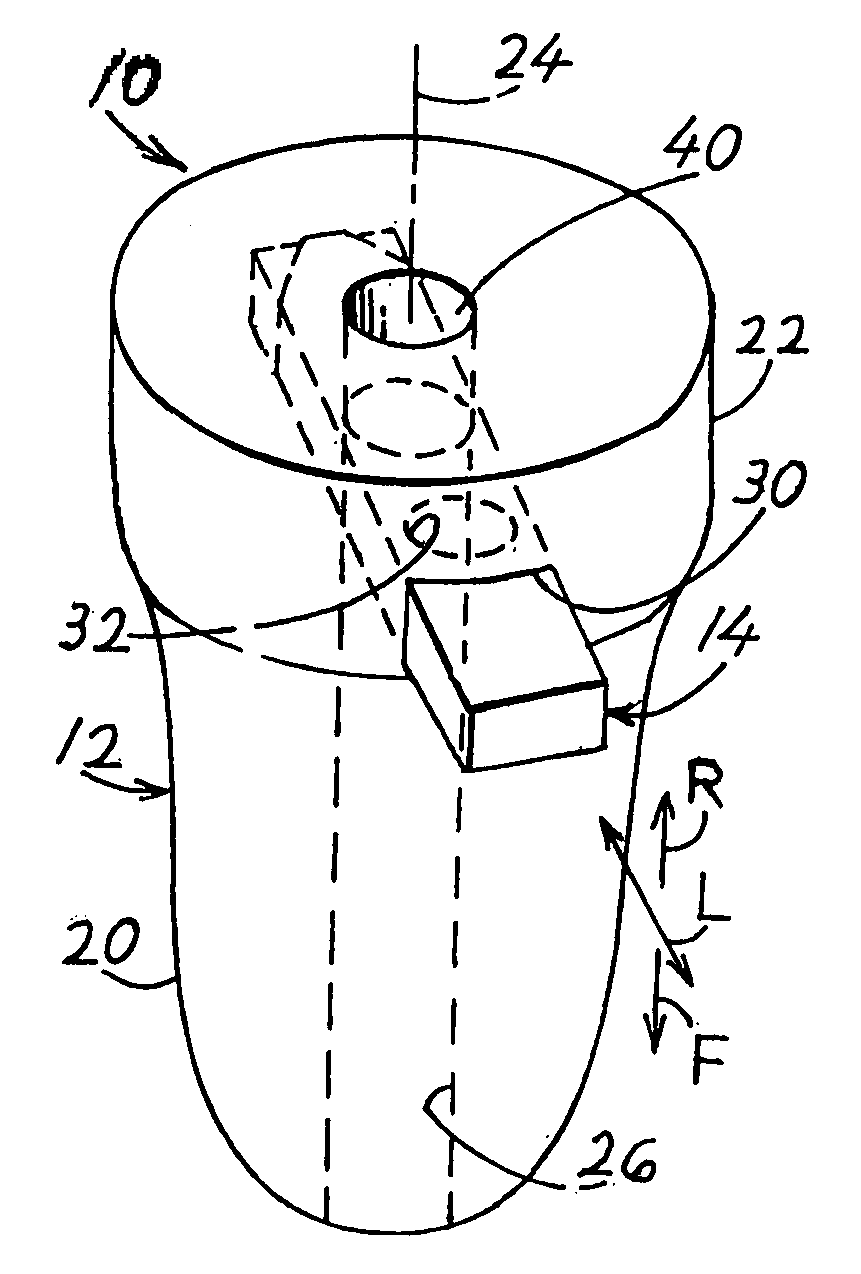

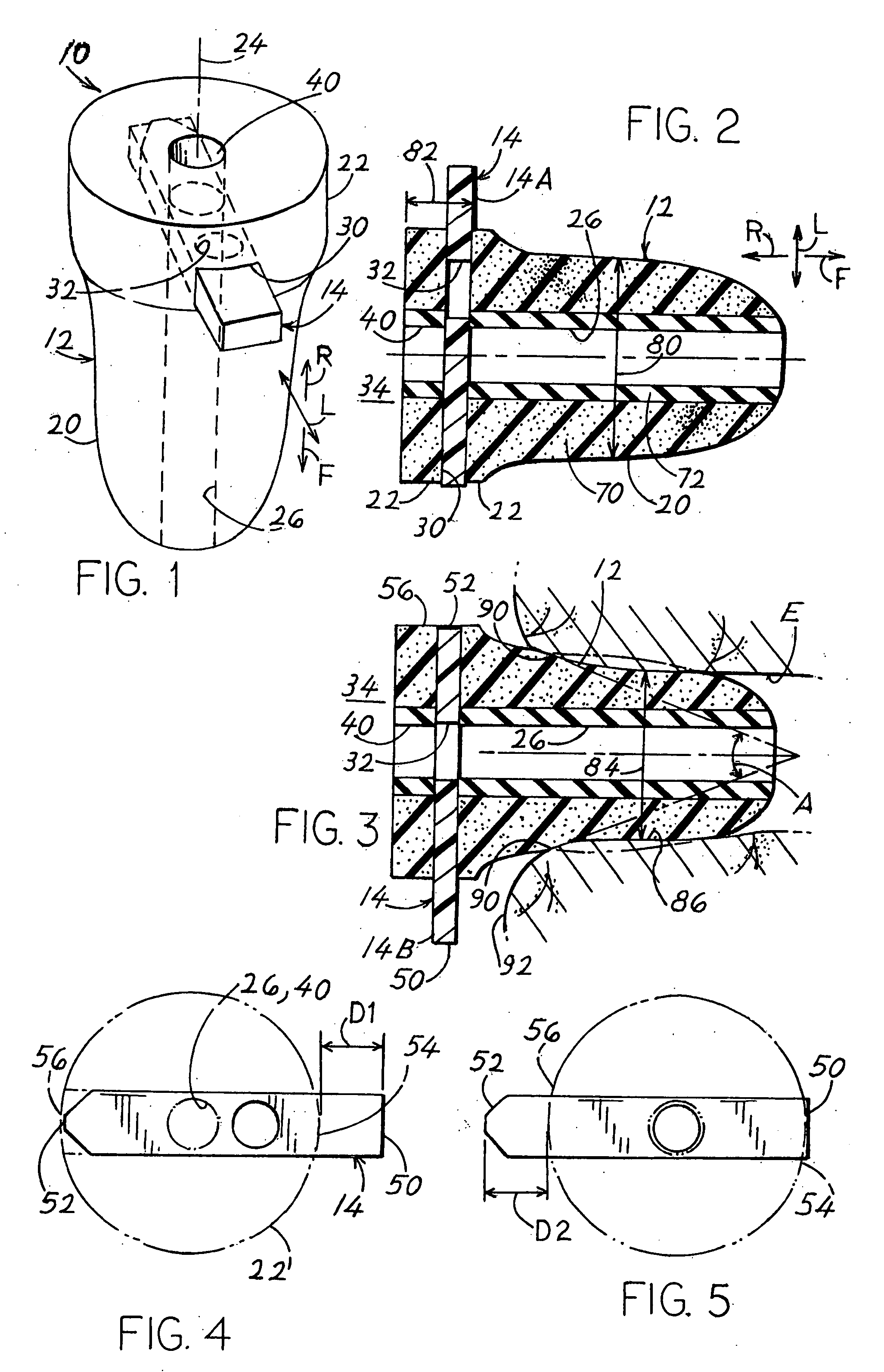

Lateral sliding adjustable earplug

An earplug has an earplug body (12) with a front sealing portion (20) that seals to a person's ear canal, a body rear portion (22) that lies out of the ear canal, and a passage (26) that extends along the body axis and that allows environmental sound to flow into the ear canal when the passage is not blocked. The body rear portion has a lateral slot (30), and the earplug includes a blocking element (14) that is laterally (L) slidable along the slot. The blocking element can slide between a first position (14A) wherein a hole (32) in the element is not aligned with the passage to prevent sound from reaching the ear canal, and a second position (14B) wherein the hole is aligned with the passage to allow sound to reach the passage.

Owner:SPERIAN HEARING PROTECTION

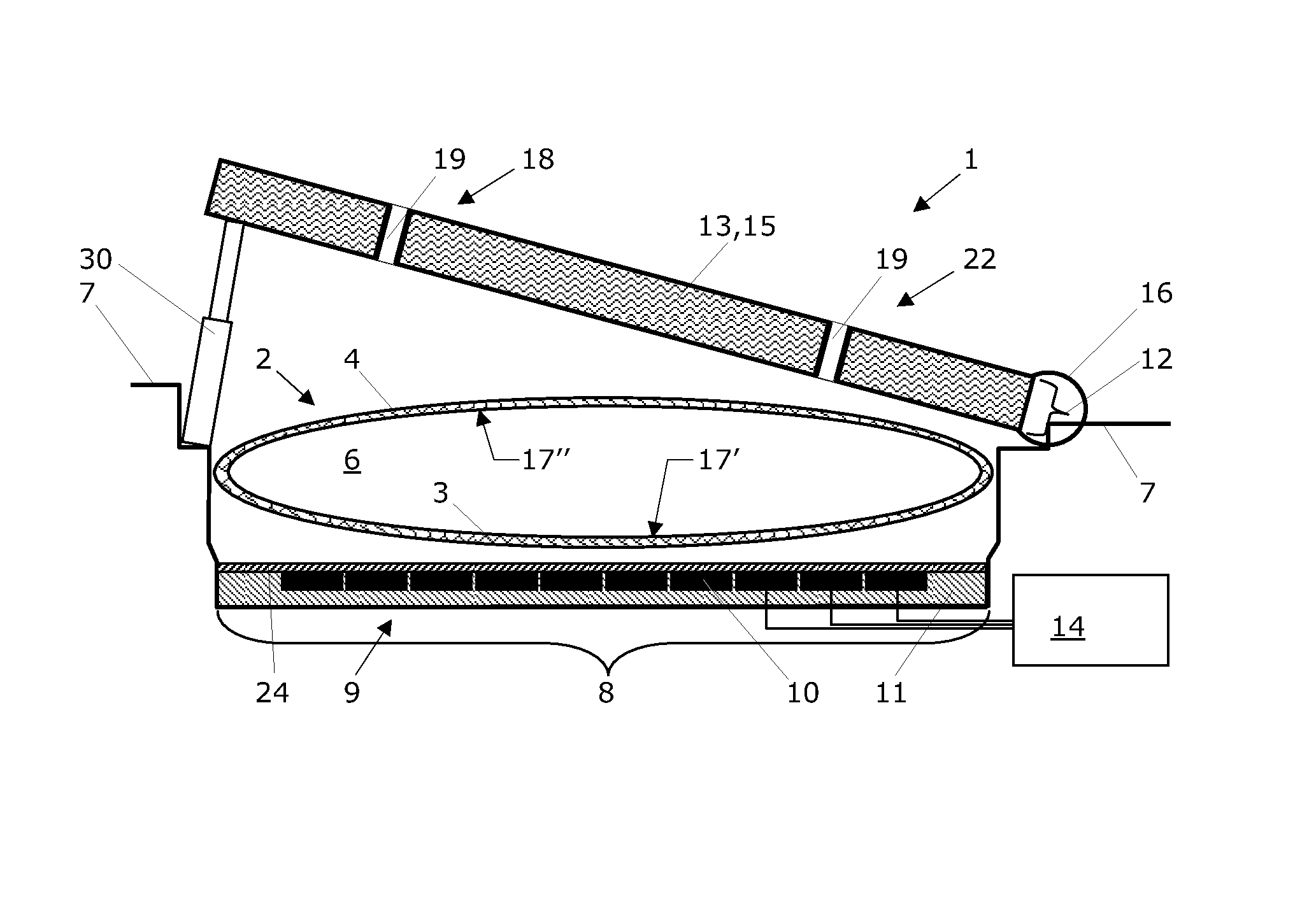

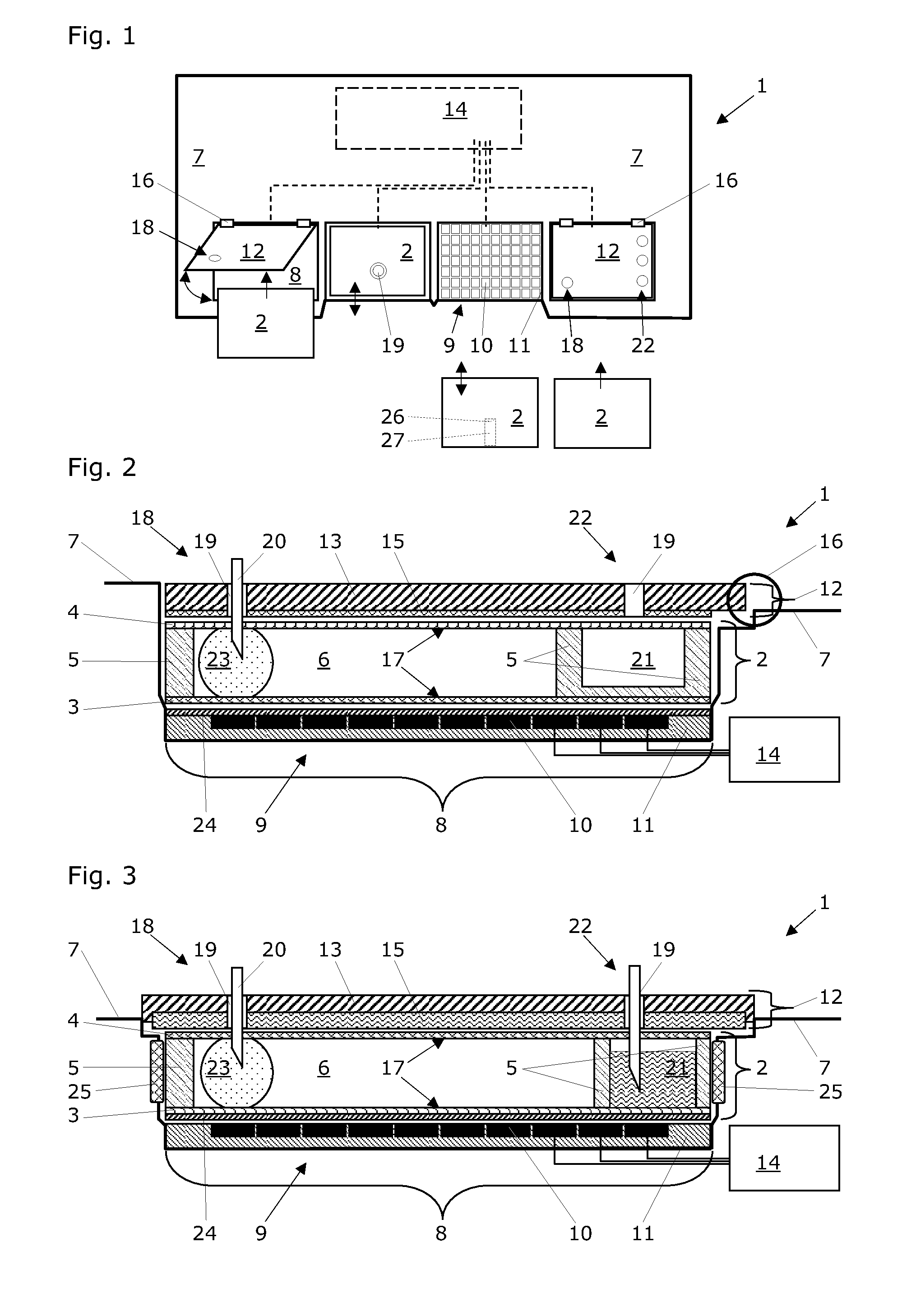

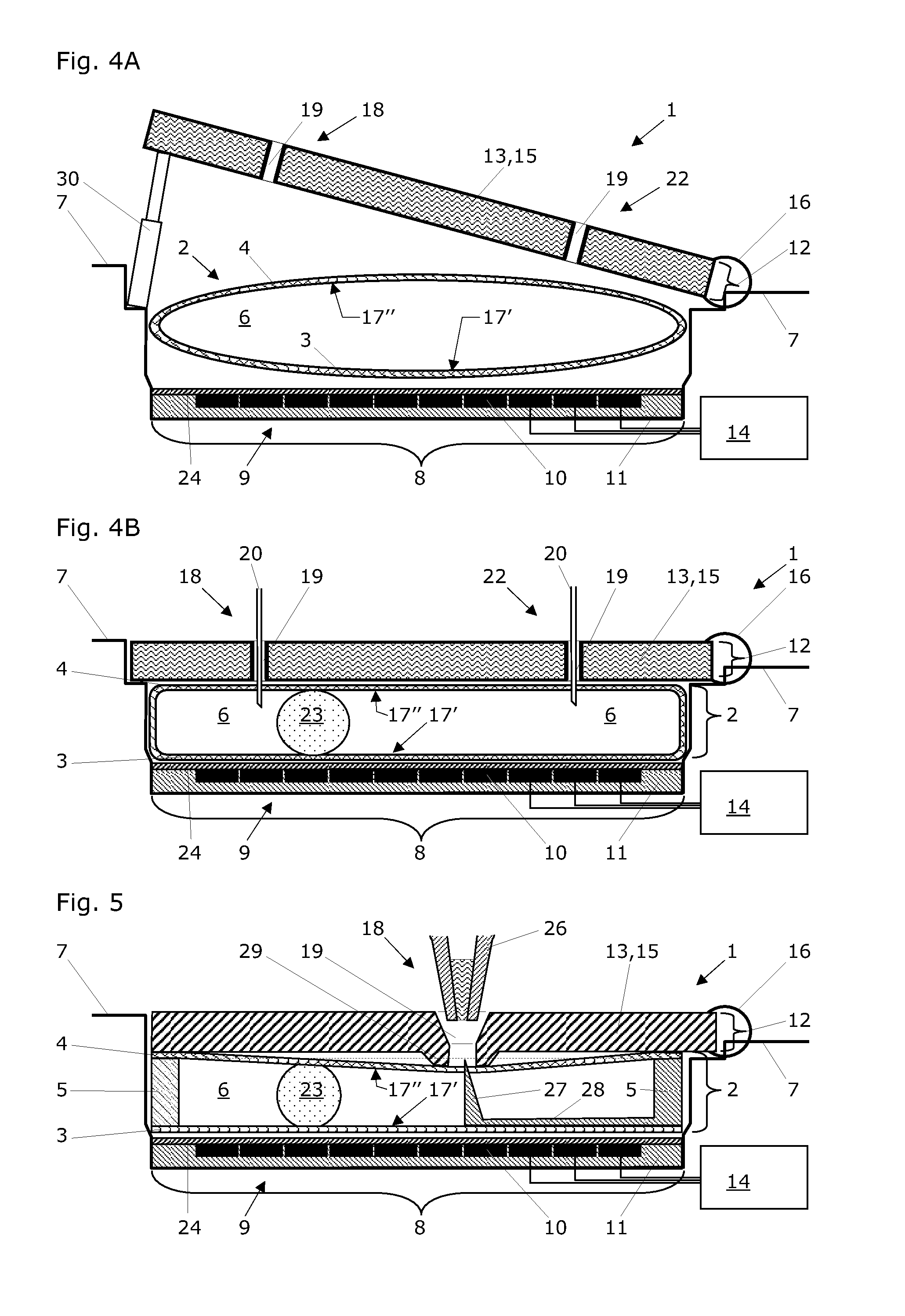

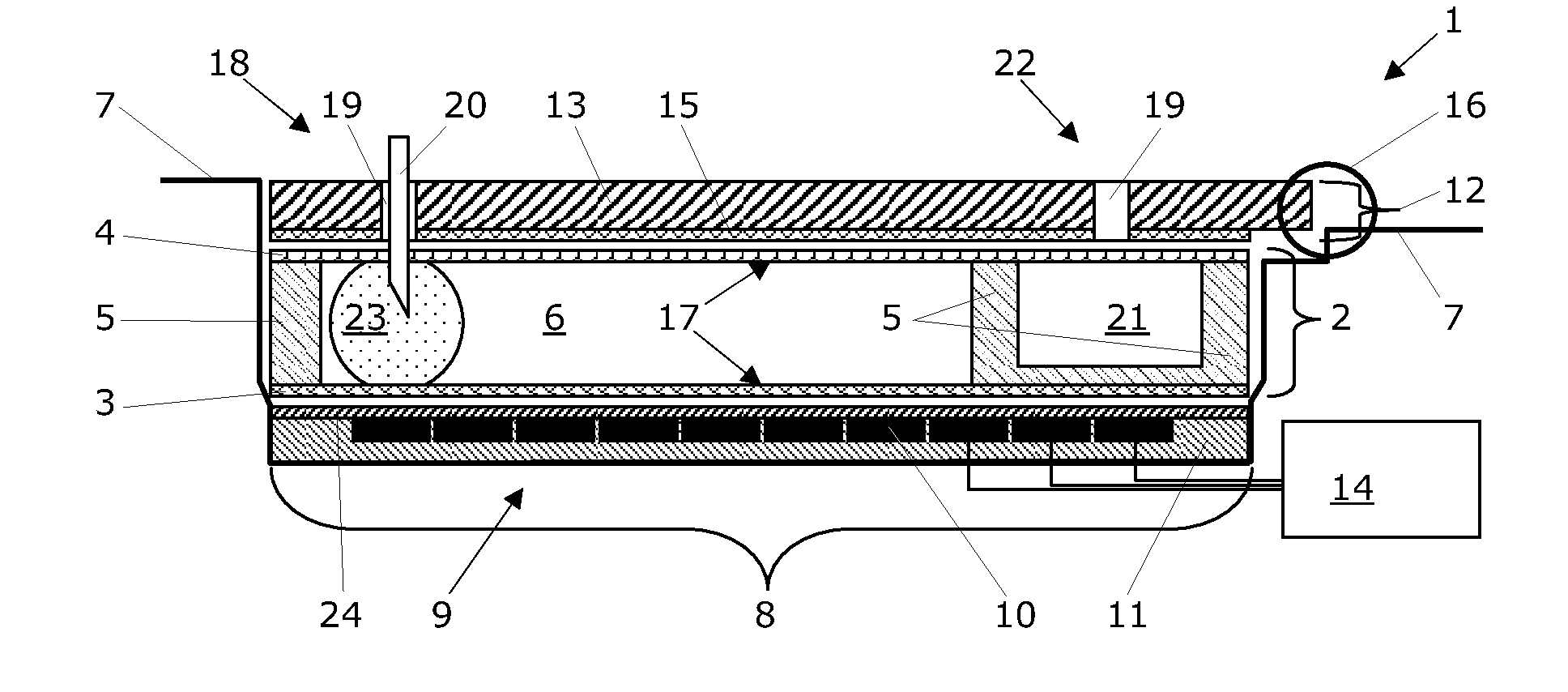

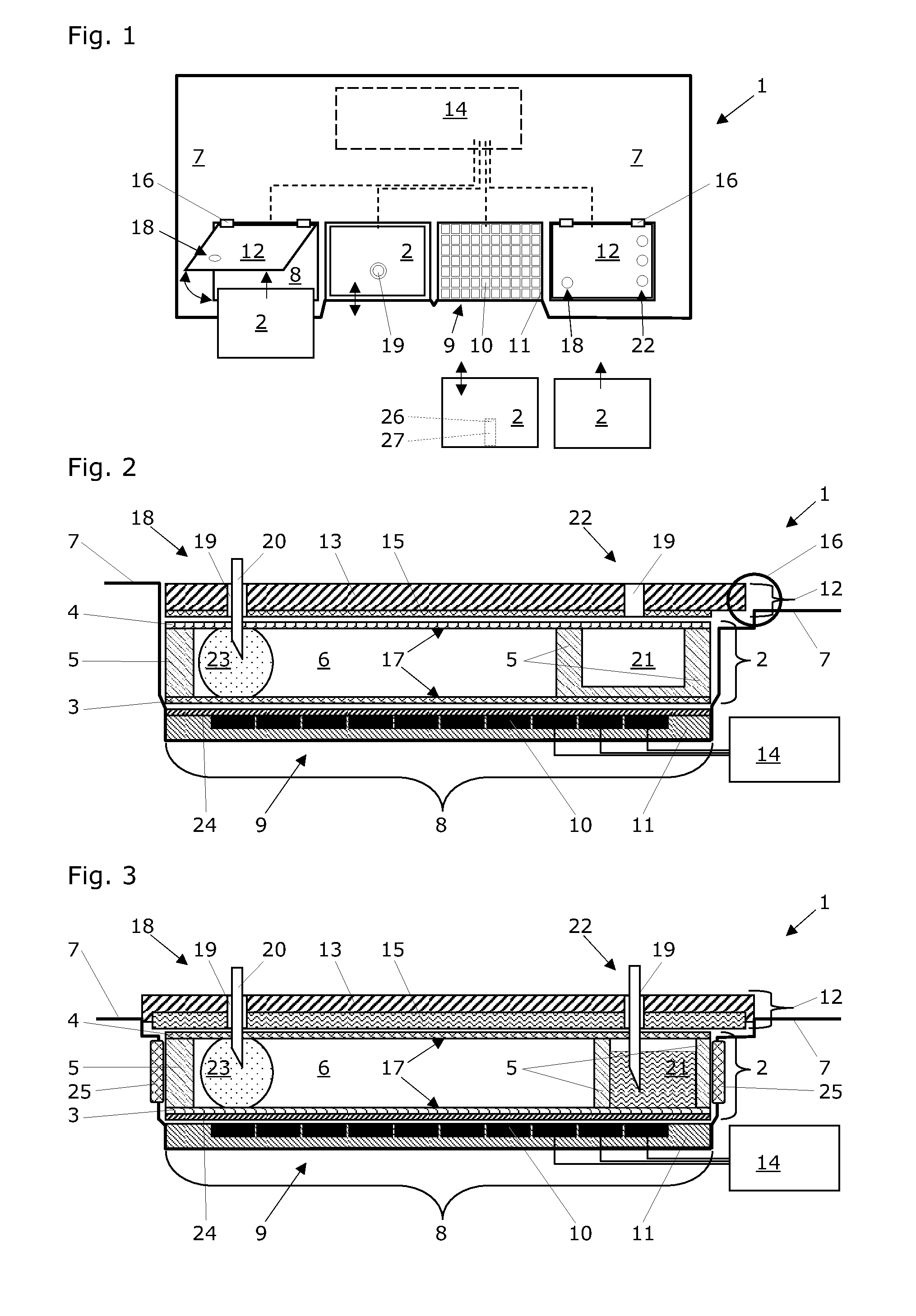

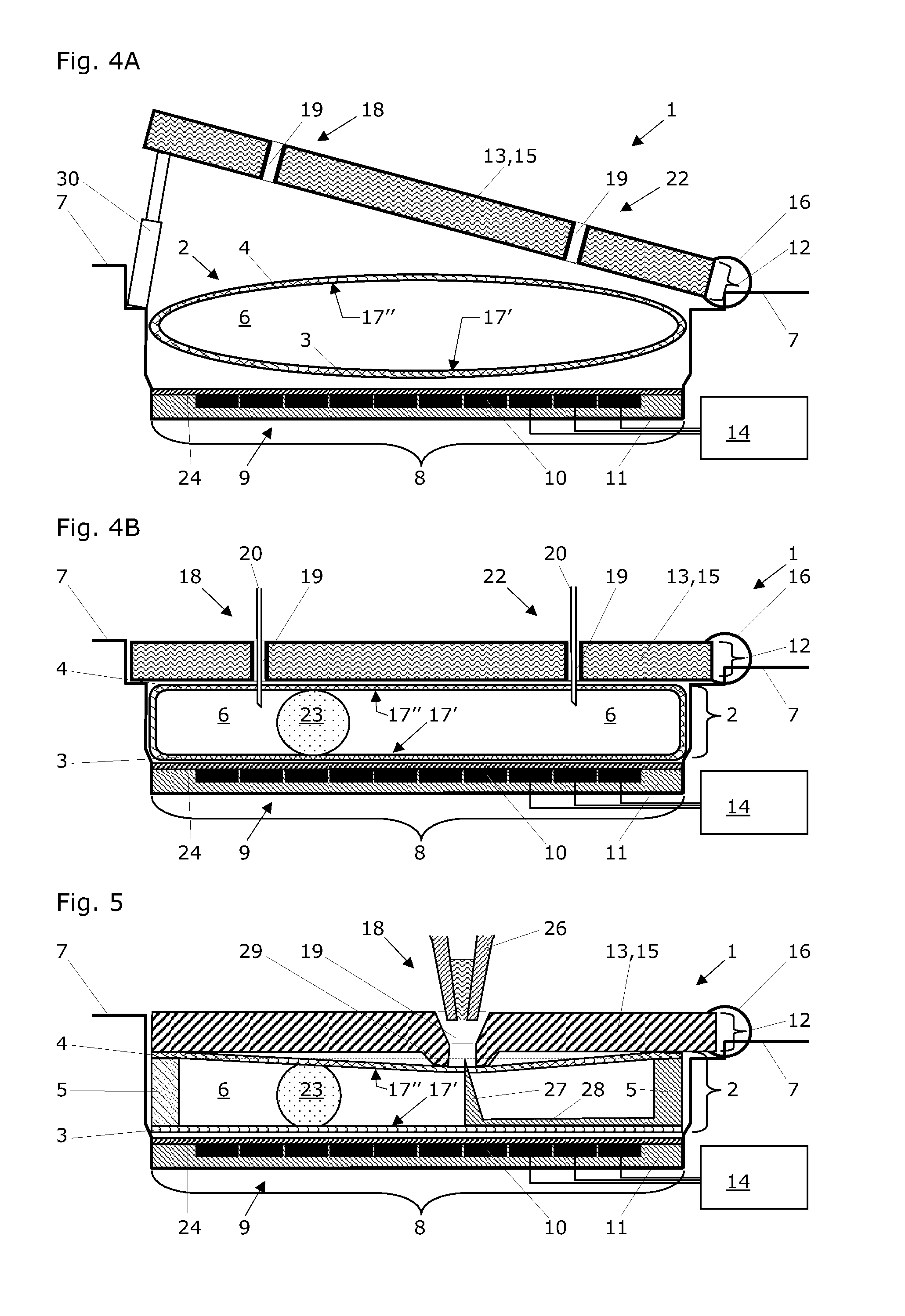

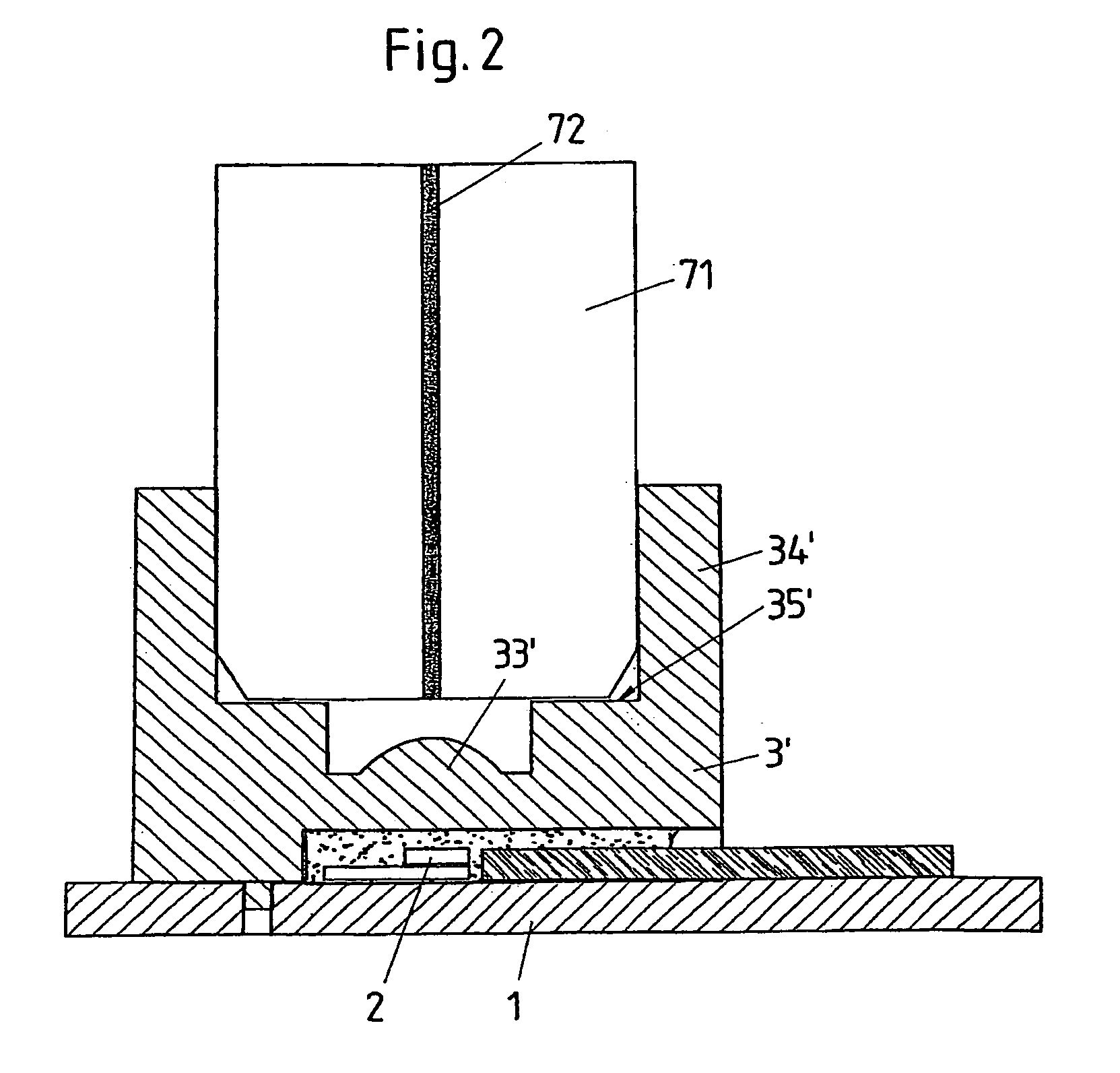

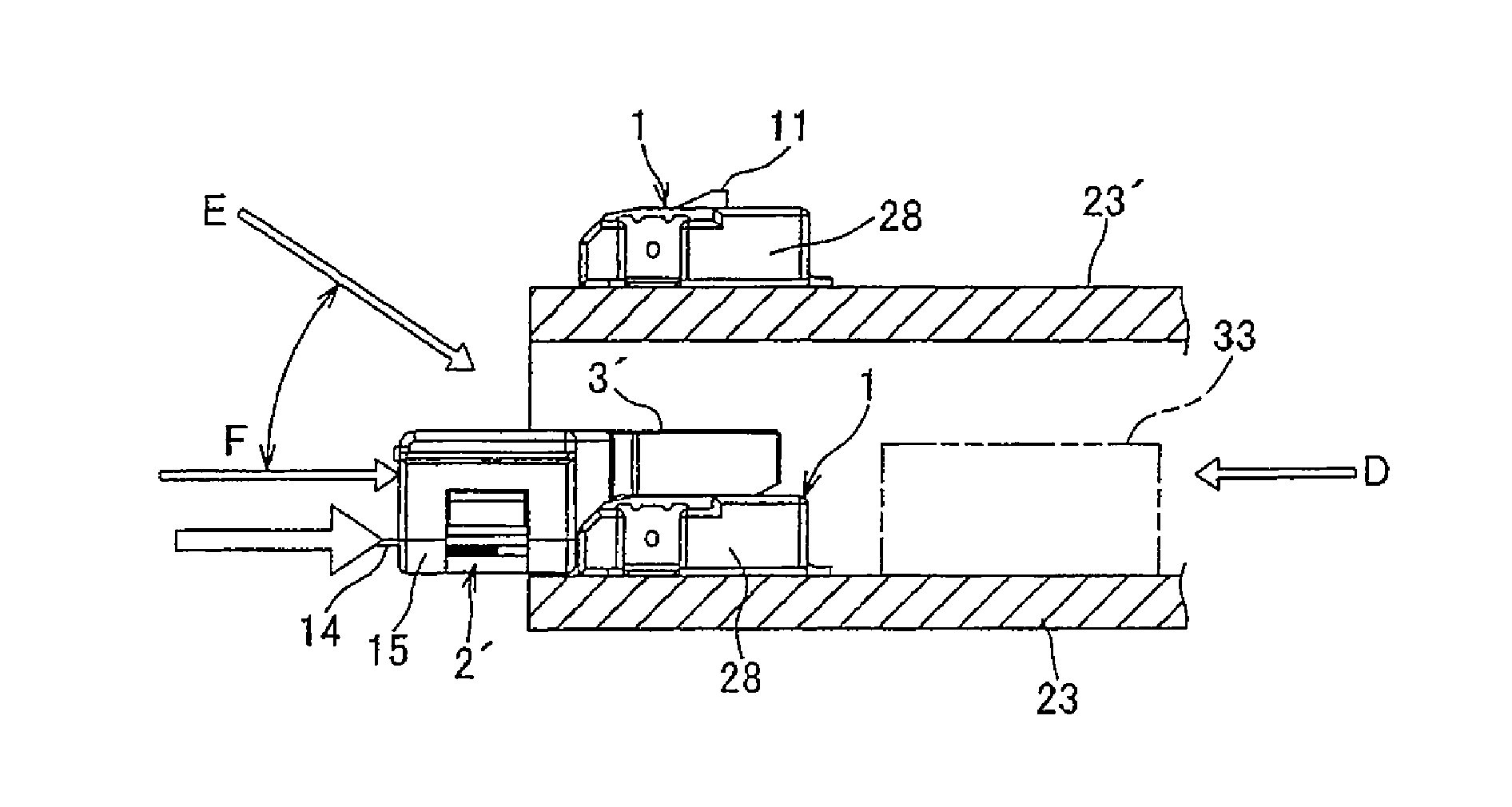

Digital microfluidics system with disposable cartridges

ActiveUS8821705B2Easy constructionSimple and low-cost constructionSludge treatmentVolume/mass flow measurementVoltage pulseEngineering

A digital microfluidics system manipulates samples in liquid droplets within disposable cartridges and has disposable cartridges each with a bottom layer, a top layer and a gap therebetween. A base unit with cartridge accommodation sites and at least one electrode array with electrodes works with a cover plate at the sites and a control unit for controlling selection of the electrodes and for providing them with voltage pulses for manipulating liquid droplets within the cartridges by electrowetting. The cover plate has an electrically conductive material that extends parallel to the array. A selection of disposable cartridges and a method for manipulating samples in liquid droplets that adhere to a hydrophobic surface can be used with the system.

Owner:TECAN TRADING AG

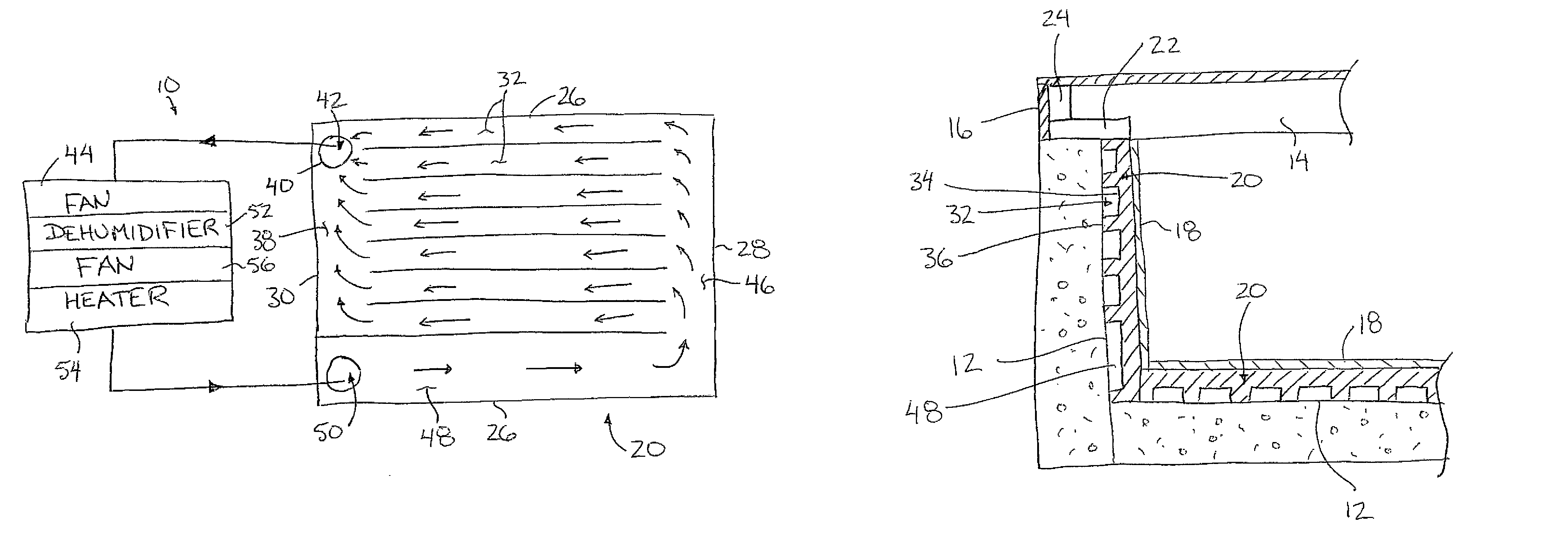

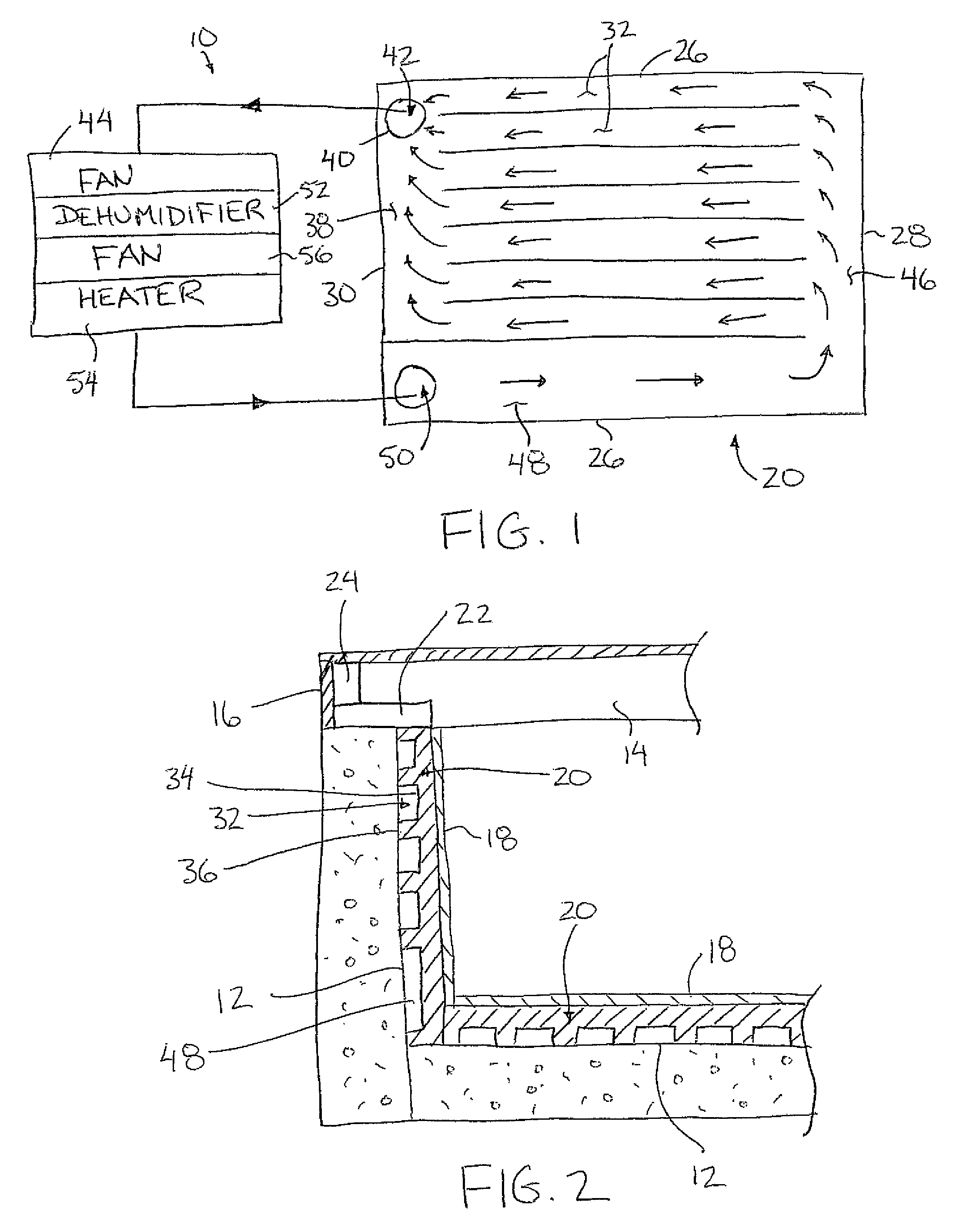

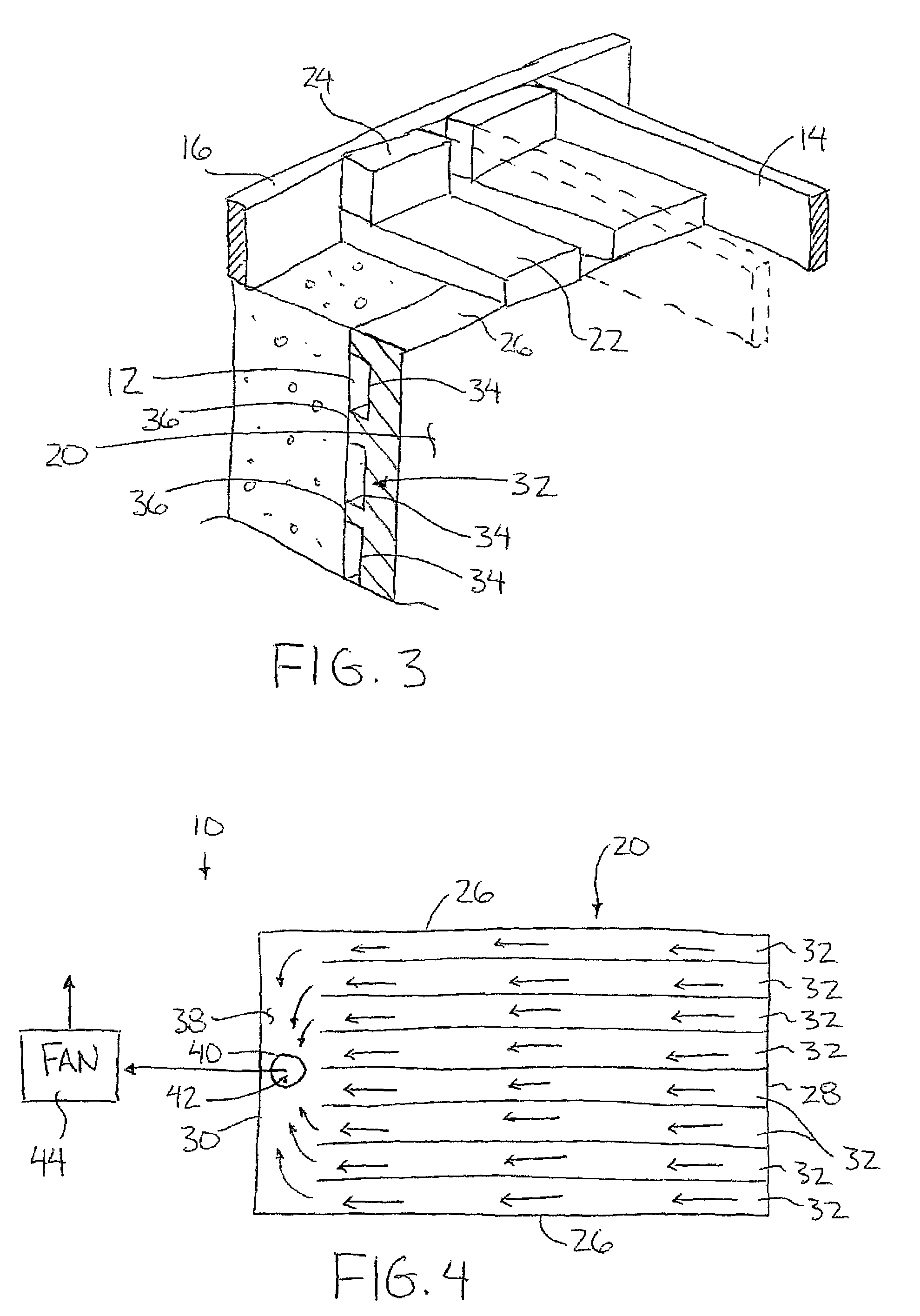

Moisture removal system

ActiveUS8056252B2EfficientlyEasy to installSpace heating and ventilationUsing liquid separation agentVacuum pressureEngineering

A sheathing layer spans a supporting surface from which moisture is to be removed. In one exemplary system, ventilation channels extend between opposed ends of the substrate layer, communicating with an outlet opening at one end and with a duct at the opposing end which in turn communicates with an inlet opening at the same end of the substrate layer as the outlet opening. A fan is arranged to circulate air through channels from the inlet opening to the outlet opening to replace humid air in the channels with drier replacement air. In another example, a substrate layer includes ventilation channels communicating only between the supporting surface and an outlet opening. The outlet opening connects to a fan which maintains the channels at a vacuum pressure to withdraw moisture therefrom.

Owner:FERNANDES JOAO PASCOA

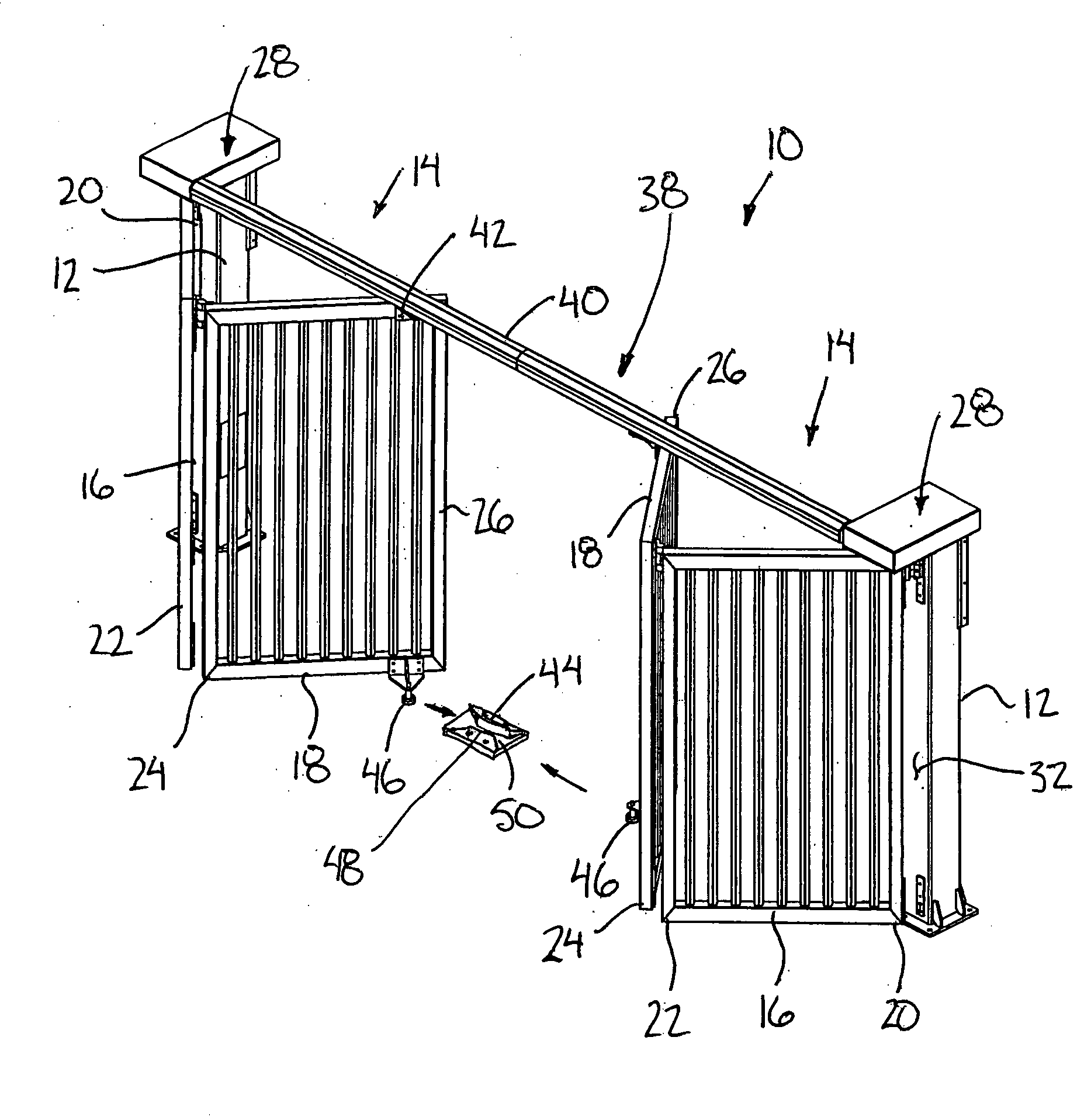

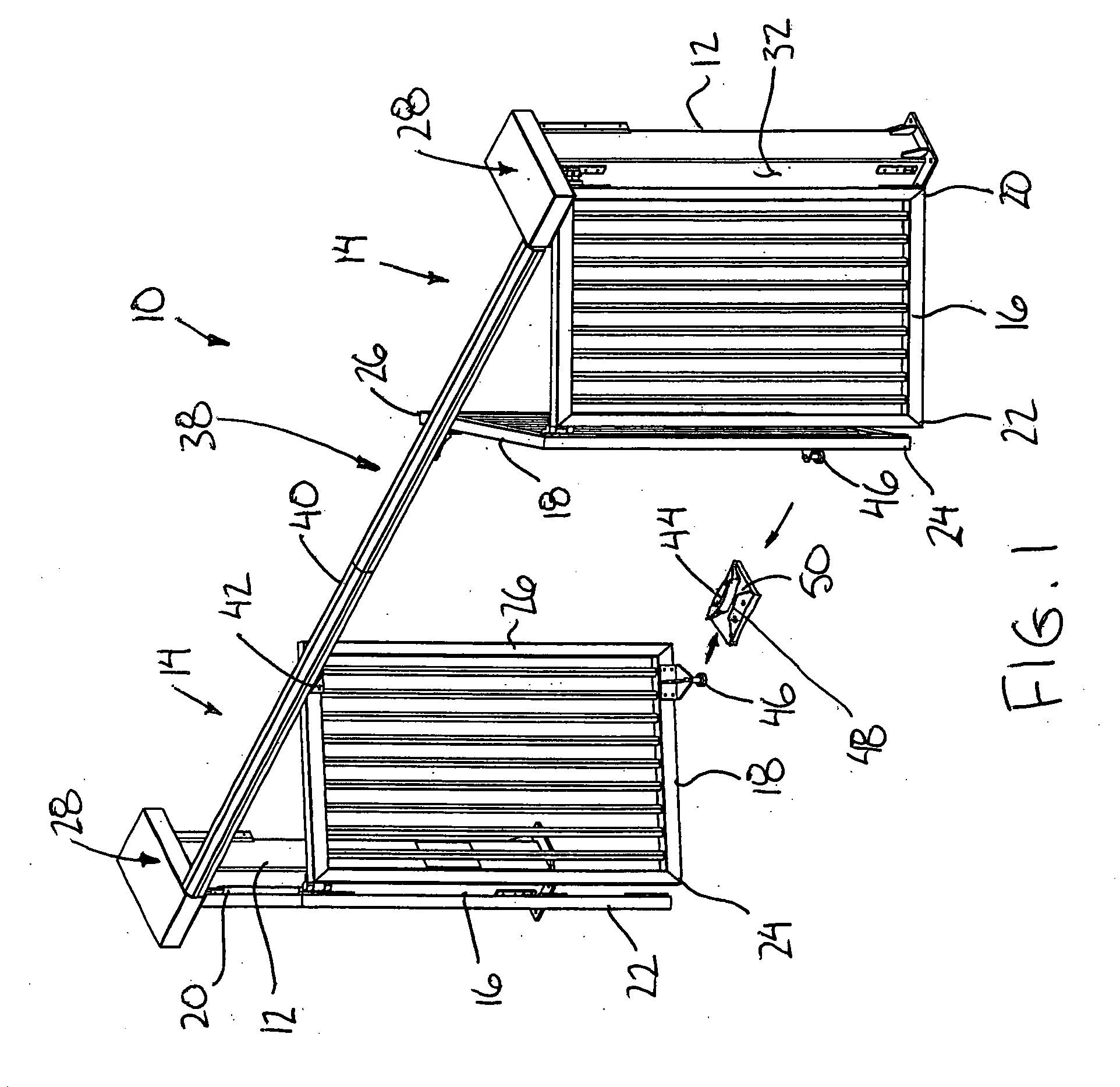

Security gate

InactiveUS20080216408A1Well formedEasy to installMan-operated mechanismPower-operated mechanismEngineeringElectrical and Electronics engineering

Owner:LETKEMAN JORDAN +3

Digital microfluidics system with disposable cartridges

ActiveUS20130134039A1Easy constructionSimple and low-cost constructionSludge treatmentVolume/mass flow measurementVoltage pulseControl selection

A digital microfluidics system manipulates samples in liquid droplets within disposable cartridges and has disposable cartridges each with a bottom layer, a top layer and a gap therebetween. A base unit with cartridge accommodation sites and at least one electrode array with electrodes works with a cover plate at the sites and a control unit for controlling selection of the electrodes and for providing them with voltage pulses for manipulating liquid droplets within the cartridges by electrowetting. The cover plate has an electrically conductive material that extends parallel to the array. A selection of disposable cartridges and a method for manipulating samples in liquid droplets that adhere to a hydrophobic surface can be used with the system.

Owner:TECAN TRADING AG

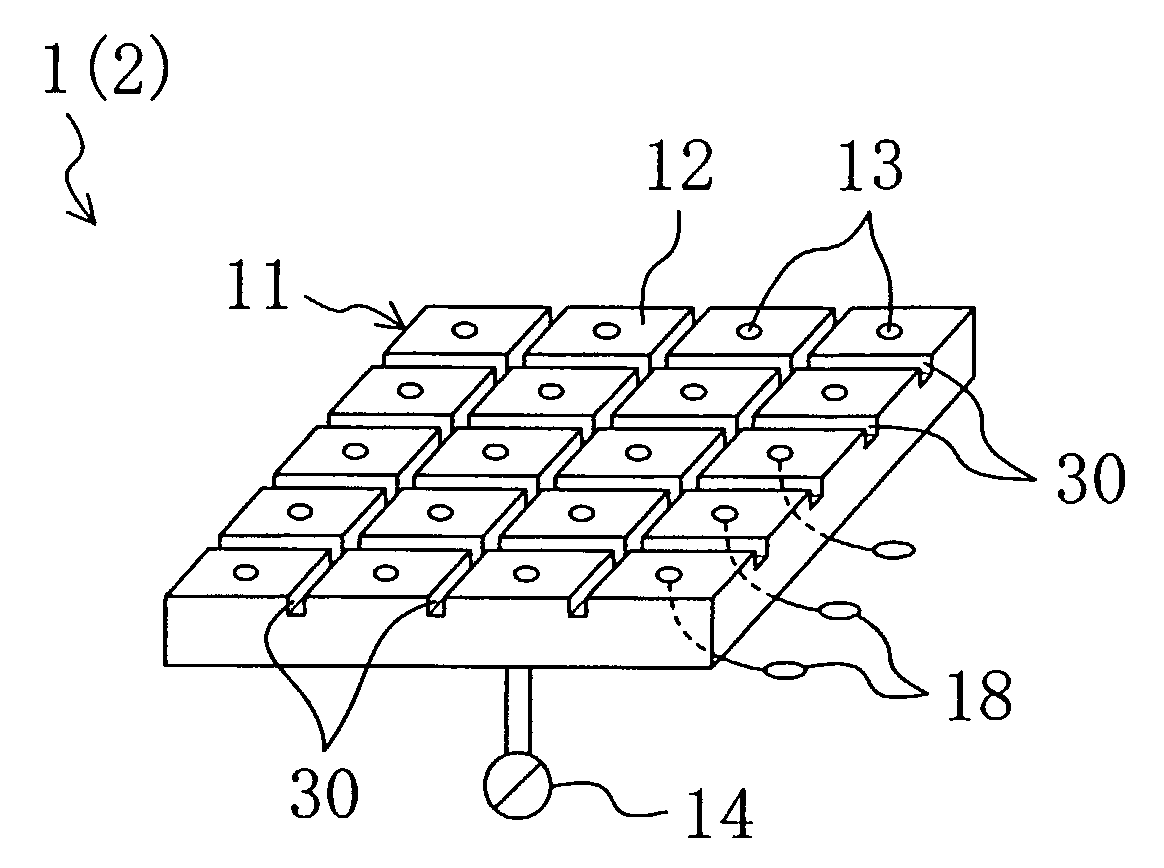

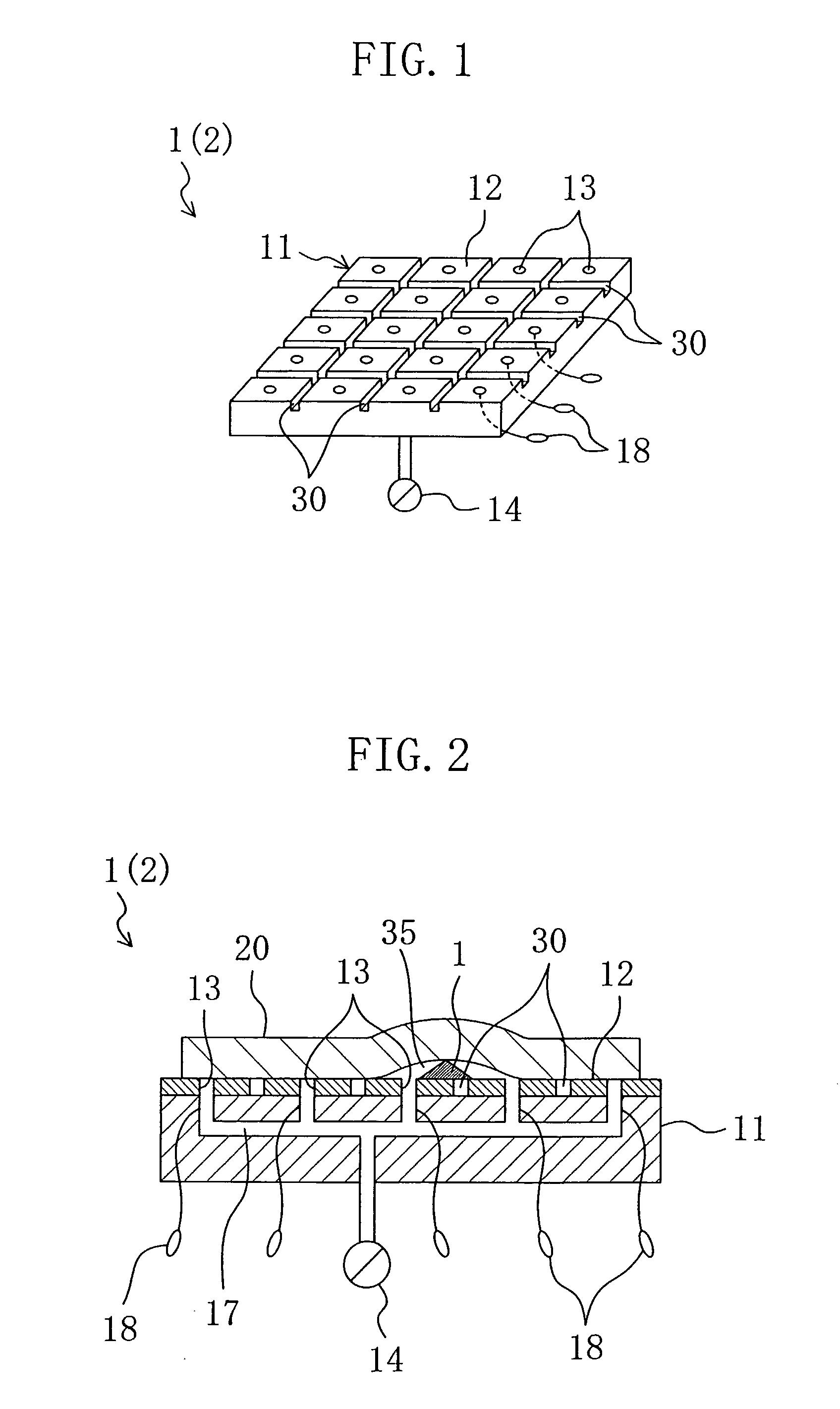

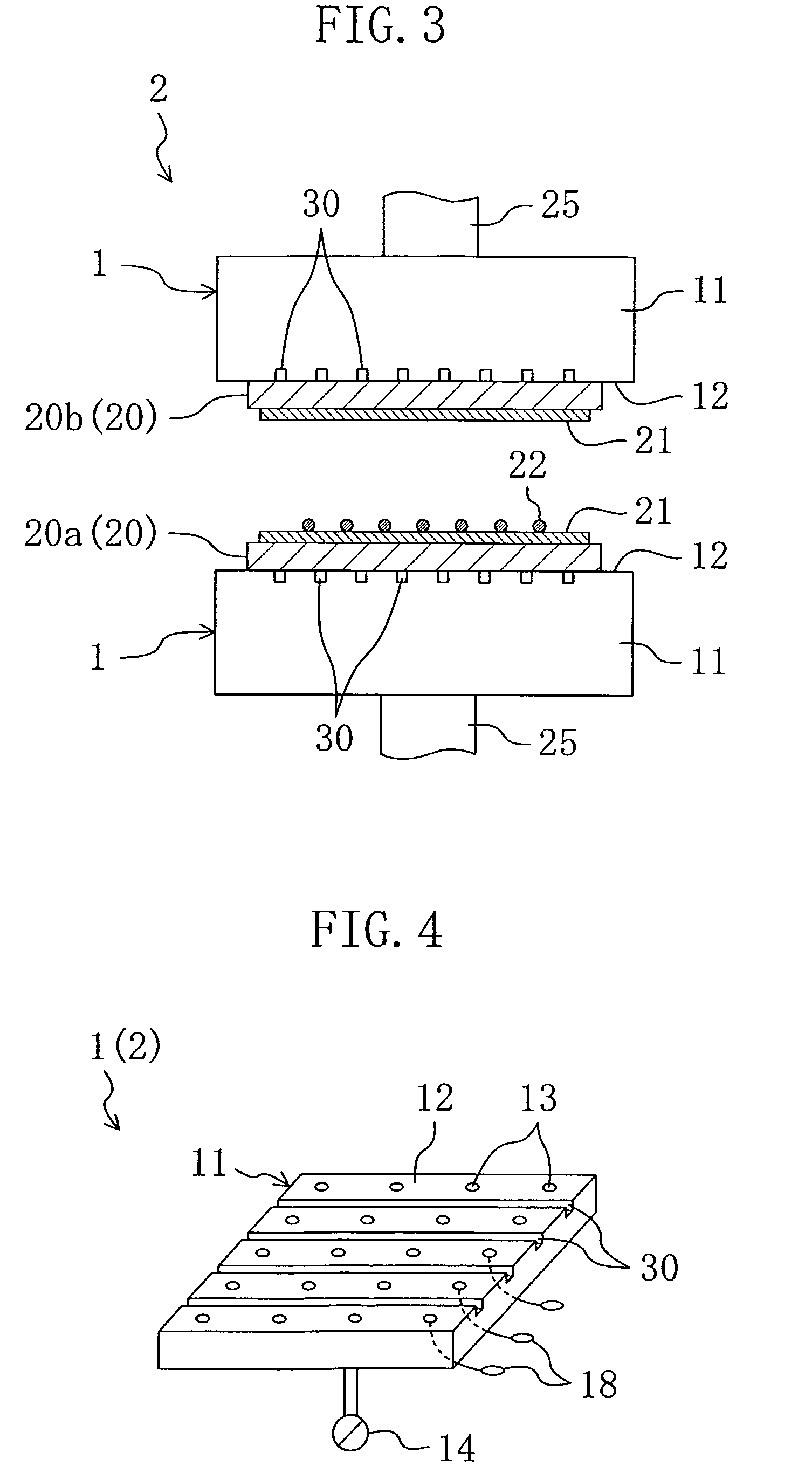

Substrate adsorption device and substrate bonding device

InactiveUS20070158031A1Securely holdPreventing a flaw on a substrateSemiconductor/solid-state device manufacturingLaminationForeign matterEngineering

A substrate adsorption device 1 includes: a stage 11 having an adsorption face 12 for holding a substrate 20; a plurality of adsorption ports 13 formed in a region of the adsorption face 12 of the stage 11; and a vacuum pump 14 connected to each adsorption port through an air discharge path 17. A pressure sensor 18 for detecting the pressure in the air discharge path 17 is provided, and a plurality of leak trenches 30 open to both the adsorption face 12 of the stage 11 and a side face of the stage 11 are formed in a region of the stage 11 except the region where the adsorption ports 13 are formed. With such a low-cost and simple structure, a foreign matter 15, which is a factor of inviting damage to the substrate 20, is detected, to prevent damage to the substrate 20.

Owner:SHARP KK

Vehicular crash attenuator

InactiveUS7438337B1Limited protectionSimple and low cost constructionPasturing equipmentElastic dampersModularityTruck

A truck mounted attenuator (TMA) is constructed to minimize length during use in a horizontal position and height in a vertical transport position, as well as to minimize wind resistance and buffeting at highway speeds. A modular construction is employed, so that only damaged portions of the TMA can be removed and replaced in the field after a vehicle impact. The TMA comprises a plurality of outwardly curved tubular structural members which are designed to buckle upon application to the TMA of forces resulting from vehicular impact. The rigid tubes buckle at a high initial force, then proceed to crush at a lower force once the sides have buckled outwardly sufficiently to protect vehicle occupants during the critical first two feet of travel after impact. This design also provides increased protection for errant vehicles which impact the TMA device from an angle (i.e. “coffin corner” impact).

Owner:TRAFFIX DEVICES INC

Seatbelt use indicating apparatus and method

InactiveUS7199703B2Easy to identifySimple and low-cost constructionDigital data processing detailsBelt control systemsEngineering

Owner:TOYOTA JIDOSHA KK

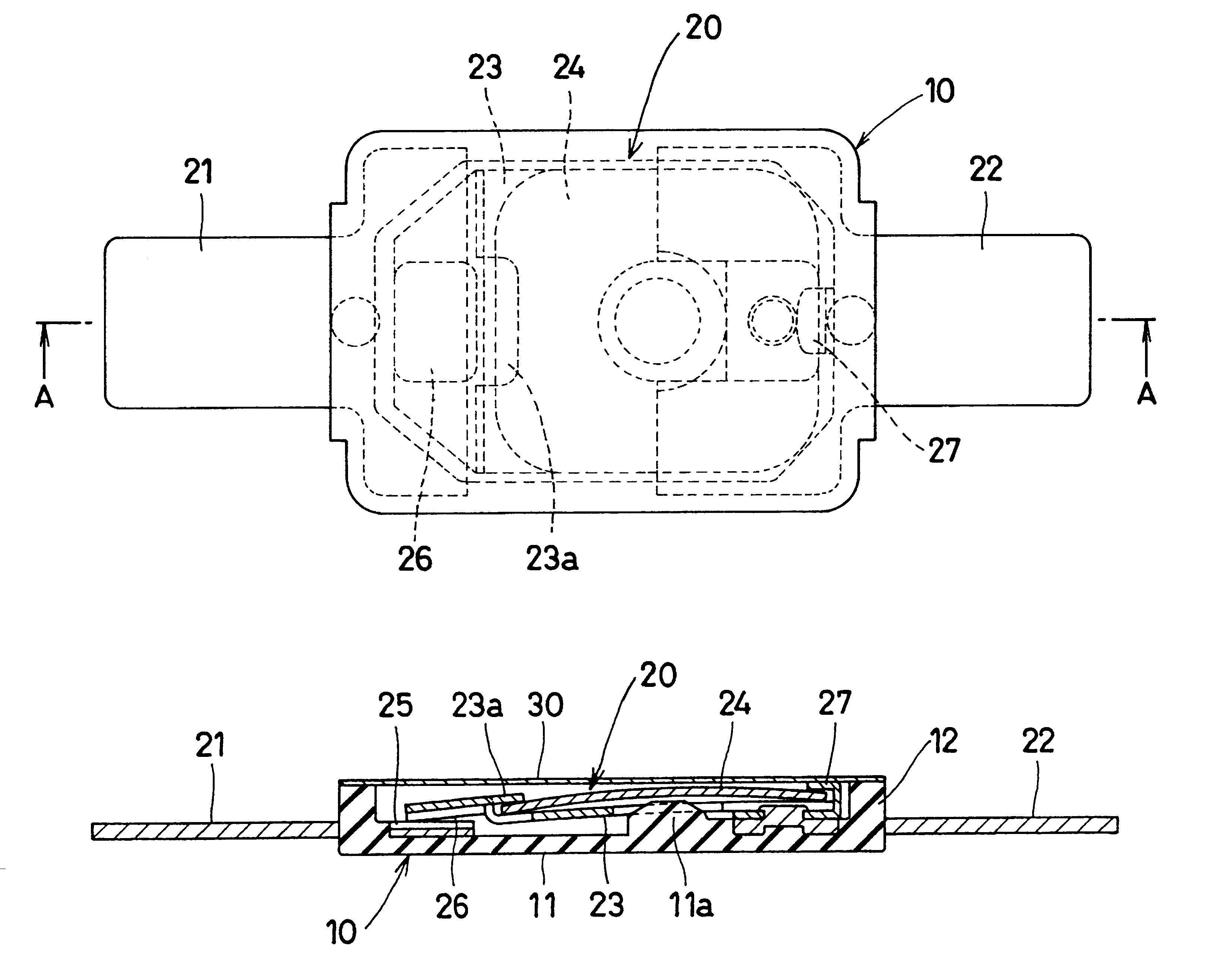

Thermal protector

InactiveUS6597273B2Improve sealingSimple and low-cost constructionHeating/cooling contact switchesThermal switch detailsExternal connectionProjector

A thermal projector includes a switching mechanism section having a fixed contact, a movable contact disposed so as to face the fixed contact. There are first and second external connection terminals projecting sideward and connected electrically to the fixed contact and movable contact, respectively. The switching mechanism section is constructed so that the movable contact is displaced by a deforming operation of a thermally-actuated element so as to be separated from and brought into contact with the fixed contact. A resin bottomed case having a peripheral wall is located around the switching mechanism section in a manner so that the first and second external connection terminals penetrate the peripheral wall, and the penetrating portions are adhesively sealed by molding the peripheral wall integrally with the connection terminals. There is a film formed member of an electric insulating material. The cover member is adhesively fixed to the upper end face of the peripheral wall of the case so as to seal the upper opening of the case.

Owner:UCHIYA THERMOSTAT

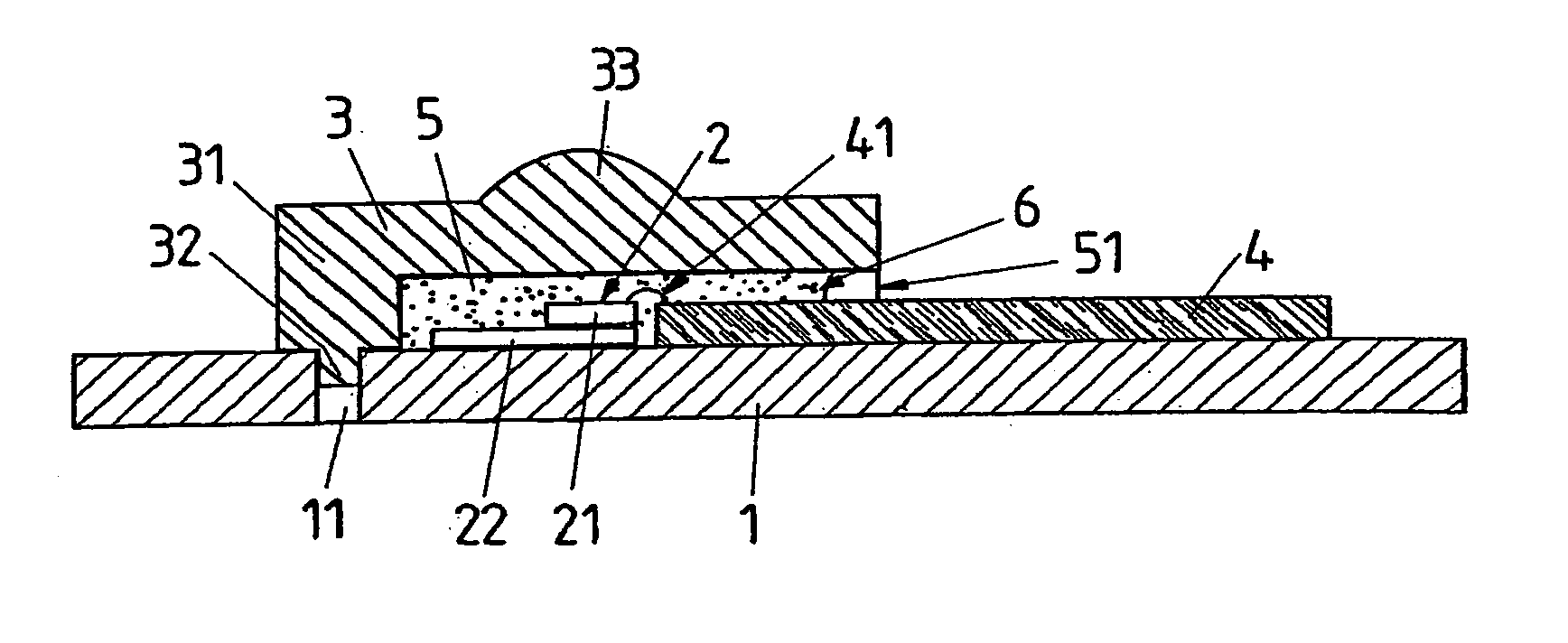

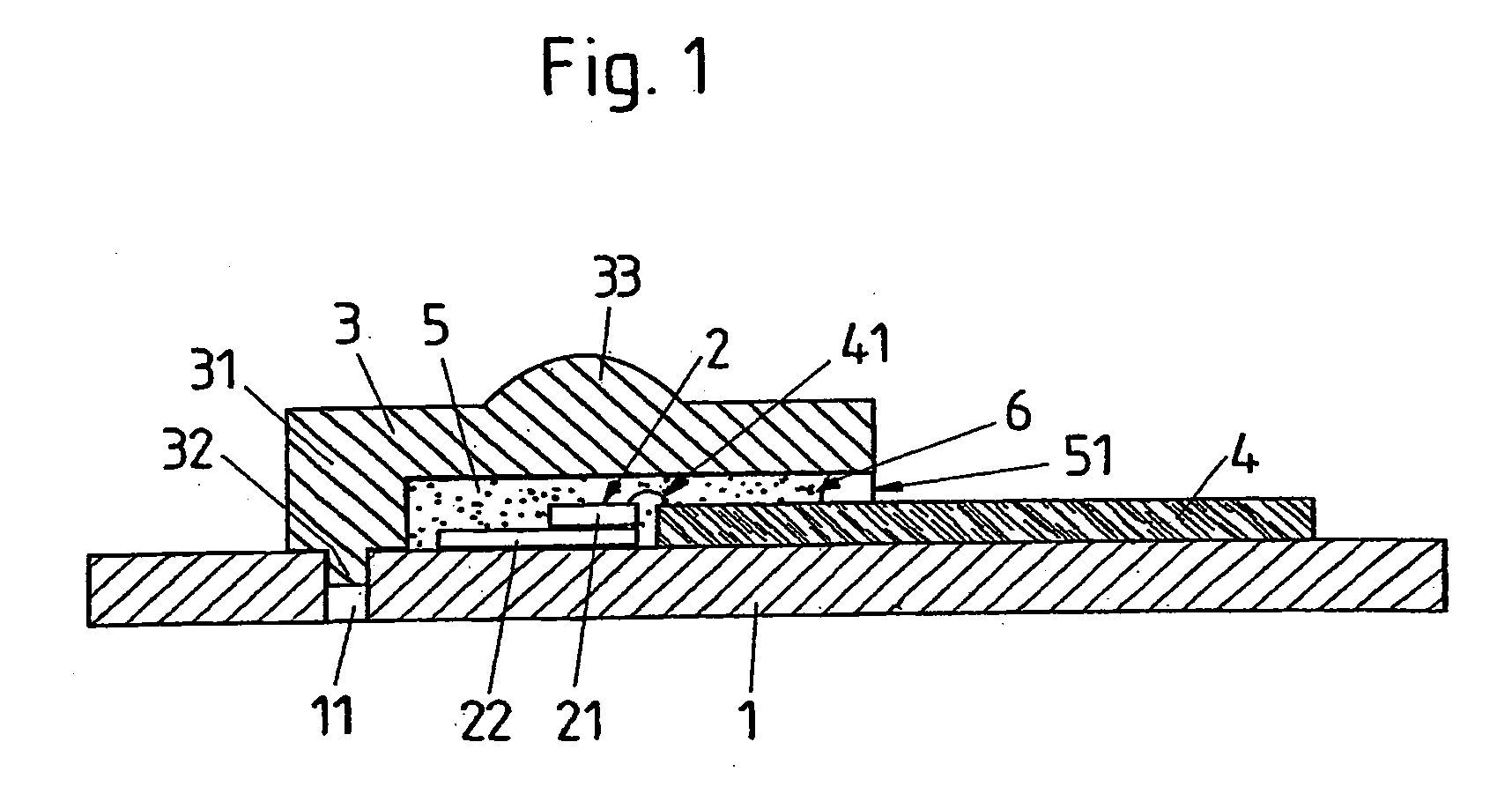

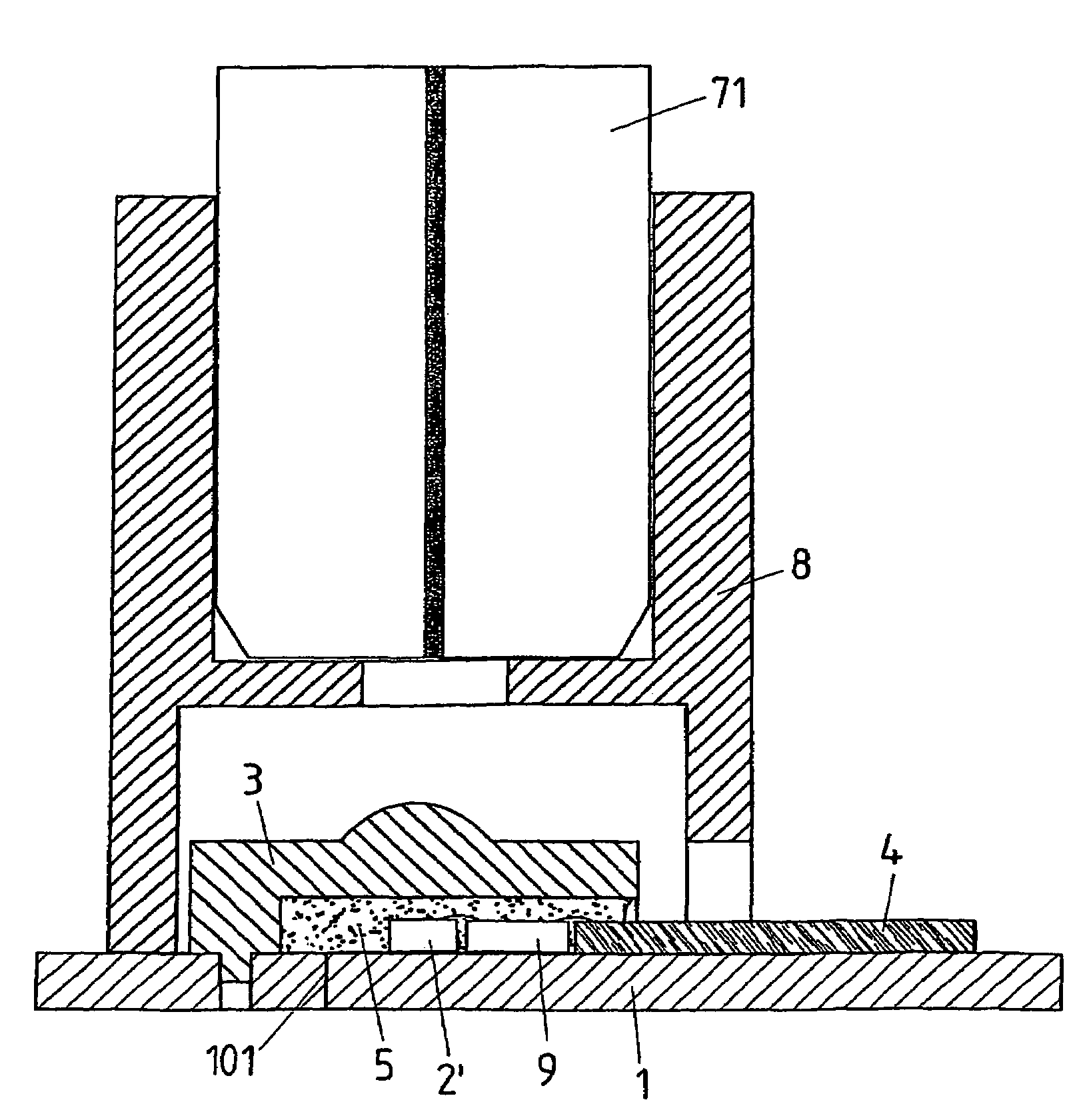

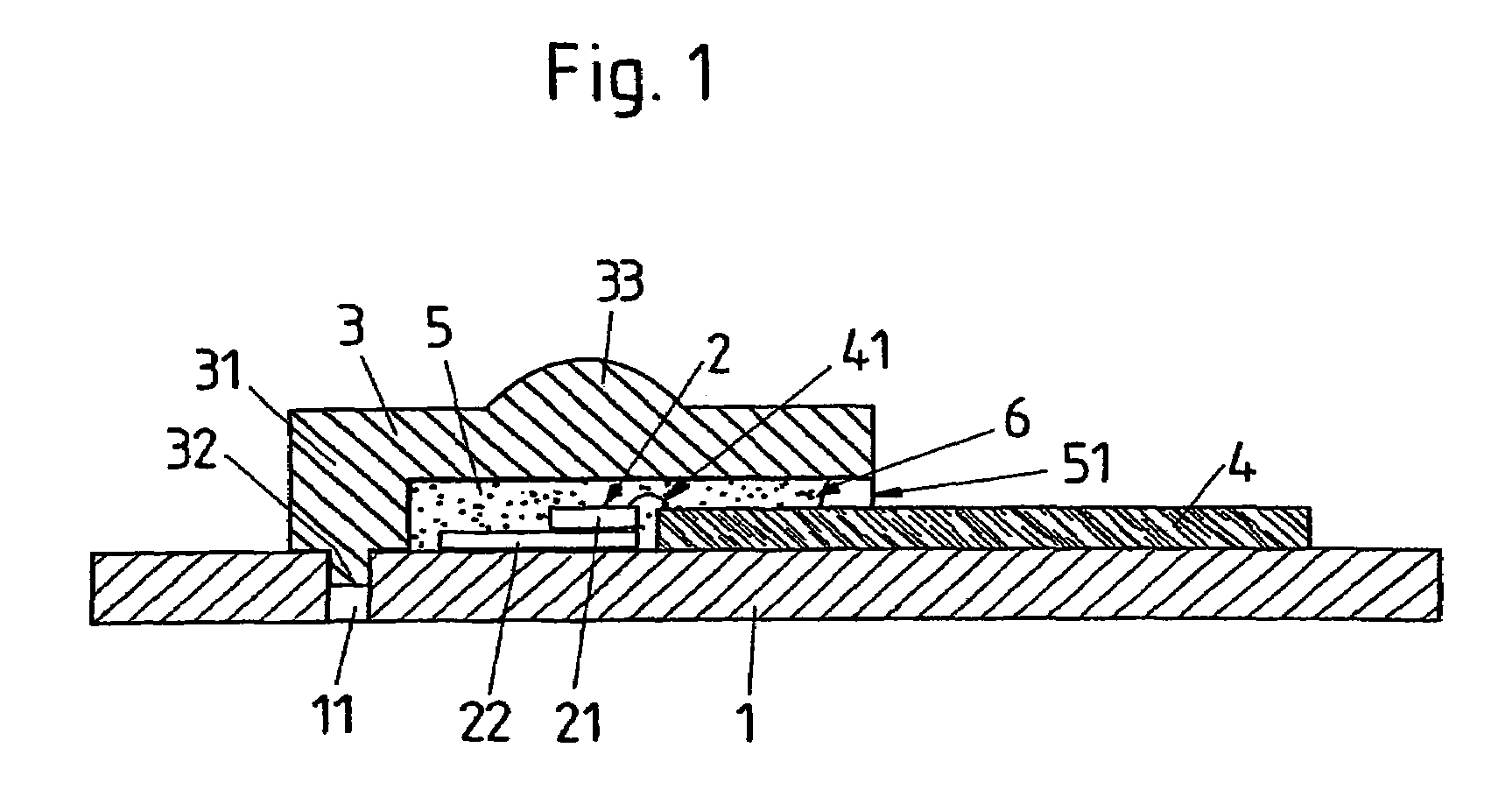

Transmitter and/or receiver arrangement of optical signal trasmission

InactiveUS20050036732A1Prevent returnEnhanced radiationSolid-state devicesCoupling light guidesEngineeringTransmitter

An optical transmitting and / or receiving arrangement including an optical element mounted in an intermediate space between a base plate and a lens. The lens is supported by a structure that is mounted on the base plate, and a carrier element mounted on the base plate and has an end portion extending through an opening formed in the structure and into the intermediate space. The end portion of the carrier element is positioned adjacent to the optical element, and includes electrical feed lines that are connected to the optical element by wires or bands. A transparent casting compound is then injected through the opening into the intermediate space.

Owner:II VI DELAWARE INC

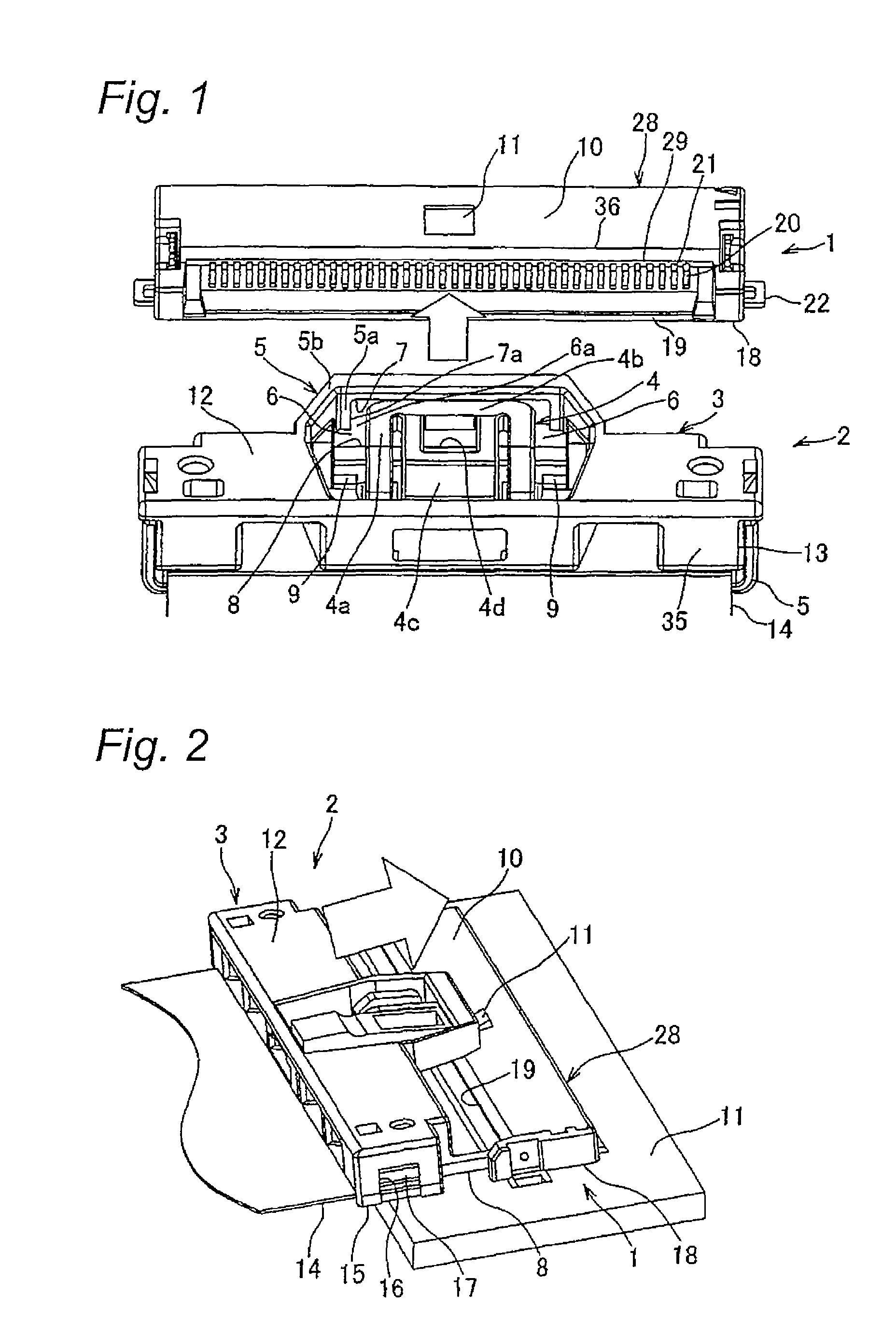

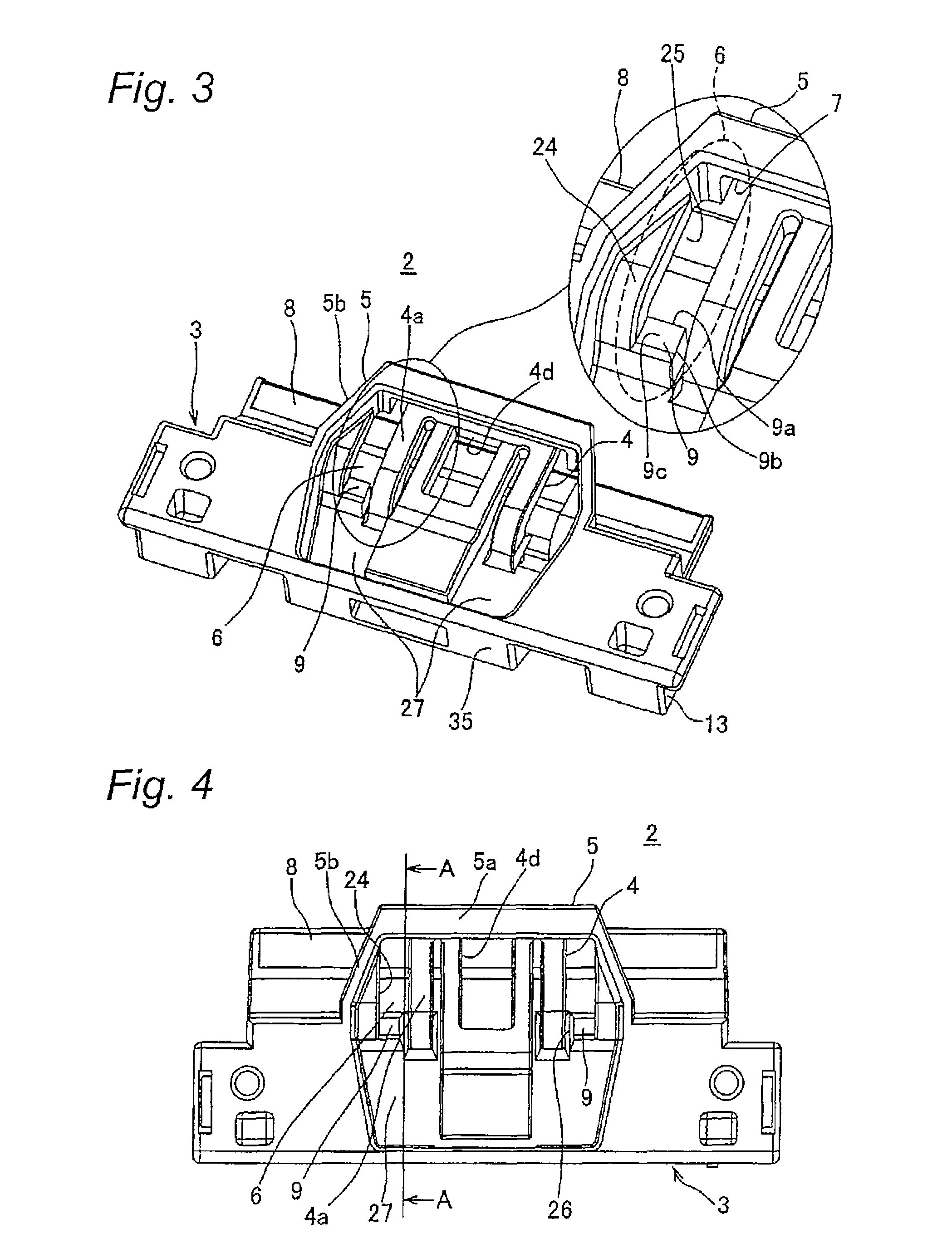

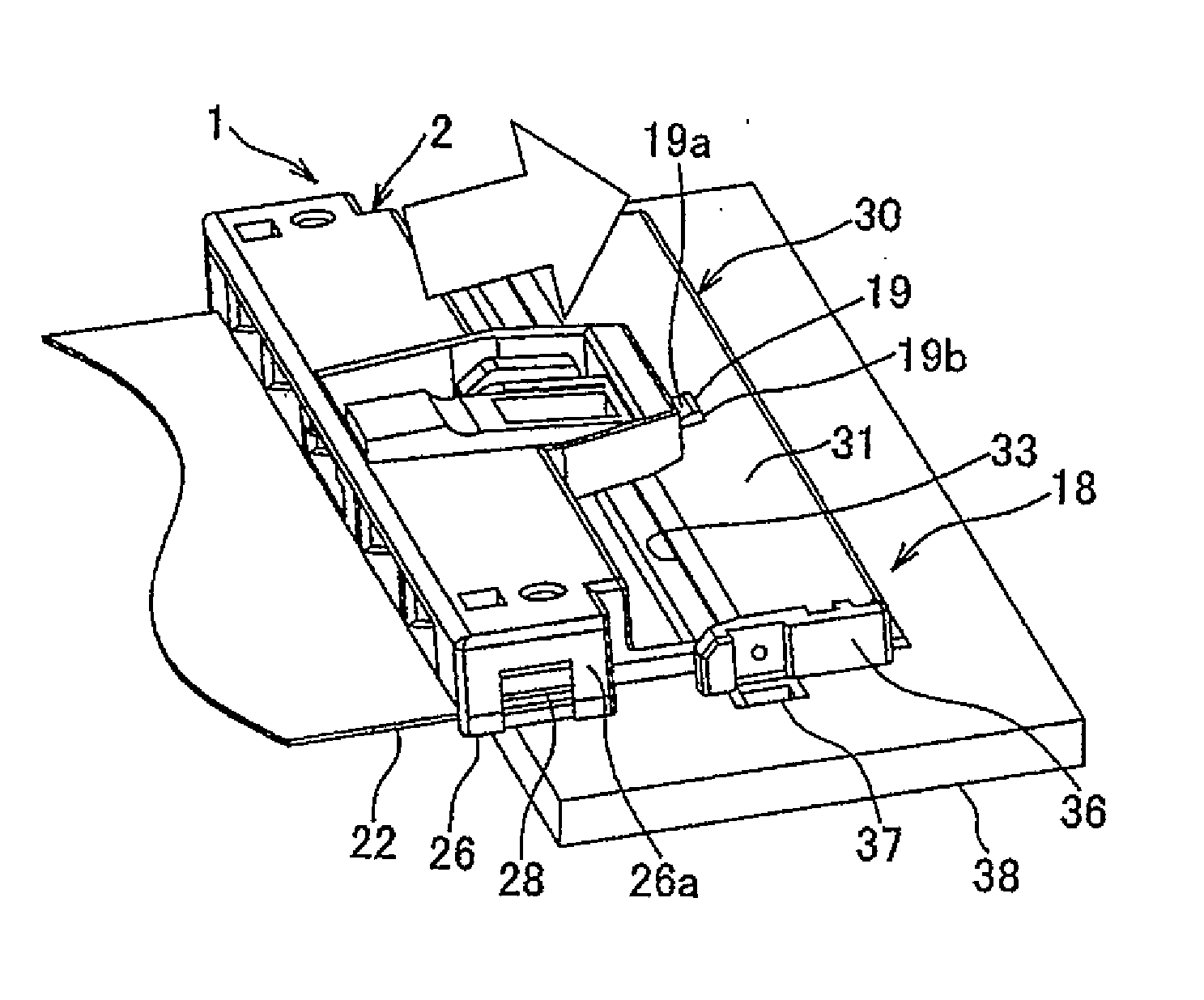

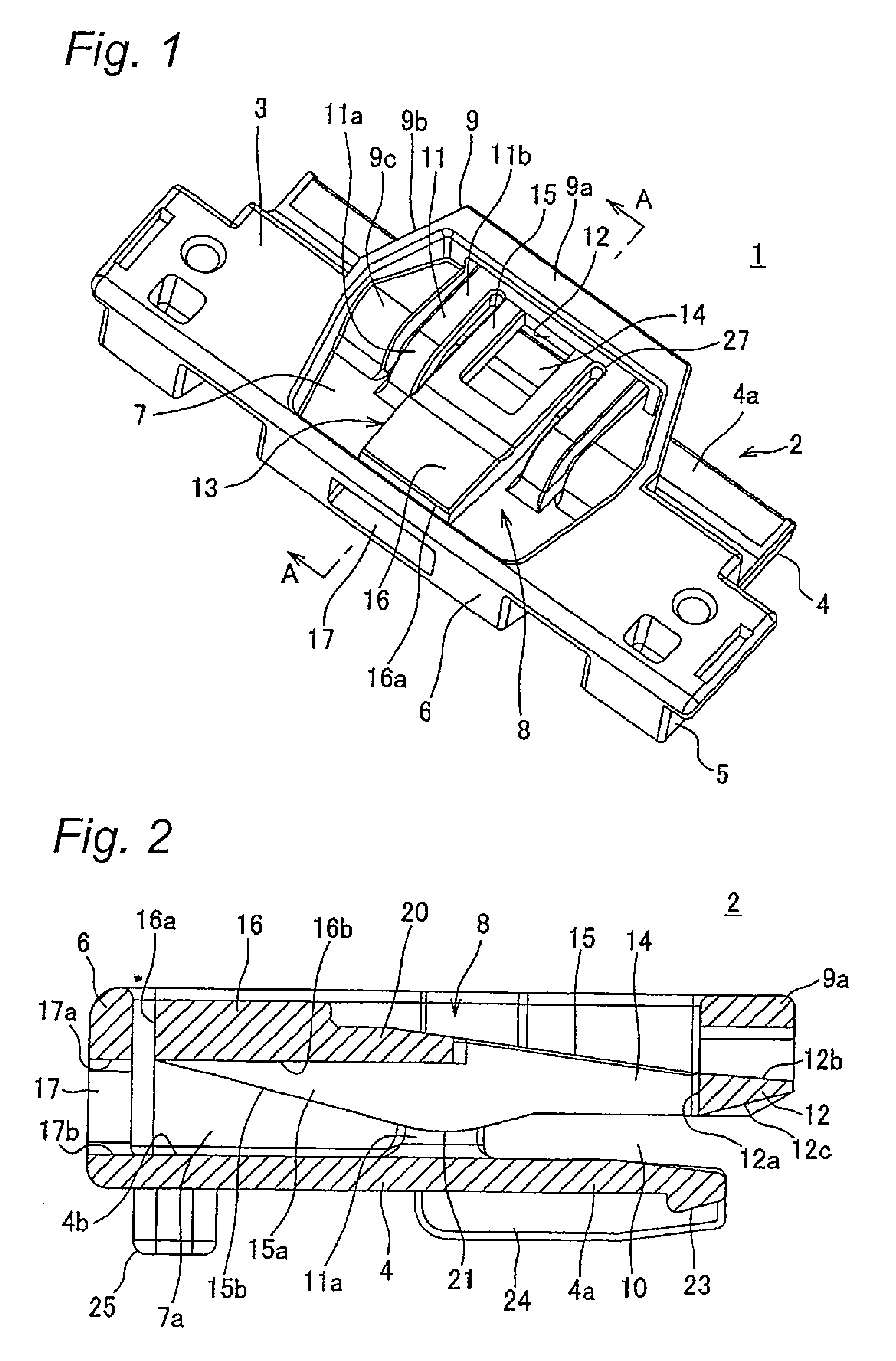

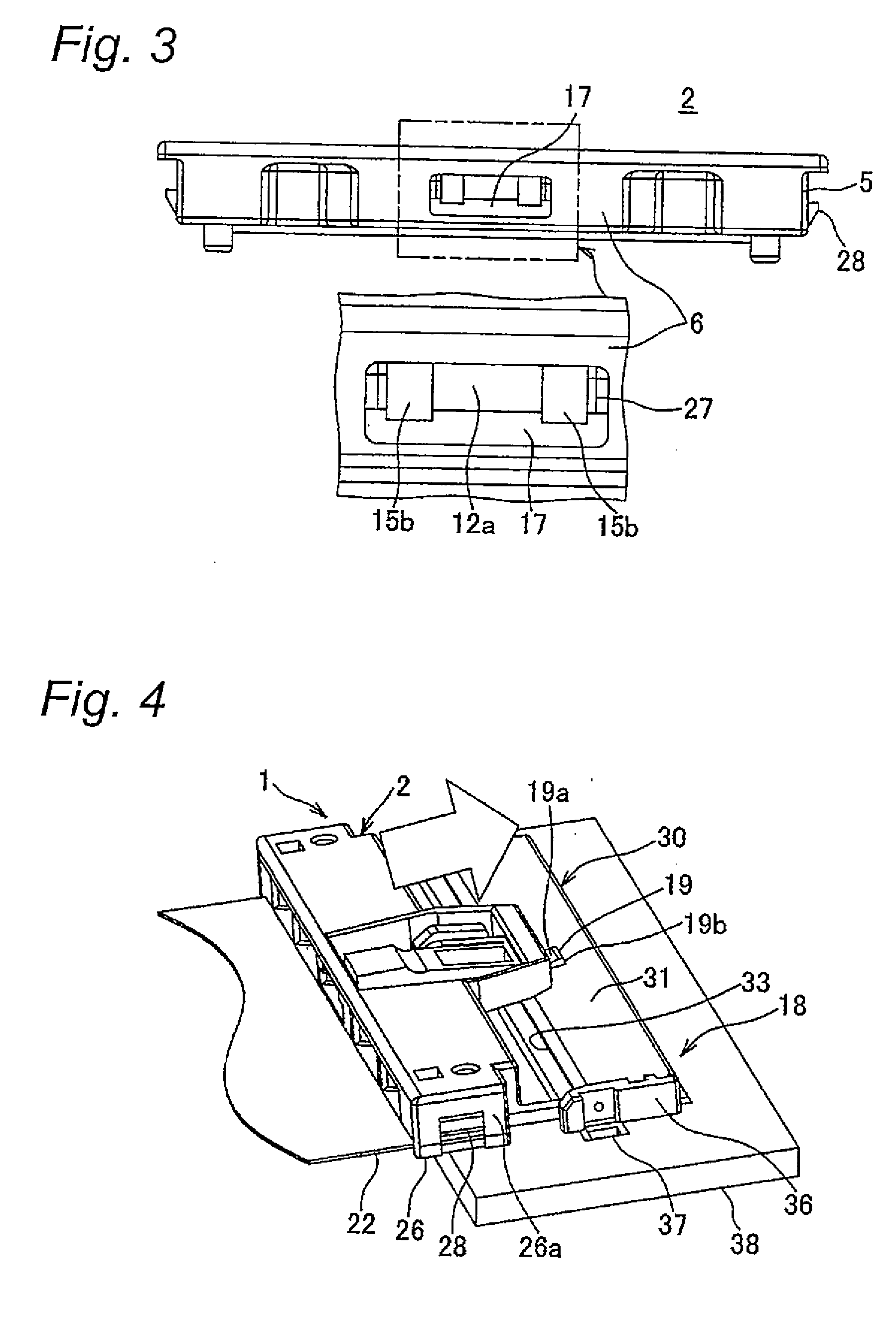

Fitting confirmation construction of connector for connecting circuit board

ActiveUS8758043B2Simple and low-cost constructionEasy constructionEngagement/disengagement of coupling partsElectrically conductive connectionsElectrical and Electronics engineeringBuilding construction

Owner:YAZAKI CORP

Fitting confirmation construction for connectors

ActiveUS20130005172A1Simple and low-cost constructionEasy to detectCoupling device detailsMechanical engineering

Owner:YAZAKI CORP

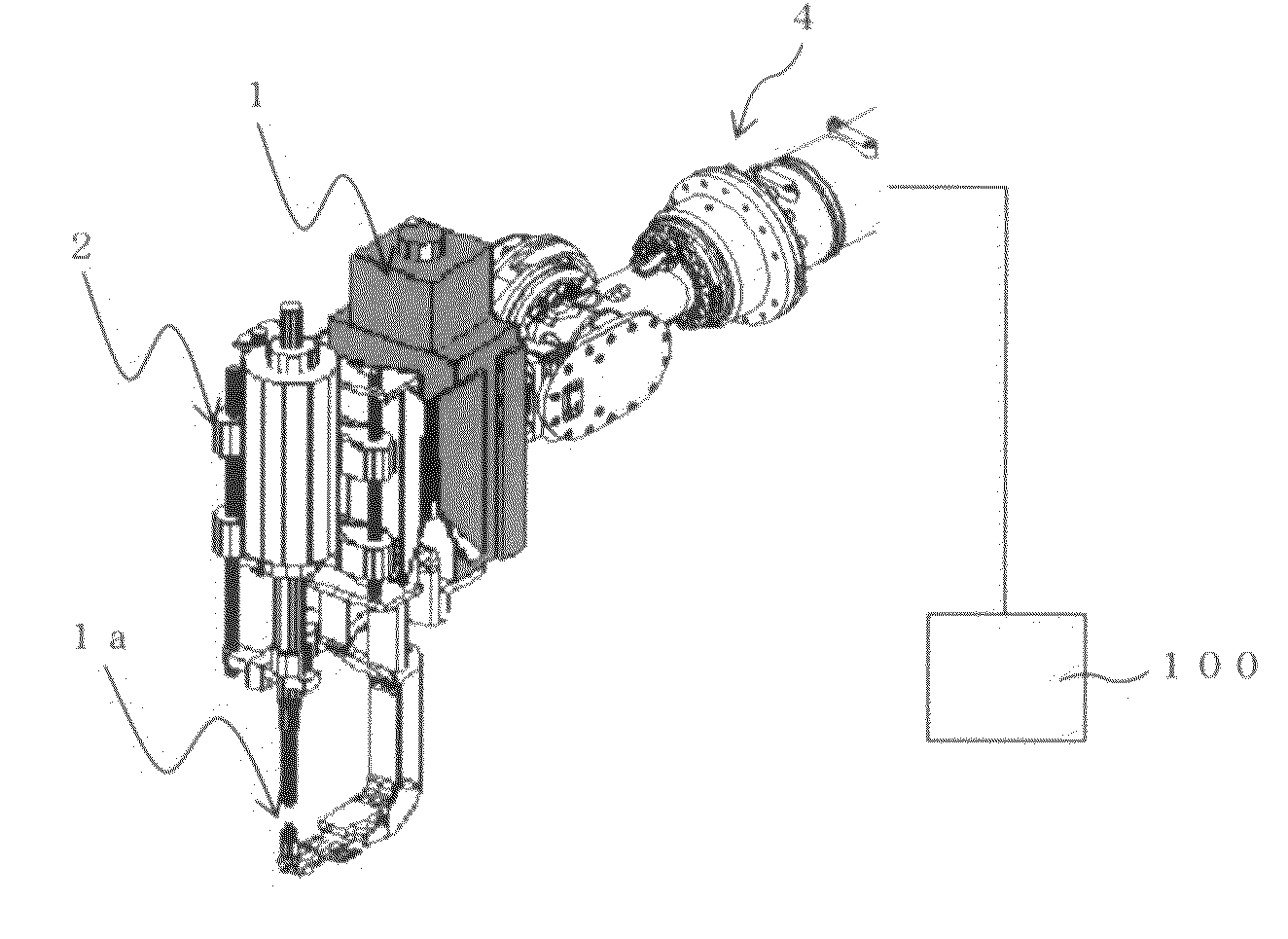

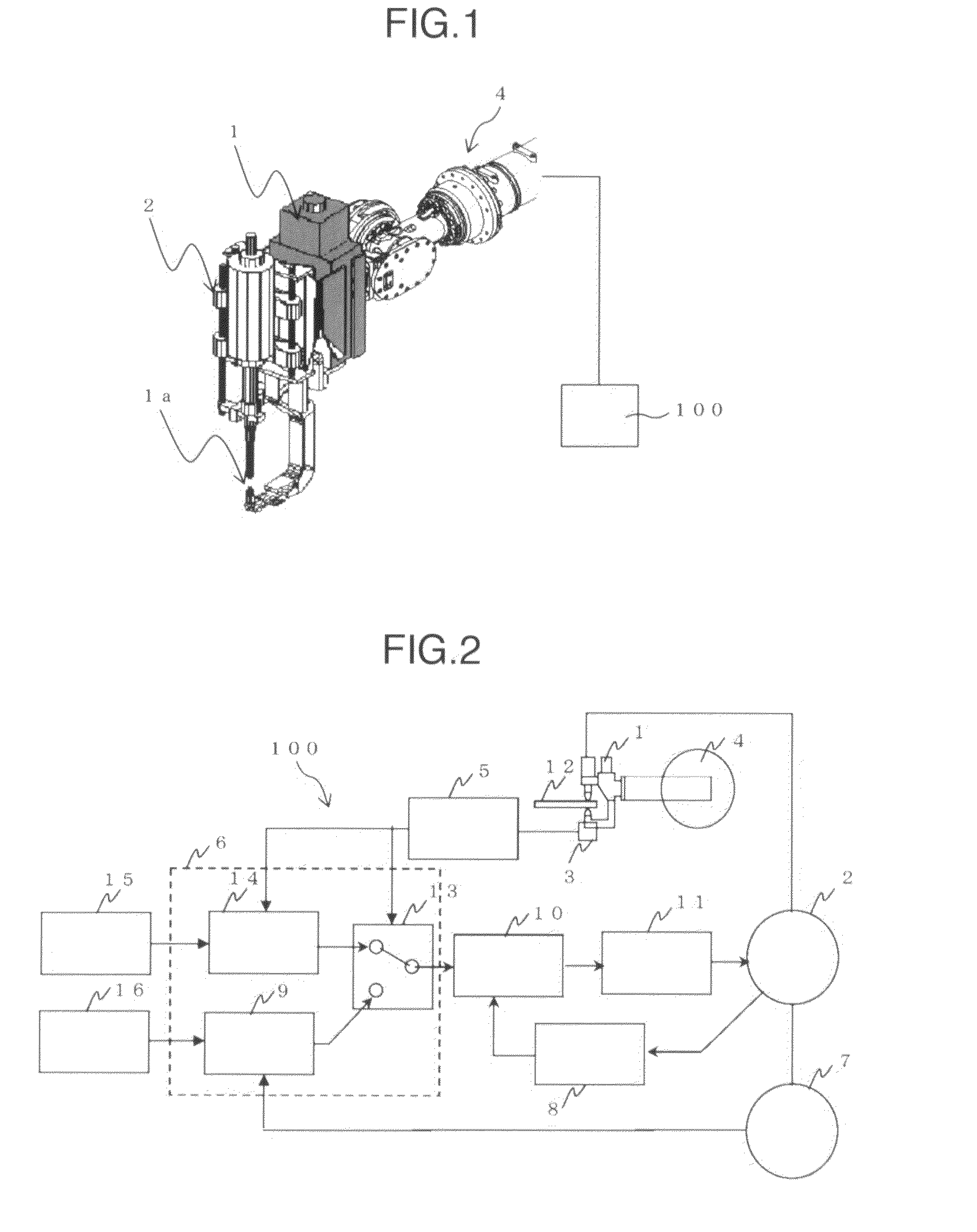

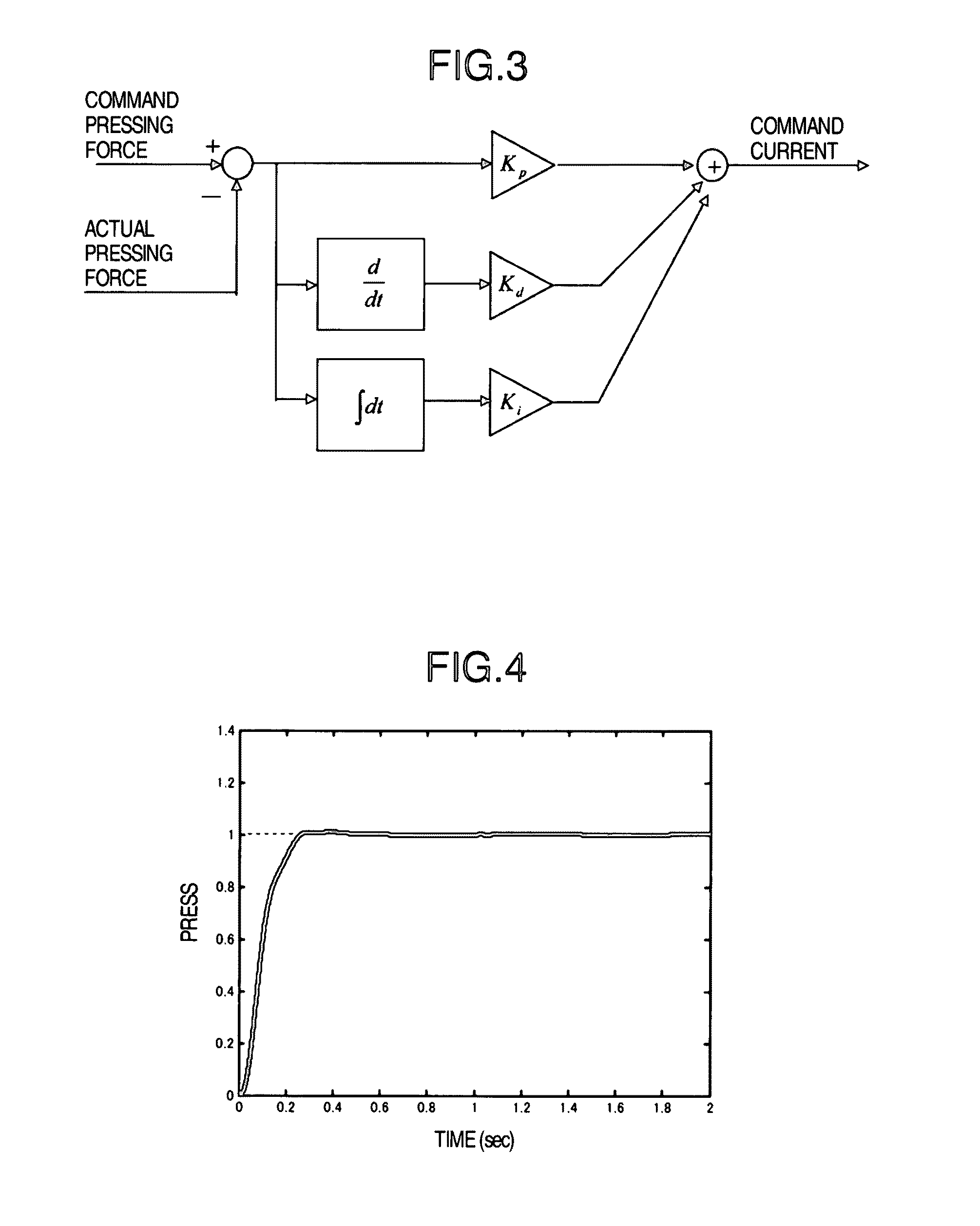

Spot Welding Method and Spot Welding System

InactiveUS20090302008A1Easy to controlSimple and low-cost constructionResistance welding apparatusDriving currentEngineering

A spot welding system and method where pressing force of a welding electrode applied by driving a servomotor is accurately controlled. The spot welding system has a pair of welding electrodes, a servomotor (2) for driving the welding electrodes and clamping and pressing an article (12) to be welded, and a controller (100) for controlling the welding electrodes and operation of the servomotor. A pressing force detector (3) is provided in order to measure pressing force actually applied to the article (12) to be welded. The controller (100) regulates a driving current to the servo motor (2) based on the measurement value of the pressing force detector (3), controlling the pressing force applied to the article (12).

Owner:NACHI-FUJIKOSHI

Transmitter and/or receiver arrangement of optical signal transmission

InactiveUS7359646B2Simple and low-cost constructionSolid-state devicesCoupling light guidesEngineeringFeed line

Owner:II VI DELAWARE INC

Truck mounted crash attenuator

InactiveUS7243964B1Limited protectionSimple and low cost constructionPasturing equipmentElastic dampersModularityTruck

A truck mounted attenuator (TMA) is constructed to minimize length during use in a horizontal position and height in a vertical transport position, as well as to minimize wind resistance and buffeting at highway speeds. A modular construction is employed, so that only damaged portions of the TMA can be removed and replaced in the field after a vehicle impact. The TMA comprises a plurality of outwardly curved tubular structural members which are designed to buckle upon application to the TMA of forces resulting from vehicular impact. The rigid tubes buckle at a high initial force, then proceed to crush at a lower force once the sides have buckled outwardly sufficiently to protect vehicle occupants during the critical first two feet of travel after impact. This design also provides increased protection for errant vehicles which impact the TMA device from an angle (i.e. “coffin corner” impact).

Owner:TRAFFIX DEVICES INC

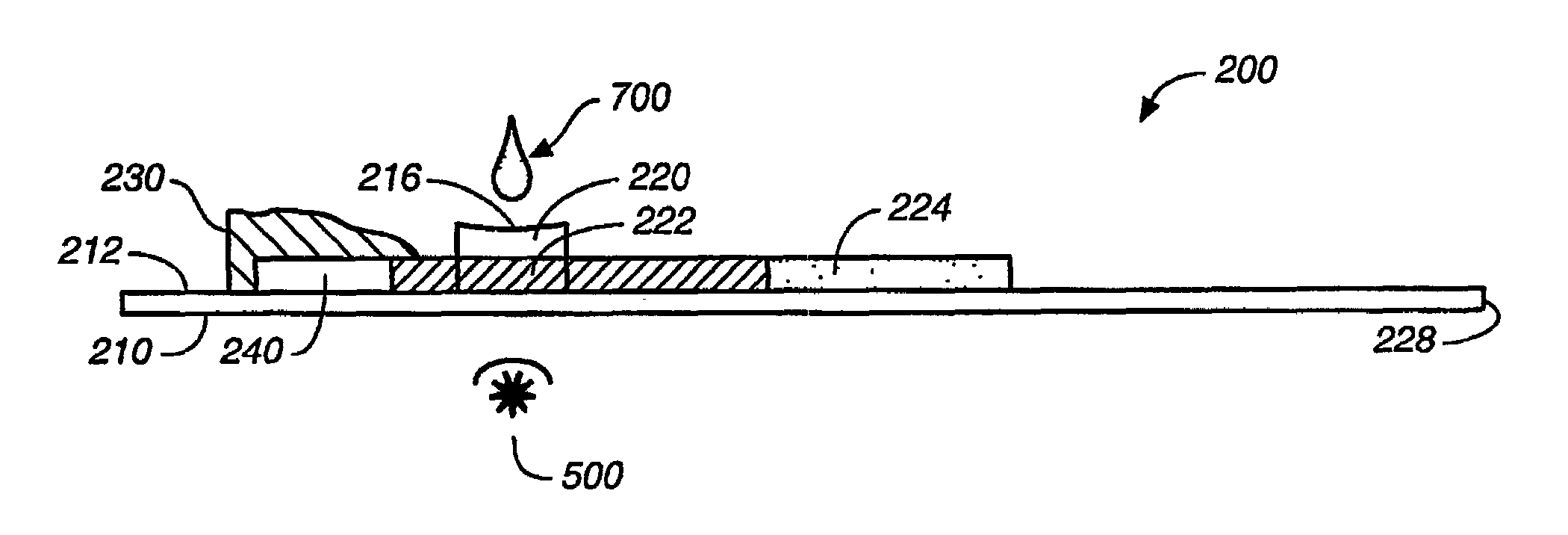

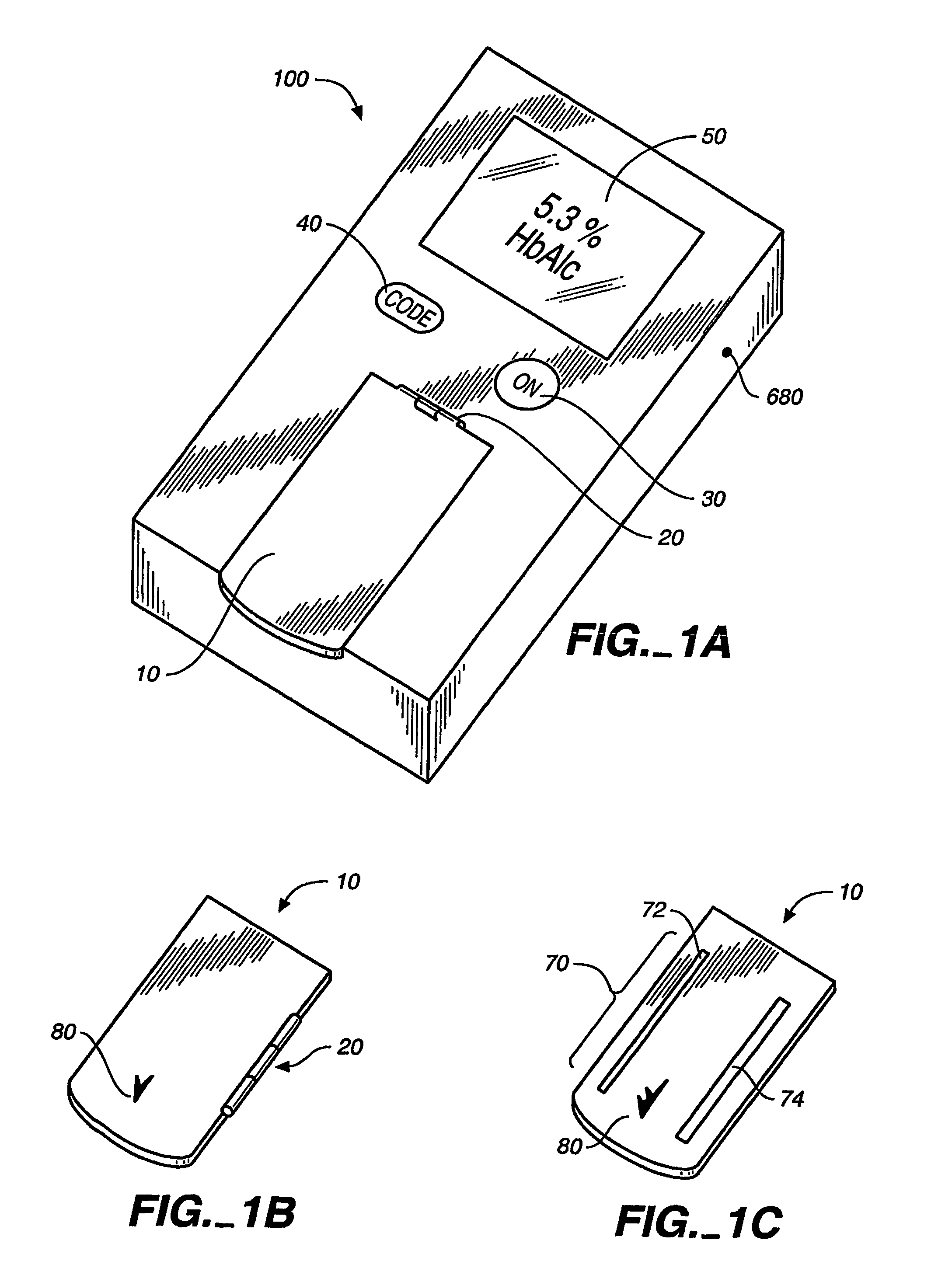

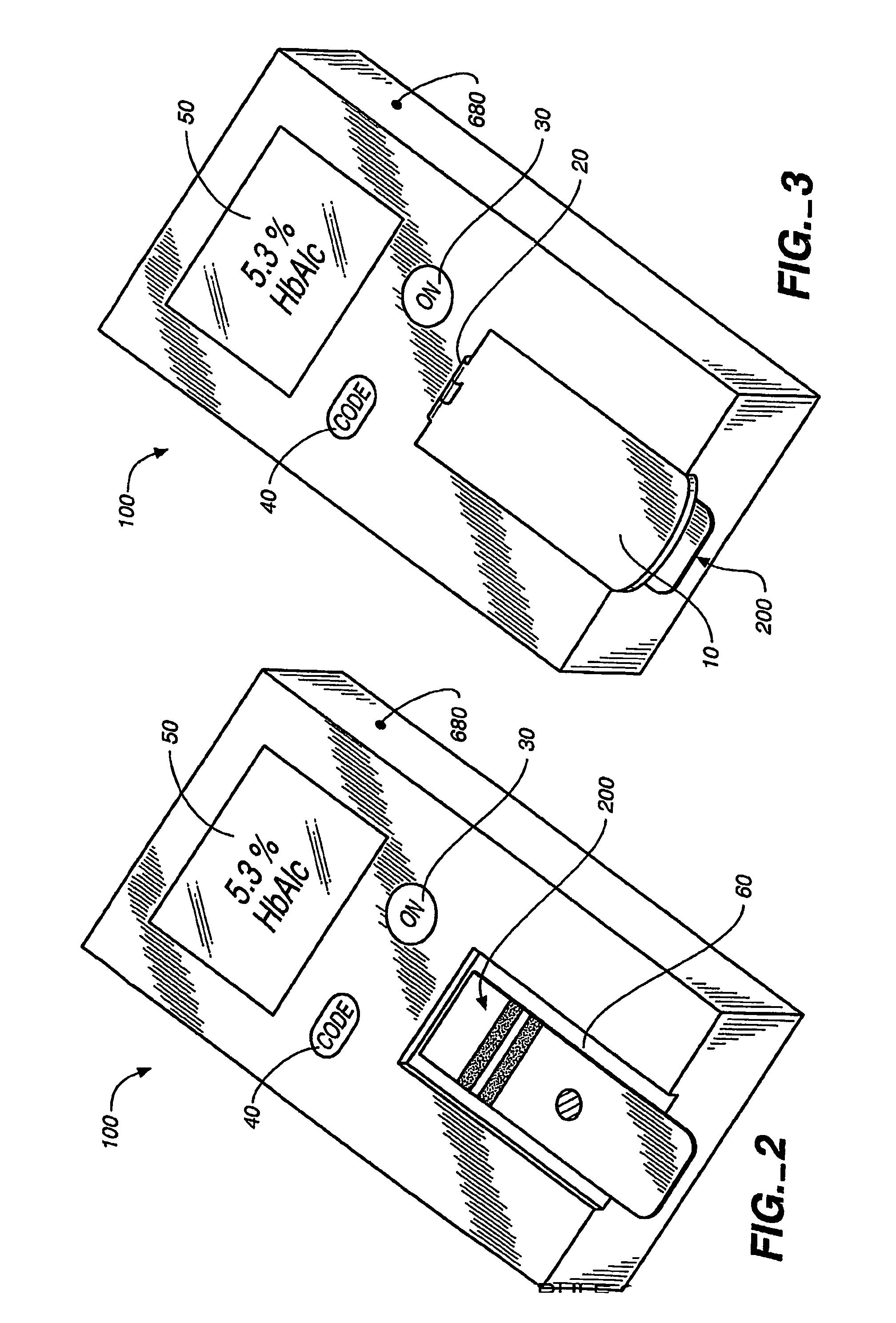

Assay device, system and method

InactiveUS7670853B2Simple and low-cost constructionSmall footprintBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteSmall sample

A system for treating a blood sample (700) having an analyte of interest comprises a strip (200) having a membrane (218), respective portions (216, 220 and 222, or 300) which are provided for receiving the sample, for lysing cells of the sample to liberate hemoglobin, and for capturing glycated hemoglobin. The latter two portions (220 and 222, or 300) of the membrane are treated with lysing and capture agents, respectively. A portion of the strip (214 or 230 or 240) is provided for holding an eluting agent and for releasing the agent upon a release condition. A system for detecting analyte comprises an optical subsystem (550) that is aligned with the strip to provide a signal corresponding to an amount of analyte, and an electronic subsystem (650) for processing the signal (560) to provide a result, such as an amount or percentage of glycated hemoglobin. To use these systems, the user simply applies a small sample (700) to the membrane (218) and closes a door (10) of the detection system over the strip (200) such that the door triggers the release of the eluting agent. No sample pre-treatment is required. The preferably handheld system (100) is a simple and convenient monitoring tool for the user, such as a diabetic patient who must monitor blood glucose on an on-going basis. While the systems are useful in the monitoring of blood glucose, they may be used for treating a sample other than blood and detecting an analyte other than an analyte in blood.

Owner:ABBOTT DIABETES CARE INC

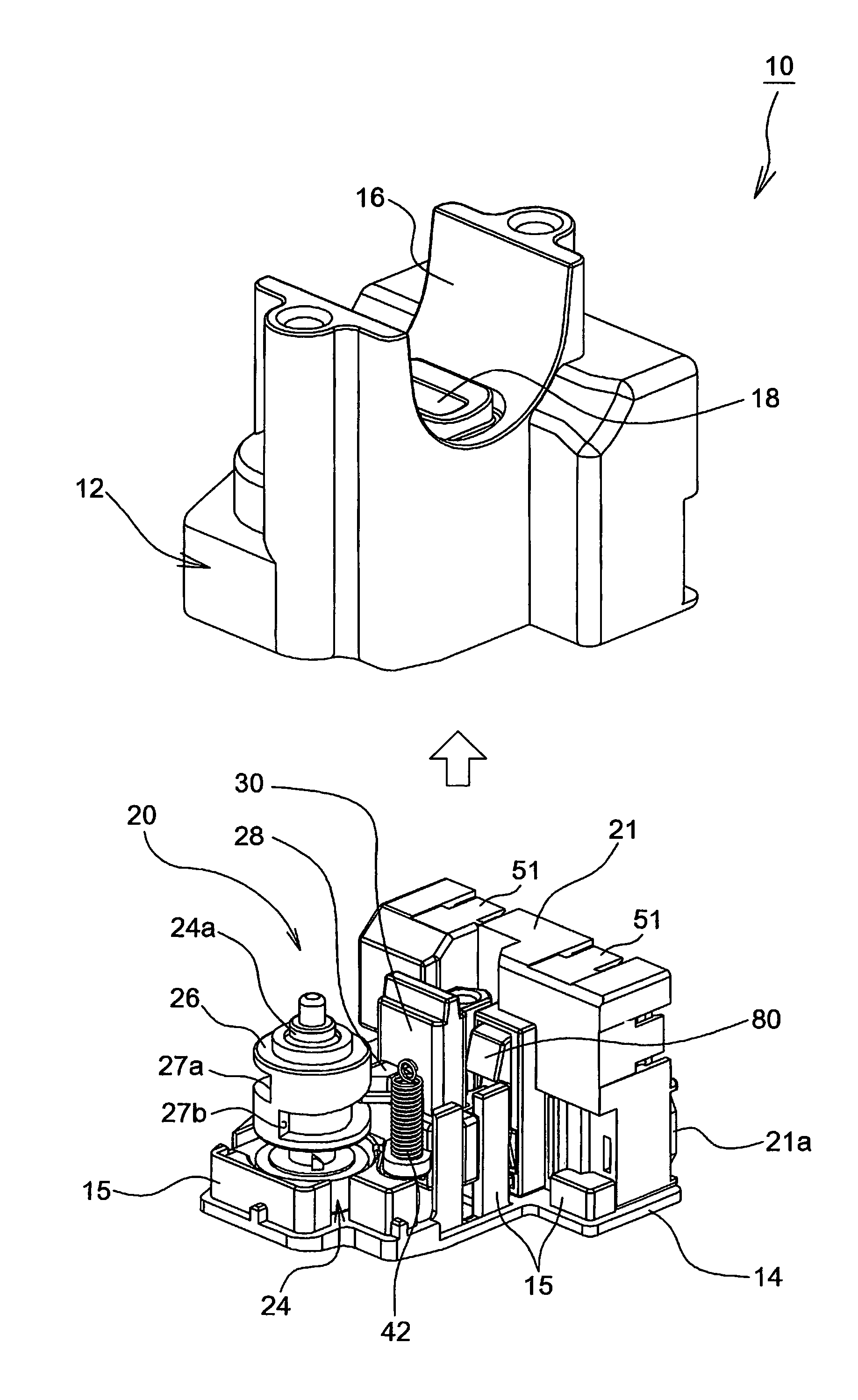

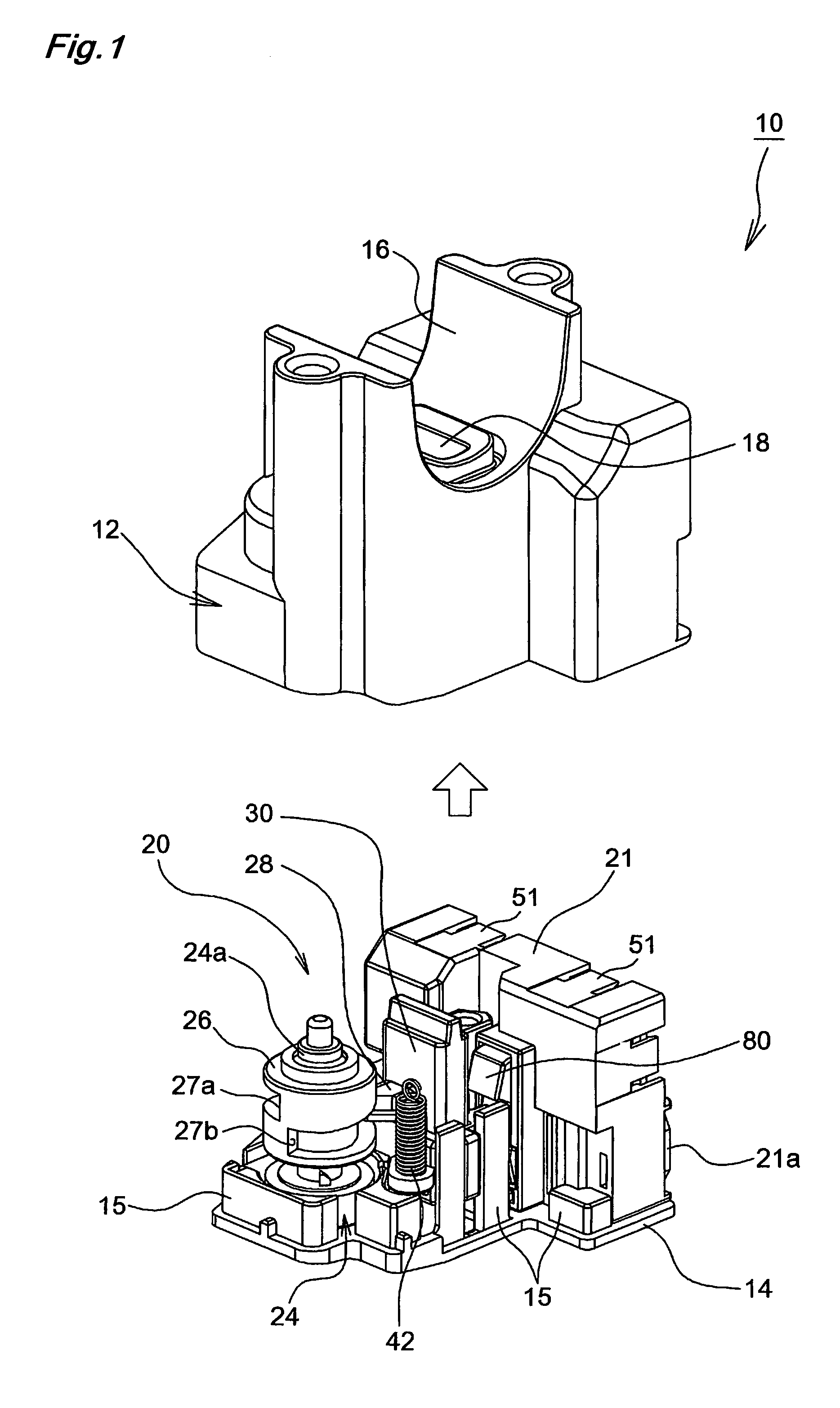

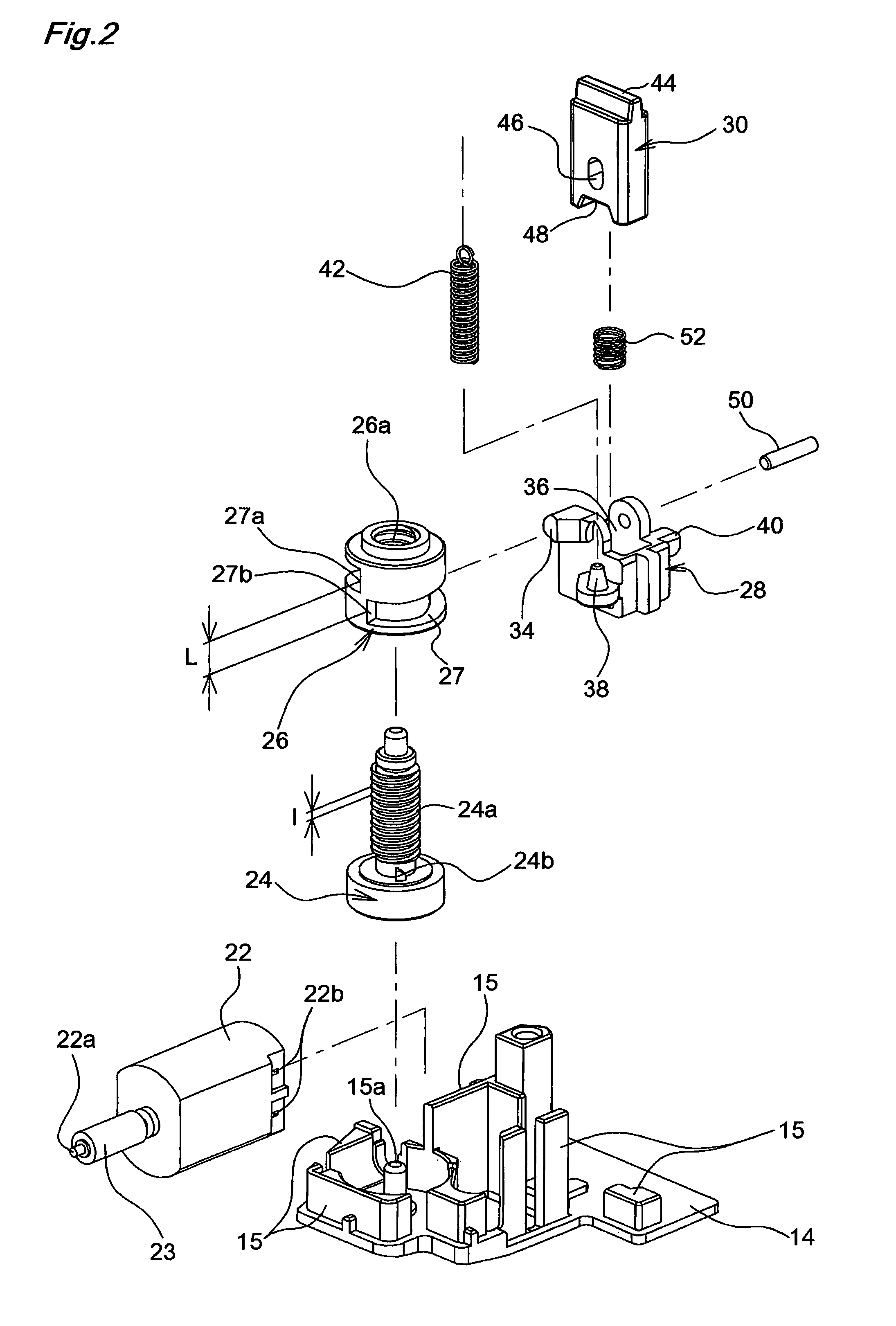

Steering lock unit

InactiveUS7762110B2Accurate detectionSimple and low cost constructionBuilding locksAnti-theft devicesOperating speedNormal state

A steering lock unit in which it is possible to place priority on the operating speed or the extracting force of the lock member according to the engagement state of the lock member in the movable member. In a steering lock unit (10) including a transmission mechanism which transmits a power of an electric motor (22) to the lock shaft (30) which holds and releases engagement with a steering shaft. The transmission mechanism includes: a shaft portion (24a) which is adapted to rotate in response to operation of the electric motor (22); and a winder (26) which engages with the shaft portion (24a) and transmits the operation of the electric motor (22) to the lock shaft (30). When releasing the engagement of the lock shaft (30) with the steering shaft, the shaft portion (24a) and the winder (26) integrally rotate in a normal state, while the winder (26) moves in an axial direction with respect to the shaft portion (24a) in a case in which a pull-out force of the lock shaft, greater than a predetermined quantity, is necessary.

Owner:U SHIN LTD

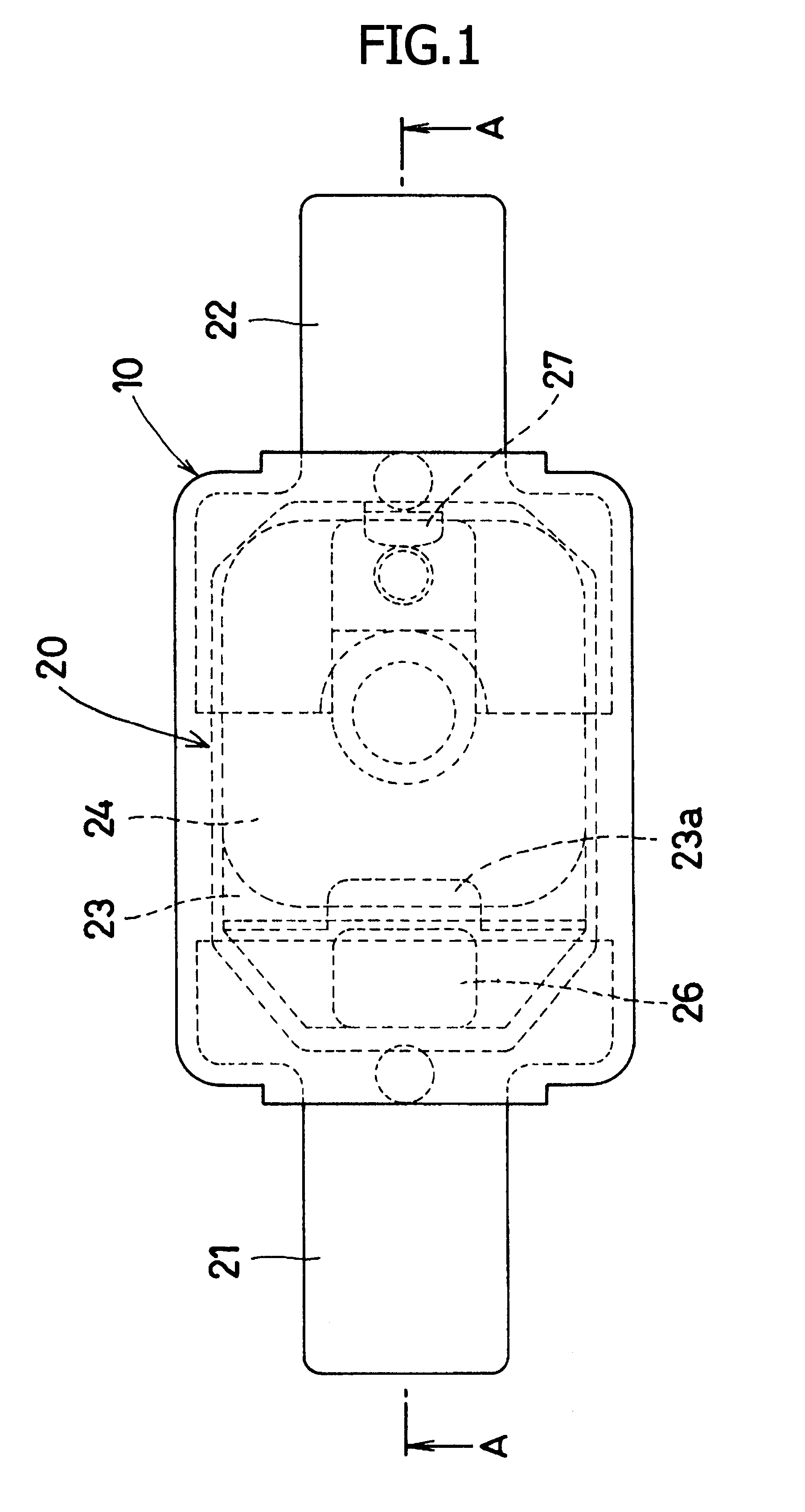

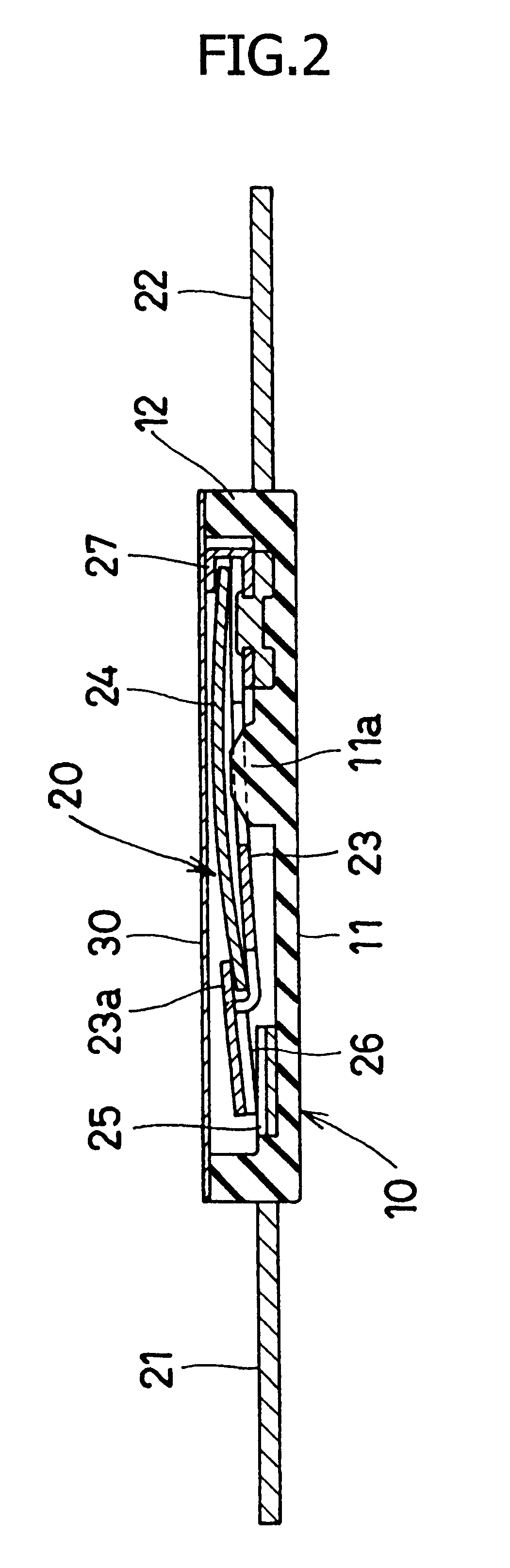

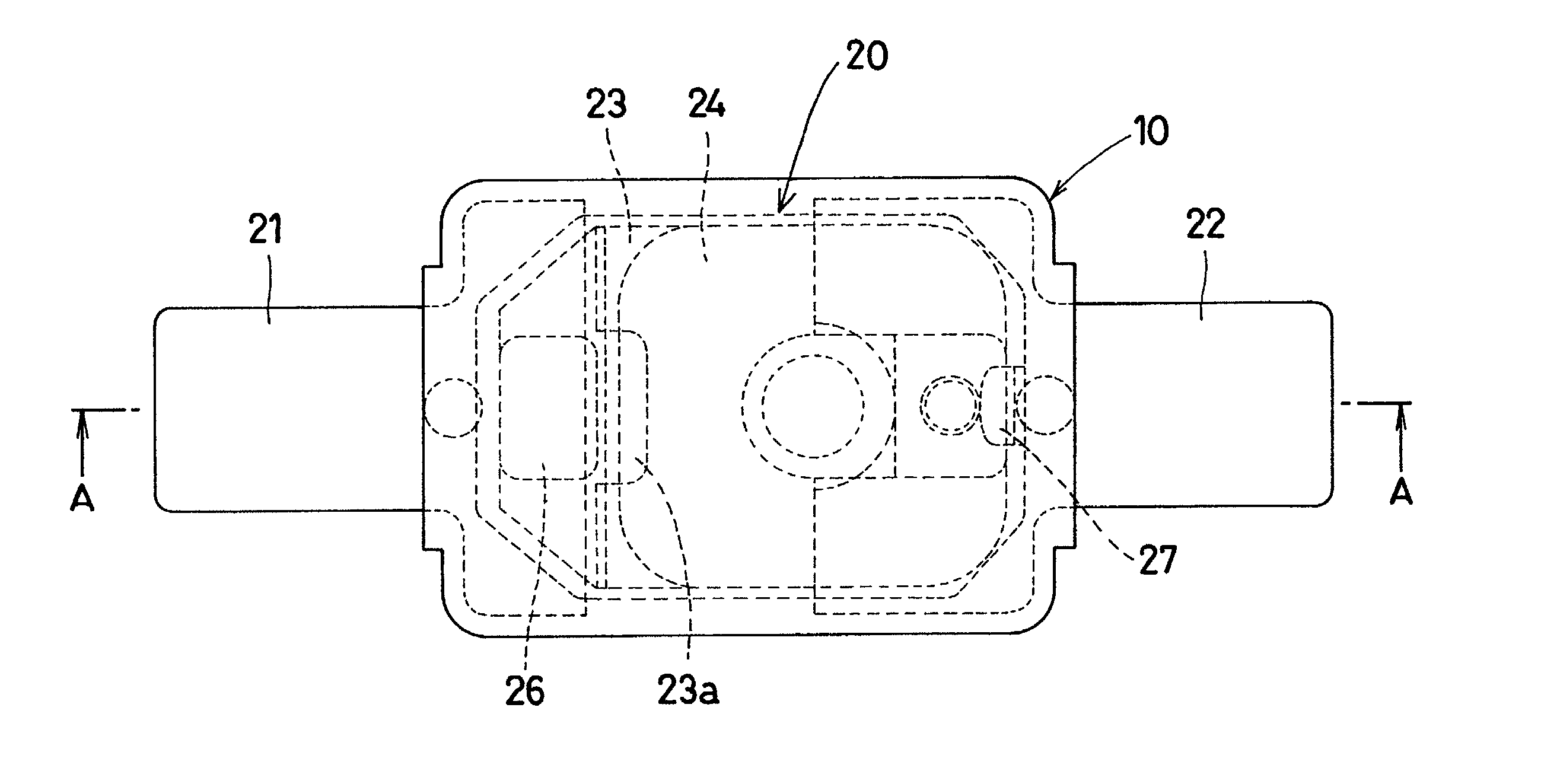

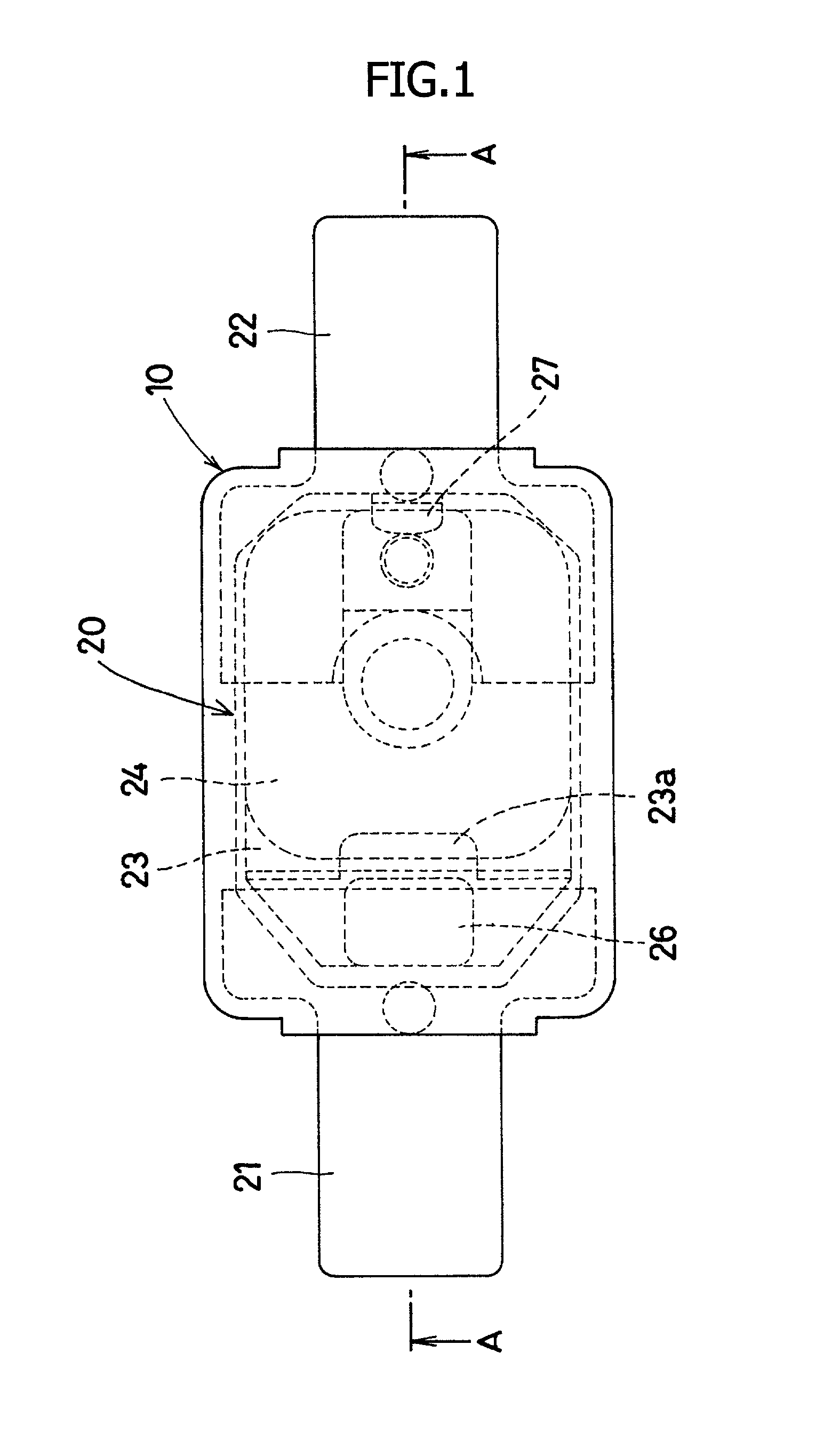

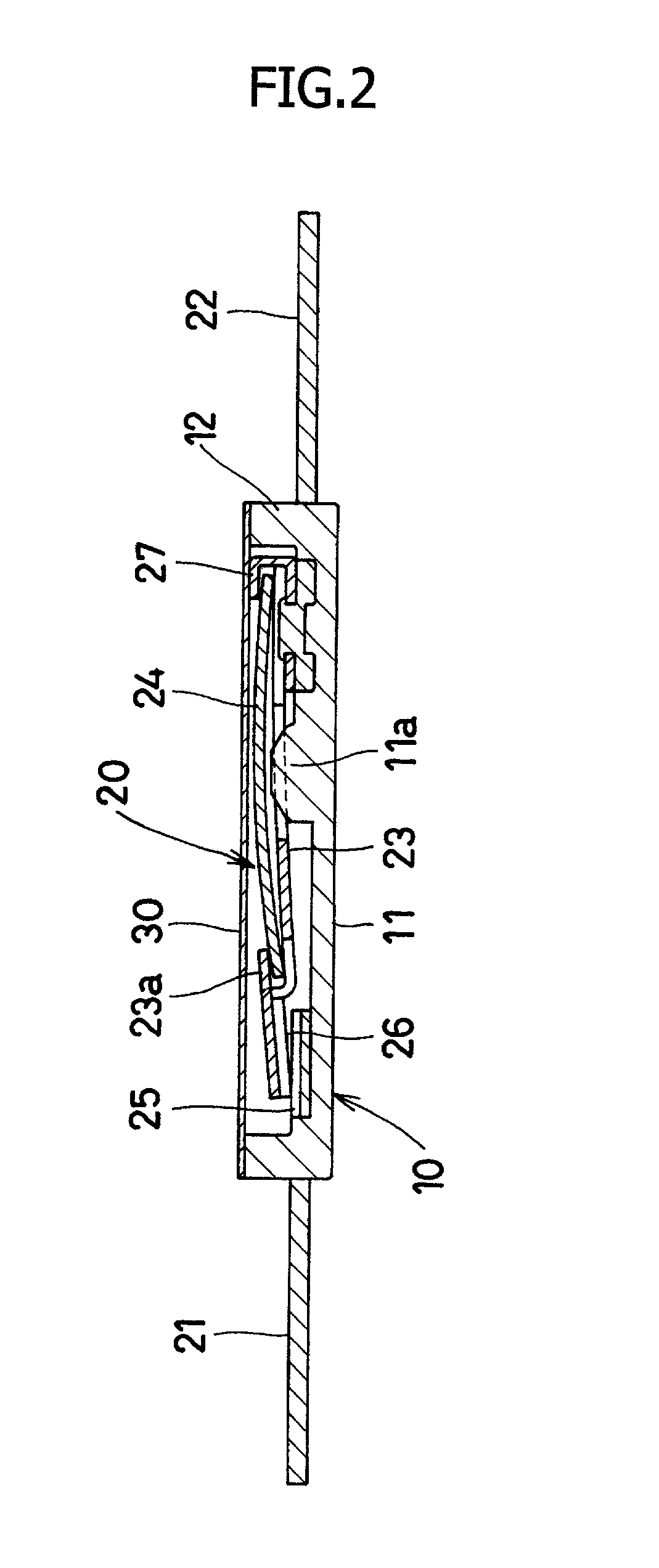

Thermal protector

InactiveUS20020003465A1Improve sealingSimple and low-cost constructionHeating/cooling contact switchesThermal switch detailsEngineeringExternal connection

A thermal protector includes a switching mechanism section 20 having a fixed contact 25, a movable contact 26 disposed so as to face the fixed contact 25, and first and second external connection terminals 21 and 22 projecting sideward and connected electrically to the fixed contact 25 and movable contact 26, respectively, the switching mechanism section 20 being constructed so that the movable contact 26 is displaced by a deforming operation of a thermally-actuated element 24 so as to be separated from and brought into contact with the fixed contact 25; a resin made bottomed case 10 having a peripheral wall 12 located around the switching mechanism section 20 in such a manner that the first and second external connection terminals 21 and 22 penetrate the peripheral wall 12, in which the penetrating portions of the external connection terminals 21 and 22 are adhesively sealed by molding the peripheral wall 12 integrally with the connection terminals 21 and 22; and a film-form cover member 30 formed of an electric insulating material, the cover member 30 being adhesively fixed to the upper end face of the peripheral wall 12 of the case 10 so as to seal the upper opening of the case 10.

Owner:UCHIYA THERMOSTAT

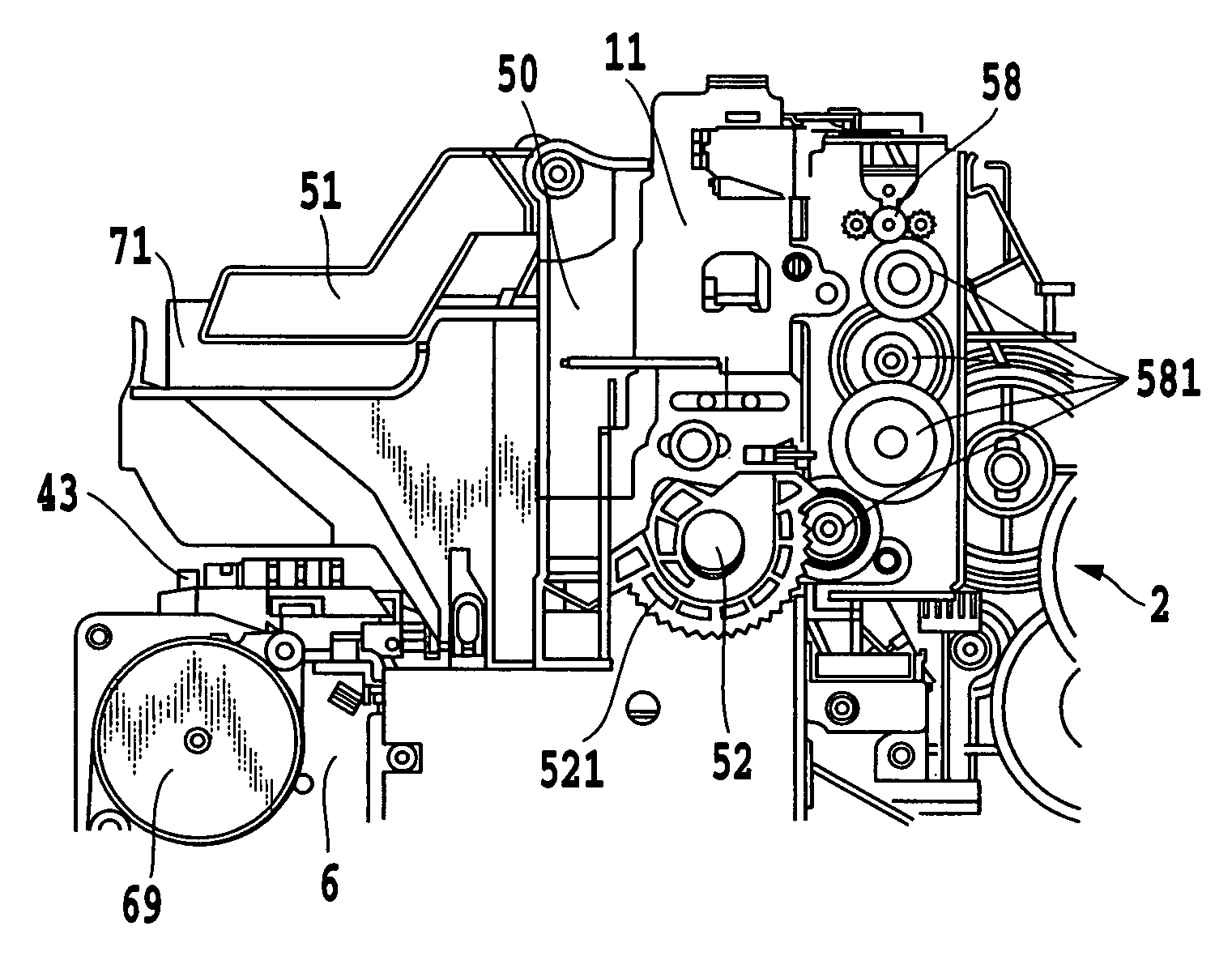

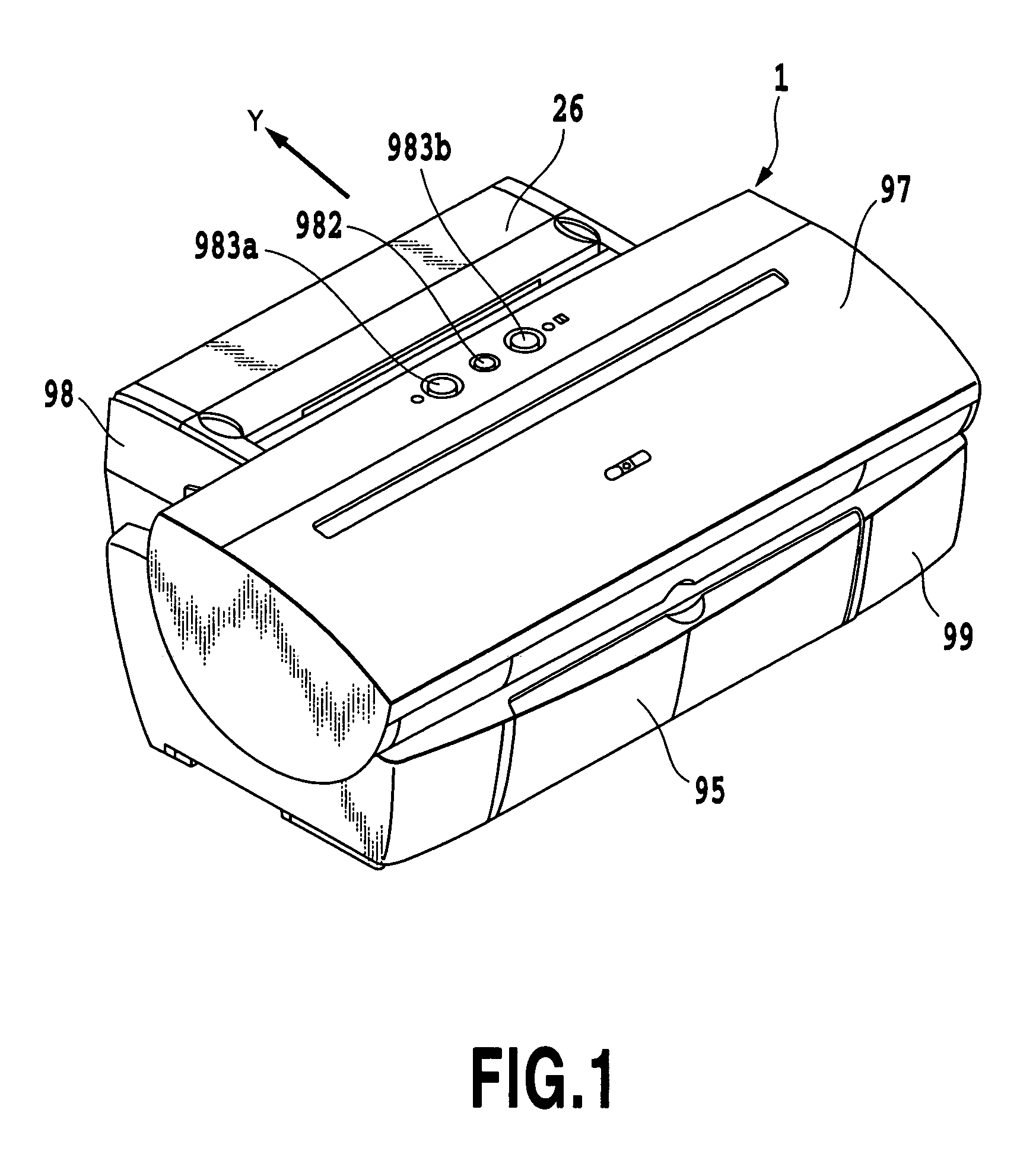

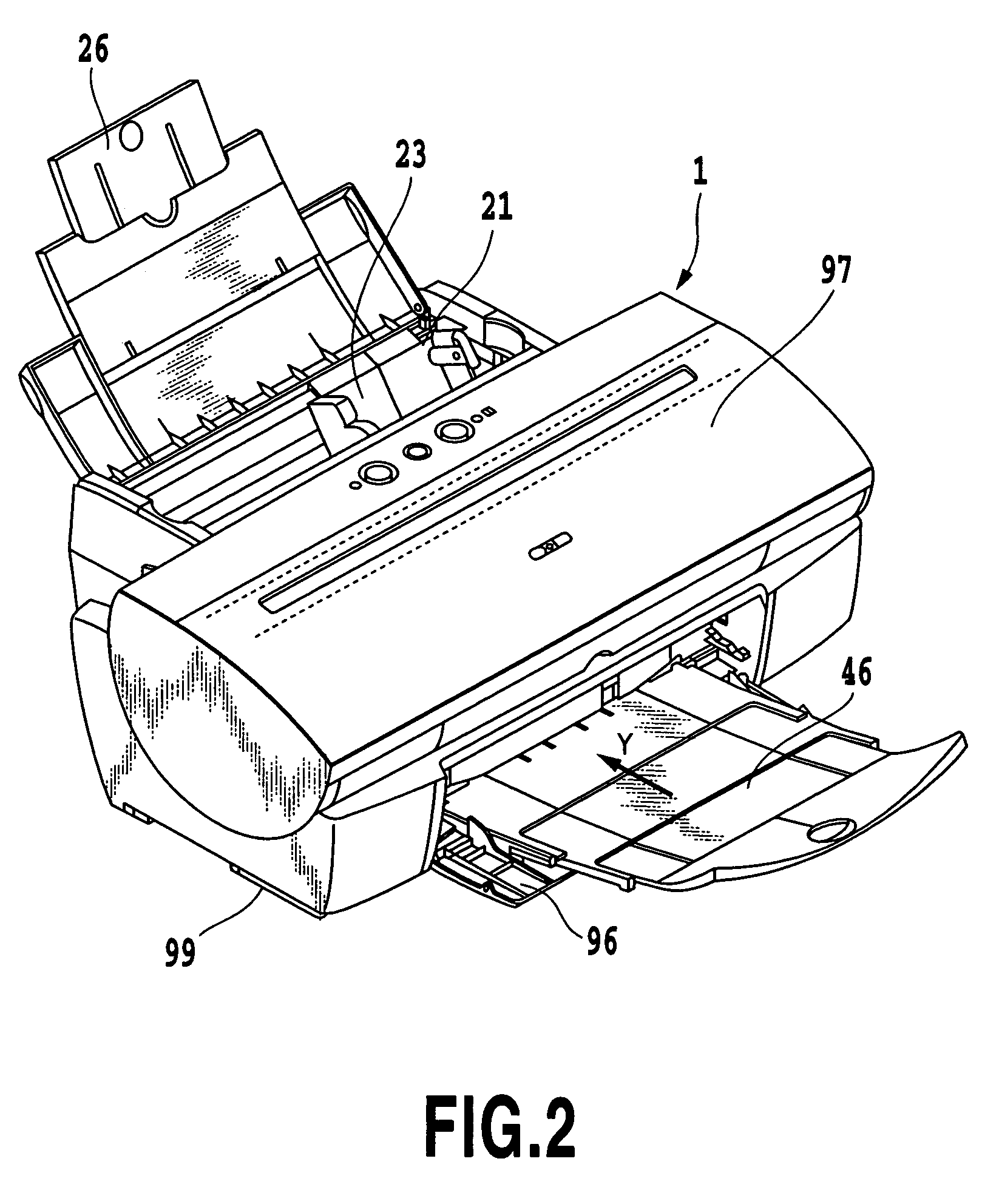

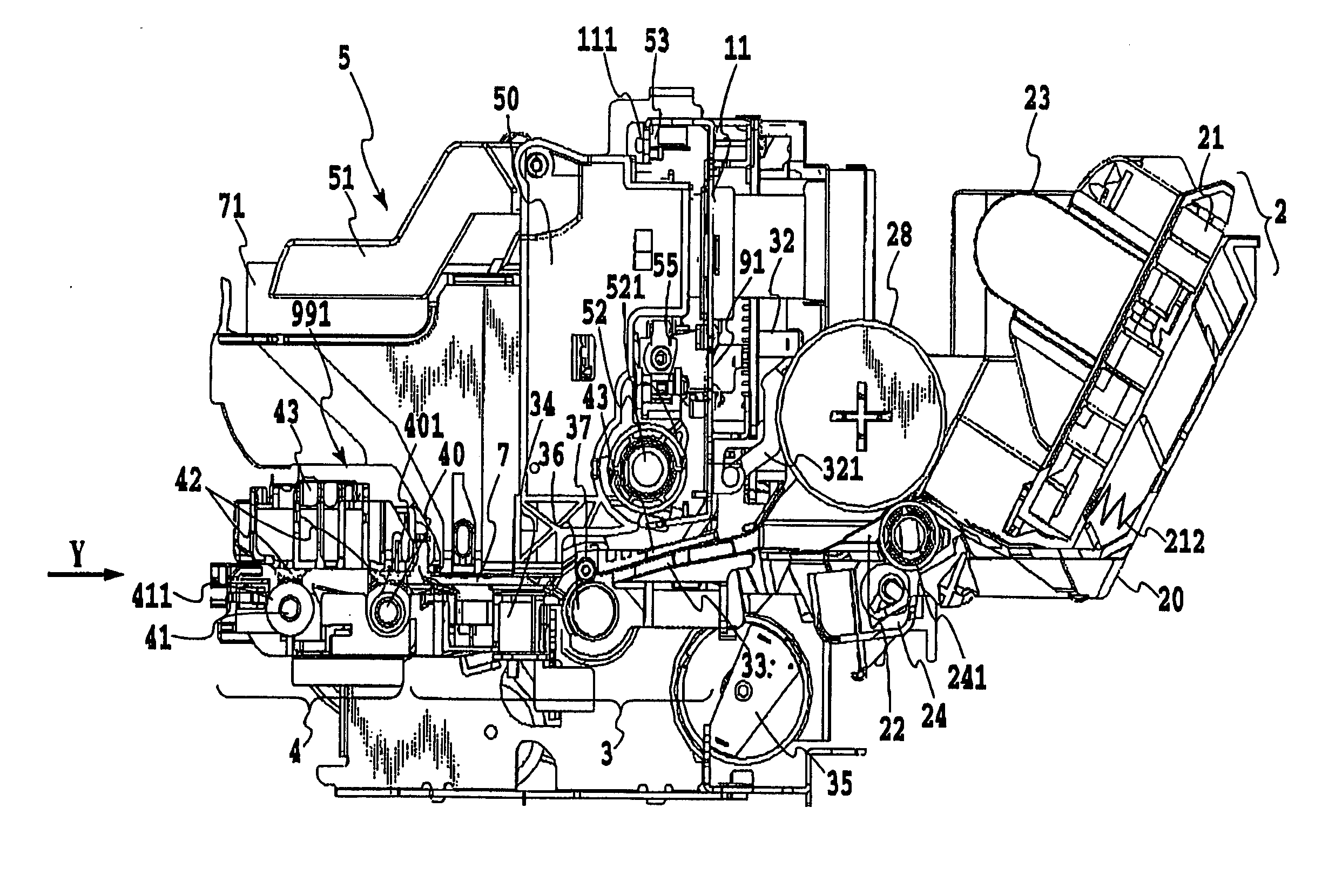

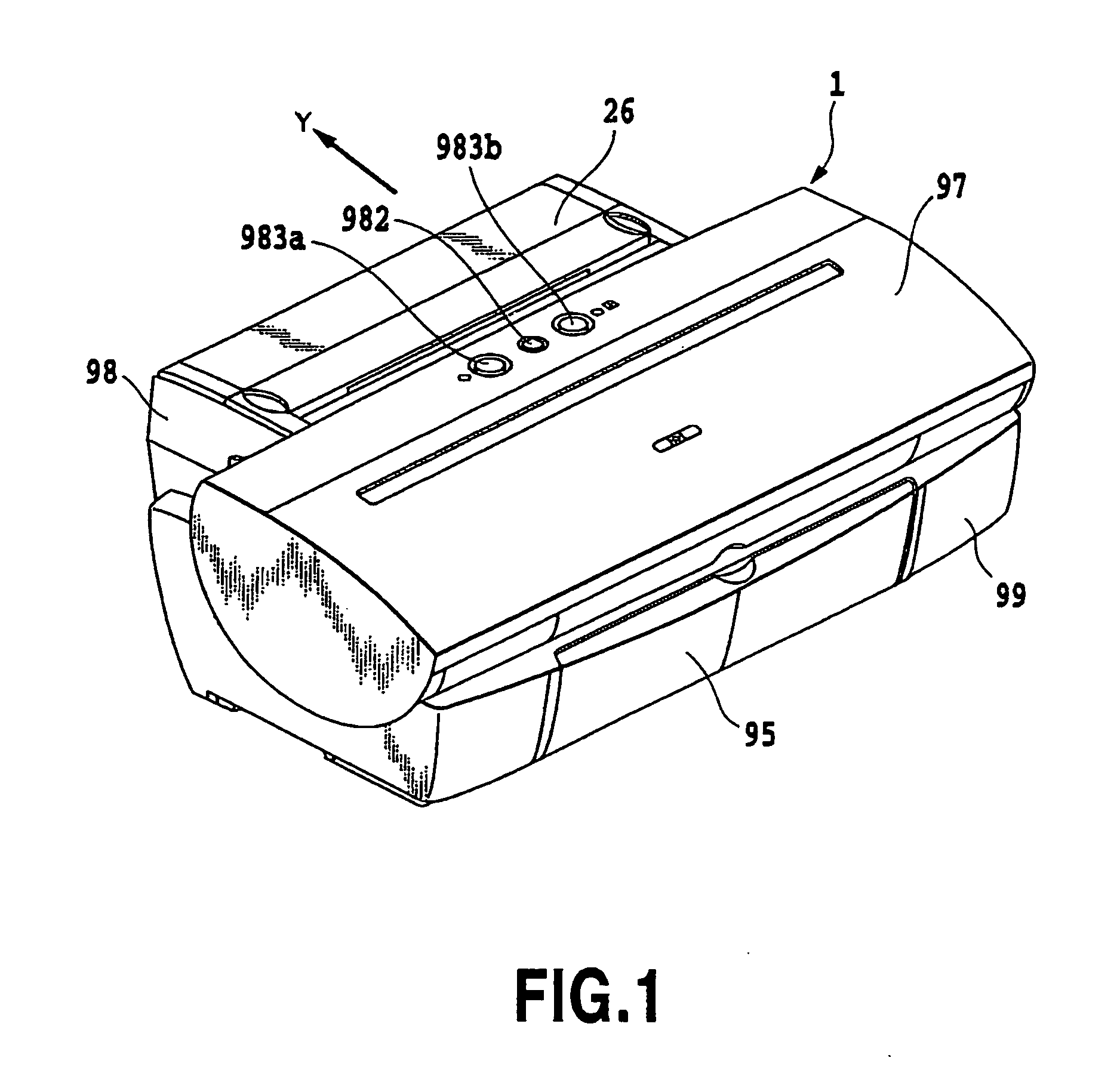

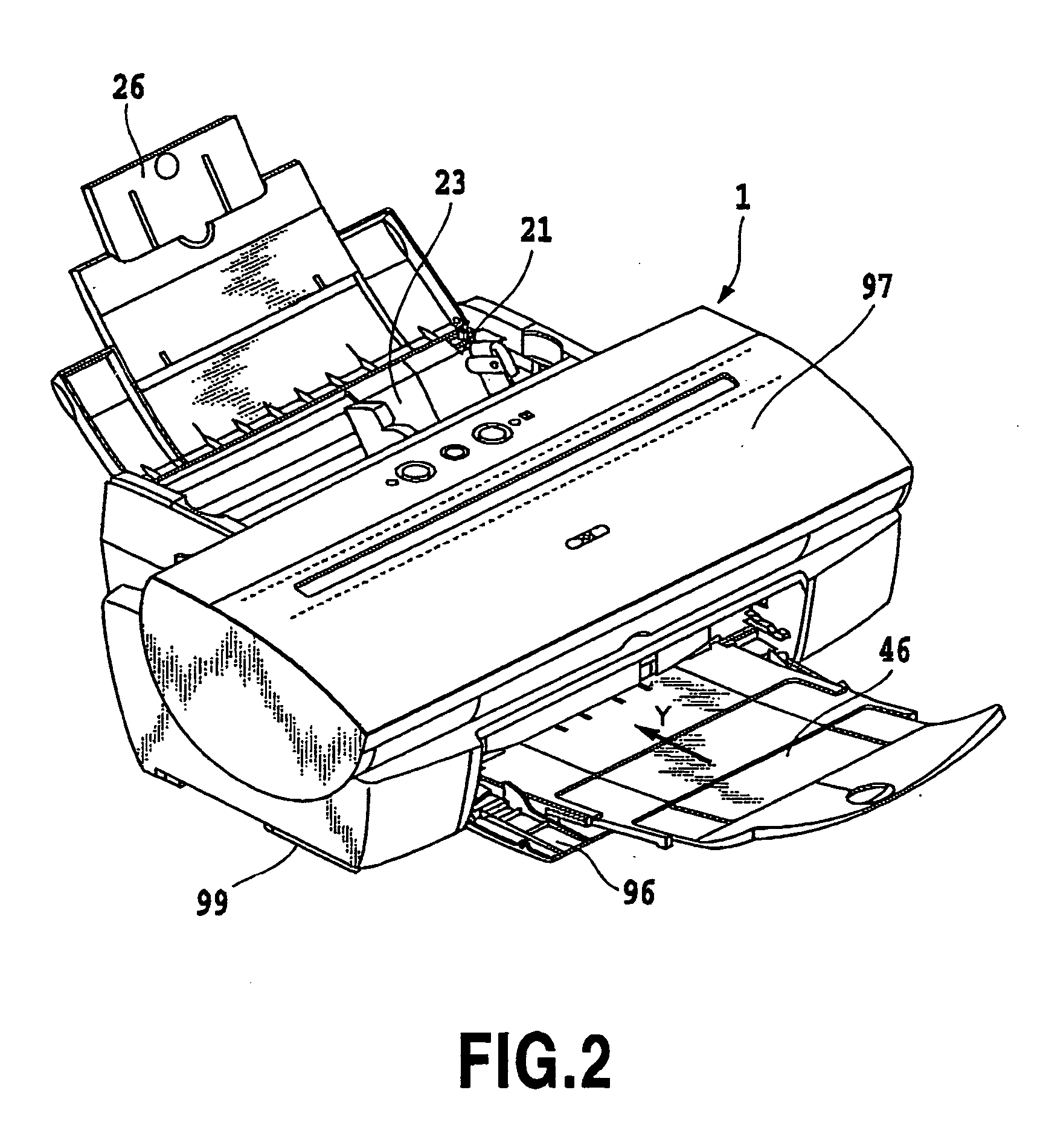

Ink jet printing apparatus and ink jet printing method

InactiveUS7044570B2Improve reliabilityEasy constructionSpacing mechanismsPower drive mechanismsReciprocating motionControl unit

Owner:CANON KK

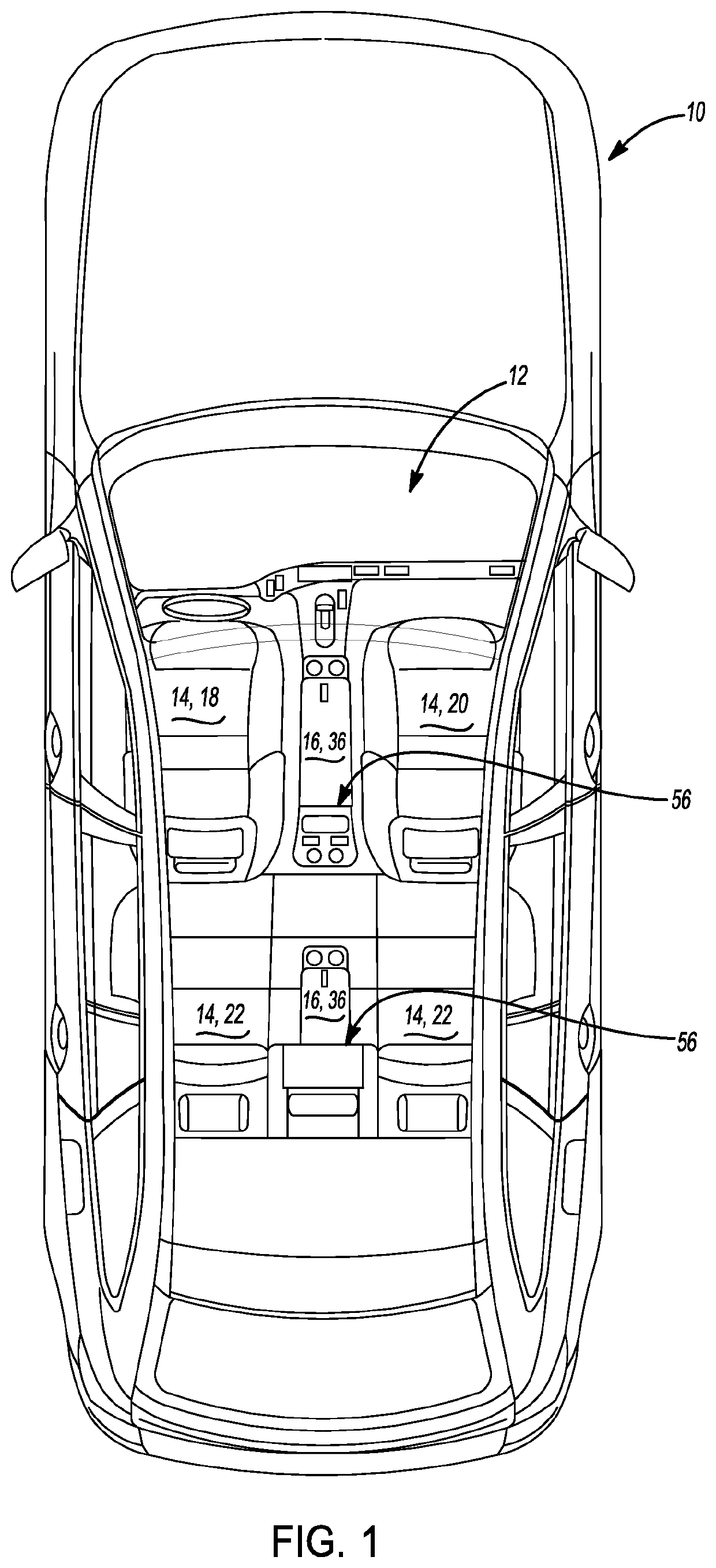

Hinged multi-tier storage compartments

InactiveUS20200114794A1Easy constructionImprove organizationPassenger spaceArm restsEngineeringComputer hardware

A console for a motor vehicle includes a console compartment formed in the console and having first, second, third, and fourth sides connected to a bottom side and partially enclosing a first volume, and a movable compartment lid disposed overtop the console compartment and articulating through a first range of motion. The console further includes a plurality of storage compartments in movable connection with each of the others of the plurality of storage compartments and in movable connection with the console compartment and the movable compartment lid, such that when the lid articulates through the first range of motion, the plurality of storage compartments move vertically and horizontally with respect to the console compartment and the movable compartment lid.

Owner:GM GLOBAL TECH OPERATIONS LLC

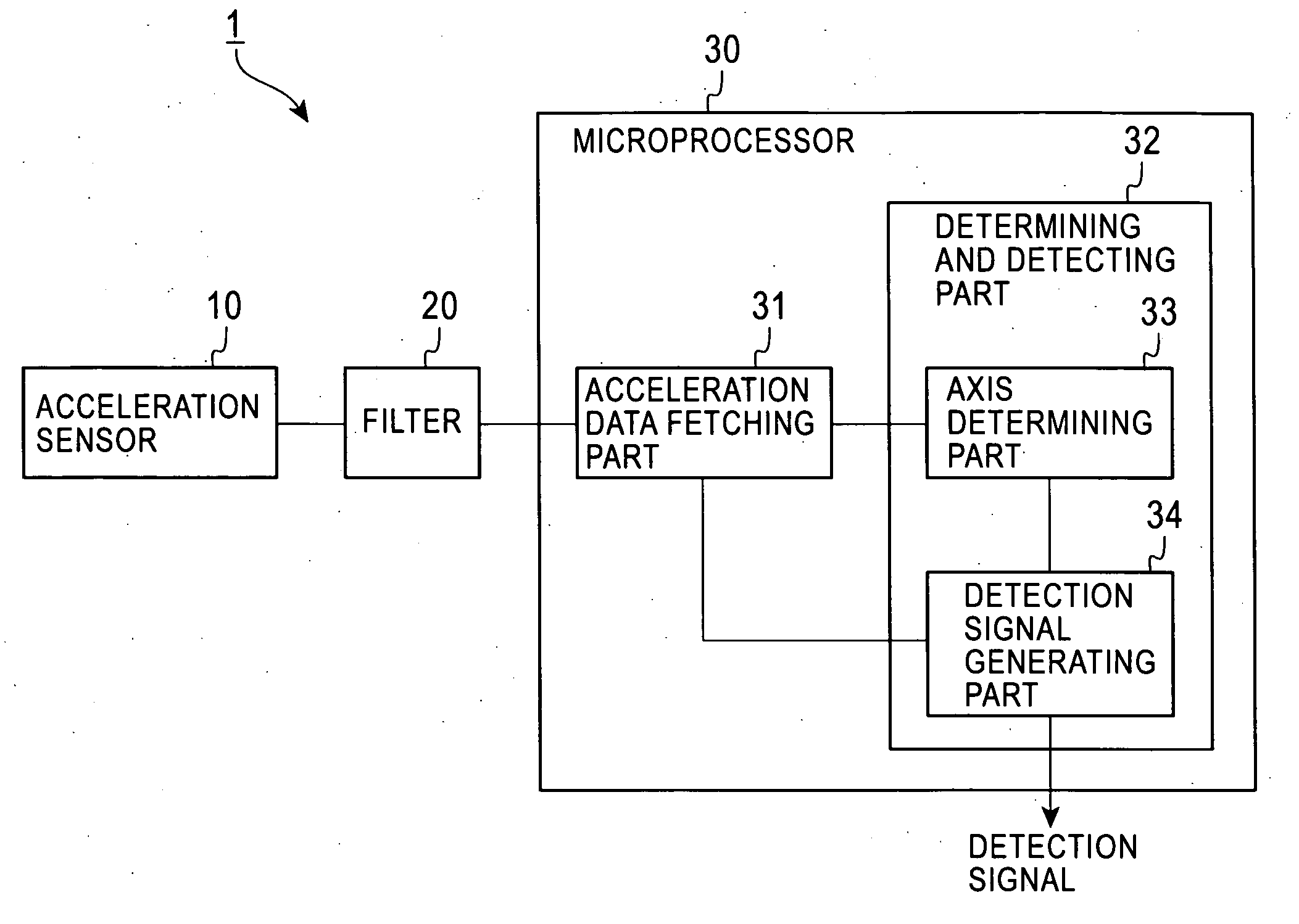

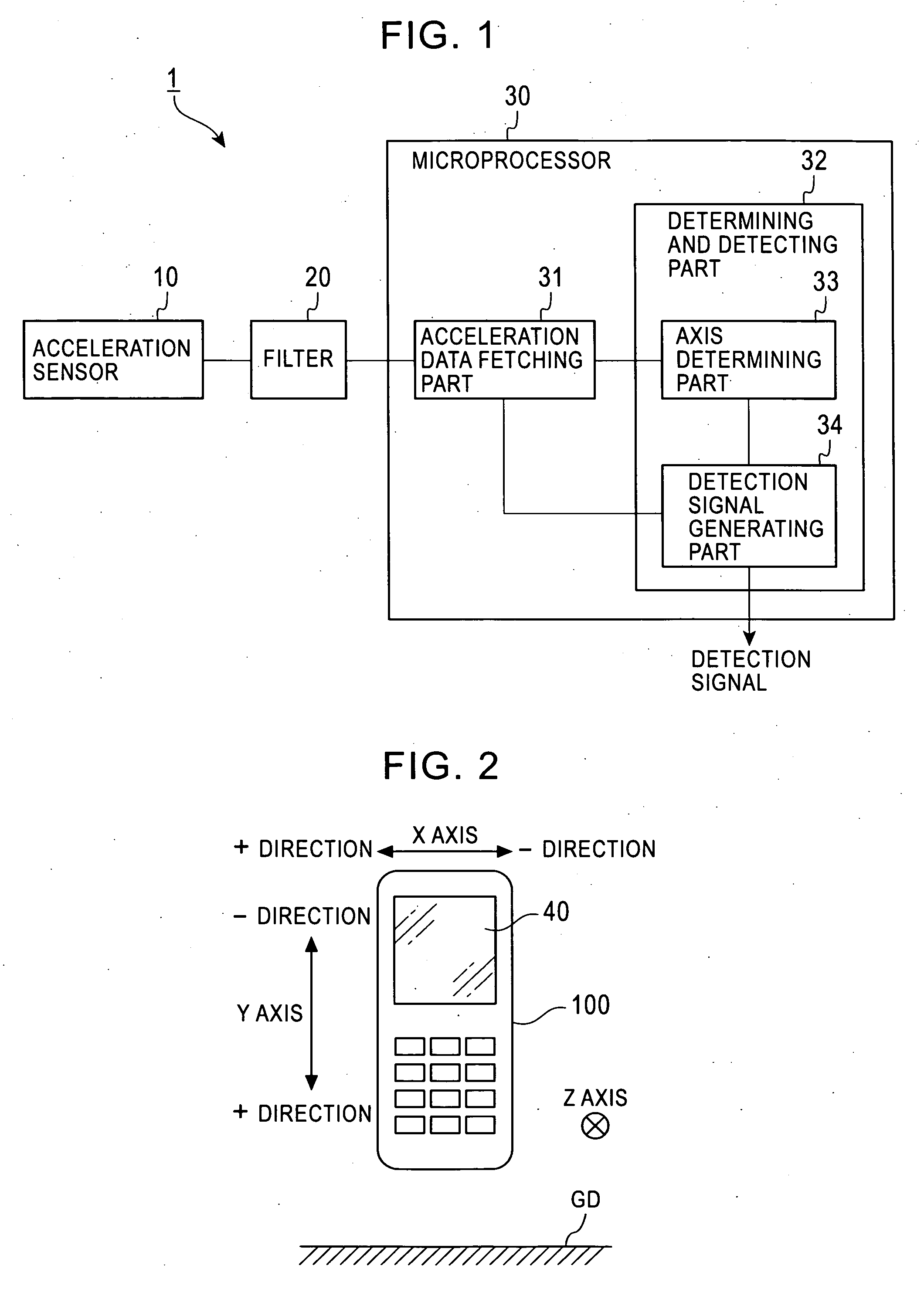

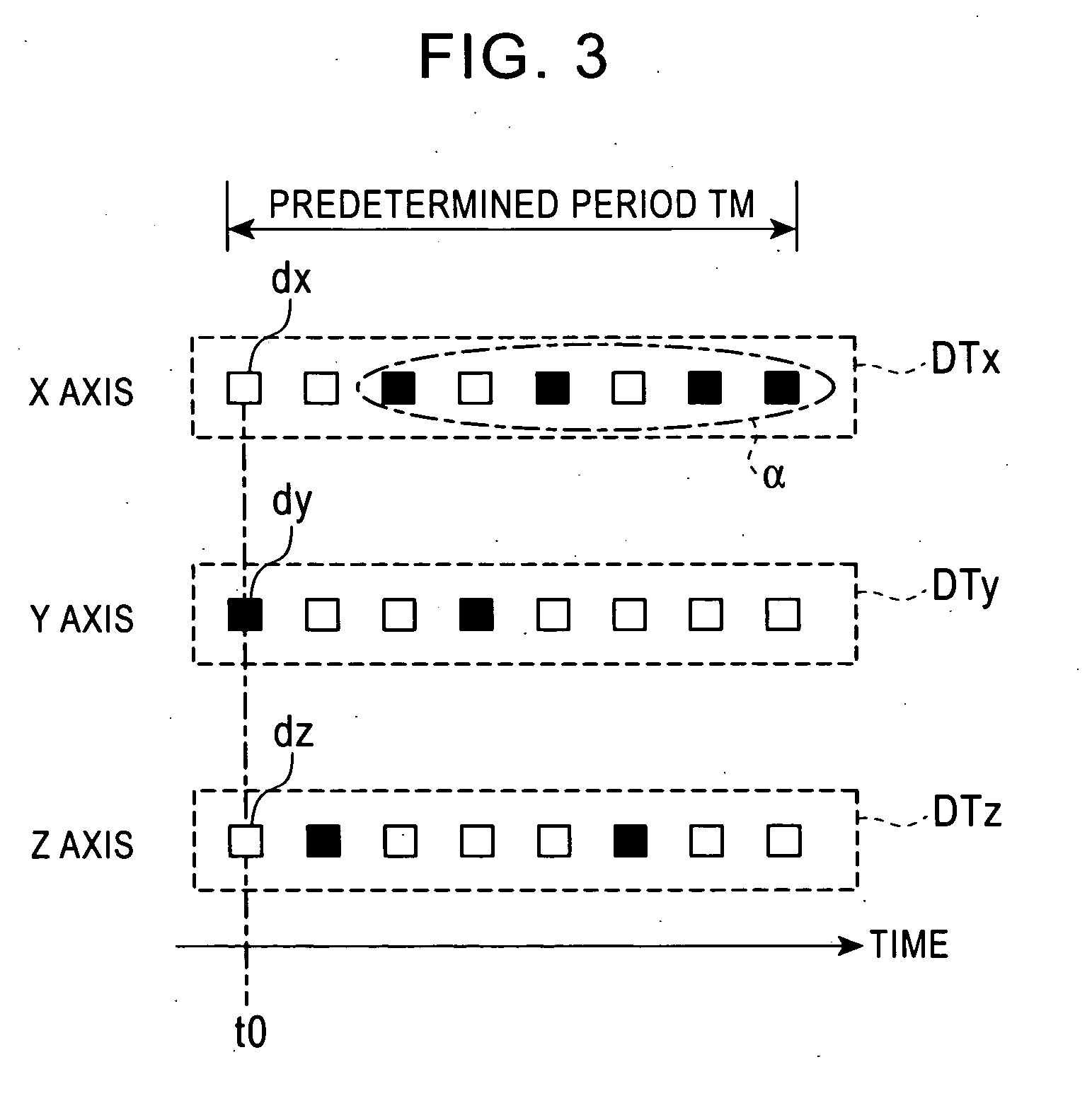

Gravity axis determination apparatus and mobile terminal apparatus using the same

ActiveUS20100130258A1Easy constructionSimple and low-cost constructionInput/output for user-computer interactionDigital data processing detailsTerminal equipmentTime zone

A gravity axis determination apparatus which can determine the gravity direction in a short time. The apparatus is low in cost and has a simple construction. Data values of acceleration data trains in a same time zone are mutually compared and one of the three axes is determined as a gravity axis.

Owner:LAPIS SEMICON CO LTD

Ink jet printing apparatus and ink jet printing method

InactiveUS20050206666A1Improve printing reliabilitySmall sizeSpacing mechanismsPower drive mechanismsReciprocating motionEngineering

The present invention provides an ink jet printing apparatus of a low-cost and simple construction which can detect with high reliability a gap between a print medium and a print head mounted on a carriage. The ink jet printing apparatus, which reciprocally moves in a predetermined scan direction the carriage holding the print head for ejecting ink onto the print medium, includes a gap changing mechanism for changing the gap between the print head held in the carriage and the print medium and a control unit for controlling a driving of the gap changing mechanism and a reciprocal movement of the carriage, wherein the control unit drives the gap changing mechanism and reciprocally moves the carriage to check the operation state of the gap changing mechanism.

Owner:CANON KK

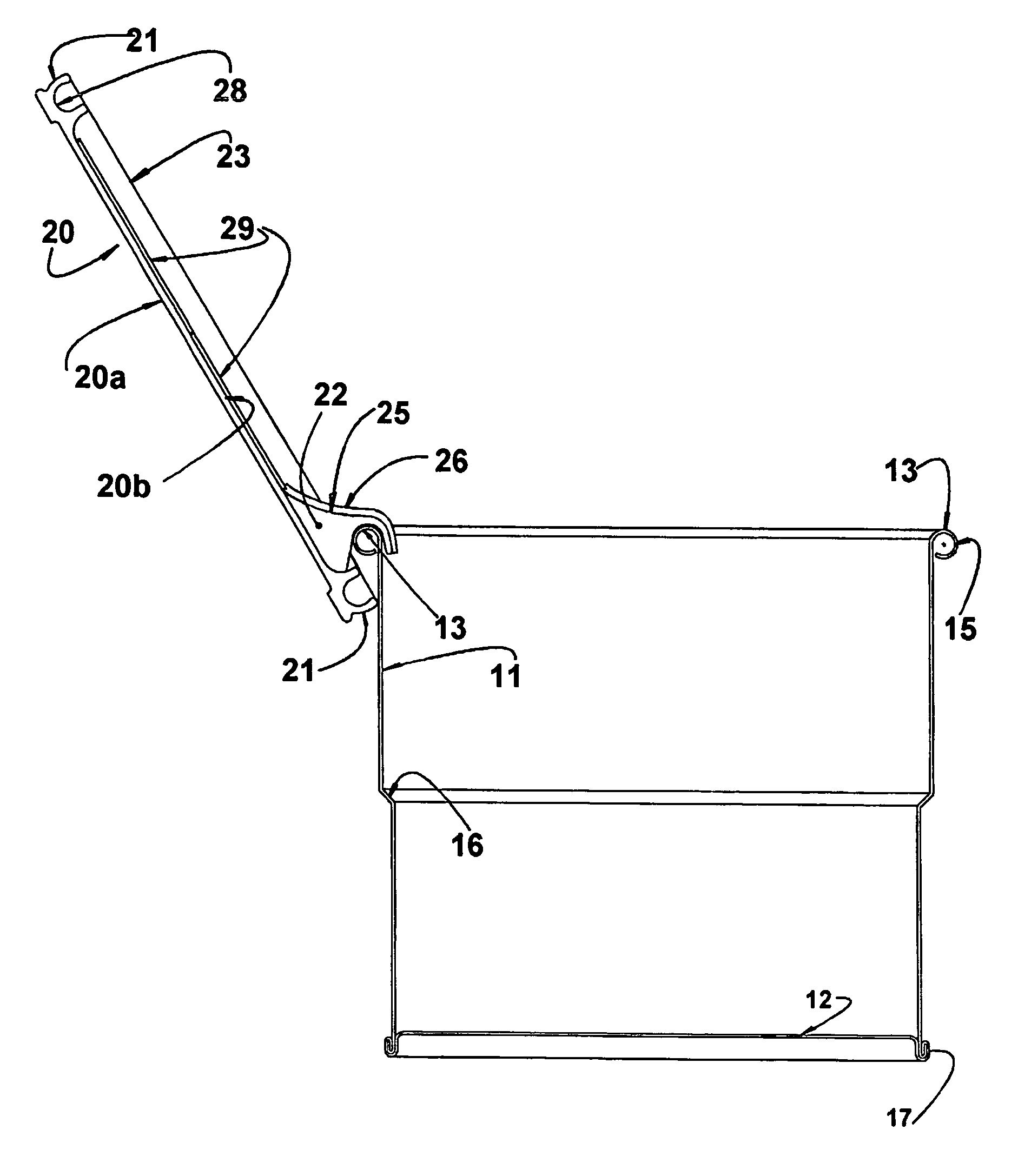

Removable lid of a paint container

InactiveUS7665626B2Simple and low cost constructionEasy to openCapsClosure capsEngineeringLower face

Owner:BRASILATA S A EMBALAGENS METALICAS

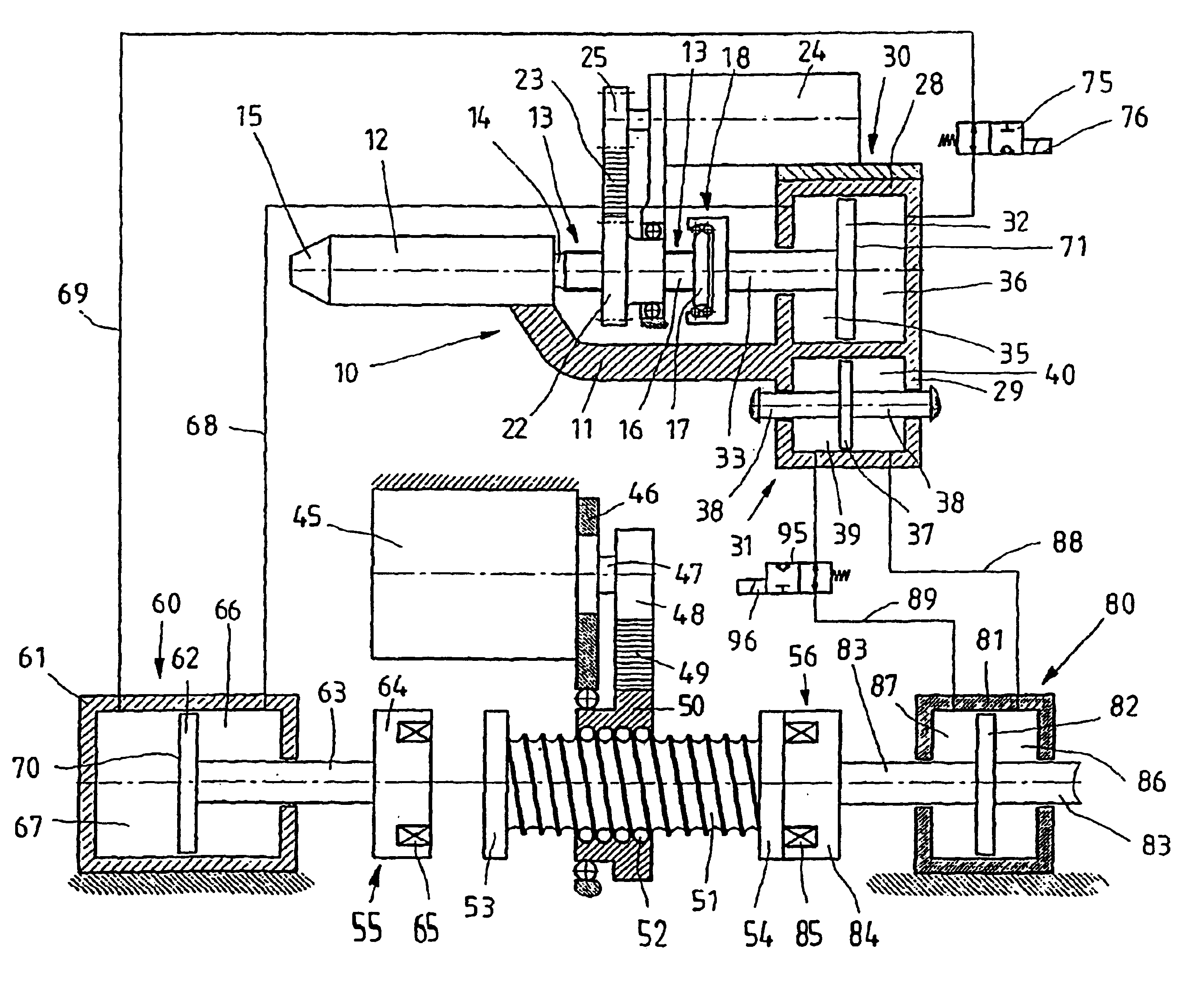

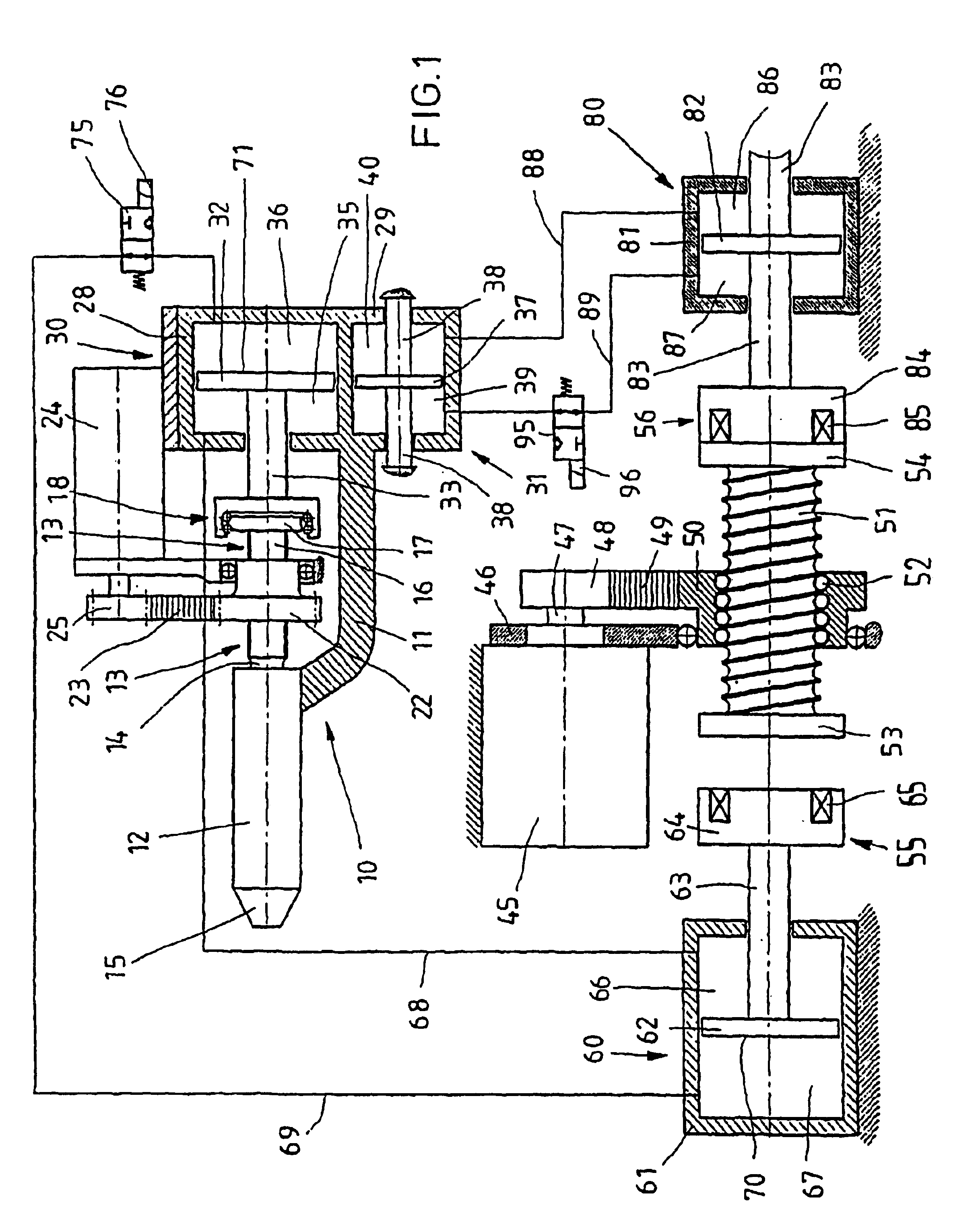

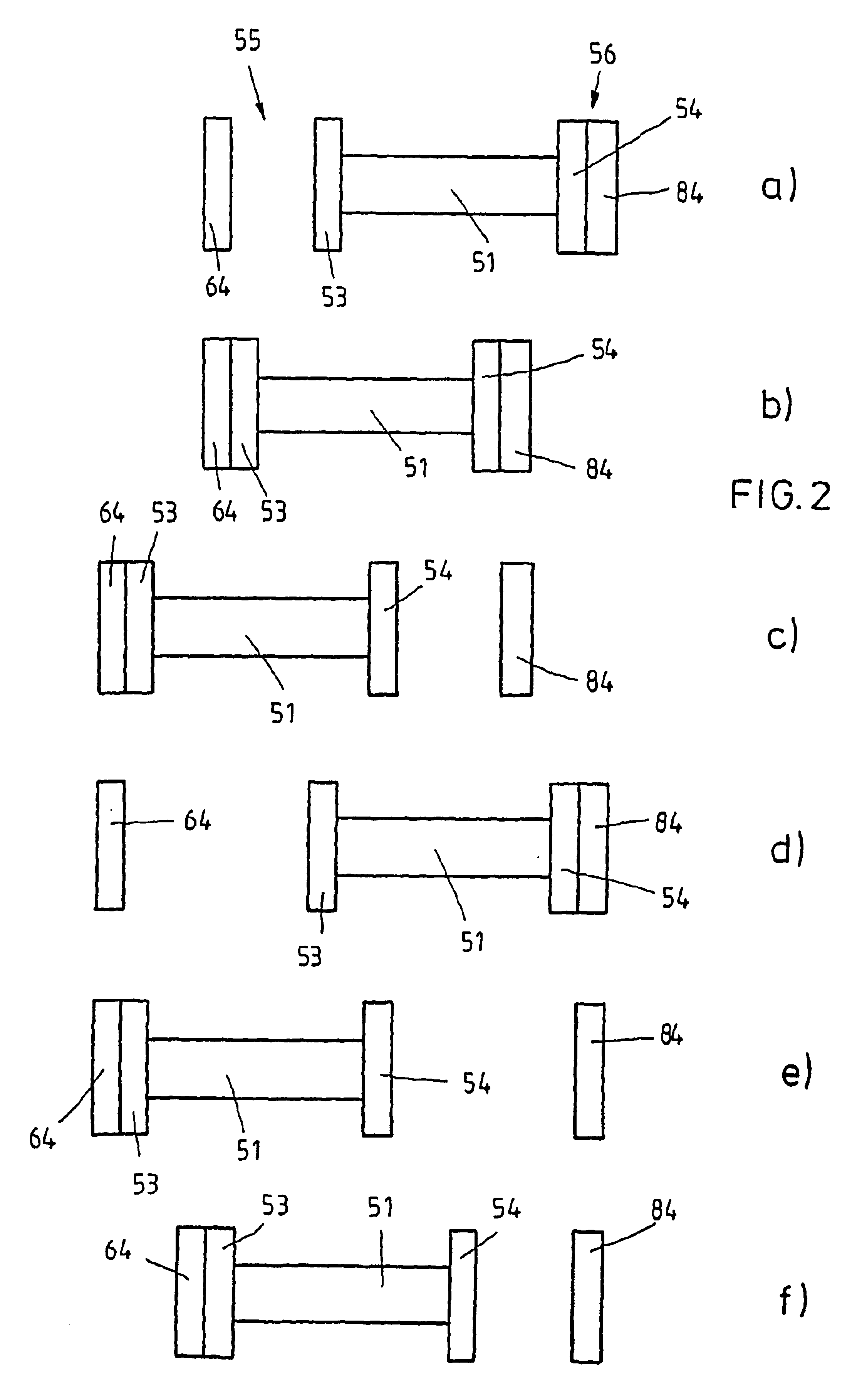

Drive device for displacing two linearly moveable components pertaining to a plastic injection moulding machine

InactiveUS6913456B2Not easy to wearSimple and low-cost constructionFood shapingLinear motionEngineering

A drive device which is intended for displacing two linearly movable components of a plastics injection-molding machine at least partly at successive times, in particular for displacing the injection unit for bringing the injection nozzle into contact with a mold and for displacing the injection mechanism for injecting polymer into the mold. With a known drive device, arranged downstream of an electric rotating motor are two clutches, by which rotational movements are transmitted on the basis of frictional engagement, and with which wear accordingly occurs. Each clutch is followed by a threaded drive, by which the rotational movement of the output element of a clutch is transformed into the linear movement of the machine component to be displaced. To make the known drive device for a plastics injection-molding machine less susceptible to wear and less costly in a first way the threaded drive is arranged between the electric motor and the two clutches and, for displacing the one movable component, the linearly movable drive output element of the threaded drive is able to be moved beyond the displacement distance necessary for displacing the other movable component. In a second way the electric motor is an electric linear motor with a linearly movable drive output element, arranged downstream of which in the force chains are the two clutches, and for displacing the one movable component, the drive output element is movable beyond the displacement distance necessary for displacing the other movable component.

Owner:BOSCH REXROTH AG

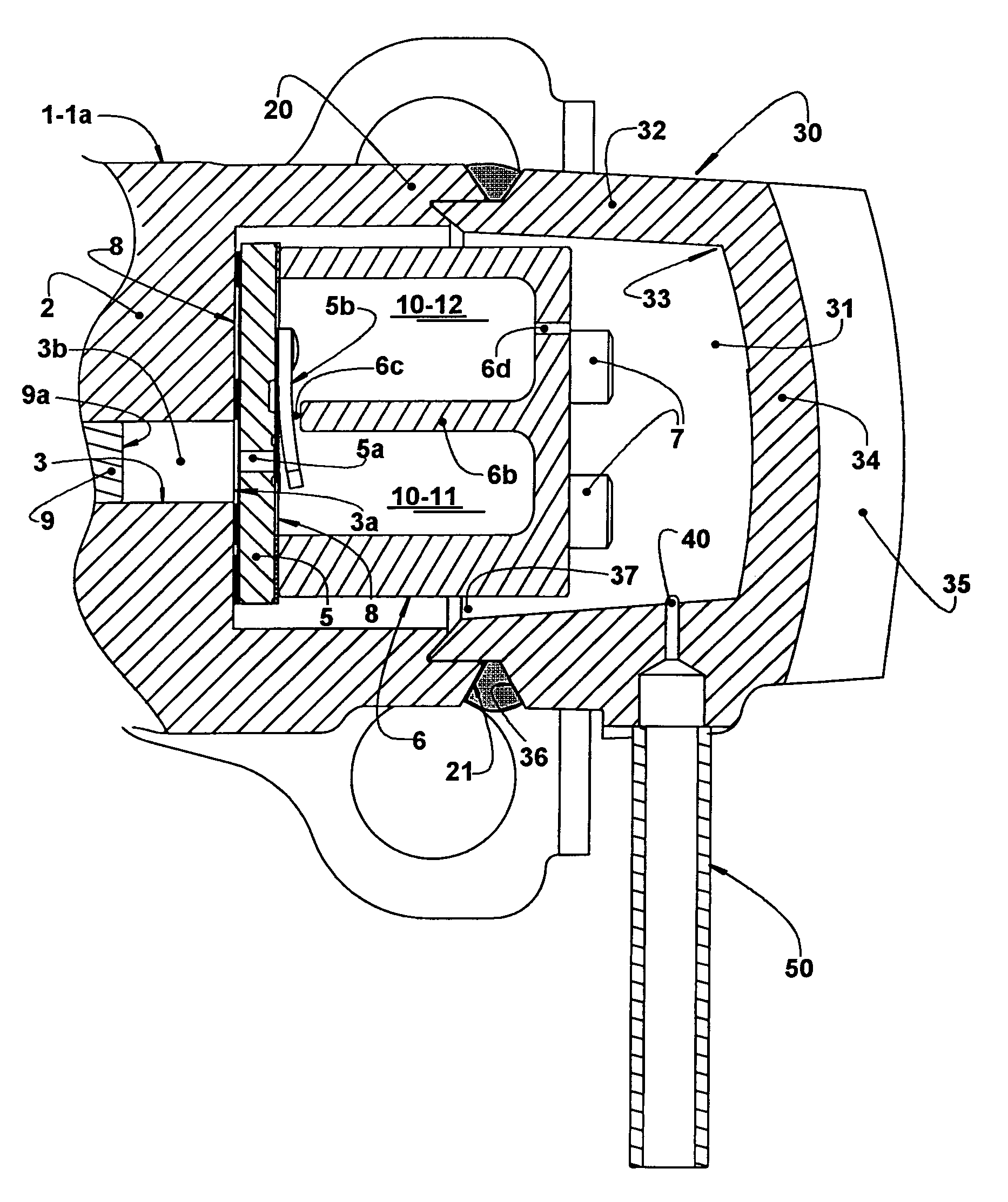

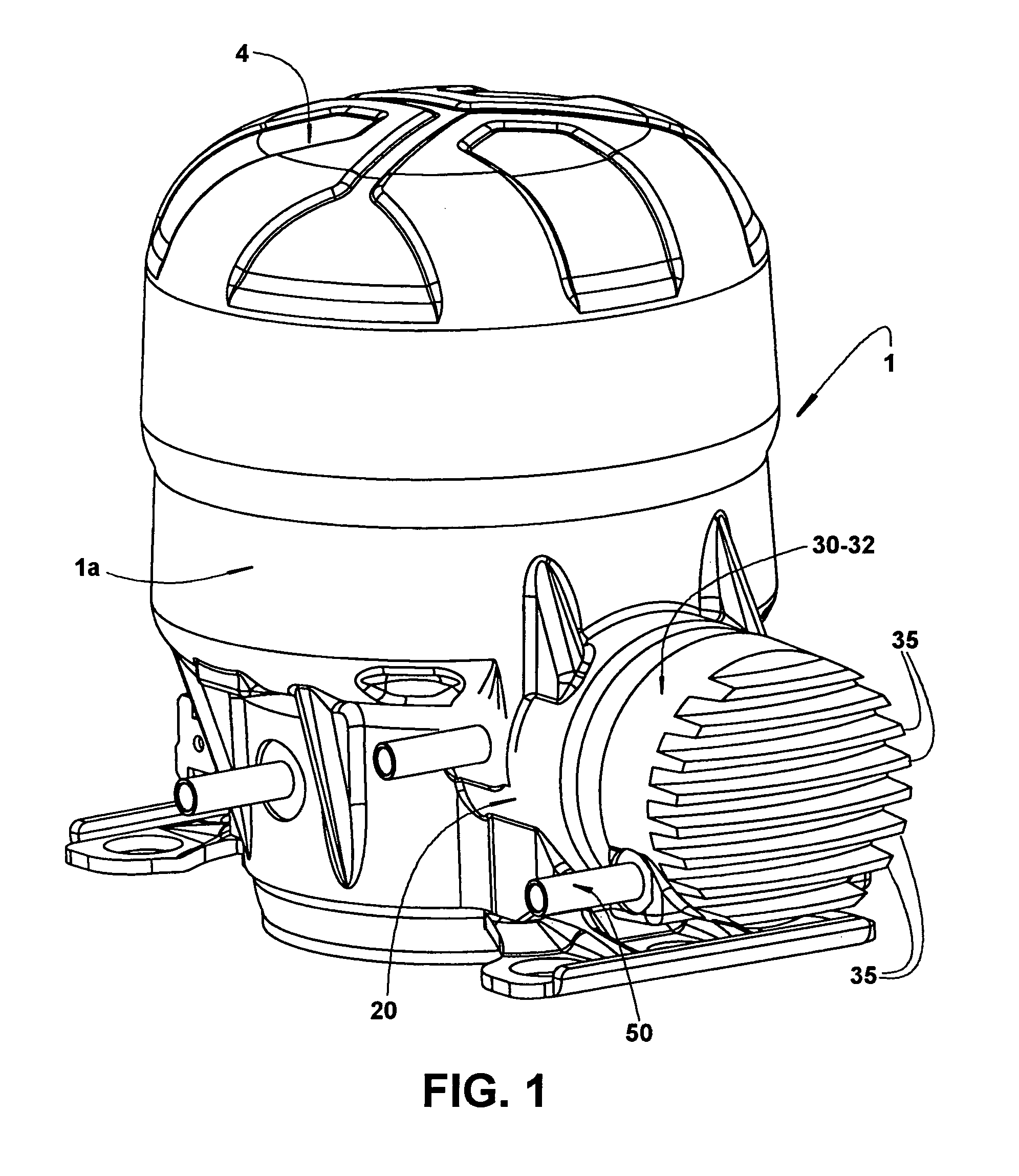

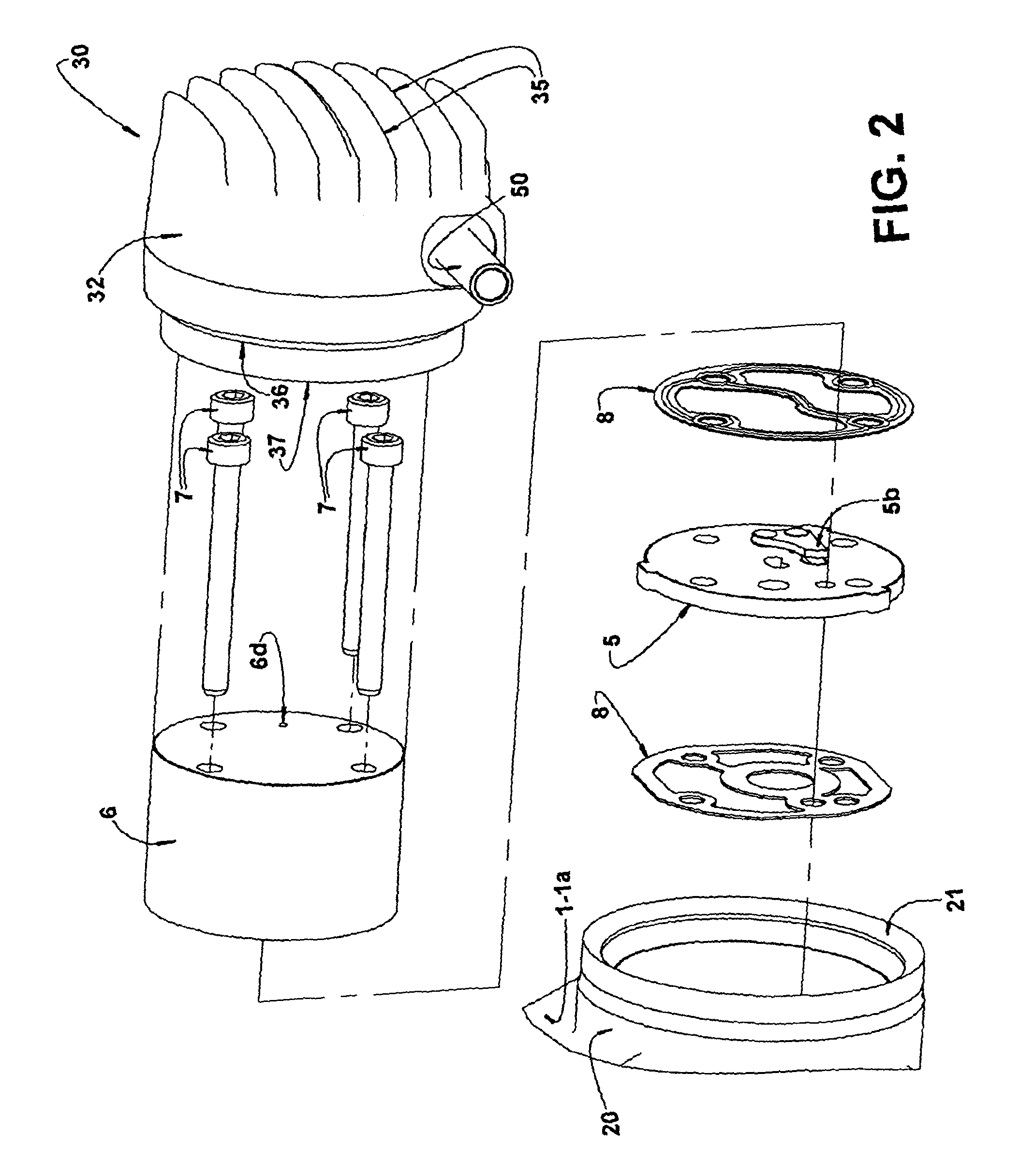

Constructive arrangement for a hermetic refrigeration compressor

InactiveUS8858194B2Improved noise attenuationImprove cooling effectPositive displacement pump componentsCompression machines with non-reversible cycleRefrigeration compressorEngineering

A hermetic compressor, comprises: a hermetic shell (1); a cylinder block (2) defining, a shell portion (Ia) and a compression cylinder (3) having an end (3a) opened to the exterior of the hermetic shell (1) and closed by a valve plate (5); a head (6) affixed to the cylinder block (2), over the valve plate (5) so as to define, with the latter, at least one discharge chamber (10). The cylinder block (2) incorporates a tubular projection (20) surrounding the valve plate (5) and at least part of the head (6). An outer cover (30) is hermetically affixed to the tubular projection (20) for defining therewith a discharge plenum (31) in fluid communication with the discharge chamber (10), the tubular projection (20) or the outer cover (30) being provided with a refrigerant gas outlet (40) opened to the exterior of the hermetic shell (1).

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

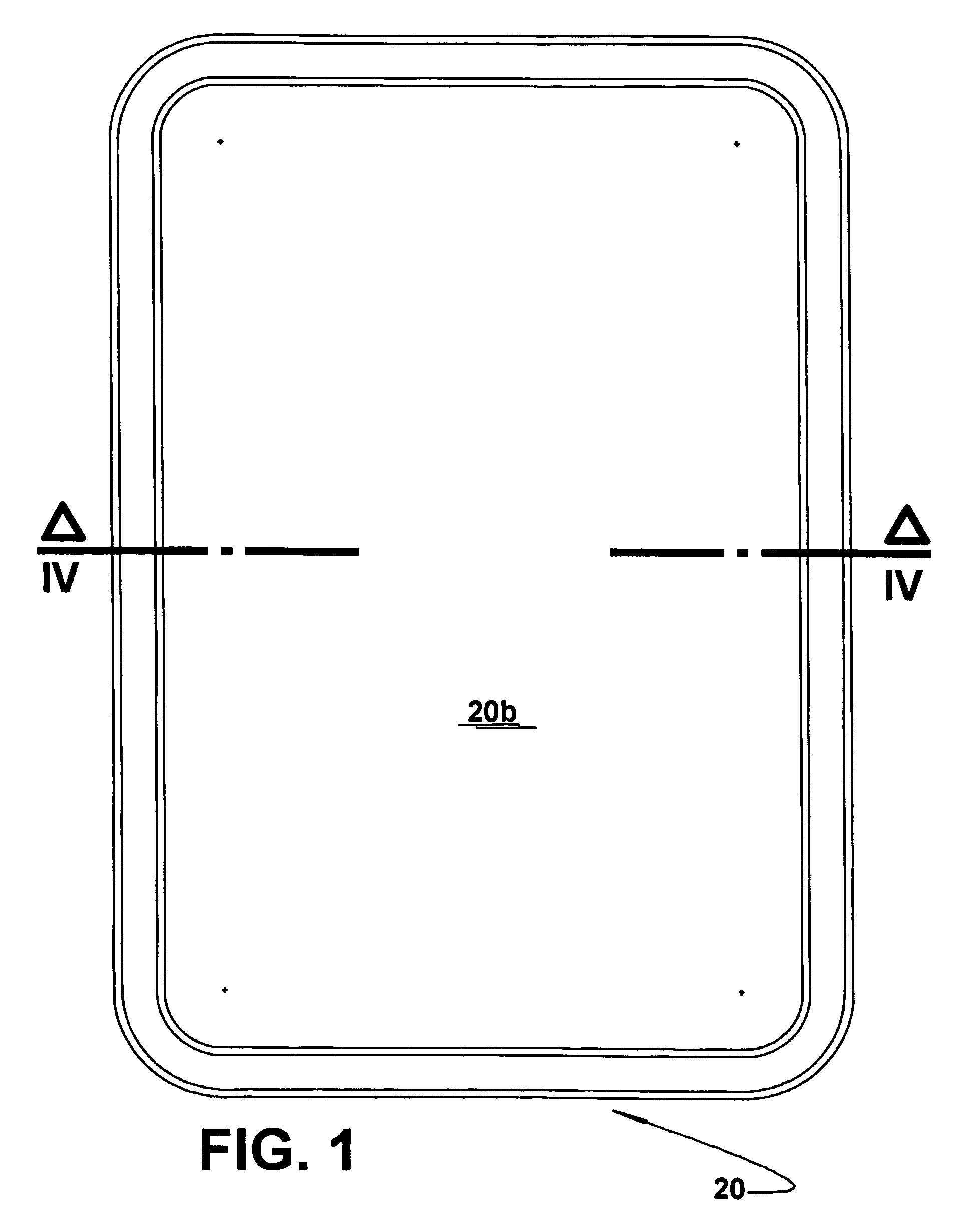

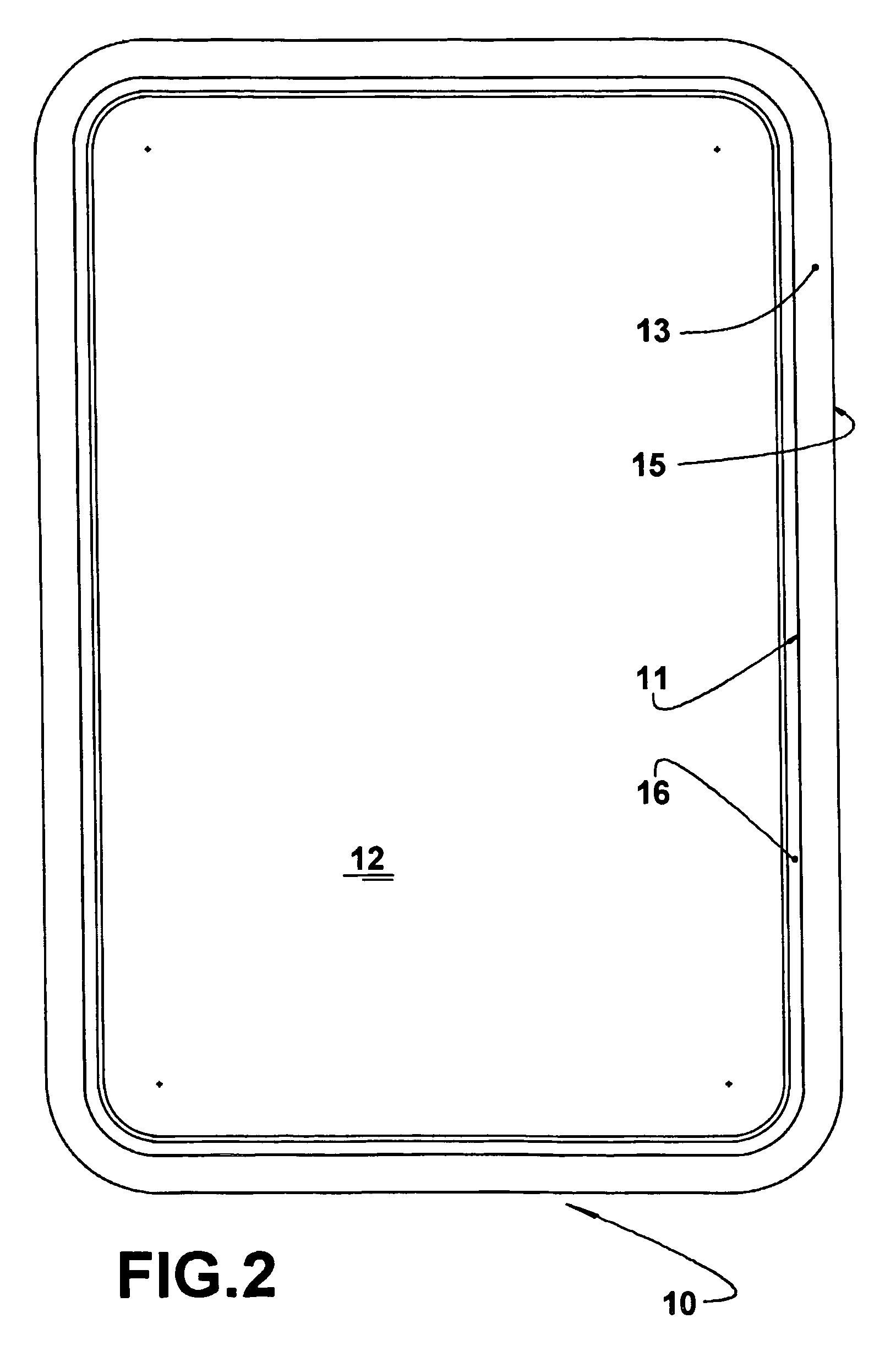

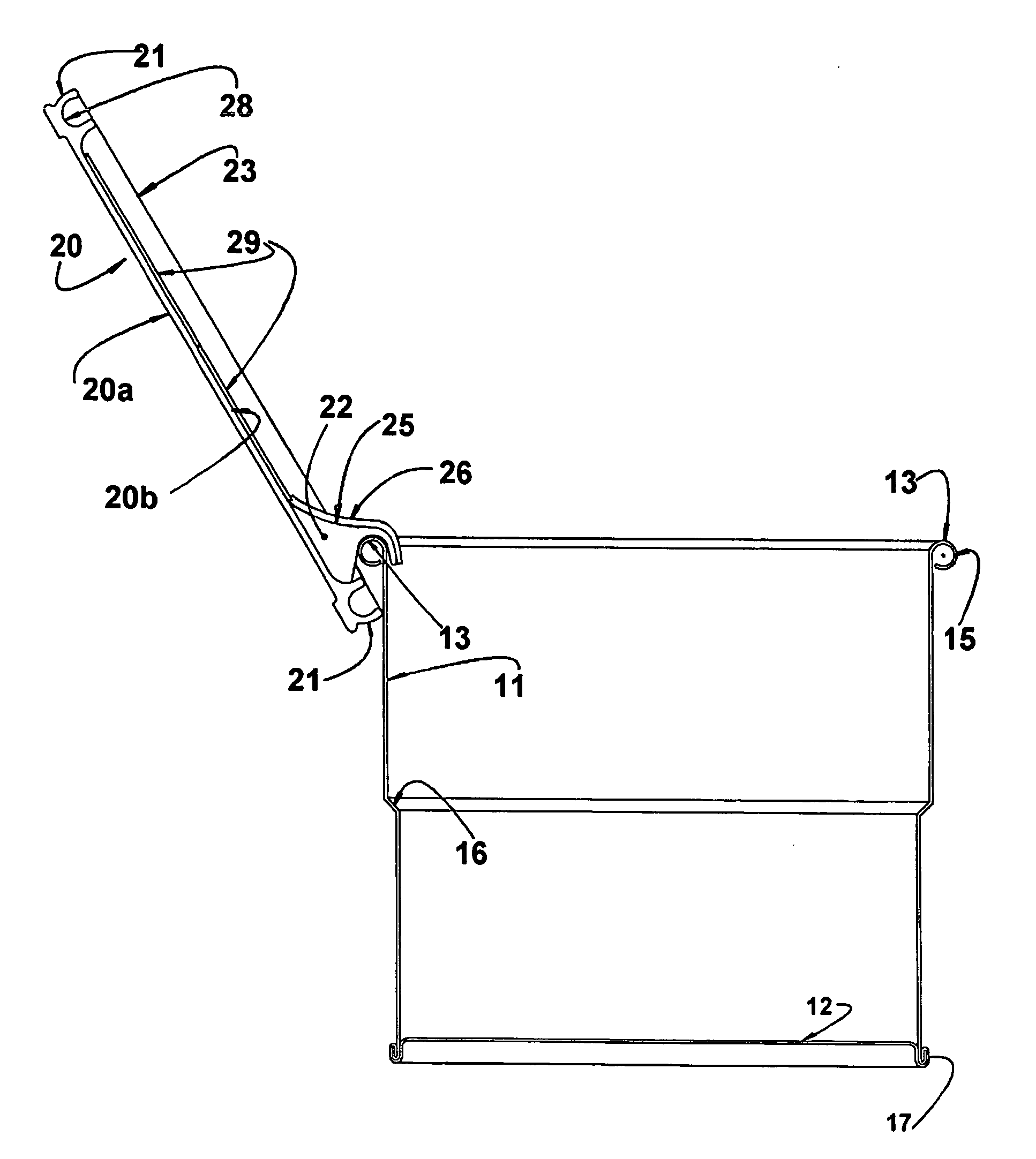

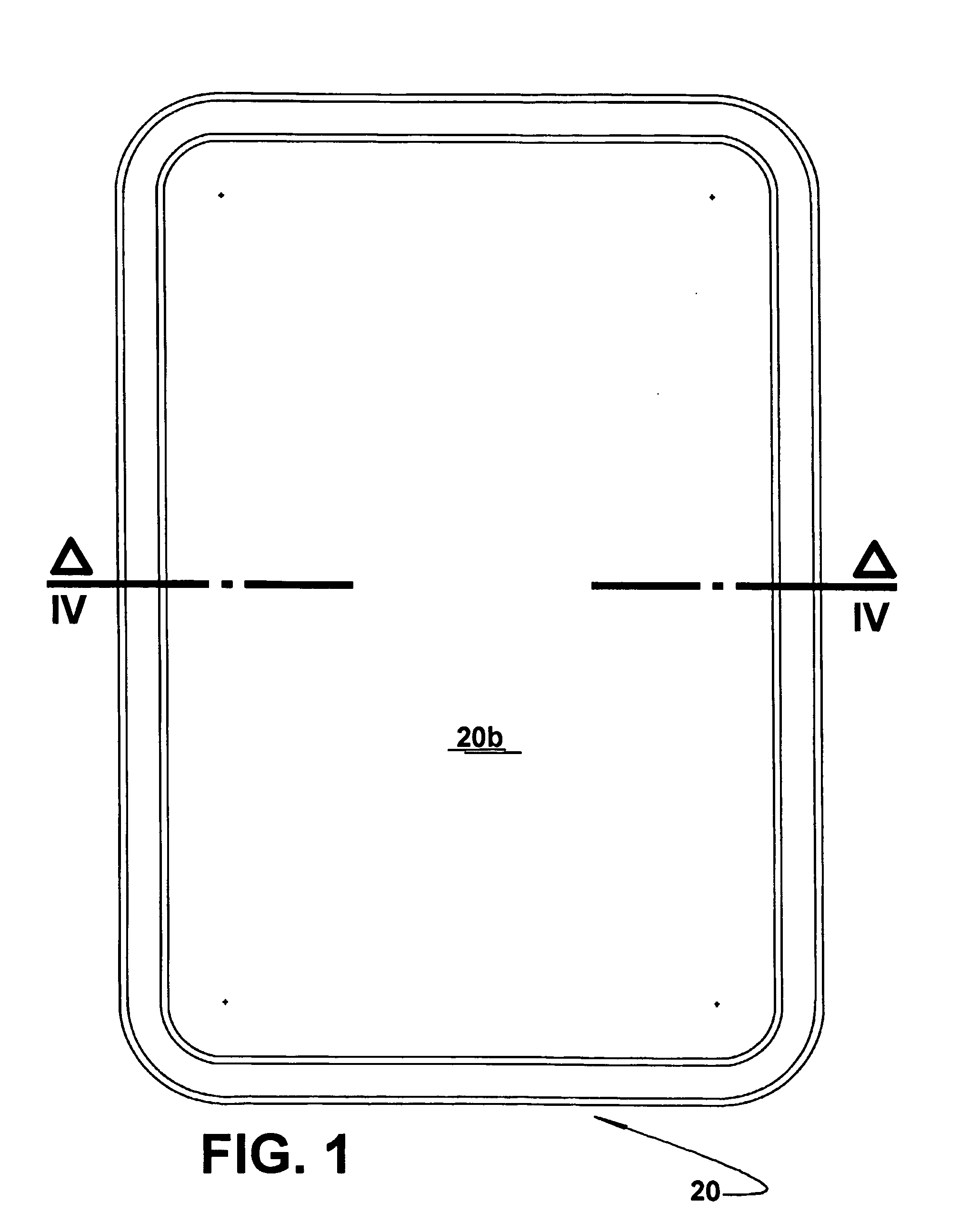

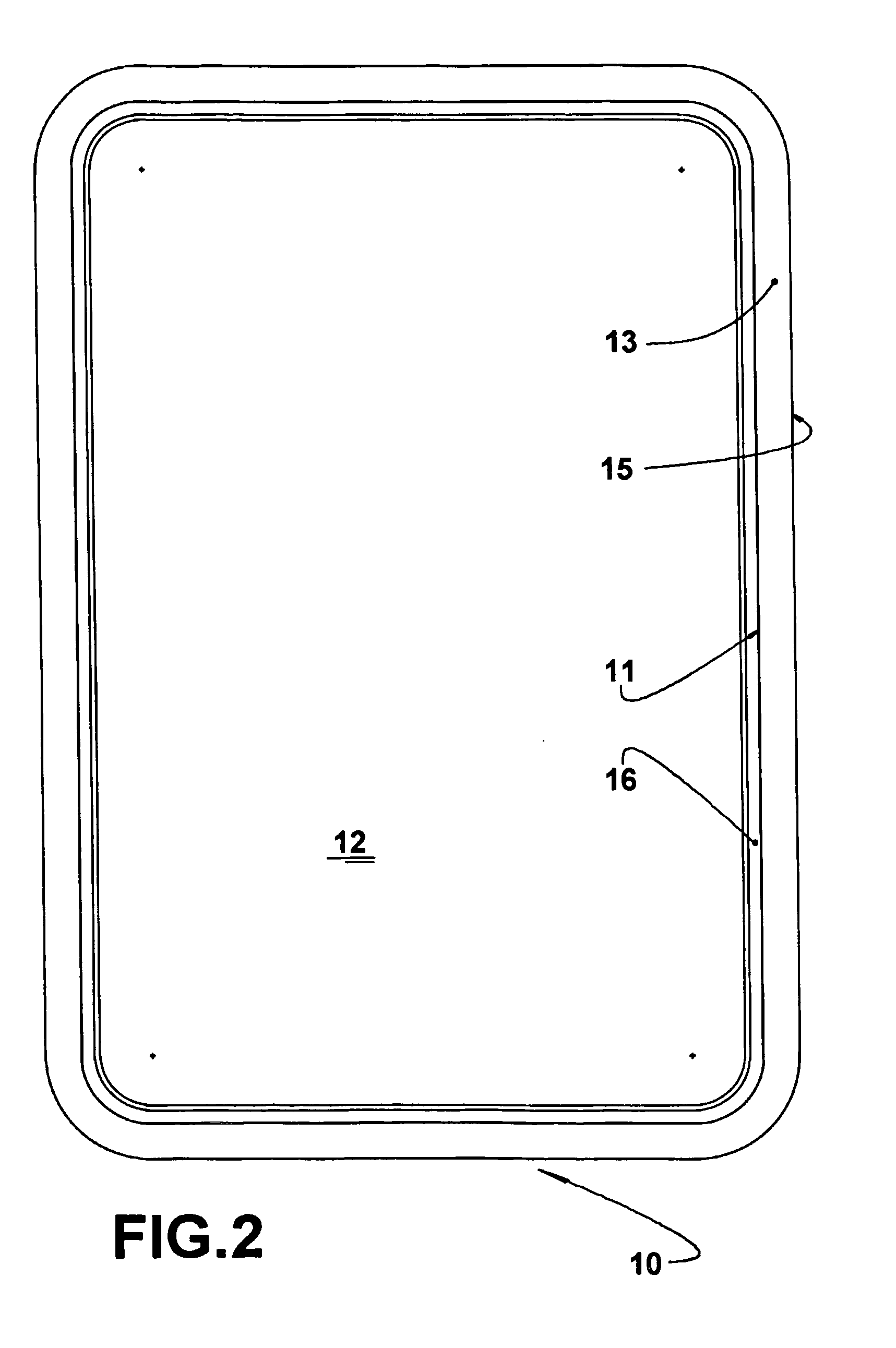

Removable lid of a paint container

InactiveUS20060255034A1Rapidly and easily removedSimple and low cost constructionCapsClosure capsClassical mechanicsStructural engineering

A paint container, comprising a body (10) with a polygonal cross section, presenting upper edge portions (13) and a lid (20) having lateral edge portions (21) which are removably seated and tightly retained in a seat (15) defined along the upper edge portions (13) of the body (10). The lid (20) presents a lower face (20a) incorporating a downwardly projecting support means (22) which is engaged with an adjacent upper edge portion (13) of the body (10) after the opening of the lid (20), in order to maintain the latter with its adjacent lateral edge portion (21) externally seated against the lateral wall (11) of the body (10) and in an inclined position with its lower face (20a) forming a paint drip tray, said support means (22) defining a deflecting chute (25) for directing, to the interior of the body (10), the paint that is gravitationally dripping down the internal face (20a) of the lid (20).

Owner:BRASILATA S A EMBALAGENS METALICAS

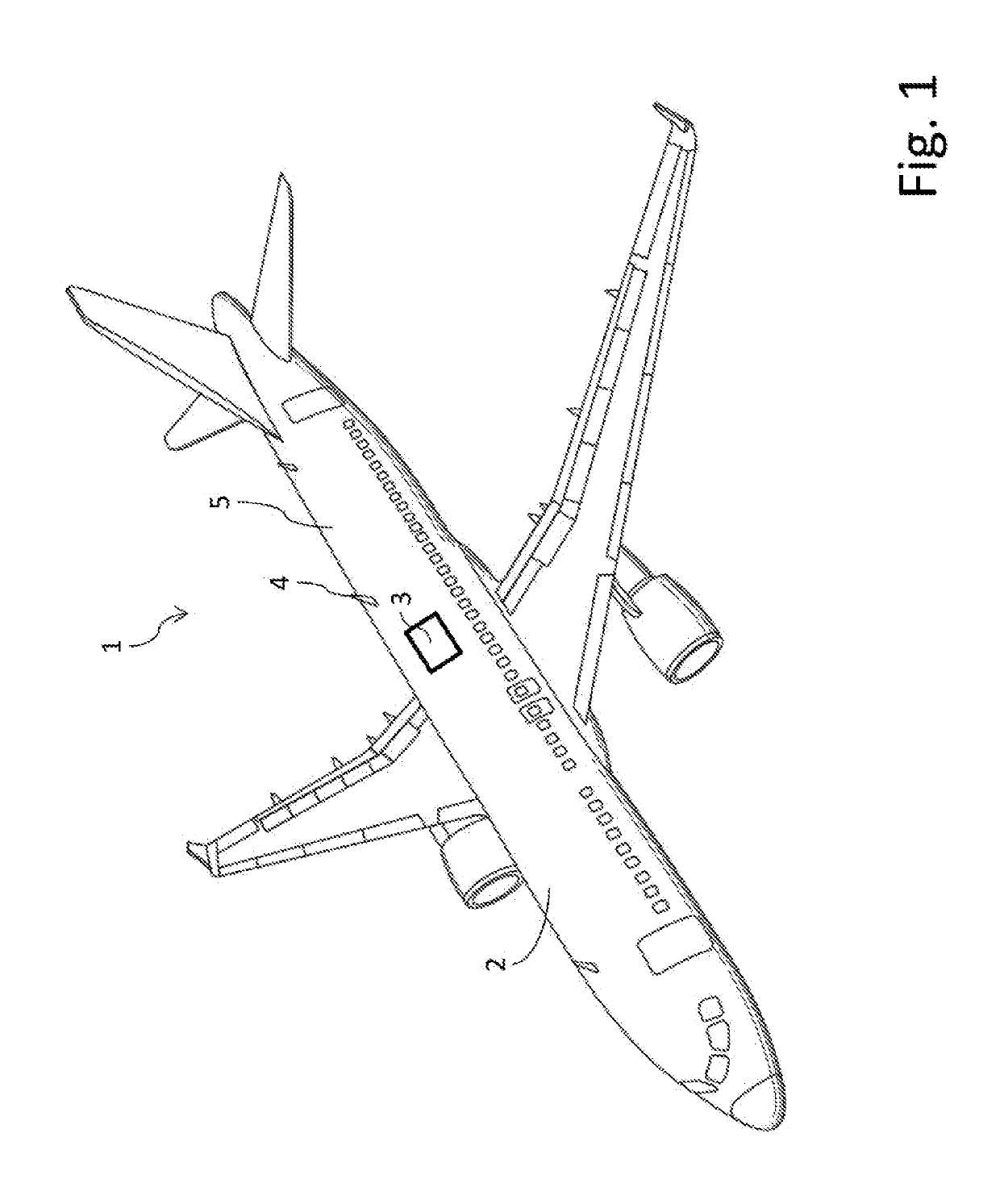

Antenna Assembly For An Aircraft

ActiveUS20190245264A1Simple and low-cost constructionEasy to installAntenna supports/mountingsAntenna adaptation in movable bodiesAntenna elementAirplane

An aircraft antenna assembly has a support element having a first and a second surface on opposite sides, an antenna element arranged on or in the support element, and a sealing device. The first surface and the sealing device are configured such that the antenna assembly is arranged on an outer skin section of an aircraft such that the first surface faces the outer skin section, the sealing device is situated between the support element and the outer skin section, and a cavity is defined by the sealing device, the outer skin section and the first surface. The support element or the sealing device y has a flow channel having a first and a second opening at opposite ends, the flow channel connecting the cavity and the environment and opening into the cavity at the first opening and opening into the environment at the second opening.

Owner:AIRBUS OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com