Dynamic Force Chain Observation Device of Abrasive Group in Flexible Polishing

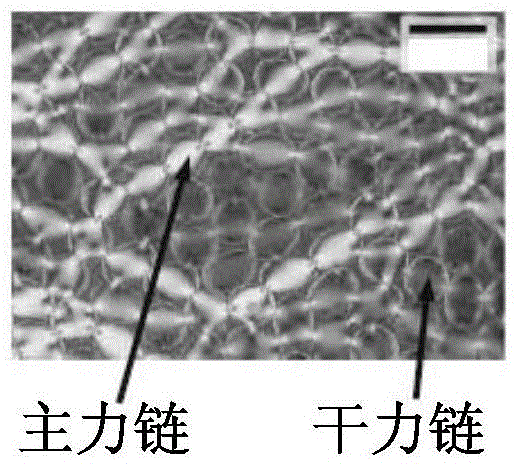

A flexible polishing and observation device technology, which is applied in the measurement of the change force of the optical properties of the material when it is stressed, can solve the problems that the particles are difficult to directly observe, and the microscopic mechanical properties of the abrasive particle group are difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further illustrate the present invention below in conjunction with accompanying drawing

[0019] Referring to the attached picture:

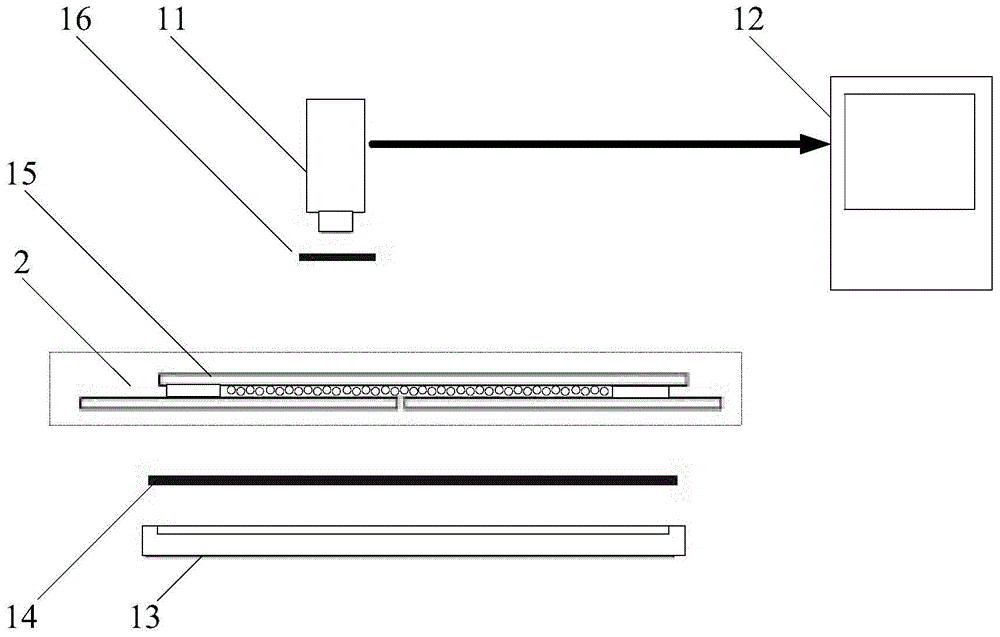

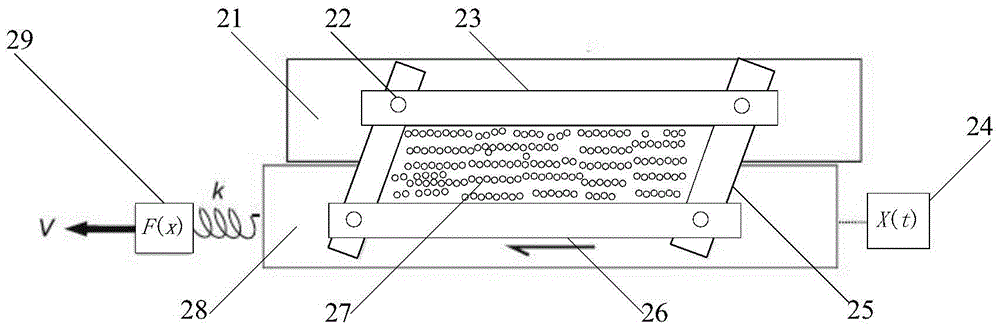

[0020] The flexible polishing abrasive particle group dynamic force chain observation device of the present invention includes an image processing device 1 and a particle control device 2, and the image processing device 1 includes a light source generator 13, a light source collector 11, and a data analyzer 12, The light source generator 13 is located at the lowest end of the observation area, and the light source emitted by the light source generator 13 passes through the lower polarizer 14 and points to the particles between the observation area composed of the lower polarizer 14 and the upper polarizer 16 Control device 2; the upper surface of the particle control device 2 is covered with a transparent baffle 15; the light source collector 11 is located directly above the upper polarizer 16, and the light source collection field of vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com