Electricity supply system for argon arc welding machine

A technology of argon arc welding machine and power supply system, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of waste, inconvenient portability, high cost, etc., achieve small steady-state error, improve control performance, and good convergence speed and the effect of optimizing the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

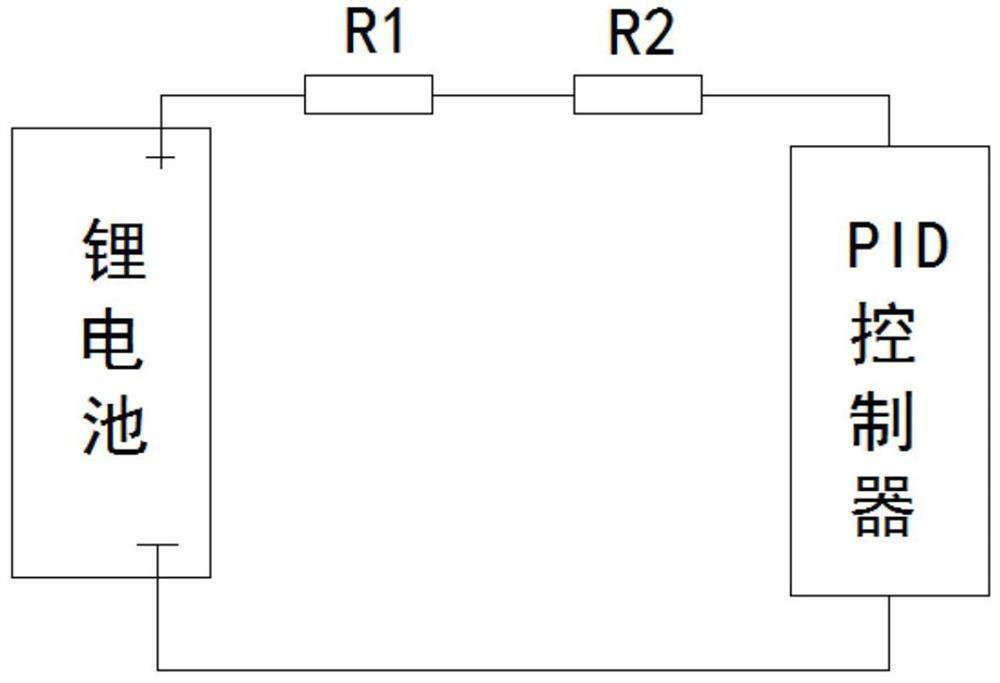

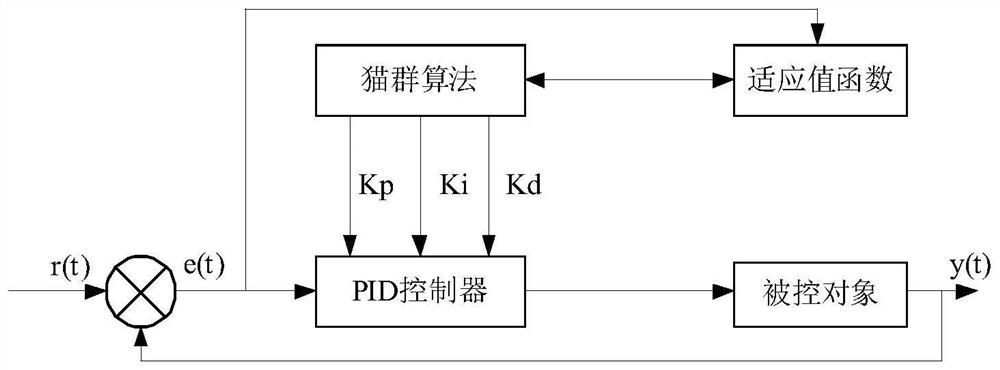

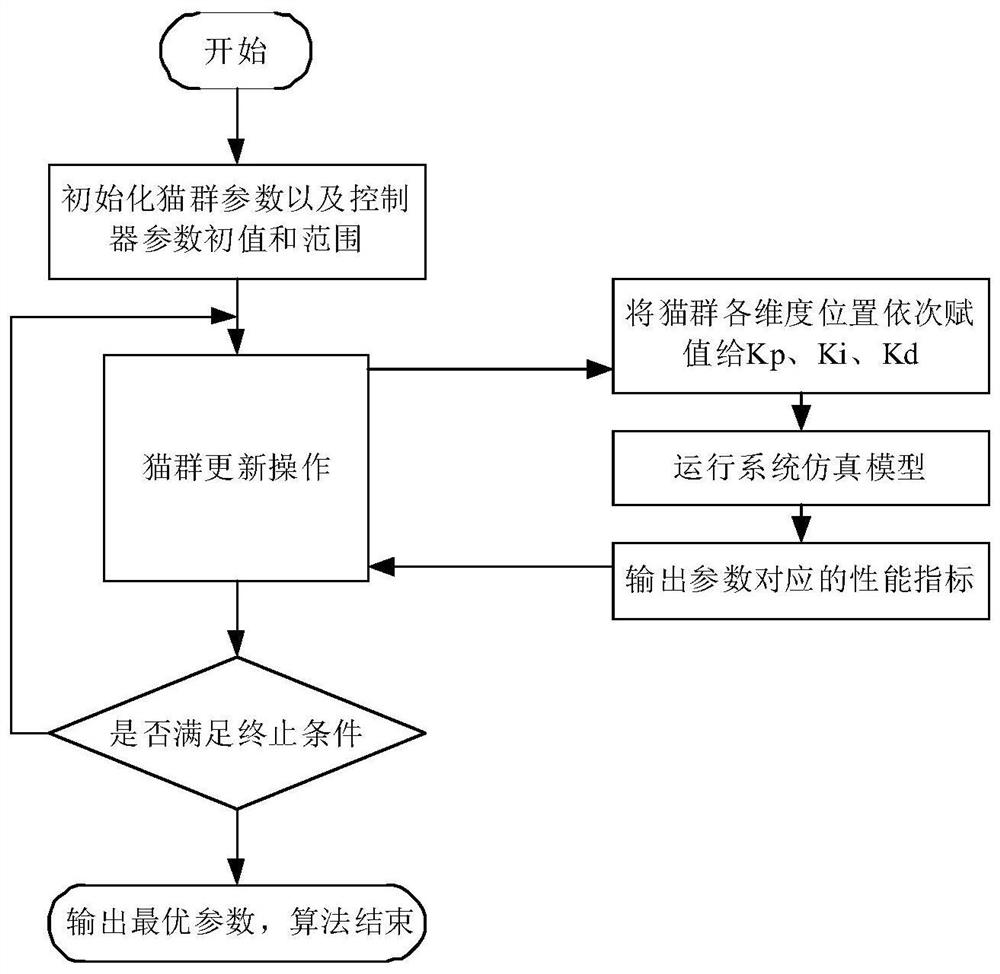

[0031] One embodiment of the present invention discloses a power supply system for an argon arc welder, including a lithium battery used to power the argon arc welder and a management system for managing the lithium battery. The management system includes charging and discharging control system and output control system, the charge and discharge control system includes a battery sampling circuit and a PID controller, such as figure 1 As shown, the battery sampling circuit includes a first resistor R1 and a second resistor R2, the first end of the first resistor R1 is connected to the positive electrode of the lithium battery, the second end of the first resistor R1 is connected to the second resistor R2 The first end is connected, and the second end of the second resistor R2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com