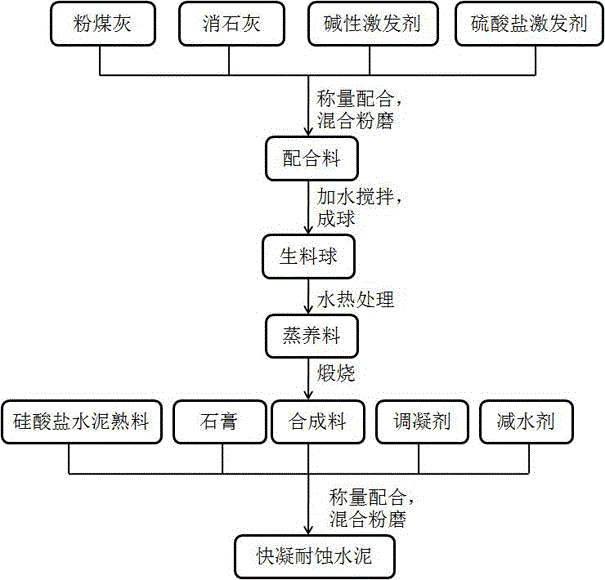

A kind of fast-setting corrosion-resistant cement using fly ash as raw material and preparation method thereof

A fly ash and raw material technology, which is applied in the field of fast-setting corrosion-resistant cement and its preparation, can solve the problems of poor cement performance and achieve the effects of less emissions, reduced steam curing heat consumption, and low calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The batch contains the following ingredients in parts by mass:

[0032]

[0033] Take fly ash, slaked lime, sodium hydroxide, and Glauber's salt according to the above mass ratio and grind together until the fineness is 80 μm and the sieve residue is 4.2%. After adding 20 parts of water, stir for 3 minutes, and prepare a ball with a diameter of 8-12mm material balls, the material balls are steamed in a steaming box at 90°C for 16 hours to obtain steamed nutrients, and the steamed nutrients are calcined at 750°C for 90 minutes and then blown to obtain synthetic materials. 75 parts of synthetic materials, Portland cement 20 parts of clinker, 8 parts of dihydrate gypsum, 0.3 part of sodium citrate, and 0.3 part of sodium methylene dimethyl dinaphthalene sulfonate polymer are jointly ground to a sieve residue of 80 μm to 3.1%, and a fast-setting resistant Erosion cement.

Embodiment 2

[0035] The batch contains the following ingredients in parts by mass:

[0036]

[0037] Weigh fly ash, slaked lime, potassium hydroxide, and dihydrate gypsum according to the above mass ratio and grind together until the fineness is 80 μm and the sieve residue is 3.8%, add 22 parts of water, stir for 3 minutes, and form a ball into a diameter The material ball is 8-12mm. The material ball is steamed in a steaming box at 95°C for 12 hours to obtain a steamed feed. The steamed feed is calcined at 800°C for 60 minutes and then blown to obtain a synthetic material. 80 parts of the synthetic material, silicate 15 parts of cement clinker, 5 parts of anhydrous gypsum, 1.0 part of sodium polyphosphate and 0.3 part of sodium lignosulfonate were ground together until the sieve residue of 80 μm was 2.8%, and a fast-setting corrosion-resistant cement was prepared.

Embodiment 3

[0039] The batch contains the following ingredients in parts by mass:

[0040]

[0041] Weigh fly ash, slaked lime, sodium carbonate, and Glauber's salt according to the above mass ratio and grind together until the fineness is 80 μm and the sieve residue is 3.3%. After adding 23 parts of water, stir for 3 minutes, and form a ball disc with a diameter of 8 ~ 12mm material balls, the material balls are steamed in a steaming box at 95°C for 12 hours to obtain steamed nutrients, and the steamed nutrients are calcined at 850°C for 30 minutes and then blown to obtain synthetic materials, 80 parts of synthetic materials, Portland cement clinker 15 parts are ground together with 7 parts of dihydrate gypsum, 0.5 parts of sodium gluconate, and 0.5 parts of sodium methylene dimethyl dinaphthalene sulfonate polymer until the 80 μm sieve is 2.5%, and a fast-setting corrosion-resistant cement is prepared .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com