Method for preparing germanium nano cubic crystals through ionic liquid electro-deposition

An ionic liquid and nanocube technology, which is applied in the field of preparing germanium nanocube structure by using ultraviolet irradiation-assisted ionic liquid electrodeposition method, can solve the problems of difficult repetition and difficult control, and achieve the effects of easy implementation, convenient operation and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: A method for preparing germanium nanocubic crystals by ionic liquid electrodeposition according to the present embodiment is carried out according to the following steps:

[0020] 1. Put the ITO conductive glass substrate with surface resistance ≤ 15Ω / □ into acetone, methanol and ultrapure water for ultrasonic cleaning;

[0021] Two, 1-ethyl-3-methylimidazole bis trifluoromethanesulfonimide salt (EmimTF 2 N) the ionic liquid is purified by distillation under reduced pressure, and then the concentration of high-purity germanium tetrachloride is 0.1mol / L~0.3mol / L. In the glove box, high-purity germanium tetrachloride is added to the purified 1- Ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt ionic liquid, aging for 12h to 24h to obtain an electrolyte;

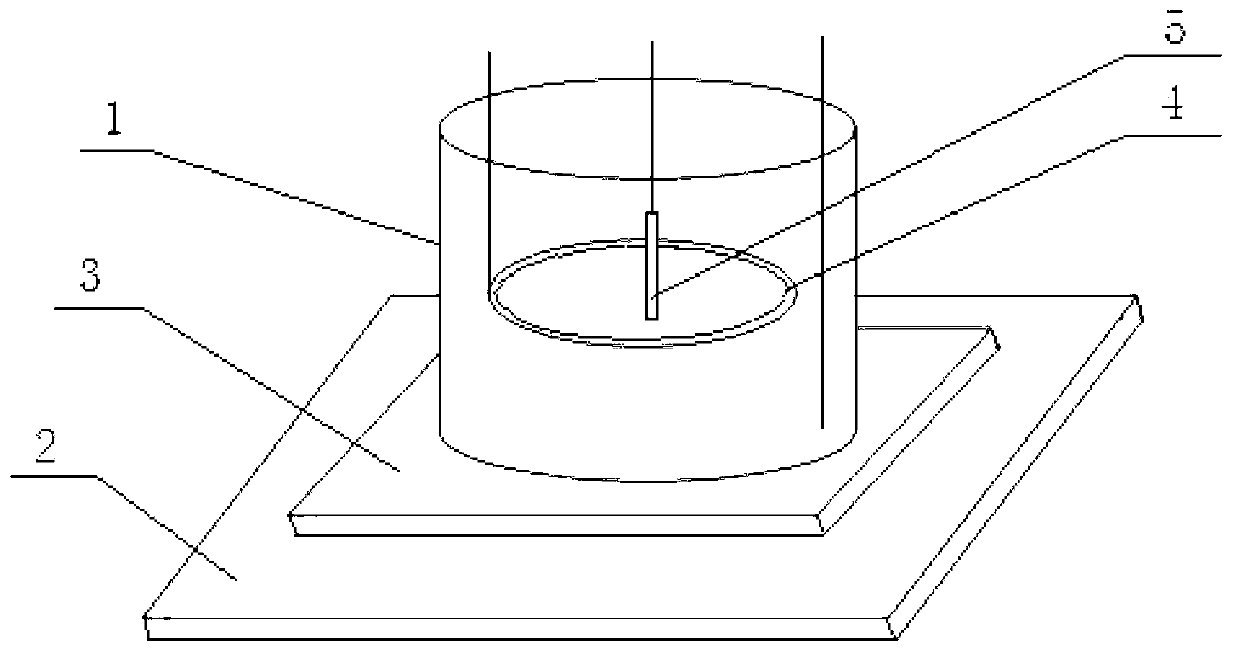

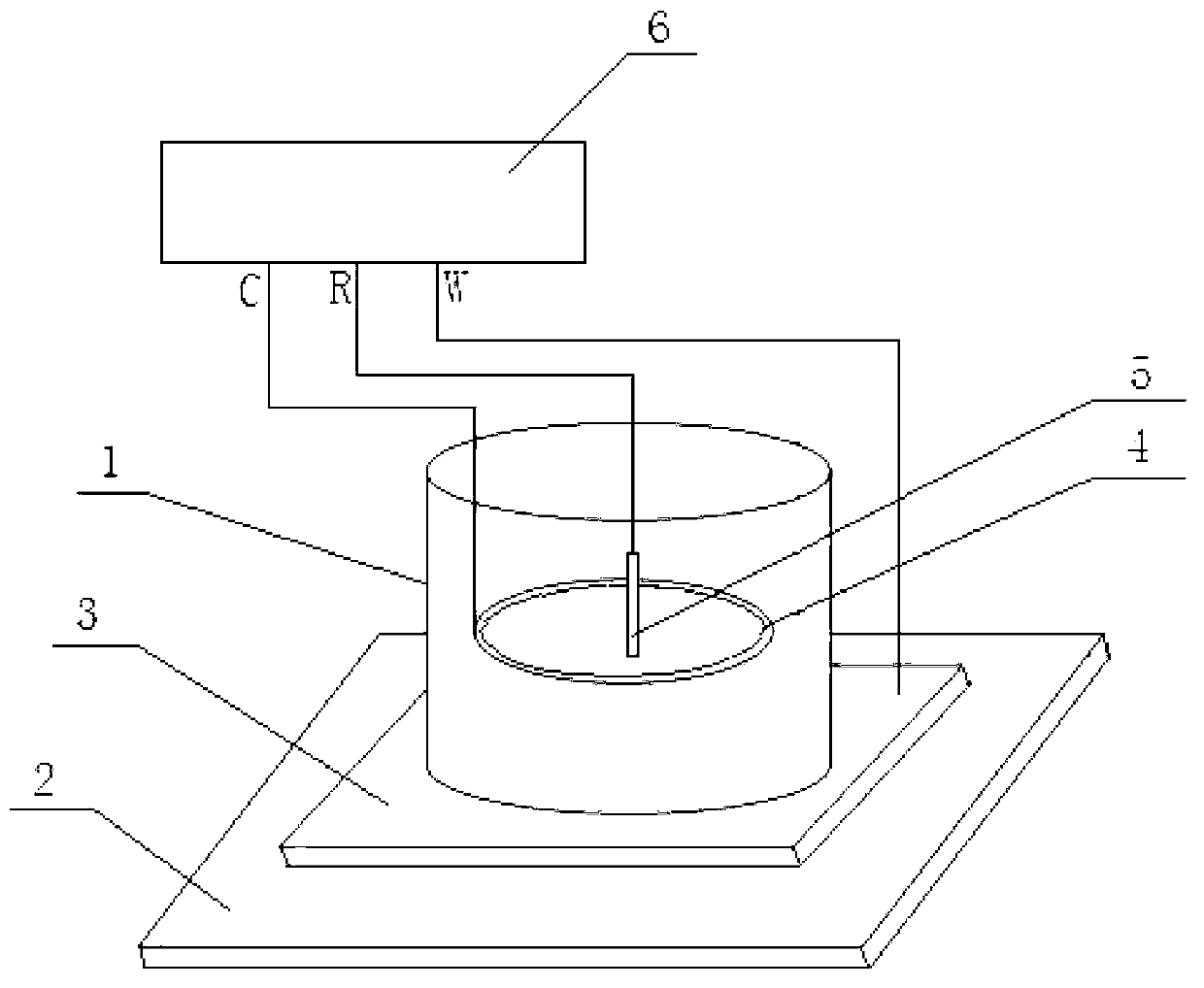

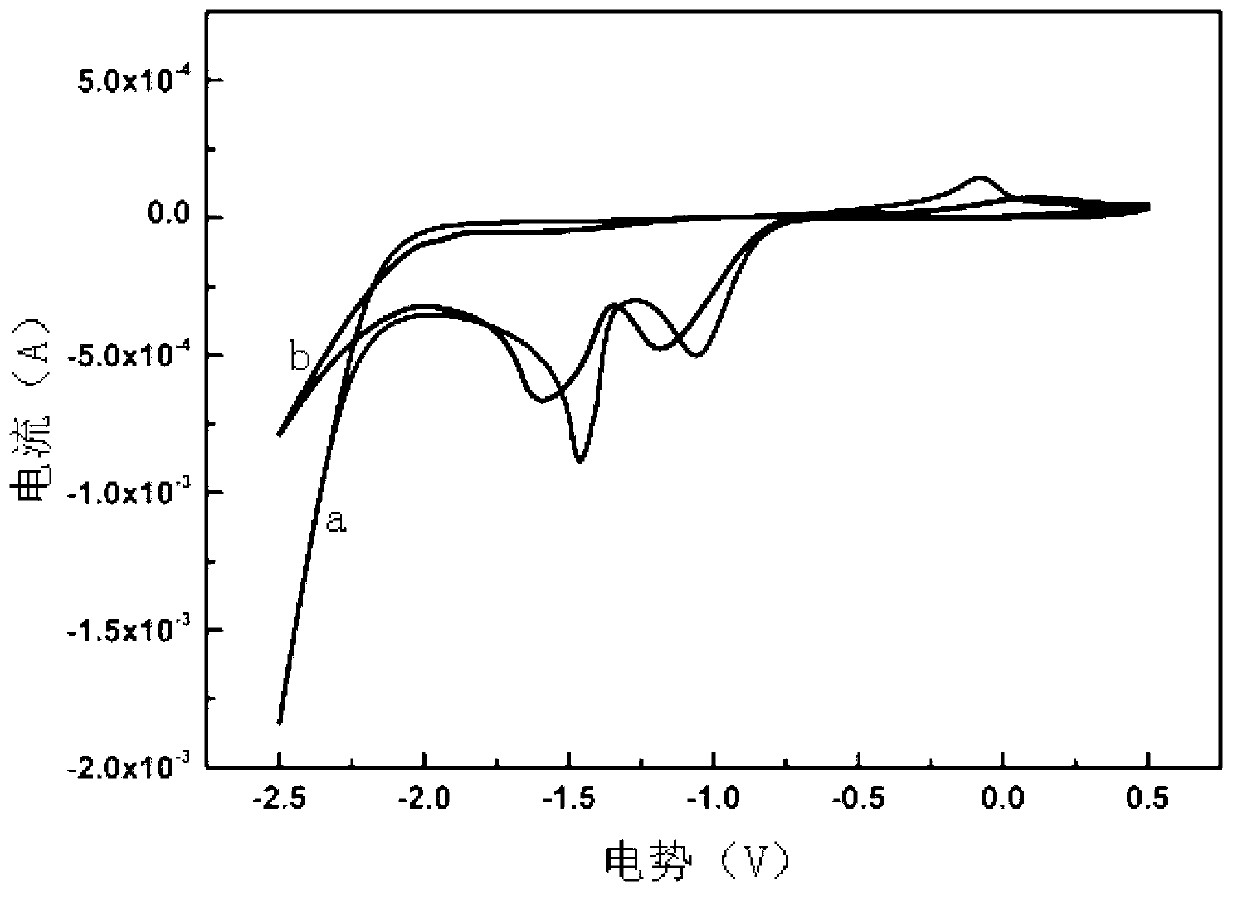

[0022] 3. Put the electrolytic cell into the glove box. The electrolytic cell uses a platinum ring as a contrast electrode, a silver wire as a reference electrode, and the ITO conductive glass su...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the ultrasonic frequency during ultrasonic cleaning in step 1 is 20-40 kHz, and the cleaning time is 10-20 minutes; other aspects are the same as Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the vacuum degree of vacuum distillation in step 2 is 2 * 10 -4 Pa~5×10 -4 Pa, the temperature of the vacuum distillation is 100-120° C., and the time of the vacuum distillation is 12-24 hours; the others are the same as the specific embodiment 1 or 2.

[0029] In this embodiment, a vacuum distillation method is used for purification treatment, so as to prevent the water in the ionic liquid from affecting the electrodeposition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com