Preparation method of long-fiber carbon ceramic fastener

A fastener and carbon ceramic technology, which is applied in the field of preparation of long-fiber carbon ceramic fasteners, can solve the problems of low thermal expansion coefficient, low gas source conversion rate, long preparation period, etc. Deposition rate, effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

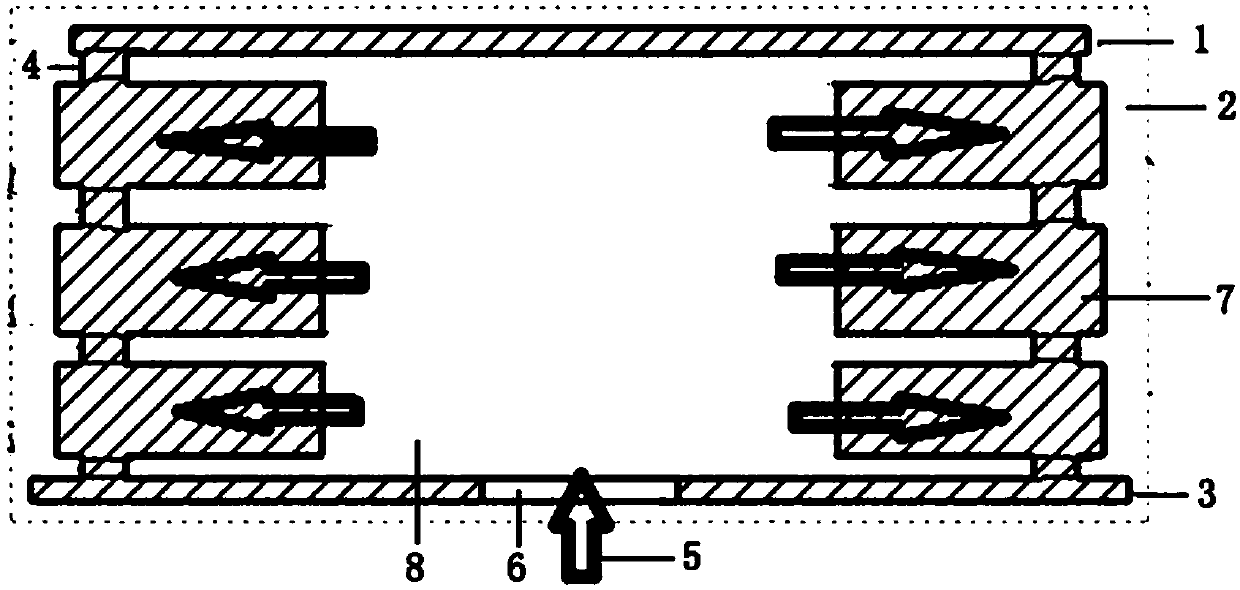

Method used

Image

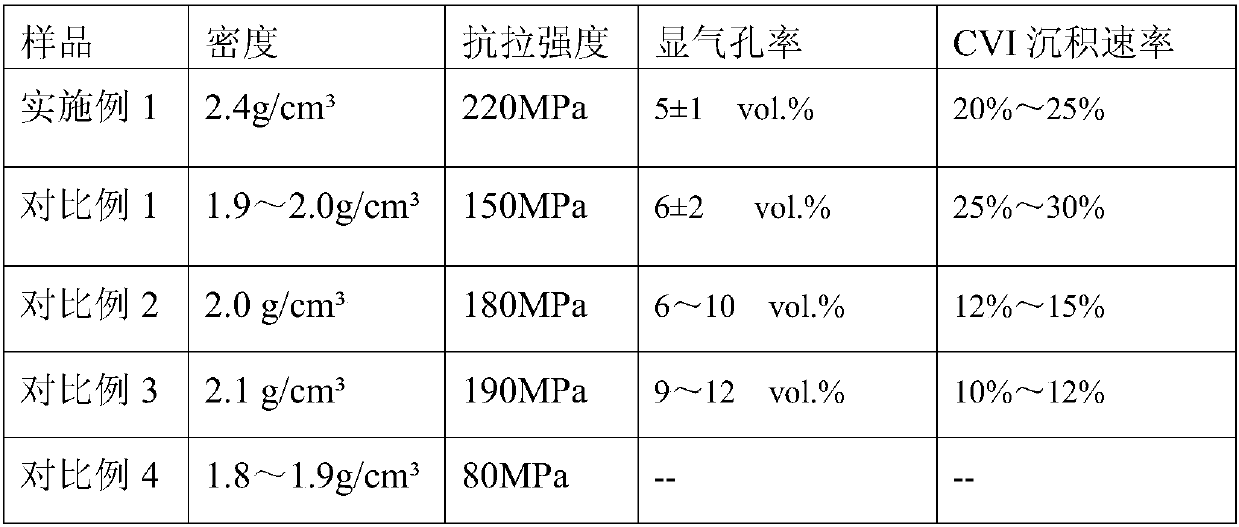

Examples

Embodiment 1

[0039] A method for preparing long-fiber carbon-ceramic fasteners includes the steps:

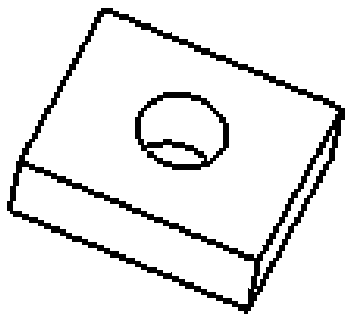

[0040] (1) A layer of long-fiber weft-free cloth (length * width is 400*400mm, long fiber length is 400mm, fineness is 0.6mm), a layer of short fiber mesh (length * width is 400*400mm, short The fiber length is 65mm and the fineness is 0.6mm) alternately. The angle between adjacent long-fiber non-weft fabric layers is 90°. Each layer of short-fiber mesh is needle punched, and the final weave is The thickness is up to 30mm. Needle density is 20 needles / cm 2 , The interlayer density is 16 layers / cm, the mass content of long-fiber non-weft fabric is 85%, the mass content of short-fiber mesh is 15%, and the final weave is 0.5g / cm. 3 Three-dimensional acupuncture preform, and finally cut into figure 1 As shown, the center is a three-dimensional needle punched preform with a through hole, and the diameter of the through hole is about φ50 mm.

[0041] (2) Place the three-dimensional needle-punched pre...

Embodiment 2

[0045] A method for preparing long-fiber carbon-ceramic fasteners includes the steps:

[0046] (1) A layer of long-fiber weft-free cloth (length * width is 400*400mm, long fiber length is 400mm, fineness is 0.6mm), a layer of short fiber mesh (length * width is 400*400mm, short The fiber length is 65mm and the fineness is 0.6mm) alternately. The angle between adjacent long-fiber non-weft fabric layers is 90°. Each layer of short-fiber mesh is needle punched, and the final weave is The thickness is up to 30mm. Needle density is 25 needles / cm 2 , The density between layers is 18 layers / cm, the mass content of long-fiber latitude cloth is 75%, the mass content of short-fiber mesh is 25%, and the final weave is 0.6g / cm. 3 Three-dimensional acupuncture preform, and finally cut into figure 1 As shown, the center is a three-dimensional needle punched preform with a through hole, the diameter of the through hole is about φ50mm;

[0047] (2) Place the three-dimensional needle-punched prefo...

Embodiment 3

[0051] A method for preparing long-fiber carbon-ceramic fasteners includes the steps:

[0052] (1) A layer of long-fiber weft-free cloth (length * width is 400*400mm, long fiber length is 400mm, fineness is 0.6mm), a layer of short fiber mesh (length * width is 400*400mm, short The fiber length is 60mm and the fineness is 0.6mm) alternately. The angle between adjacent long-fiber non-weft fabric layers is 90°. Each layer of short-fiber mesh is needle punched and finally woven into The thickness is up to 30mm. Needle density is 23 needles / cm 2 , The interlayer density is 17 layers / cm, the mass content of long-fiber non-weft cloth is 80%, the mass content of short-fiber mesh is 20%, and the final weave is 0.55g / cm. 3 Three-dimensional acupuncture preform, and finally cut into figure 1 As shown, the center is a three-dimensional needle punched preform with a through hole, the diameter of the through hole is φ50mm;

[0053] (2) Place the three-dimensional needle-punched preform obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com