Method of carbon nanotube for modifying polyacrylonitrile-based carbon fiber interface produced in China

A technology of polyacrylonitrile-based carbon and carbon nanotubes, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of high production cost, low carbon fiber strength, poor uniformity and stability, and achieve densification time The effect of shortening, high material mechanical properties, and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

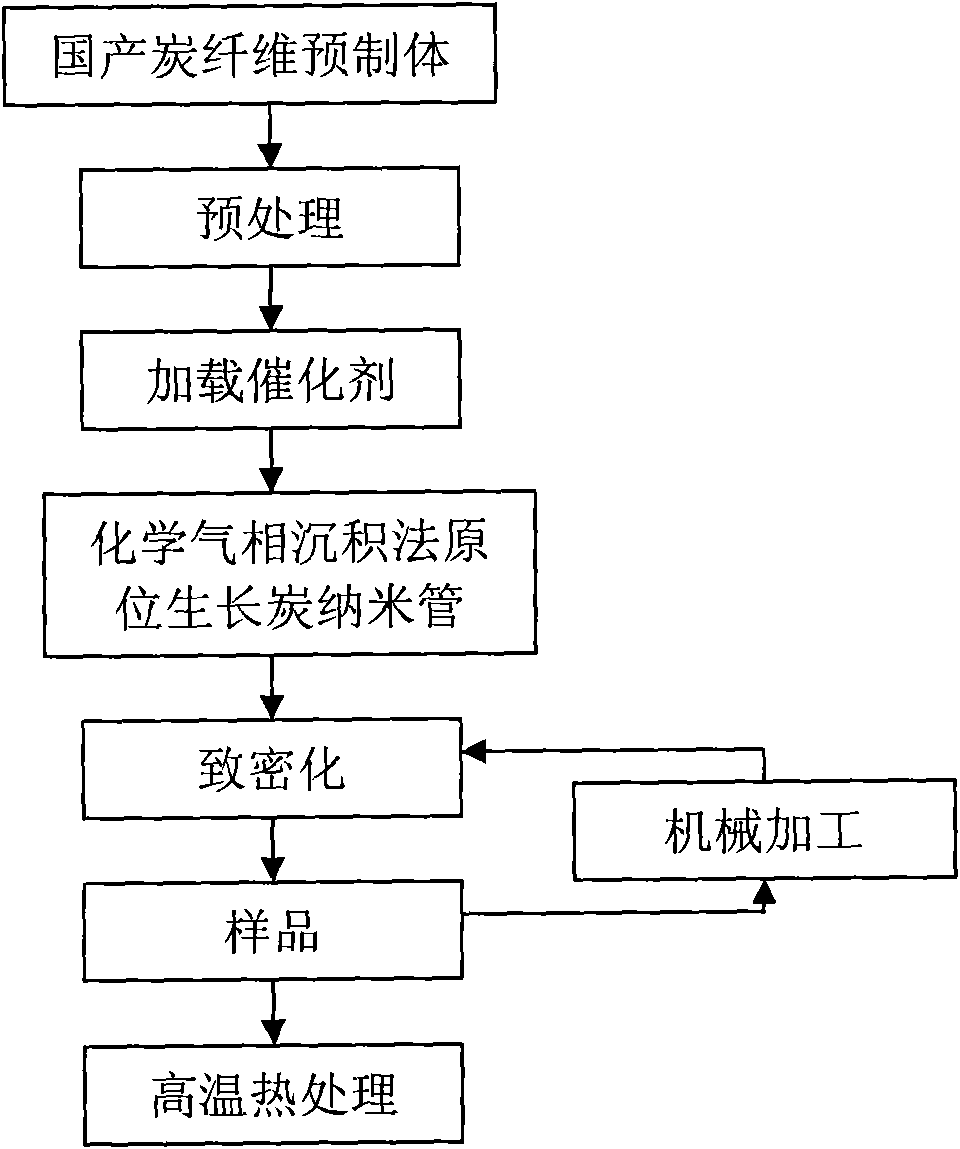

[0036] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

[0037] 1. Surface treatment of polyacrylonitrile-based carbon fiber

[0038] The preform is made of polyacrylonitrile-based domestic carbon fiber needled felt with a size of 10×10×100mm. Before the carbon nanotubes are grown on the surface by the in-situ growth method, the needled felt preform is first treated at 700°C to remove the carbon fiber surface And then use a mixed acid of nitric acid and sulfuric acid (the volume ratio of sulfuric acid and nitric acid is: sulfuric acid: nitric acid = 3:1, where the purity of sulfuric acid is analytically pure, and the purity of nitric acid is 68%). Pretreatment (70°C, 50min) to remove impurities on the surface of the fiber and improve the activity of the carbon fiber, and then repeatedly immerse in distilled water to neutrality and then dry.

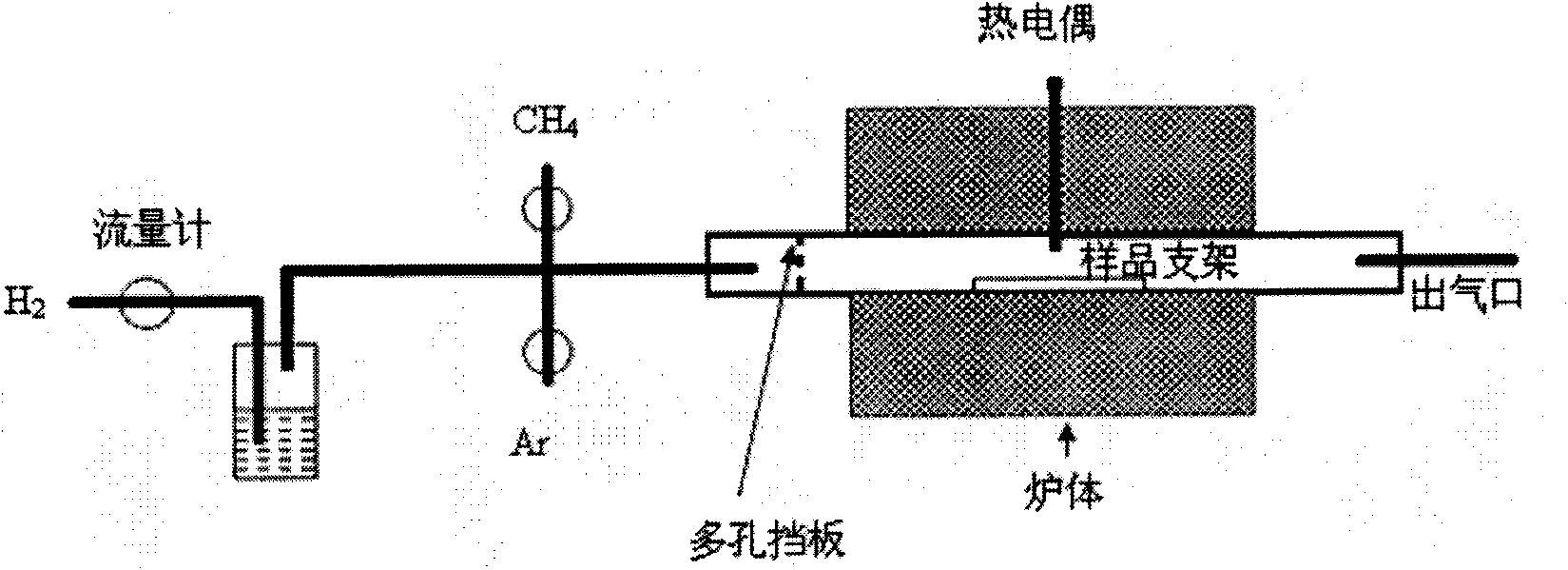

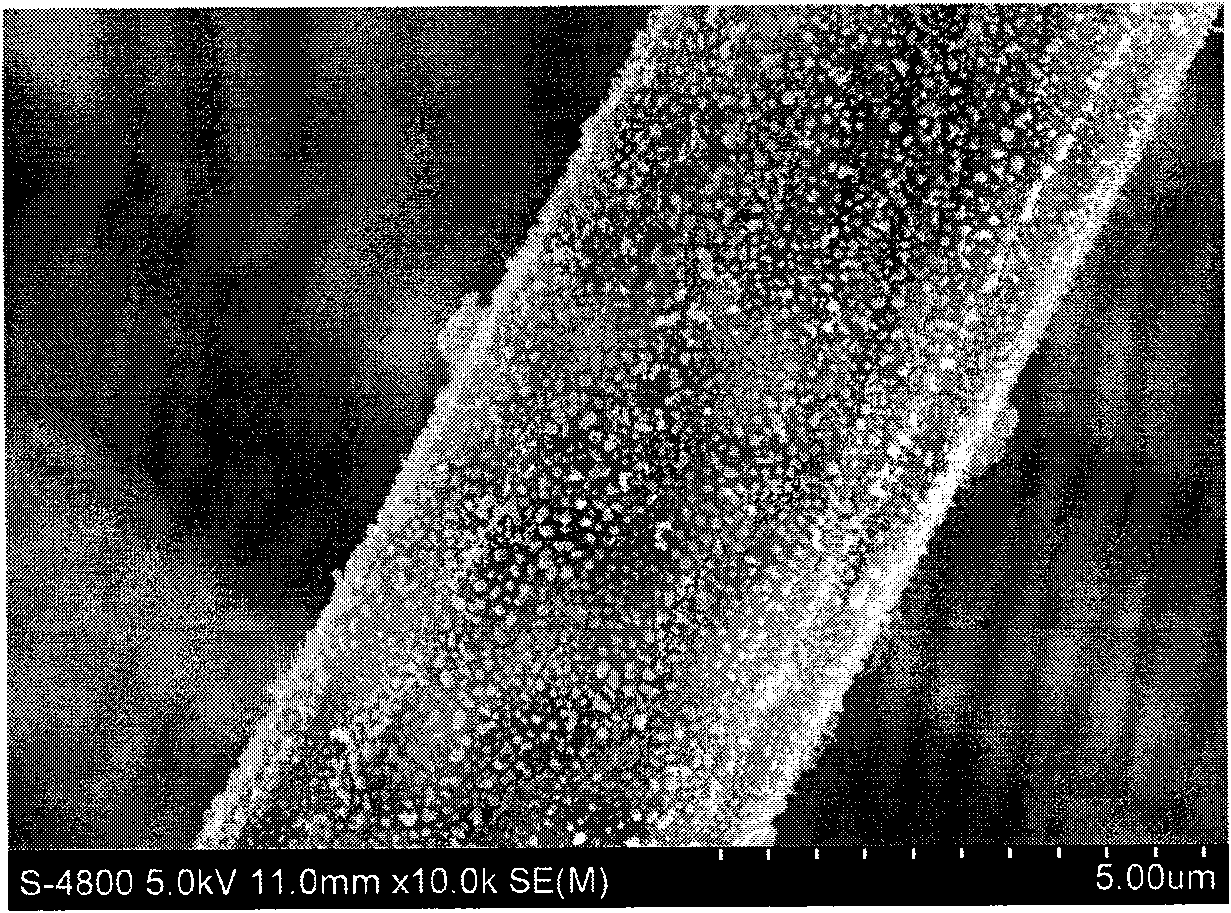

[0039] 2. Preparation of domestic carbon fiber preform with carbon n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com