Preparation method of nano-crystalline zinc plating layer by using direct current electrodeposition

A technology of zinc coating and direct current, applied in the field of surface engineering and surface treatment, to achieve the effect of fine grain, small investment and short deposition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation process and steps in this embodiment are as follows:

[0019] a. First prepare the acidic sulfate bath, 350g of ZnSO 4 ·7H 2 O was dissolved in distilled water to prepare 1L of plating solution, adding concentrated sulfuric acid to adjust the pH value to 2;

[0020] b. Then add CTAB, BA and PEG three additives one by one to the prepared ZnSO 4 In the solution; the concentration of various additives is 0.5g / L, and the temperature of the plating solution is 25°C;

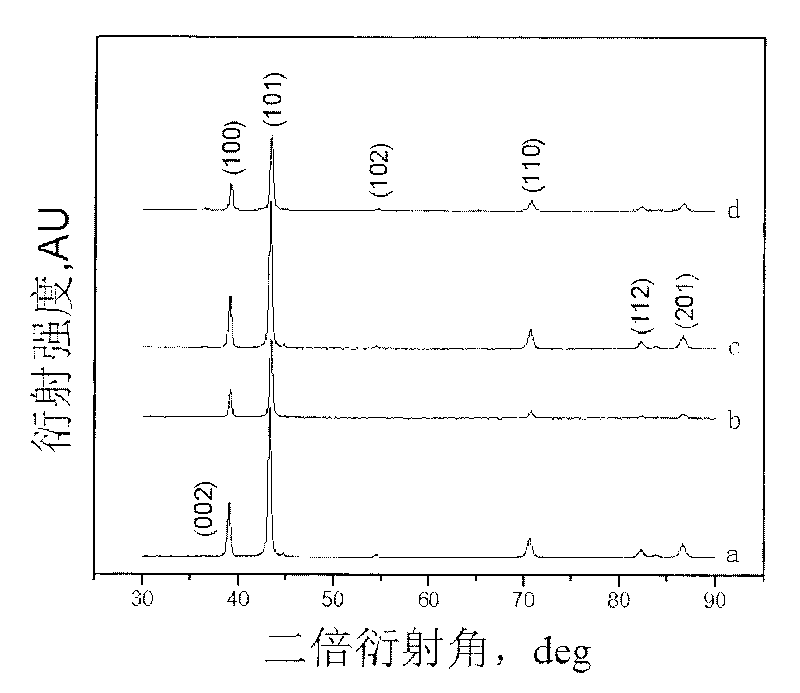

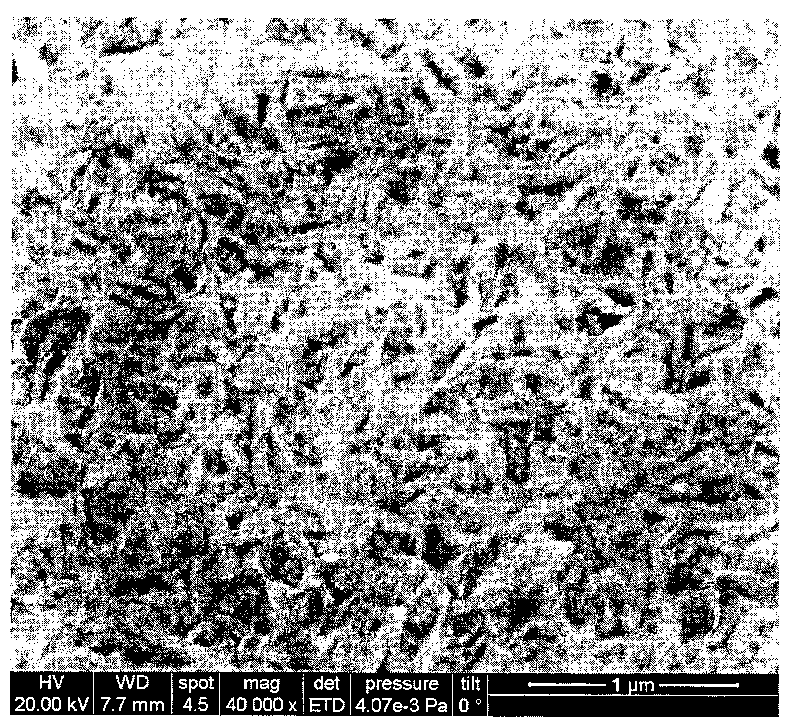

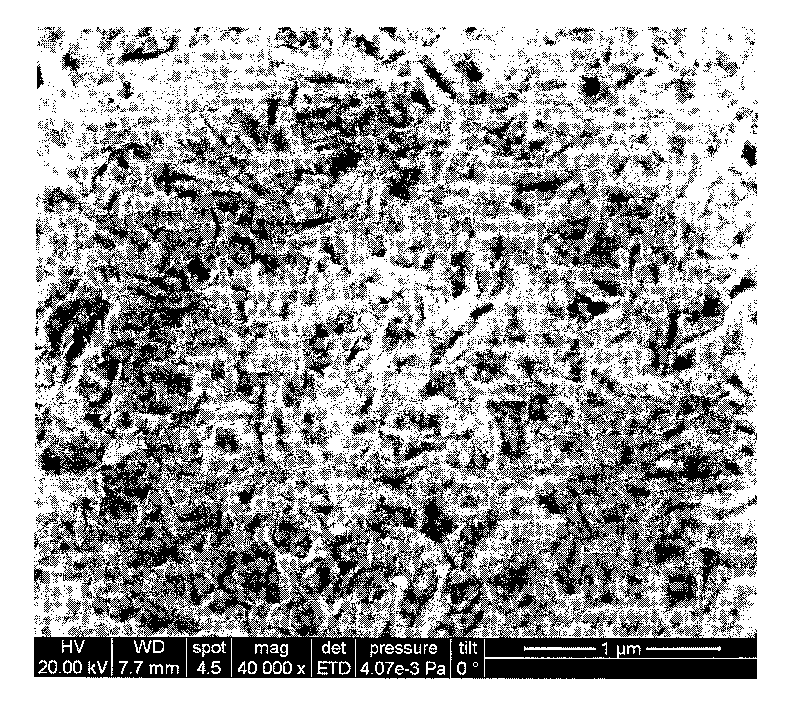

[0021] c. Electrodeposition is carried out by DC electroplating method; in the electroplating tank filled with the above-mentioned sulfate plating solution, the carbon steel sheet of the material to be plated is used as the cathode, and the platinum sheet is used as the anode, and 1A / cm 2 DC current, electroplating 3min; such as figure 1 As shown in (a), the XRD diffraction peaks of the zinc coating have been significantly broadened, and the (101) random orientation can be calculated by usin...

Embodiment 2

[0023] The preparation process and steps in this embodiment are as follows:

[0024] a. First prepare the acidic sulfate bath, with 200g of ZnSO 4 ·7H 2 O was dissolved in distilled water to prepare 1L of plating solution, and concentrated sulfuric acid was added to adjust the pH value to 1;

[0025] b. Then add CTAB, BA and PEG three additives one by one to the prepared ZnSO 4 In the solution; the concentration of various additives is 2g / L, and the temperature of the plating solution is 60°C;

[0026] c. Electrodeposition is carried out by DC electroplating method; in the electroplating tank filled with the above-mentioned sulfate plating solution, the carbon steel sheet of the material to be plated is used as the cathode, and the platinum sheet is used as the anode, and 2A / cm 2 DC current, electroplating 1min; such as figure 1 As shown in (b), the XRD diffraction peaks of the zinc coating have been significantly broadened and are (101) random orientation. The average gra...

Embodiment 3

[0028] The preparation process and steps in this embodiment are as follows:

[0029] a. First prepare the acidic sulfate bath, 100g of ZnSO 4 ·7H 2 O was dissolved in distilled water to prepare 1L of plating solution, and concentrated sulfuric acid was added to adjust the pH value to 4;

[0030] b. Then add CTAB, BA and PEG three additives one by one to the prepared ZnSO 4 In the solution; the concentrations of various additives are 0.5, 1 and 3g / L respectively, and the temperature of the plating solution is 25°C;

[0031] c. Electrodeposition is carried out by DC electroplating method; in the electroplating tank filled with the above-mentioned sulfate plating solution, the carbon steel sheet to be plated is used as the cathode, and the platinum sheet is used as the anode, and 3.5A / cm 2 DC current, electroplating 1min; such as figure 1 As shown in (c), the XRD diffraction peaks of the zinc coating have been significantly broadened and are (101) random orientation. The aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com