Prepn process of nanometer tin dioxide rod

A technology of tin dioxide and nanorods, applied in tin oxide, nanostructure manufacturing, nanotechnology, etc., can solve problems such as complex process and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

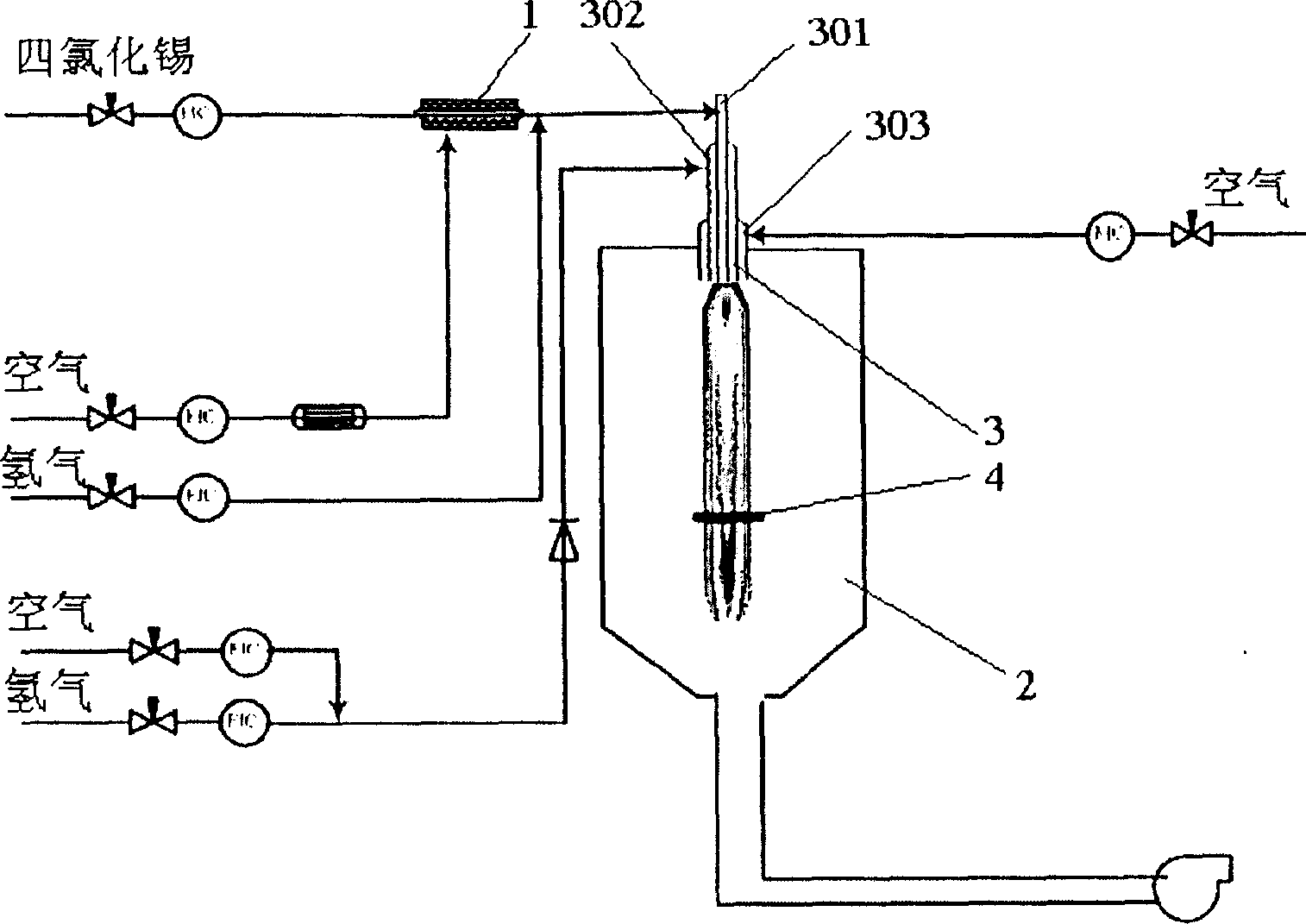

Method used

Image

Examples

Embodiment 1

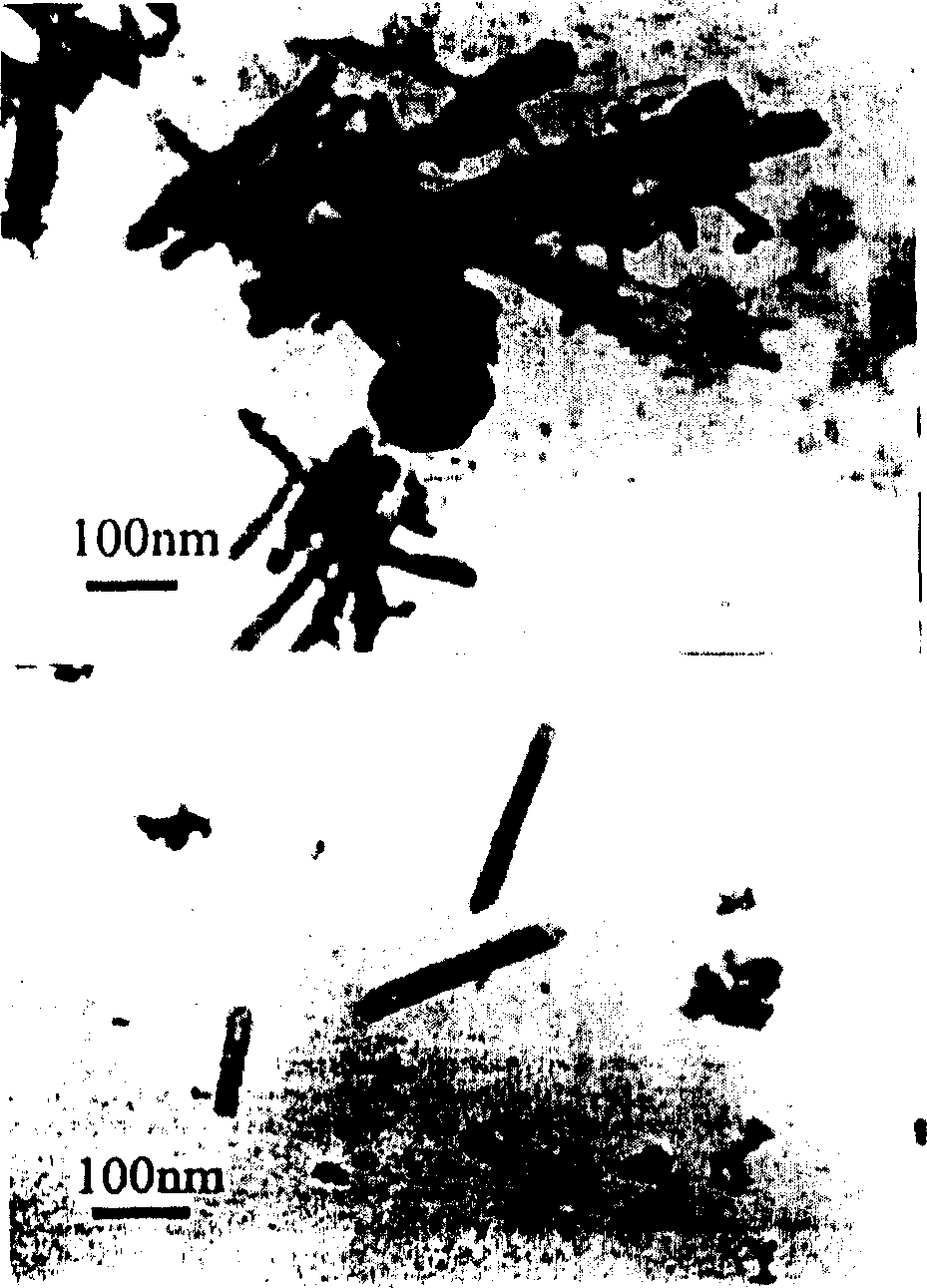

[0025] Evaporate tin tetrachloride (3ml / min) at 250°C, hydrogen (1.0m 3 / h) and air preheated to 100°C (3m 3 / h) is passed into the central pipe 301 of the multi-jet combustion reactor after mixing, and the air (1m 3 / h) and hydrogen (1m 3 / h) of the mixed gas, the three-loop pipe is fed with air at a temperature of 25°C (2m 3 / h), carry out the gas phase combustion hydrolysis reaction in the combustion reaction chamber, the flame temperature in the combustion chamber is 800 ° C, the substrate is 3 cm away from the burner outlet, the deposition time is 10 min, and the tail gas is absorbed by the absorption device. The tin dioxide nanorods produced by the reaction have a diameter of 20 nm and an aspect ratio of 9. SEM photo see figure 2 .

Embodiment 2

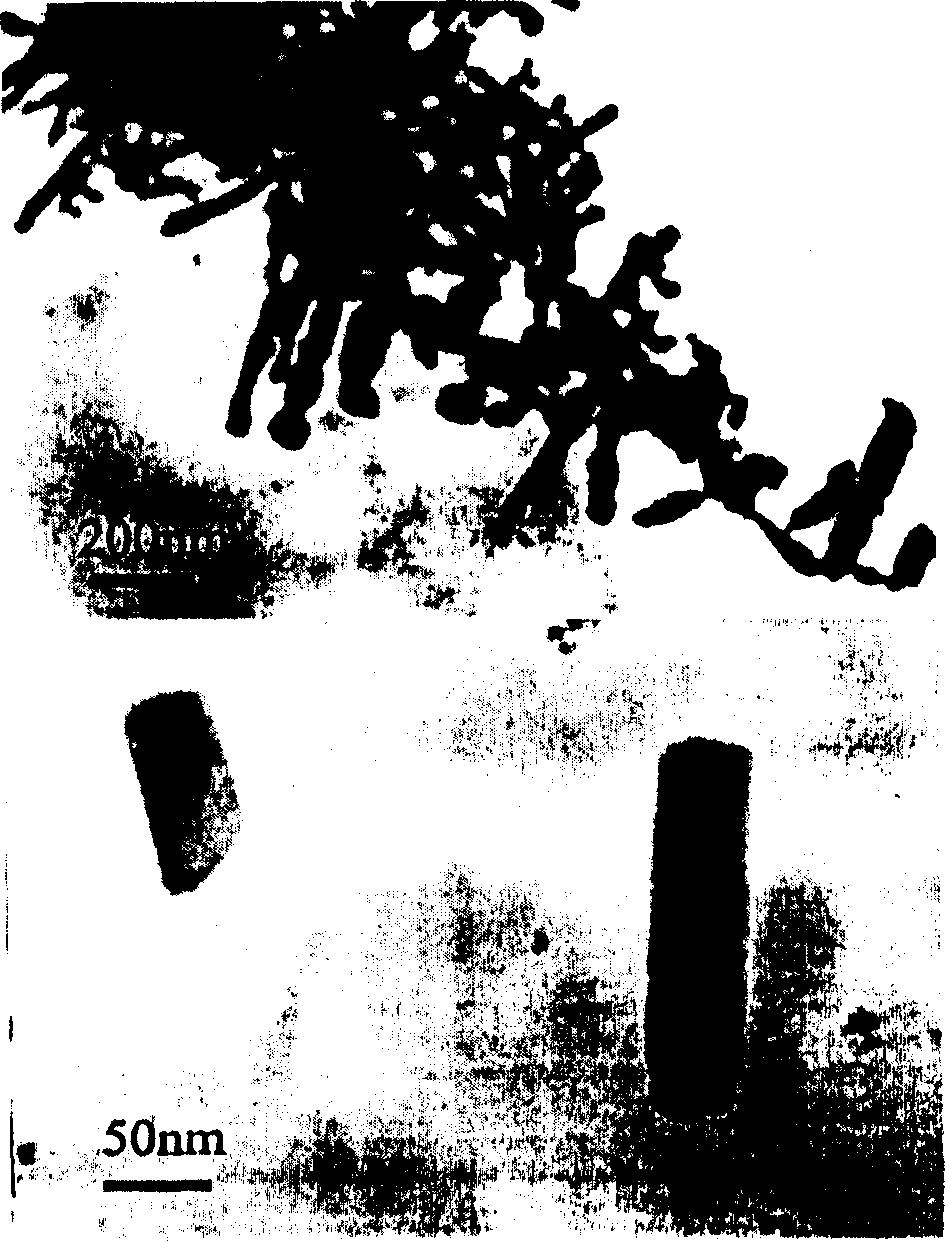

[0027] Evaporate tin tetrachloride (5ml / min) at 300°C and mix with hydrogen (2.0m 3 / h) and air preheated to 50°C (4m 3 / h) is passed into the center pipe 301 of the multi-jet combustion reactor after mixing, and at the second ring pipe 302, the air (2m 3 / h) and hydrogen (3m 3 / h) mixed gas, the three-ring pipe 303 is fed with air at a temperature of 30°C (10m 3 / h), carry out the gas phase combustion hydrolysis reaction in the combustion reaction chamber, the flame temperature in the combustion chamber is 1500°C, the substrate is 20cm away from the burner outlet, the deposition time is 60min, and the tail gas is absorbed by the absorption device. The tin dioxide nanorods produced by the reaction have a diameter of 50 nm and an aspect ratio of 5. SEM photo see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com